fork YAMAHA WR 450F 2006 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 626 of 786

5 - 50

CHAS

4. Install:

•Ring nut 1

Tighten the ring nut using the ring nut

wrench 2.

Refer to “STEERING HEAD INSPEC-

TION AND ADJUSTMENT” section in the

CHAPTER 3.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

5. Check the steering shaft by turning it lock

to lock. If there is any binding, remove the

steering shaft assembly and inspect the

steering bearings.

6. Install:

•Plain washer 1

7. Install:

•Front fork 1

•Handle crown 2

•Main switch 3

•Hose guide bracket 4

NOTE:

•Temporarily tighten the pinch bolts (under

bracket).

•Do not tighten the pinch bolts (handle crown)

yet.

8. Install:

•Guide (speed sensor lead) 1

NOTE:

After installing the guide as shown, pass the

speed sensor lead through the guide.

1

STEERING

Page 628 of 786

5 - 51

CHASSTEERING

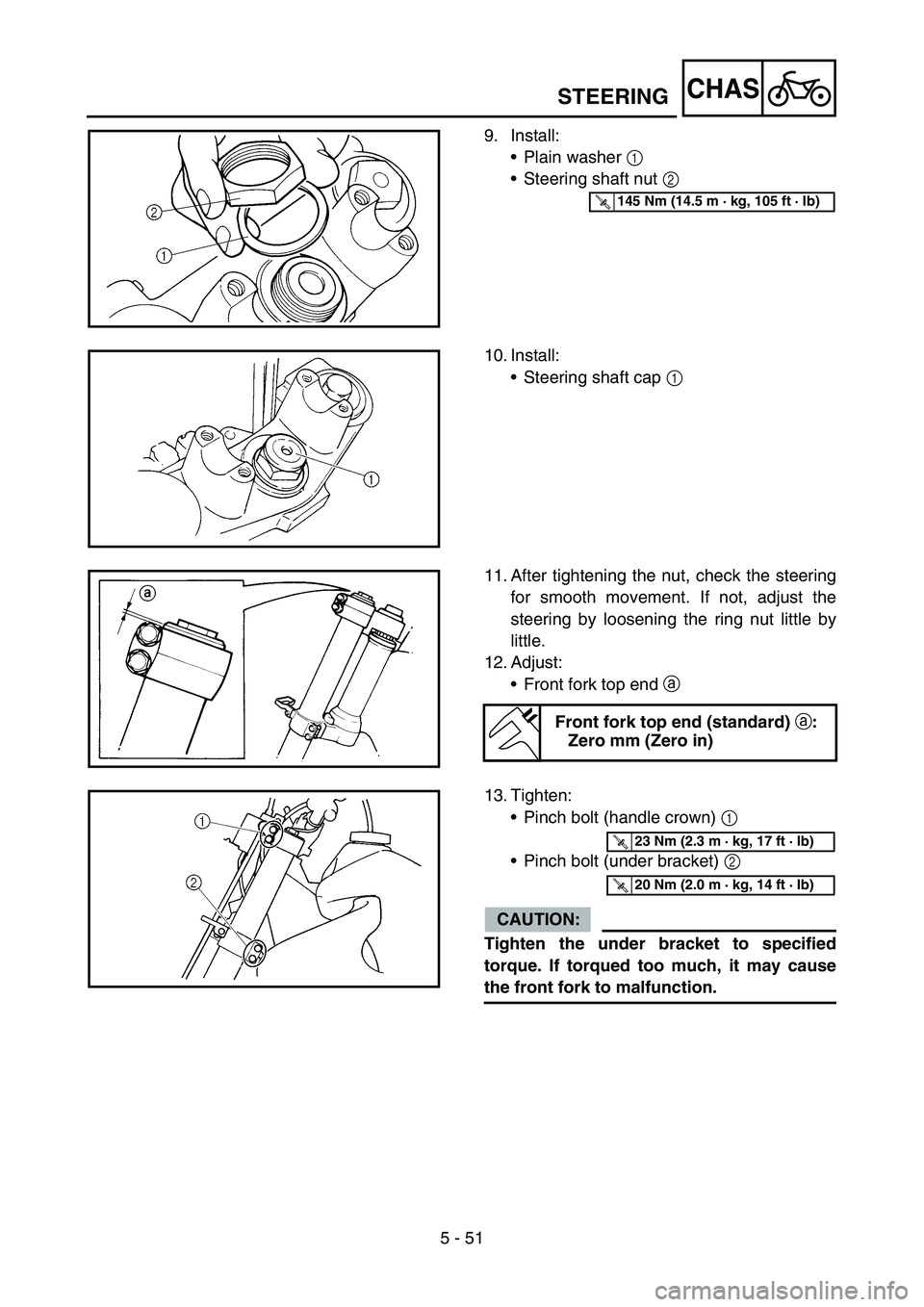

9. Install:

•Plain washer 1

•Steering shaft nut 2

T R..145 Nm (14.5 m · kg, 105 ft · lb)

10. Install:

•Steering shaft cap 1

11. After tightening the nut, check the steering

for smooth movement. If not, adjust the

steering by loosening the ring nut little by

little.

12. Adjust:

•Front fork top end a

Front fork top end (standard)

a:

Zero mm (Zero in)

13. Tighten:

•Pinch bolt (handle crown) 1

•Pinch bolt (under bracket) 2

CAUTION:

Tighten the under bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 760 of 786

