engine YAMAHA WR 450F 2008 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 450F, Model: YAMAHA WR 450F 2008Pages: 224, PDF Size: 13.7 MB

Page 45 of 224

2-18

TIGHTENING TORQUES

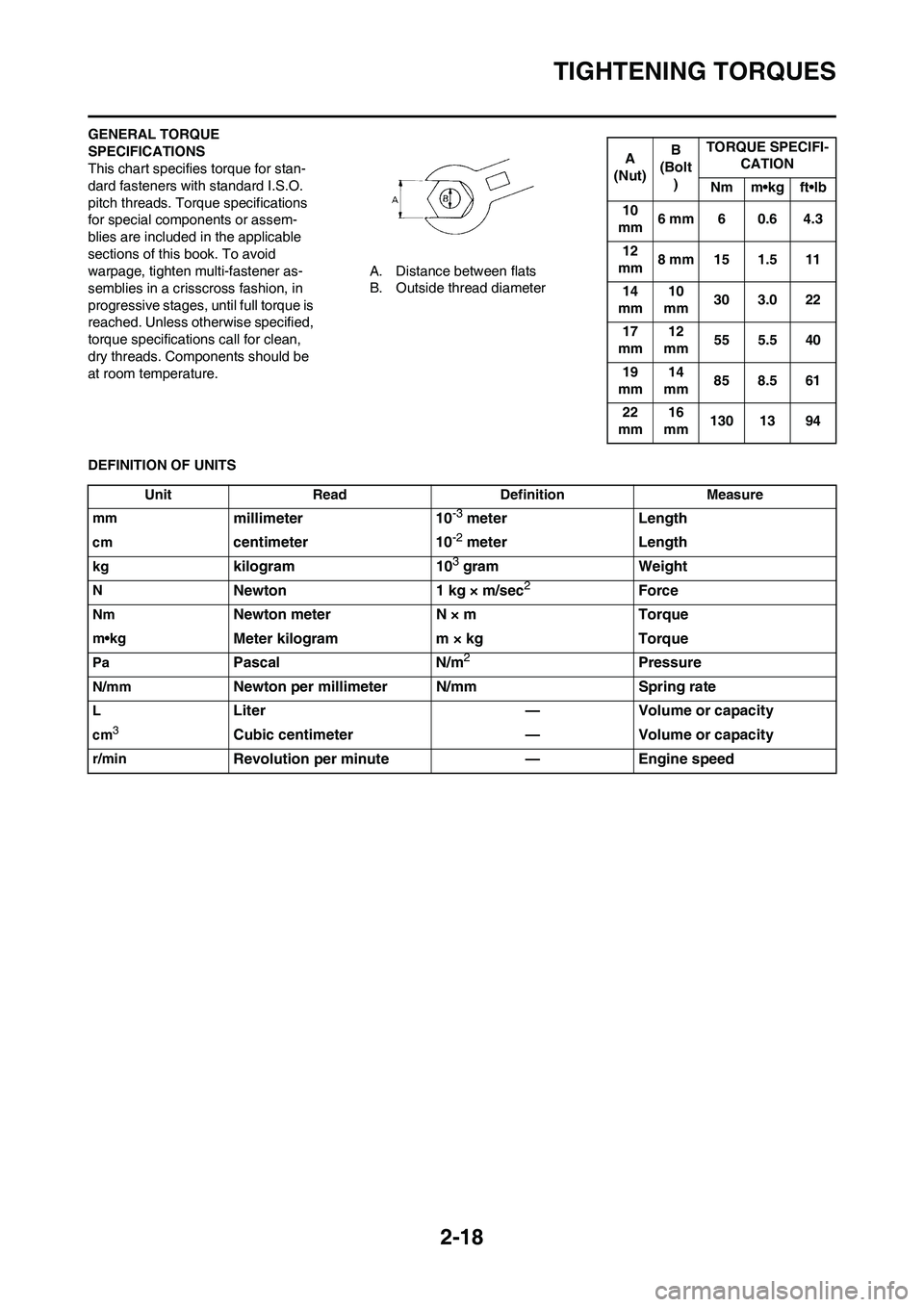

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid

warpage, tighten multi-fastener as-

semblies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature.A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut)B

