engine YAMAHA WR 450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 450F, Model: YAMAHA WR 450F 2008Pages: 224, PDF Size: 13.7 MB

Page 206 of 224

7-5

ELECTRIC STARTING SYSTEM

4. Inspect:

• Sealed portion of ignition coil "a"

• Spark plug terminal pin "b"

• Threaded portion of spark plug "c"

Wear →Replace.

CHECKING THE AC MAGNETO

1. Inspect:

• Pickup coil resistance

Out of specification→Replace.

CHECKING THE NEUTRAL

SWITCH

1. Inspect:

• Neutral switch conduction

Not conductive while it is in neutral→

Replace.

Conductive while it is engaged→Re-

place.

Set the tester selection position to "Ω

× 1".

CHECKING THE CDI UNIT

Check all electrical components. If no

fault is found, replace the CDI unit.

Then check the electrical compo-

nents again.

ELECTRIC STARTING

SYSTEM

STARTING CIRCUIT CUT-OFF

SYSTEM OPERATION

If the main switch is set to "ON", the

starter motor can only operate if at

least one of the following conditions is

met:

• The transmission is in neutral (the

neutral switch is closed).

• The clutch lever is pulled to the han-

dlebar (the clutch switch is closed).

The starting circuit cut-off relay pre-

vents the starter motor from operating

when neither of these conditions has

been met. In this instance, the start-

ing circuit cut-off relay is open so cur-

rent cannot reach the starter motor.

When at least one of the above con-

ditions has been met the starting cir-

cuit cut-off relay is closed and the

engine can be started by pressing the

start switch.

WHEN THE TRANSMISSION IS IN

NEUTRAL

WHEN THE CLUTCH LEVER IS

PULLED TO THE HANDLEBAR1. Battery

2. Main fuse

3. Main switch

4. Starting circuit cut-off relay

5. Start switch

6. Diode

7. Clutch switch

8. Neutral switch

9. Starter relay

10. Starter motor Tester (+) lead→Red lead "1"

Tester (-) lead→White lead "2"

Pickup coil

resistanceTester se-

lector posi-

tion

248–372 Ω

at 20 °C (68

°F) Ω × 100

Tester (+) lead→Sky blue lead "1"

Tester (-) lead→Ground "2"

Result

Conductive (while gear

is in neutral)

