engine YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 282 of 426

SHIFT SHAFT

6-55

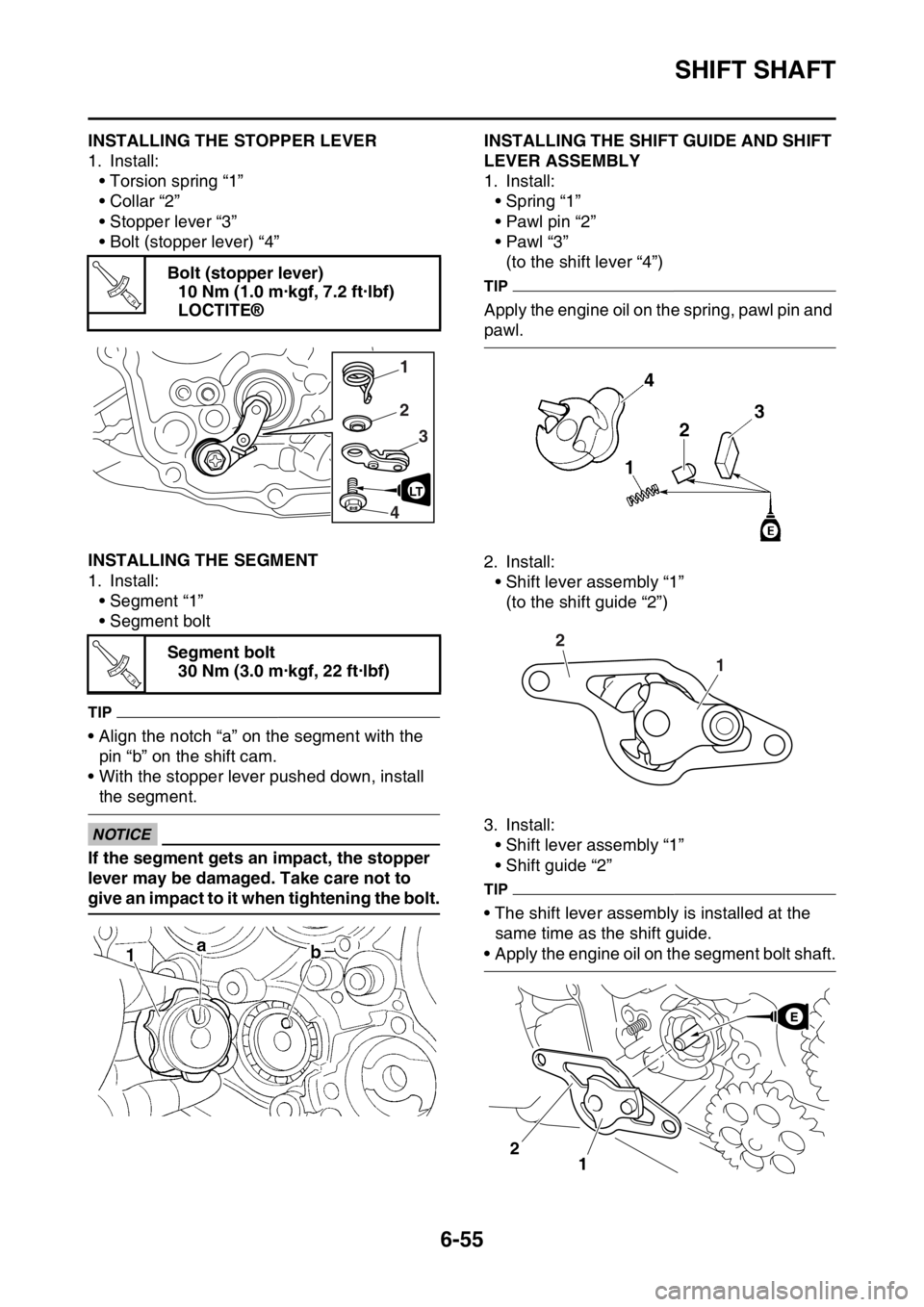

EAS2GC1293INSTALLING THE STOPPER LEVER

1. Install:• Torsion spring “1”

• Collar “2”

• Stopper lever “3”

• Bolt (stopper lever) “4”

EAS2GC1294INSTALLING THE SEGMENT

1. Install:• Segment “1”

• Segment bolt

TIP

• Align the notch “a” on the segment with the pin “b” on the shift cam.