(Bolt

)TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm6 mm 6 0.6 4.3

12

mm8 mm 15 1.5 11

14

mm10

mm30 3.0 22

17

mm12

mm55 5.5 40

19

mm14

mm85 8.5 61

22

mm16

mm130 13 94

Unit Read Definition Measure

mm

millimeter 10-3 meter Length

cmcentimeter 10-2 meter Length

kgkilogram 103 gram Weight

NNewton 1 kg × m/sec2Force

NmNewton meter N × m Torque

m•kgMeter kilogram m × kg Torque

PaPascal N/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/minRevolution per minute — Engine speed

Page 49 of 224

2-22

CABLE ROUTING DIAGRAM

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead and clutch

cable onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Fasten the throttle position sen-

sor lead onto the frame. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

F. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

G. Pass the neutral switch lead on

the inside of the engine bracket.

H. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

I. Fasten the AC magneto lead

and neutral switch lead onto the

frame. Locate the clamp end

facing toward the rear of the

frame and cut off the tie end.

J. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness.

K. Fasten the AC magneto lead

and neutral switch lead onto the

frame.

L. Pass the wire harness through

the cable guide.

M. Locate the couplers in the frame

recess.

N. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

O. Secure the coupler by pushing it

into the hole in the headlight

unit.

Page 52 of 224

2-25

CABLE ROUTING DIAGRAM

1. Clamp

2. Positive battery lead

3. Battery

4. Negative battery lead

5. Taillight coupler

6. CDI unit coupler (6-pin)

7. CDI unit coupler (3-pin)

8. CDI unit coupler (6-pin)A. Fasten the wire harness to the

upper engine bracket (left side).

Locate the clamp end facing to-

ward the upper side of the frame

with the tie end cut off on the in-

side of the frame.B. Fasten the wire harness to the

upper engine bracket (left side).

Locate the clamp end facing to-

ward the upper side of the frame

with the tie end cut off on the in-

side of the frame. Clamp the

wire harness at the marking.

C. Pass the starter motor lead

through the hole in the relay

holder.

D. Fit the cover securely.

Page 54 of 224

2-27

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket11. Main switch

12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor leadA. Fasten the start switch lead to

the handlebar with the plastic

bands.

B. Fasten the engine stop switch

lead and clutch switch lead to

the handlebar with the plastic

bands.

C. Pass the brake hose through

the hose guides.