Page 215 of 224

7-14

CHARGING SYSTEM

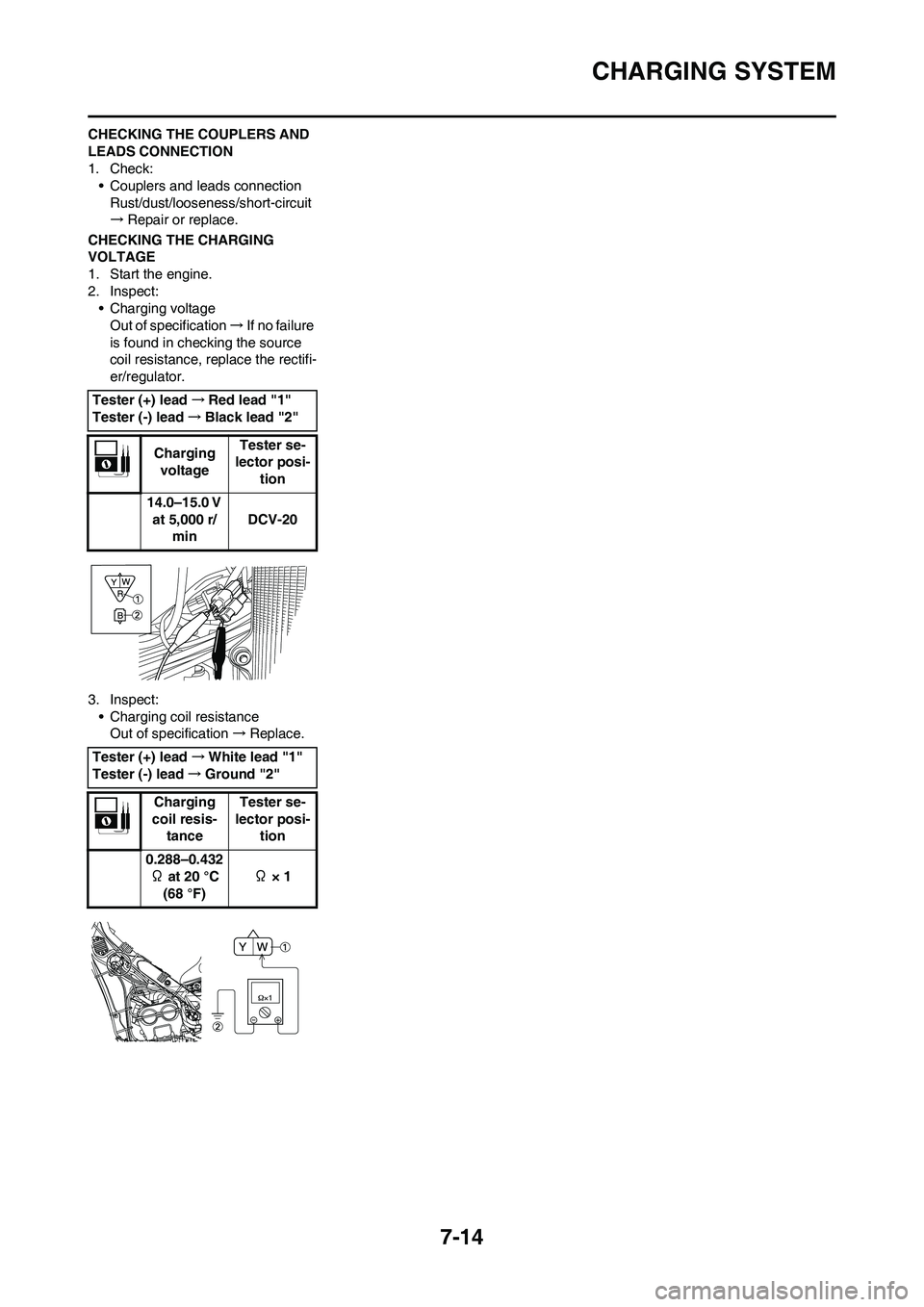

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE CHARGING

VOLTAGE

1. Start the engine.

2. Inspect:

• Charging voltage

Out of specification→If no failure

is found in checking the source

coil resistance, replace the rectifi-

er/regulator.

3. Inspect:

• Charging coil resistance

Out of specification→Replace. Tester (+) lead→Red lead "1"

Tester (-) lead→Black lead "2"

Charging

voltageTester se-

lector posi-

tion

14.0–15.0 V

at 5,000 r/

minDCV-20

Tester (+) lead→White lead "1"

Tester (-) lead→Ground "2"

Charging

coil resis-

tanceTester se-

lector posi-

tion

0.288–0.432

Ω at 20 °C

(68 °F)Ω × 1

Page 217 of 224

7-16

THROTTLE POSITION SENSOR SYSTEM

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE THROTTLE

POSITION SENSOR COIL

1. Inspect:

• Throttle position sensor coil resis-

tance

Out of specification→Replace.

2. Loosen:

• Throttle stop screw "1"

Turn out the throttle stop screw until

the throttle shaft is in the full close po-

sition.

3. Inspect:

• Throttle position sensor coil vari-

able resistance

Check that the resistance in in-

creased as the throttle grip is

moved from the full close position

to the full open position.

Out of specification→Replace.

CHANGING AND ADJUSTING THE

THROTTLE POSITION SENSOR

1. Remove:

• Throttle position sensor coupler

• Carburetor

2. Remove:

• Screw (throttle position sensor)

"1"

• Throttle position sensor "2"

Loosen the screw (throttle position

sensor) using the T25 bit.