• With the stopper lever pushed down, install

the segment.

ECA

NOTICE

If the segment gets an impact, the stopper

lever may be damaged. Take care not to

give an impact to it when tightening the bolt.

EAS2GC1295INSTALLING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Install: • Spring “1”

• Pawl pin “2”

•Pawl “3”(to the shift lever “4”)

TIP

Apply the engine oil on the spring, pawl pin and

pawl.

2. Install:

• Shift lever assembly “1”(to the shift guide “2”)

3. Install: • Shift lever assembly “1”

• Shift guide “2”

TIP

• The shift lever assembly is installed at the

same time as the shift guide.

• Apply the engine oil on the segment bolt shaft.

Bolt (stopper lever)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Segment bolt 30 Nm (3.0 m·kgf, 22 ft·lbf)

T R..

2

1

3

4

LT

T R..1

2

1

2

Page 283 of 426

SHIFT SHAFT

6-56

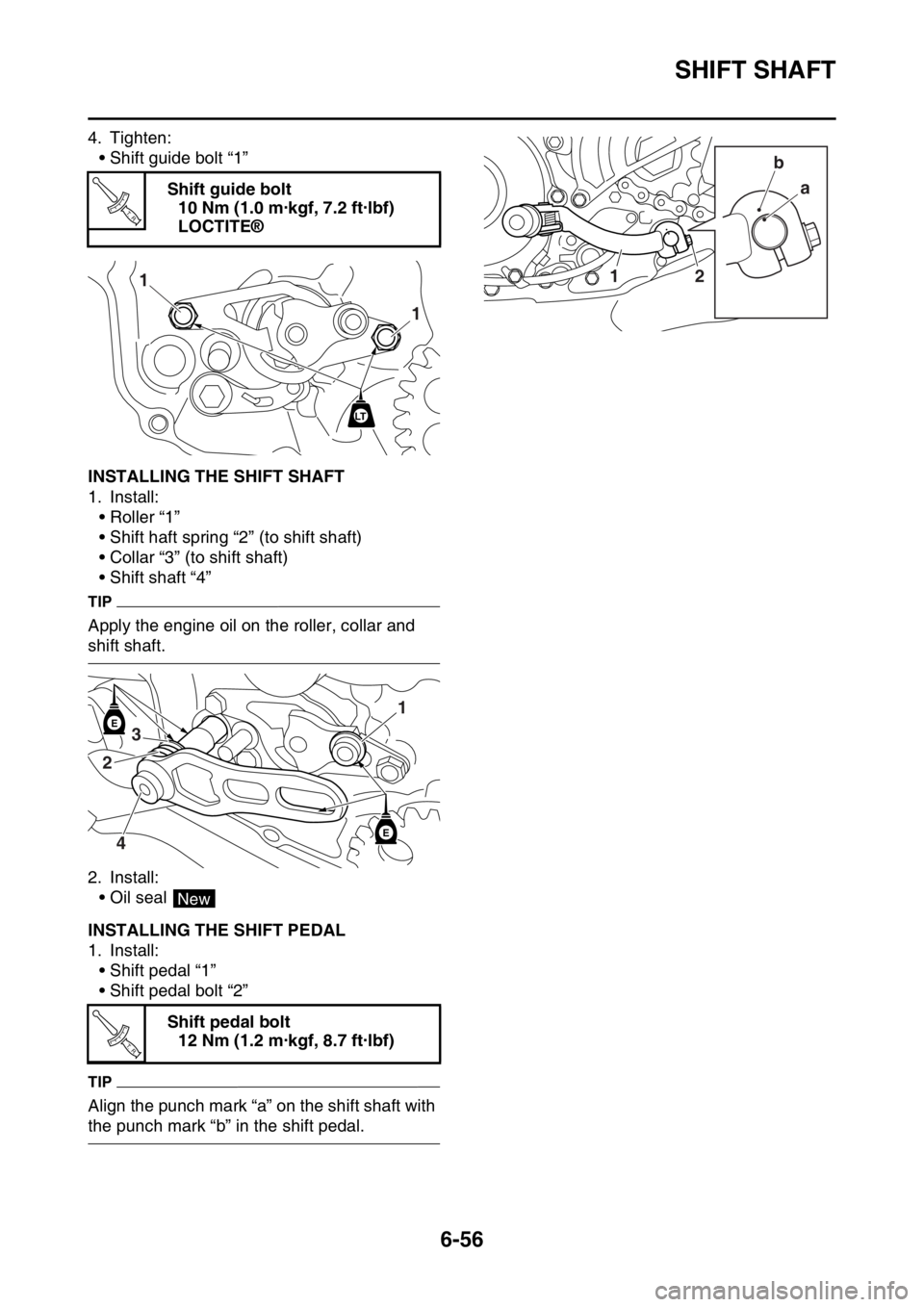

4. Tighten:• Shift guide bolt “1”

EAS2GC1296INSTALLING THE SHIFT SHAFT

1. Install:• Roller “1”

• Shift haft spring “2” (to shift shaft)

• Collar “3” (to shift shaft)

• Shift shaft “4”

TIP

Apply the engine oil on the roller, collar and

shift shaft.

2. Install:• Oil seal

EAS2GC1297INSTALLING THE SHIFT PEDAL

1. Install:• Shift pedal “1”

• Shift pedal bolt “2”

TIP

Align the punch mark “a” on the shift shaft with

the punch mark “b” in the shift pedal. Shift guide bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Shift pedal bolt 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

T R..

1

1

LT

E

E

1

2 3

4

New

T R..