Page 56 of 224

3-1

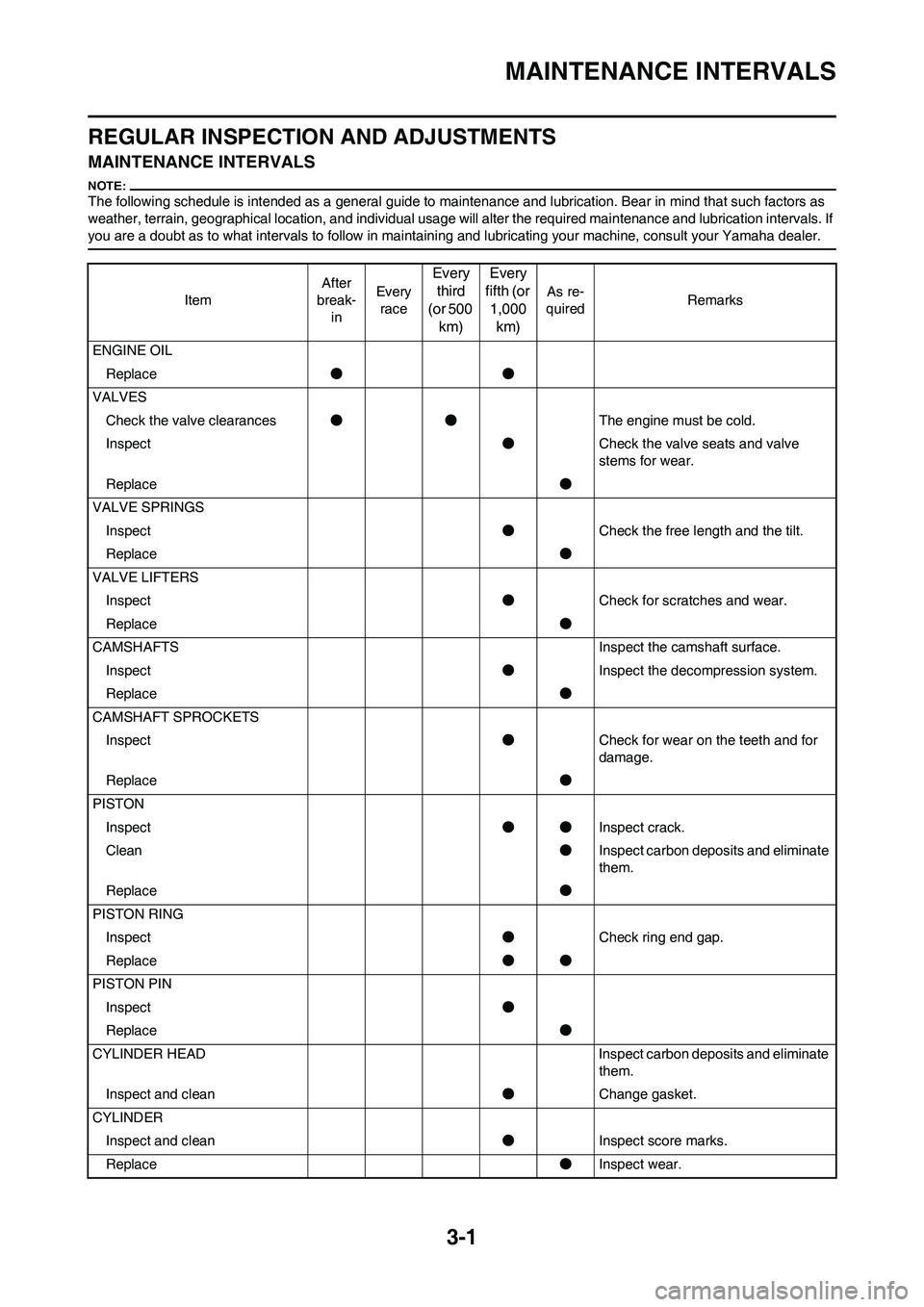

MAINTENANCE INTERVALS

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

ENGINE OIL

Replace●●

VALVES

Check the valve clearances●●The engine must be cold.

Inspect●Check the valve seats and valve

stems for wear.

Replace●

VALVE SPRINGS

Inspect●Check the free length and the tilt.

Replace●

VALVE LIFTERS

Inspect●Check for scratches and wear.

Replace●

CAMSHAFTS Inspect the camshaft surface.

Inspect●Inspect the decompression system.

Replace●

CAMSHAFT SPROCKETS

Inspect●Check for wear on the teeth and for

damage.

Replace●

PISTON

Inspect●●Inspect crack.

Clean●Inspect carbon deposits and eliminate

them.

Replace●

PISTON RING

Inspect●Check ring end gap.

Replace●●

PISTON PIN

Inspect●

Replace●

CYLINDER HEAD Inspect carbon deposits and eliminate

them.

Inspect and clean●Change gasket.

CYLINDER

Inspect and clean●Inspect score marks.

Replace●Inspect wear.