3. Replace:

• Throttle position sensor

4. Install:

• Throttle position sensor "1"

• Screw (throttle position sensor)

"2"

• Align the slot "a" in the throttle posi-

tion sensor with the projection "b"

on the carburetor.

• Temporarily tighten the screw

(throttle position sensor).

5. Install:

•Carburetor

• Throttle position sensor coupler

6. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3.

7. Insert the thin electric conductors

"2" (lead) into the throttle position

sensor coupler "1", as shown, and

connect the tester to them.

• Do not insert the electric conduc-

tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit

does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

8. Start the engine.

9. Adjust:

• Throttle position sensor output

voltage

Adjustment steps:

a. Adjust the installation angle of the

throttle position sensor "1" to ob-

tain the specified output voltage. Tester (+) lead→Blue lead "1"

Tester (-) lead→Black lead "2"

Throttle po-

sition sen-

sor coil

resistanceTester se-

lector posi-

tion

4–6 kΩ at

20°C (68 °F) kΩ×1

Tester (+) lead→Yellow lead "1"

Tester (-) lead→Black lead "2"

Throttle position

sensor coil vari-

able resistanceTester

selec-

tor po-

sition

Full

closedFull

opened

kΩ×1 Zero –2

kΩat

20°C

(68 °F)4–6

kΩat

20 °C

(68 °F)

Tester (+) lead→Yellow lead "3"

Tester (-) lead→Black lead "4"

Page 218 of 224

7-17

THROTTLE POSITION SENSOR SYSTEM

Measure the output voltage accurate-

ly with a digital electronic voltmeter

that gives an easy reading of a small

voltage.

10. Put the aligning marks "a" on the

throttle position sensor and car-

buretor.

11. Stop the engine.

12. Remove the carburetor.

13. Tighten:

• Screw (throttle position sensor)

"1"

Tighten the screw (throttle position

sensor) using the T25 bit.

14. Install the carburetor.CHECKING THE THROTTLE

POSITION SENSOR INPUT

VOLTAGE

1. Disconnect the throttle position

sensor coupler.

2. Start the engine.

3. Inspect:

• Throttle position sensor input volt-

age

Out of specification→Replace the

CDI unit. Throttle po-

sition sen-

sor output

voltageTester se-

lector posi-

tion

0.58–0.78 V DCV

Tester (+) lead→Blue lead "1"

Tester (-) lead→Black/Blue lead

"2"