7 - 11

TUNSETTING

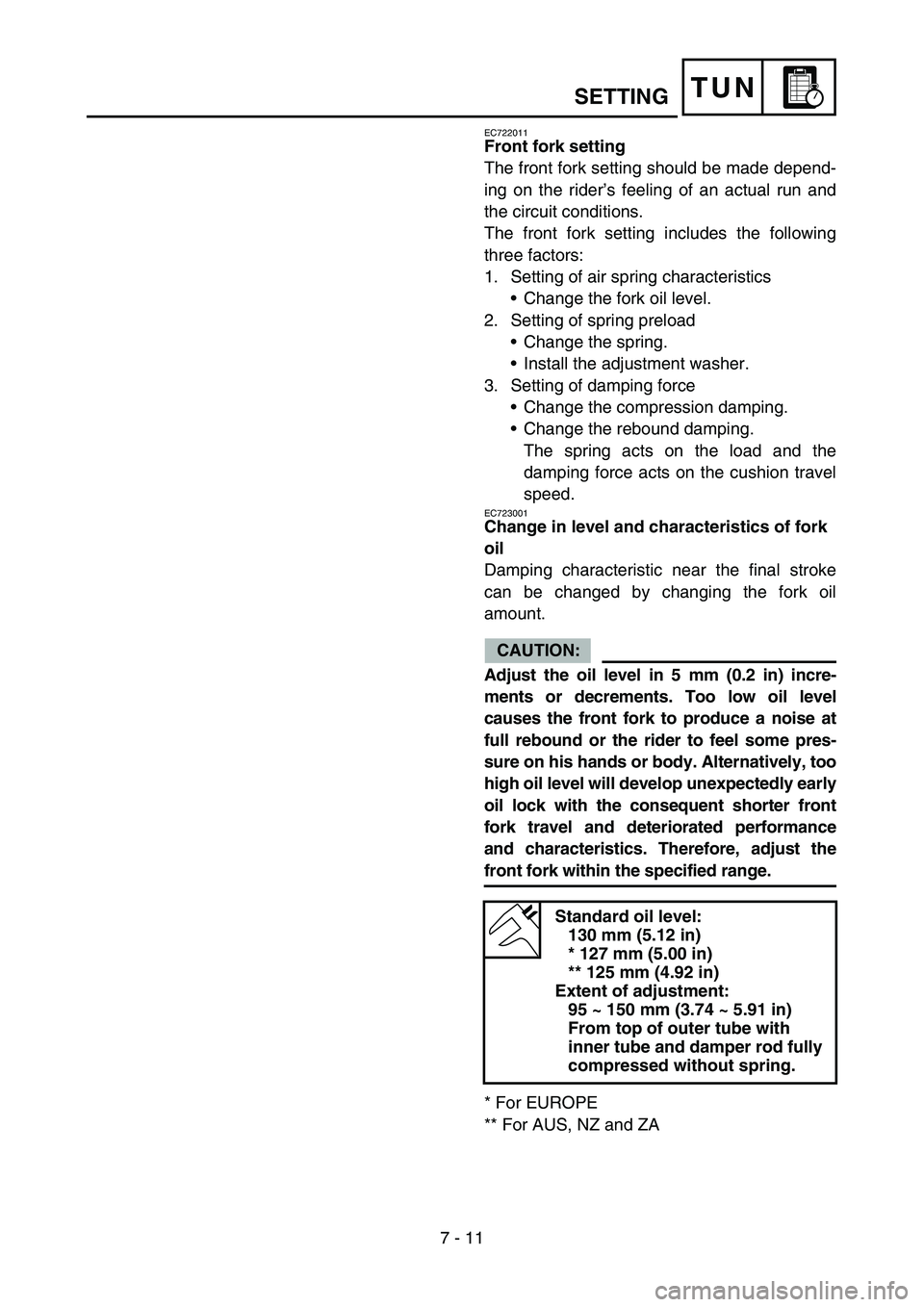

EC722011

Front fork setting

The front fork setting should be made depend-

ing on the rider’s feeling of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics

•Change the fork oil level.

2. Setting of spring preload

•Change the spring.

•Install the adjustment washer.

3. Setting of damping force

•Change the compression damping.

•Change the rebound damping.

The spring acts on the load and the

damping force acts on the cushion travel

speed.

EC723001

Change in level and characteristics of fork

oil

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

CAUTION:

Adjust the oil level in 5 mm (0.2 in) incre-

ments or decrements. Too low oil level

causes the front fork to produce a noise at

full rebound or the rider to feel some pres-

sure on his hands or body. Alternatively, too

high oil level will develop unexpectedly early

oil lock with the consequent shorter front

fork travel and deteriorated performance

and characteristics. Therefore, adjust the

front fork within the specified range.

* For EUROPE

** For AUS, NZ and ZA

Standard oil level:

130 mm (5.12 in)

* 127 mm (5.00 in)

** 125 mm (4.92 in)

Extent of adjustment:

95 ~ 150 mm (3.74 ~ 5.91 in)

From top of outer tube with

inner tube and damper rod fully

compressed without spring.