Page 60 of 224

3-5

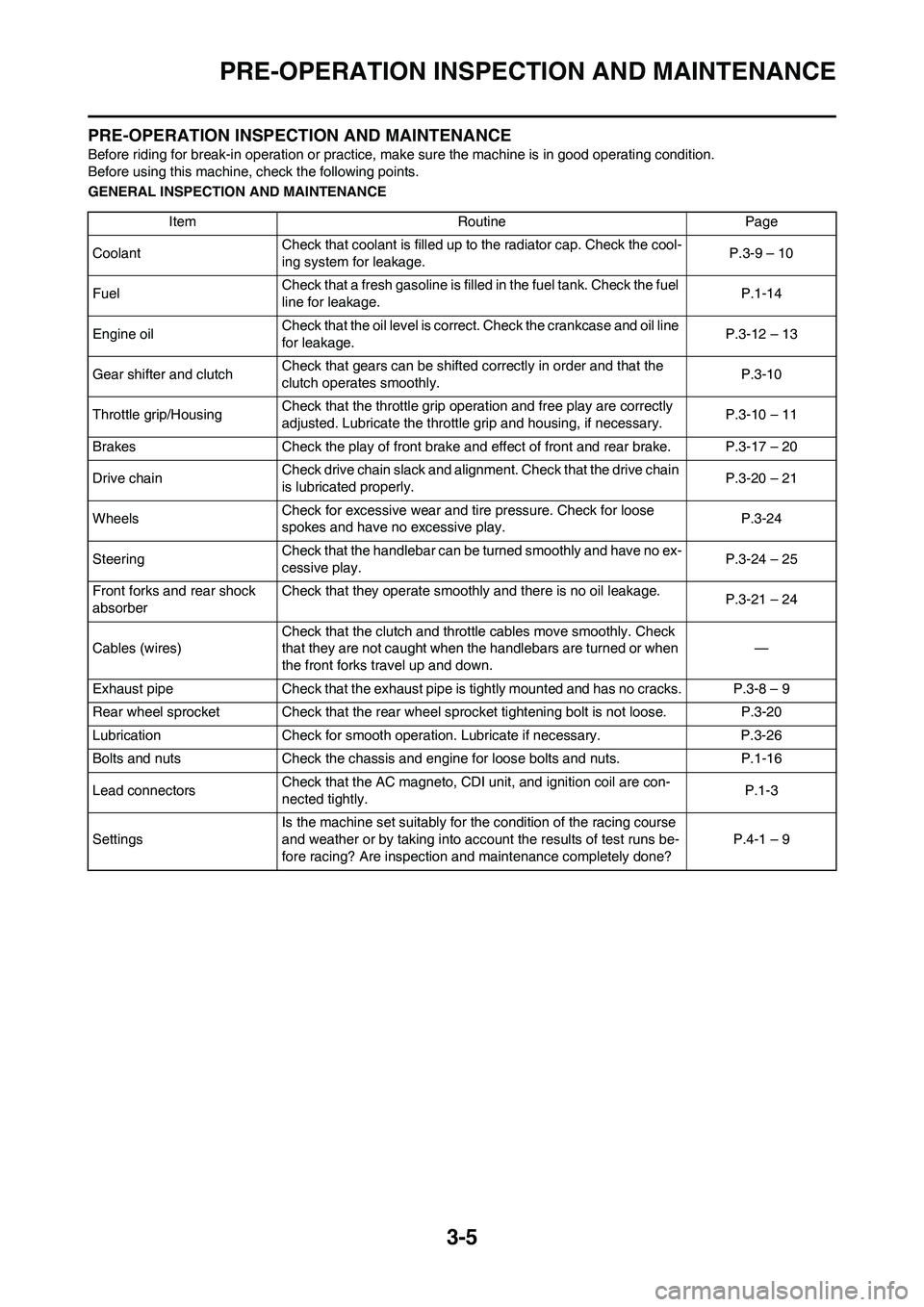

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P.3-9 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.P.1-14

Engine oilCheck that the oil level is correct. Check the crankcase and oil line

for leakage.P.3-12 – 13

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 – 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-17 – 20