a

12 b

Page 287 of 426

OIL PUMP AND BALANCER GEAR

6-60

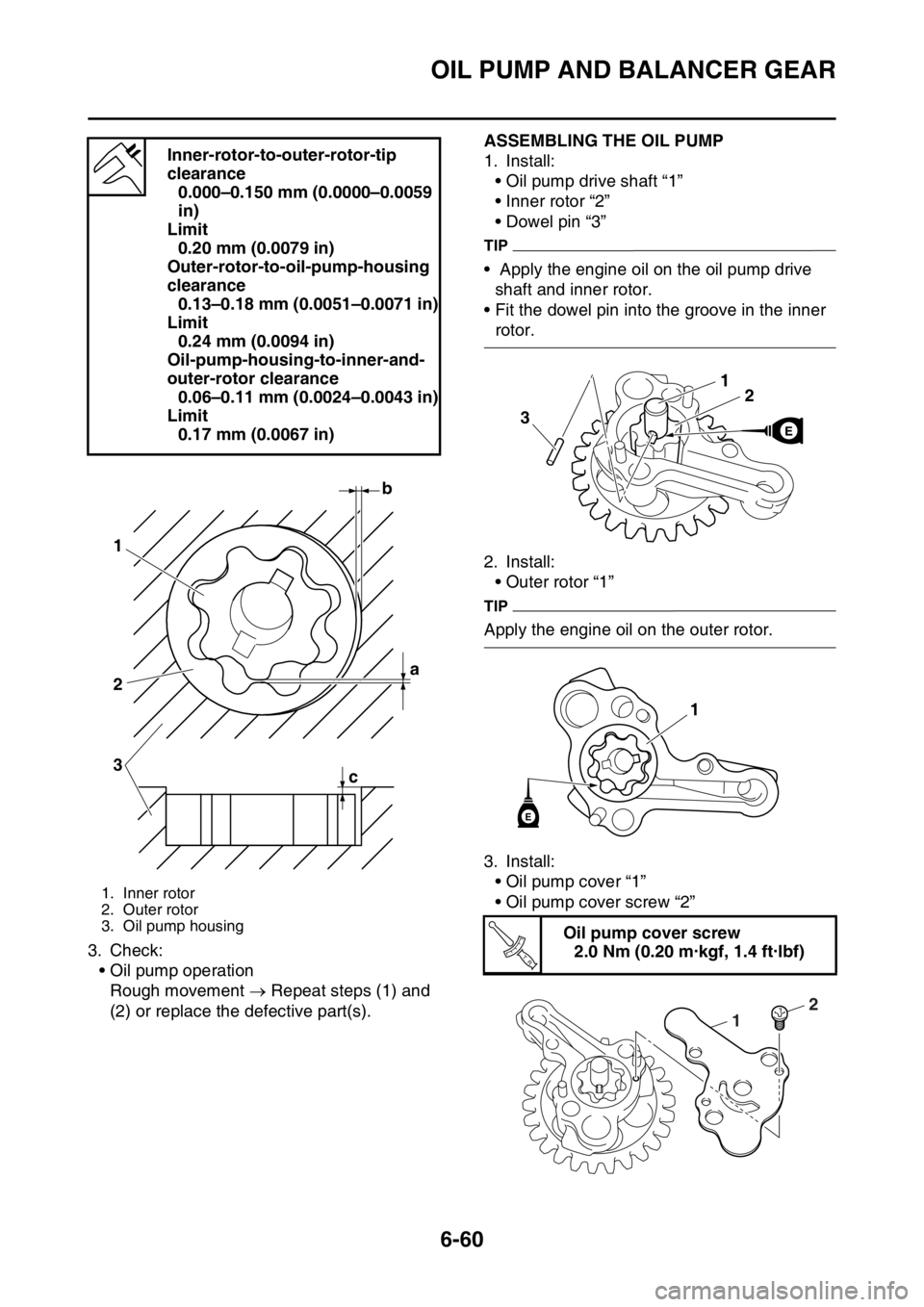

3. Check:• Oil pump operationRough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS2GC1303ASSEMBLING THE OIL PUMP

1. Install: • Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.

2. Install: • Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:• Oil pump cover “1”

• Oil pump cover screw “2”

Inner-rotor-to-outer-rotor-tip

clearance

0.000–0.150 mm (0.0000–0.0059

in)

Limit 0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing

clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-

outer-rotor clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.17 mm (0.0067 in)

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a

1

2

3

c

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

21

3

1

E

T R..