Page 762 of 786

7 - 12

TUNSETTING

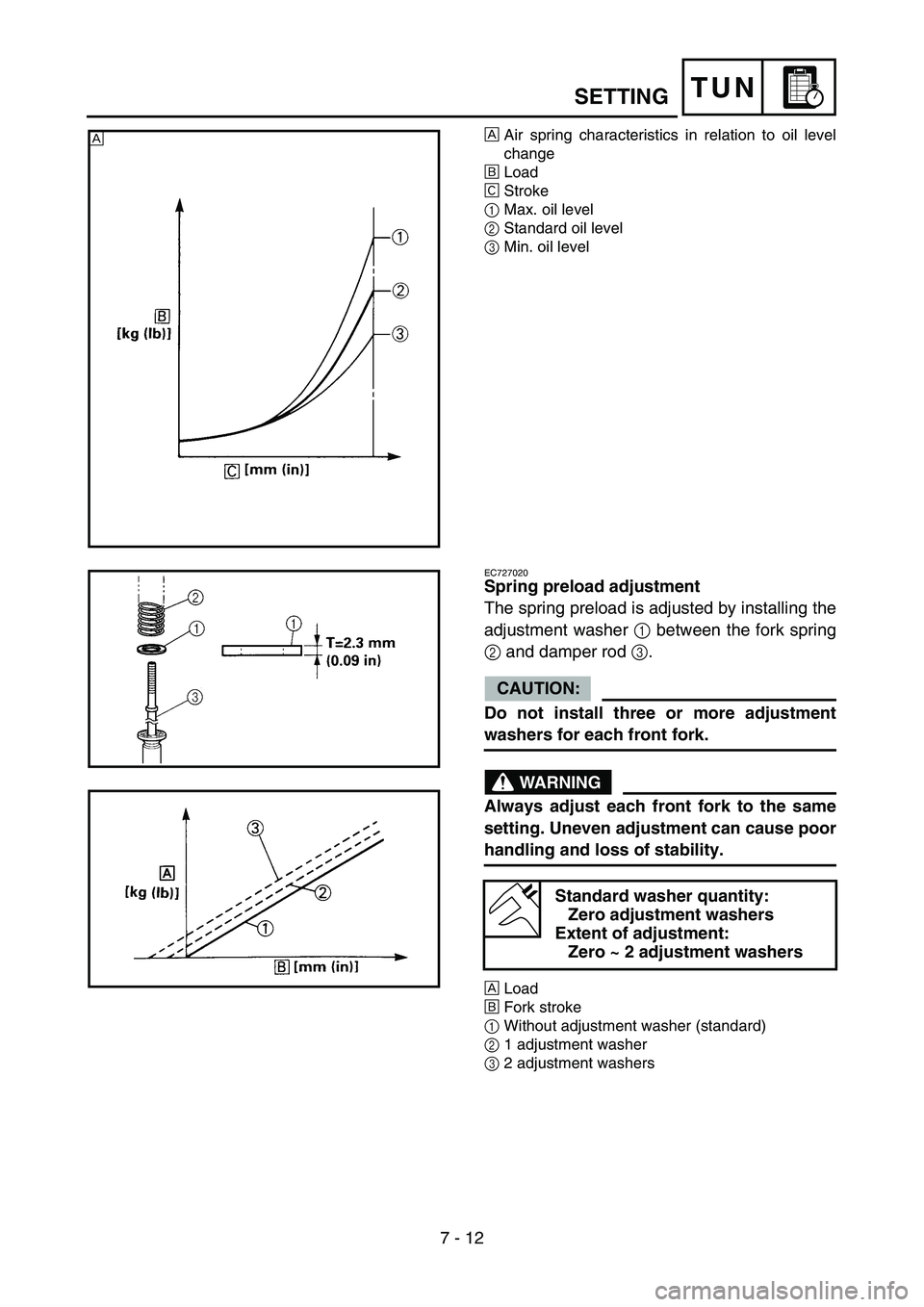

ÈAir spring characteristics in relation to oil level

change

ÉLoad

ÊStroke

1Max. oil level

2Standard oil level

3Min. oil levelÈ

EC727020

Spring preload adjustment

The spring preload is adjusted by installing the

adjustment washer 1

between the fork spring

2

and damper rod 3

.

CAUTION:

Do not install three or more adjustment

washers for each front fork.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

ÈLoad

ÉFork stroke

1Without adjustment washer (standard)

21 adjustment washer

32 adjustment washers

Standard washer quantity:

Zero adjustment washers

Extent of adjustment:

Zero ~ 2 adjustment washers

Page 764 of 786

7 - 13

TUN

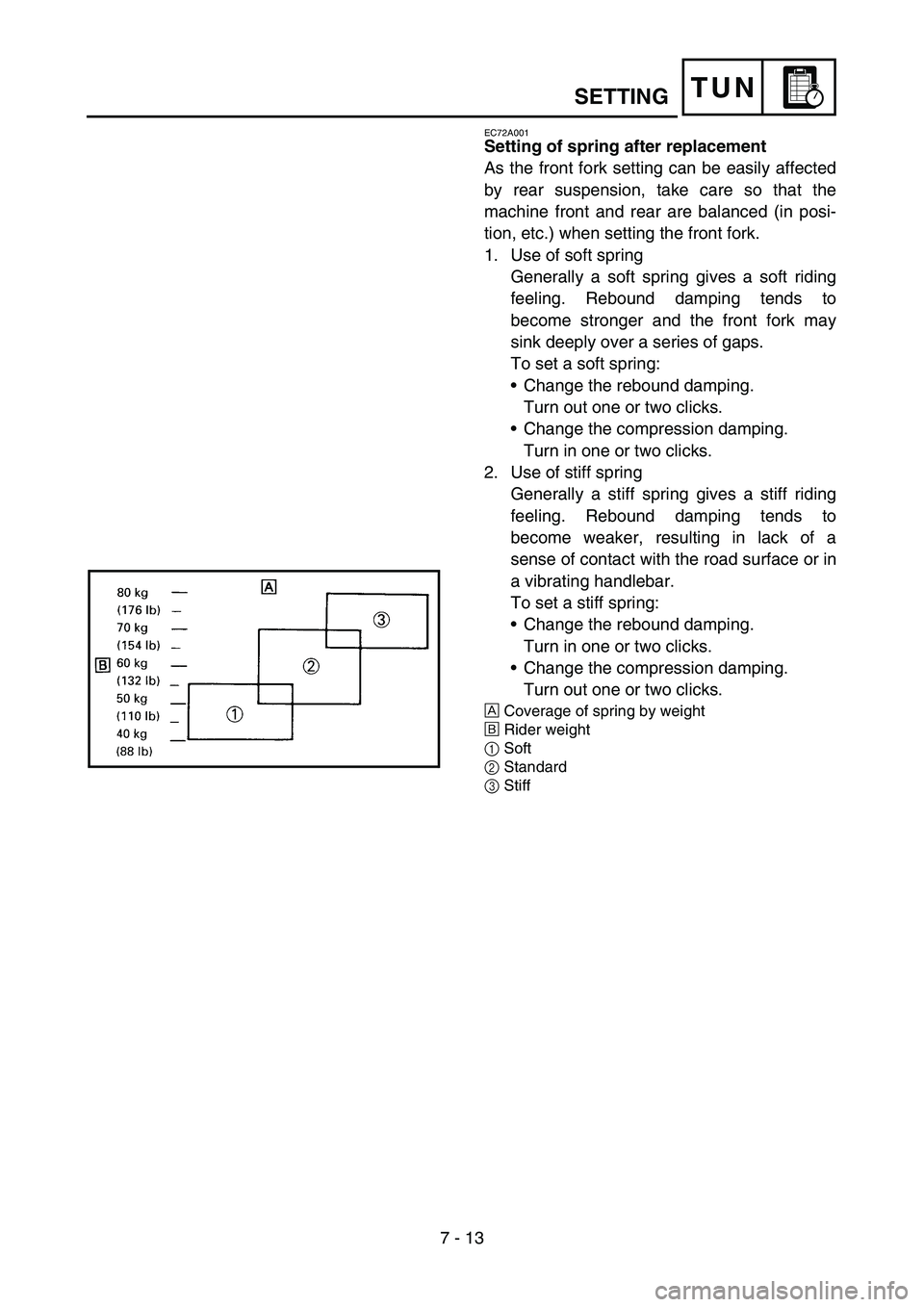

EC72A001

Setting of spring after replacement

As the front fork setting can be easily affected

by rear suspension, take care so that the

machine front and rear are balanced (in posi-

tion, etc.) when setting the front fork.

1. Use of soft spring

Generally a soft spring gives a soft riding

feeling. Rebound damping tends to

become stronger and the front fork may

sink deeply over a series of gaps.

To set a soft spring:

•Change the rebound damping.

Turn out one or two clicks.

•Change the compression damping.

Turn in one or two clicks.

2. Use of stiff spring

Generally a stiff spring gives a stiff riding

feeling. Rebound damping tends to

become weaker, resulting in lack of a

sense of contact with the road surface or in

a vibrating handlebar.

To set a stiff spring:

•Change the rebound damping.

Turn in one or two clicks.

•Change the compression damping.

Turn out one or two clicks.