Throttle po-

sition sen-

sor input

voltage Tester se-

lector posi-

tion

4–6 V DCV-20

Page 220 of 224

7-19

LIGHTING SYSTEM

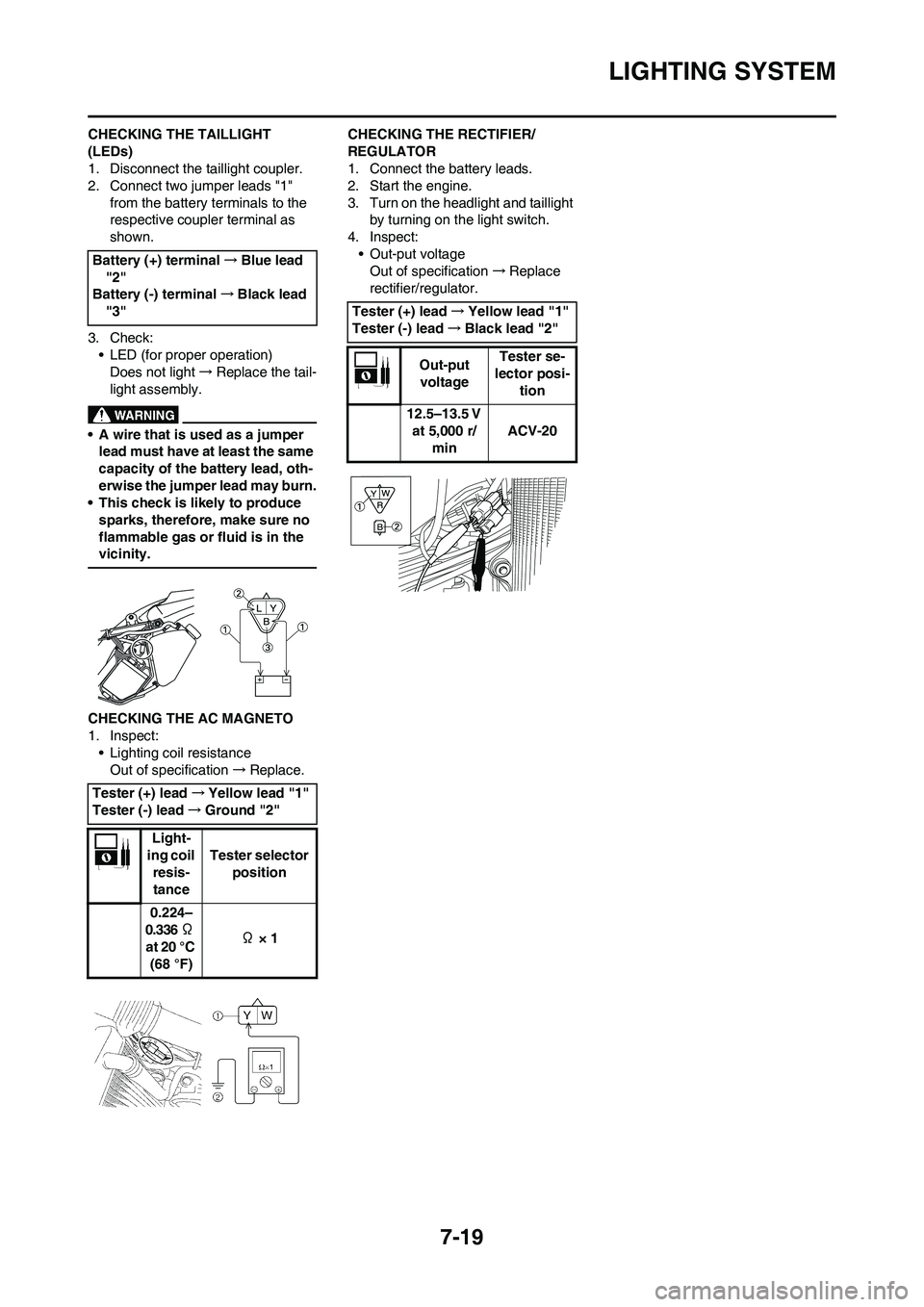

CHECKING THE TAILLIGHT

(LEDs)

1. Disconnect the taillight coupler.

2. Connect two jumper leads "1"

from the battery terminals to the

respective coupler terminal as

shown.

3. Check:

• LED (for proper operation)

Does not light→Replace the tail-

light assembly.

• A wire that is used as a jumper

lead must have at least the same

capacity of the battery lead, oth-

erwise the jumper lead may burn.

• This check is likely to produce

sparks, therefore, make sure no

flammable gas or fluid is in the

vicinity.

CHECKING THE AC MAGNETO

1. Inspect:

• Lighting coil resistance

Out of specification→Replace.CHECKING THE RECTIFIER/

REGULATOR

1. Connect the battery leads.

2. Start the engine.

3. Turn on the headlight and taillight

by turning on the light switch.

4. Inspect:

• Out-put voltage

Out of specification→Replace

rectifier/regulator. Battery (+) terminal→Blue lead

"2"

Battery (-) terminal→Black lead

"3"

Tester (+) lead→Yellow lead "1"

Tester (-) lead→Ground "2"

Light-

ing coil

resis-

tanceTester selector

position

0.224–

0.336 Ω

at 20 °C

(68 °F) Ω × 1

Tester (+) lead→Yellow lead "1"

Tester (-) lead→Black lead "2"

Out-put

voltageTester se-

lector posi-

tion

12.5–13.5 V

at 5,000 r/

minACV-20