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P.3-20 – 21

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-24

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P.3-24 – 25

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P.3-21 – 24

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.3-8 – 9

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-20

Lubrication Check for smooth operation. Lubricate if necessary. P.3-26

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-16

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-3

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?P.4-1 – 9

Page 61 of 224

3-6

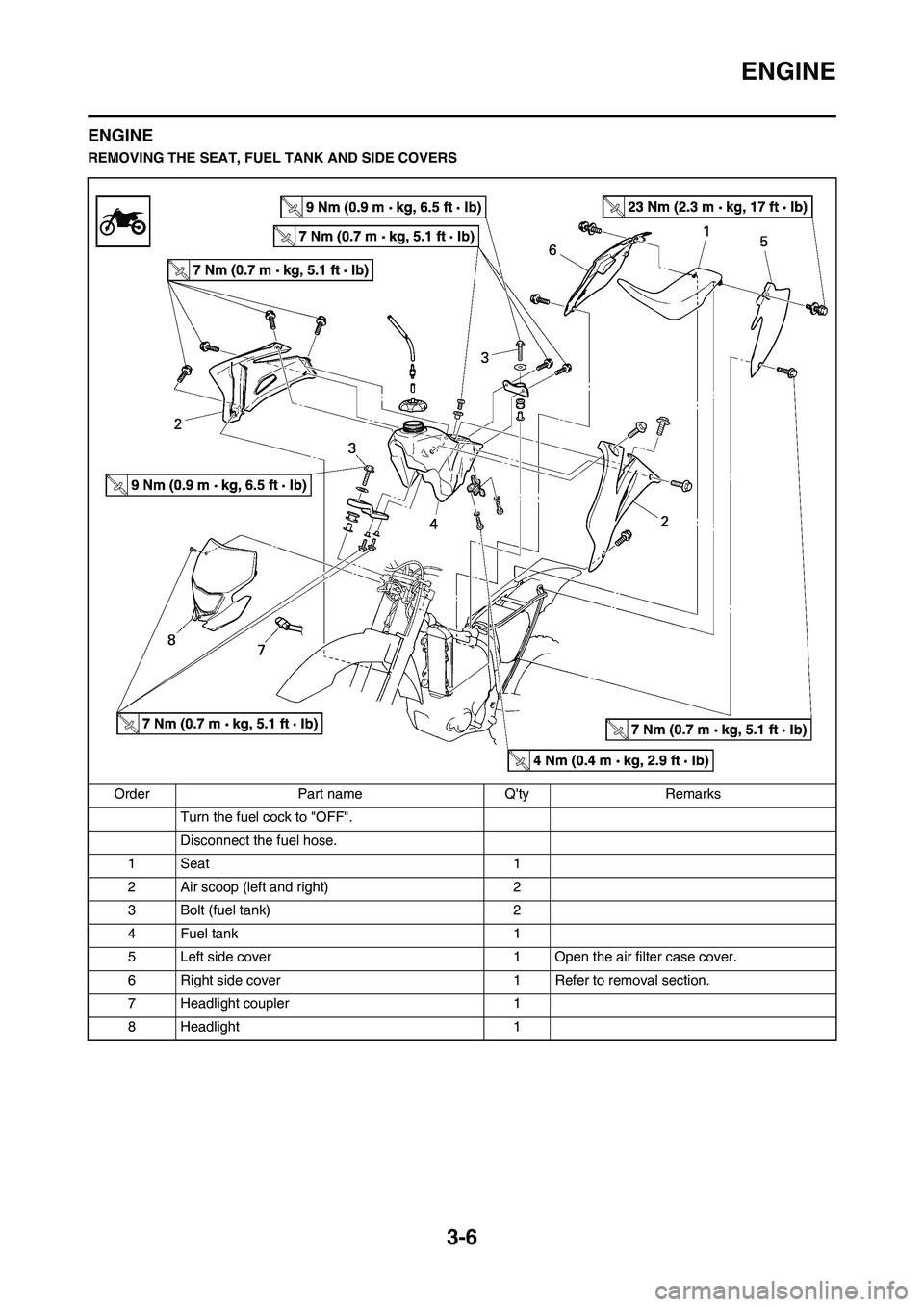

ENGINE

ENGINE

REMOVING THE SEAT, FUEL TANK AND SIDE COVERS

Order Part name Q'ty Remarks

Turn the fuel cock to "OFF".

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1 Open the air filter case cover.

6 Right side cover 1 Refer to removal section.

7 Headlight coupler 1

8 Headlight 1

Page 62 of 224

3-7

ENGINE

REMOVING THE SIDE COVER

1. Remove:

• Bolt (side cover)

• Right side cover "1"

Draw the side cover backward to re-

move it because its claw "a" is insert-

ed in the air filter case.