ÈCoverage of spring by weight

ÉRider weight

1Soft

2Standard

3Stiff

SETTING

Page 766 of 786

7 - 14

TUN

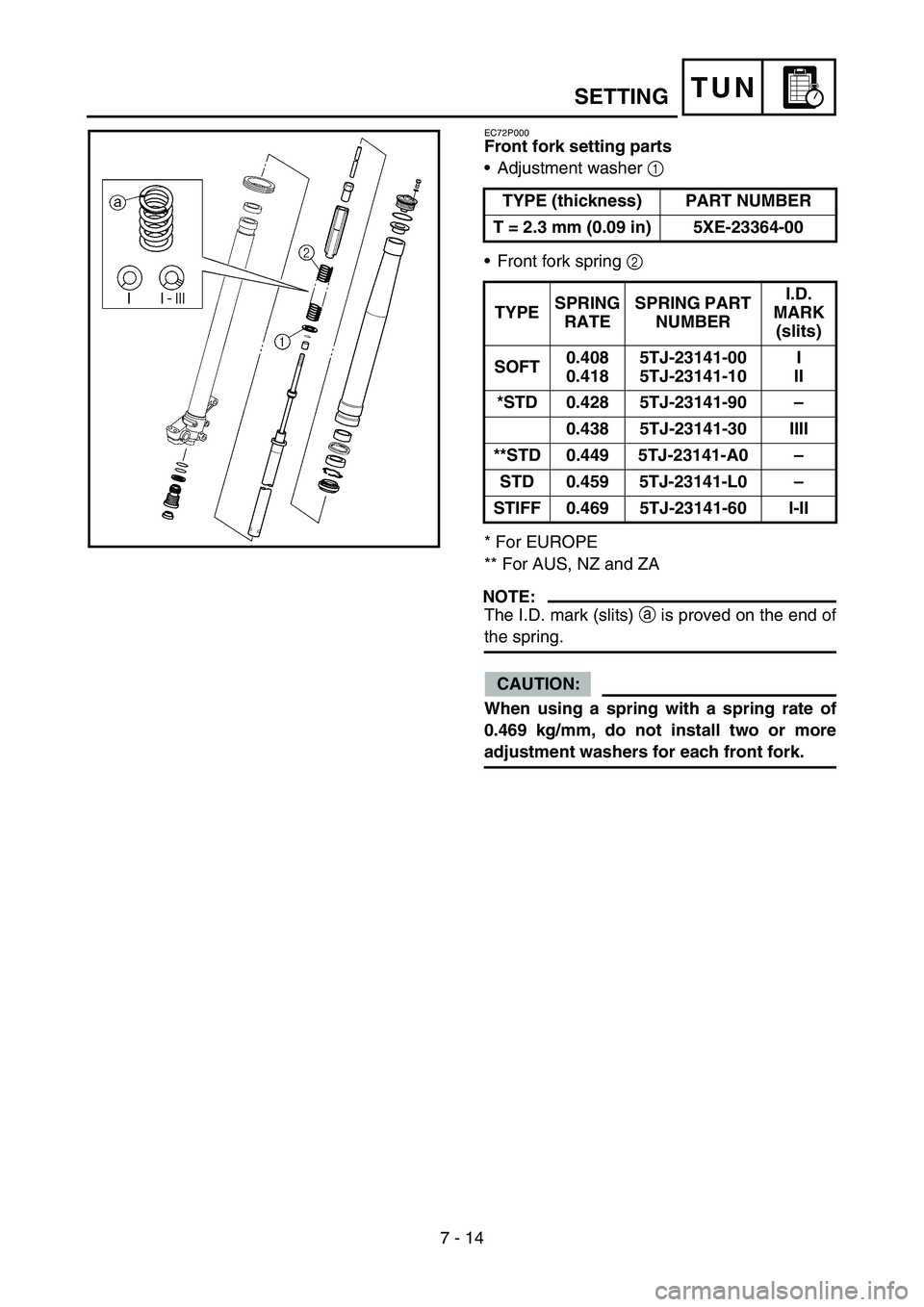

EC72P000

Front fork setting parts

•Adjustment washer 1

•Front fork spring 2

* For EUROPE

** For AUS, NZ and ZA

NOTE:

The I.D. mark (slits) a is proved on the end of

the spring.

CAUTION:

When using a spring with a spring rate of

0.469 kg/mm, do not install two or more

adjustment washers for each front fork.TYPE (thickness) PART NUMBER

T = 2.3 mm (0.09 in) 5XE-23364-00

TYPESPRING

RATESPRING PART

NUMBERI.D.

MARK

(slits)

SOFT0.408

0.4185TJ-23141-00

5TJ-23141-10I

II

*STD 0.428 5TJ-23141-90–

0.438 5TJ-23141-30 IIII

**STD 0.449 5TJ-23141-A0–

STD 0.459 5TJ-23141-L0–

STIFF 0.469 5TJ-23141-60 I-II

SETTING

Page 776 of 786

7 - 19

TUNSETTING

EC72H002

Suspension setting

•Front fork

NOTE:

•If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

•Before any change, set the rear shock absorber sunken length to the standard figure 90 ~ 100 mm

(3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire rangeCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil level (oil amount) Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Spring Replace with soft spring.

Unsmooth movement

over entire rangeOuter tube

Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Under bracket tightening

torqueRetighten to specified torque.

Poor initial

movementRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming outCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Oil level (oil amount) Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Spring Replace with stiff spring.

Stiff toward stroke

endOil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke

end, bottoming outOil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front postureCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in)

when one passenger is astride seat (lower rear pos-

ture).

Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front,

tending to upper front

postureCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in)

when one passenger is astride seat (upper rear pos-

ture).

Spring Replace with soft spring.

Oil lever (oil amount) Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).