Page 63 of 224

3-8

ENGINE

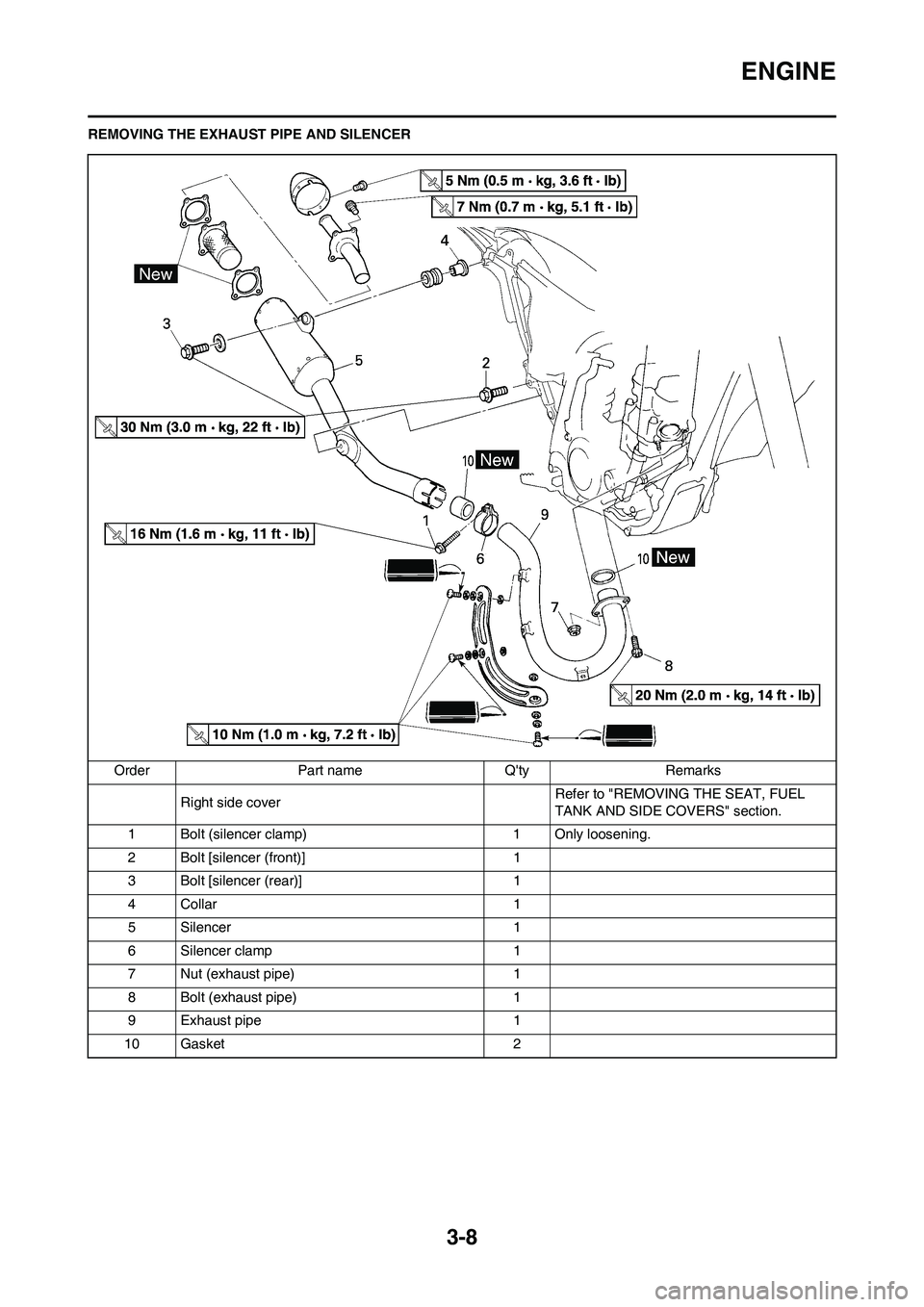

REMOVING THE EXHAUST PIPE AND SILENCER

Order Part name Q'ty Remarks

Right side coverRefer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section.

1 Bolt (silencer clamp) 1 Only loosening.

2 Bolt [silencer (front)] 1

3 Bolt [silencer (rear)] 1

4 Collar 1

5 Silencer 1

6 Silencer clamp 1

7 Nut (exhaust pipe) 1

8 Bolt (exhaust pipe) 1

9 Exhaust pipe 1

10 Gasket 2

Page 64 of 224

3-9

ENGINE

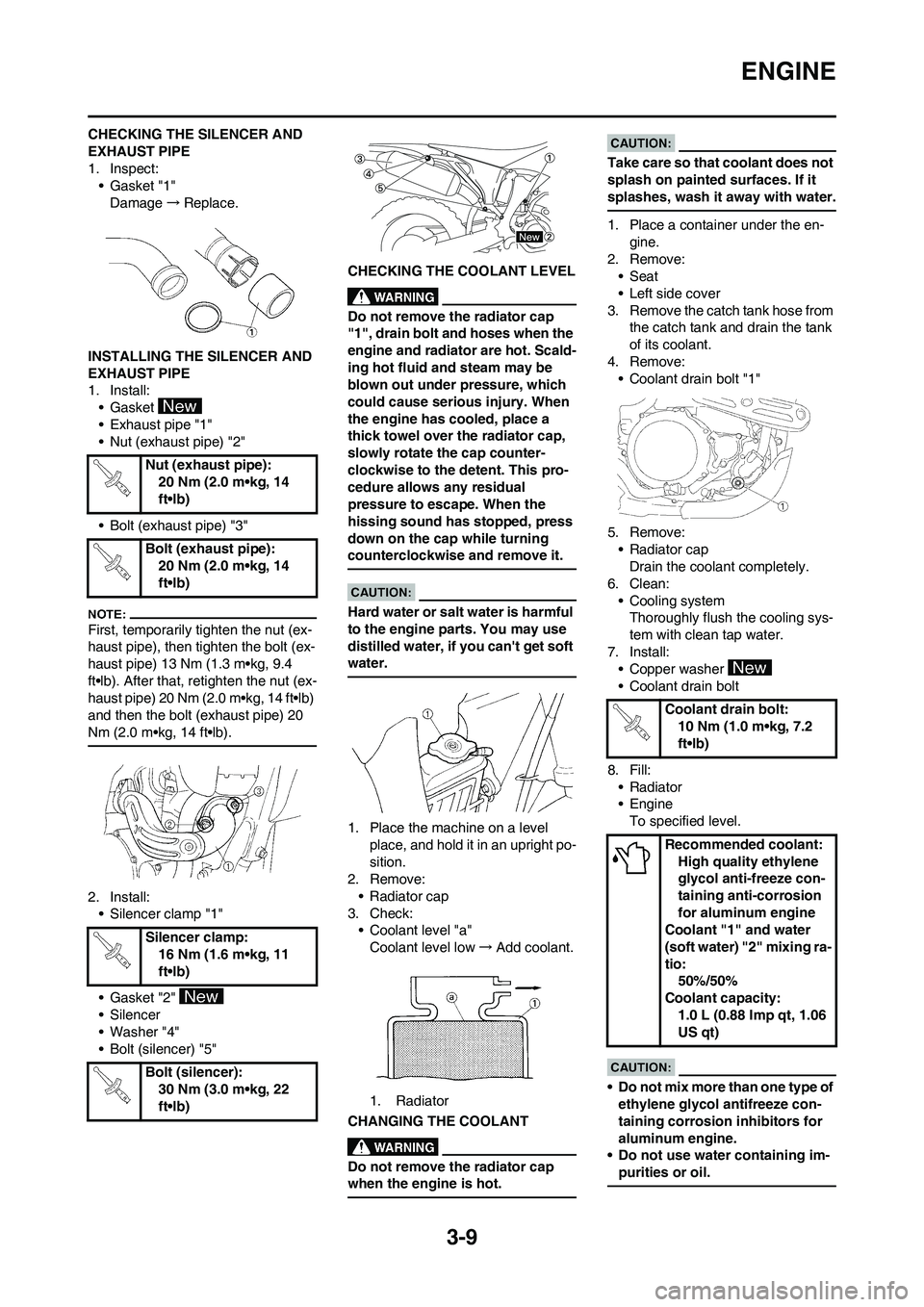

CHECKING THE SILENCER AND

EXHAUST PIPE

1. Inspect:

• Gasket "1"

Damage→Replace.

INSTALLING THE SILENCER AND

EXHAUST PIPE

1. Install:

• Gasket

• Exhaust pipe "1"

• Nut (exhaust pipe) "2"

• Bolt (exhaust pipe) "3"

First, temporarily tighten the nut (ex-

haust pipe), then tighten the bolt (ex-

haust pipe) 13 Nm (1.3 m•kg, 9.4

ft•lb). After that, retighten the nut (ex-

haust pipe) 20 Nm (2.0 m•kg, 14 ft•lb)

and then the bolt (exhaust pipe) 20

Nm (2.0 m•kg, 14 ft•lb).

2. Install:

• Silencer clamp "1"

• Gasket "2"

• Silencer

• Washer "4"

• Bolt (silencer) "5"CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove:

• Radiator cap

3. Check:

• Coolant level "a"

Coolant level low→Add coolant.

1. Radiator

CHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-

gine.

2. Remove:

• Seat

• Left side cover

3. Remove the catch tank hose from

the catch tank and drain the tank

of its coolant.

4. Remove:

• Coolant drain bolt "1"

5. Remove:

• Radiator cap

Drain the coolant completely.

6. Clean:

• Cooling system

Thoroughly flush the cooling sys-

tem with clean tap water.

7. Install:

• Copper washer

• Coolant drain bolt

8. Fill:

•Radiator

• Engine

To specified level.

• Do not mix more than one type of

ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Nut (exhaust pipe):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (exhaust pipe):

20 Nm (2.0 m•kg, 14

ft•lb)

Silencer clamp:

16 Nm (1.6 m•kg, 11

ft•lb)

Bolt (silencer):

30 Nm (3.0 m•kg, 22

ft•lb)

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio:

50%/50%

Coolant capacity:

1.0 L (0.88 Imp qt, 1.06

US qt)