2

1

Page 288 of 426

OIL PUMP AND BALANCER GEAR

6-61

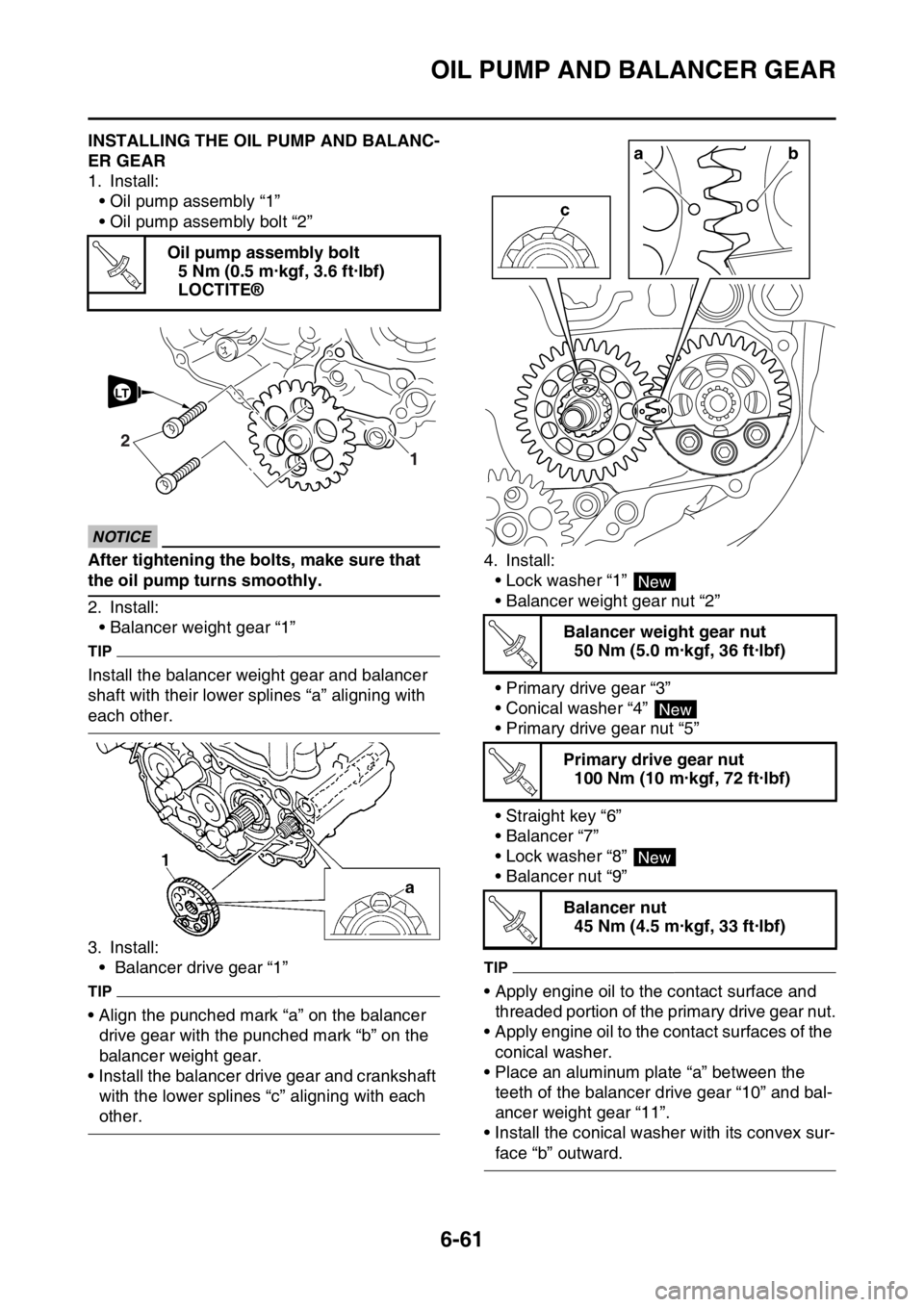

EAS2GC1304INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA1DX1023

NOTICE

After tightening the bolts, make sure that

the oil pump turns smoothly.

2. Install:• Balancer weight gear “1”

TIP

Install the balancer weight gear and balancer

shaft with their lower sp lines “a” aligning with

each other.

3. Install:

• Balancer drive gear “1”

TIP

• Align the punched mark “a” on the balancer drive gear with the punched mark “b” on the

balancer weight gear.

• Install the balancer drive gear and crankshaft with the lower splines “c” aligning with each

other. 4. Install:

• Lock washer “1”

• Balancer weight gear nut “2”

• Primary drive gear “3”

• Conical washer “4”

• Primary drive gear nut “5”

• Straight key “6”

•Balancer “7”

• Lock washer “8”

• Balancer nut “9”

TIP

• Apply engine oil to the contact surface and threaded portion of the primary drive gear nut.

• Apply engine oil to the contact surfaces of the

conical washer.

• Place an aluminum plate “a” between the teeth of the balancer drive gear “10” and bal-

ancer weight gear “11”.

• Install the conical wash er with its convex sur-

face “b” outward.

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

T R..

1

2

LT

Balancer weight gear nut50 Nm (5.0 m·kgf, 36 ft·lbf)

Primary drive gear nut 100 Nm (10 m·kgf, 72 ft·lbf)

Balancer nut 45 Nm (4.5 m·kgf, 33 ft·lbf)

ba

New

T R..

New

T R..

New

T R..

Page 290 of 426

GENERATOR AND STARTER CLUTCH

6-63

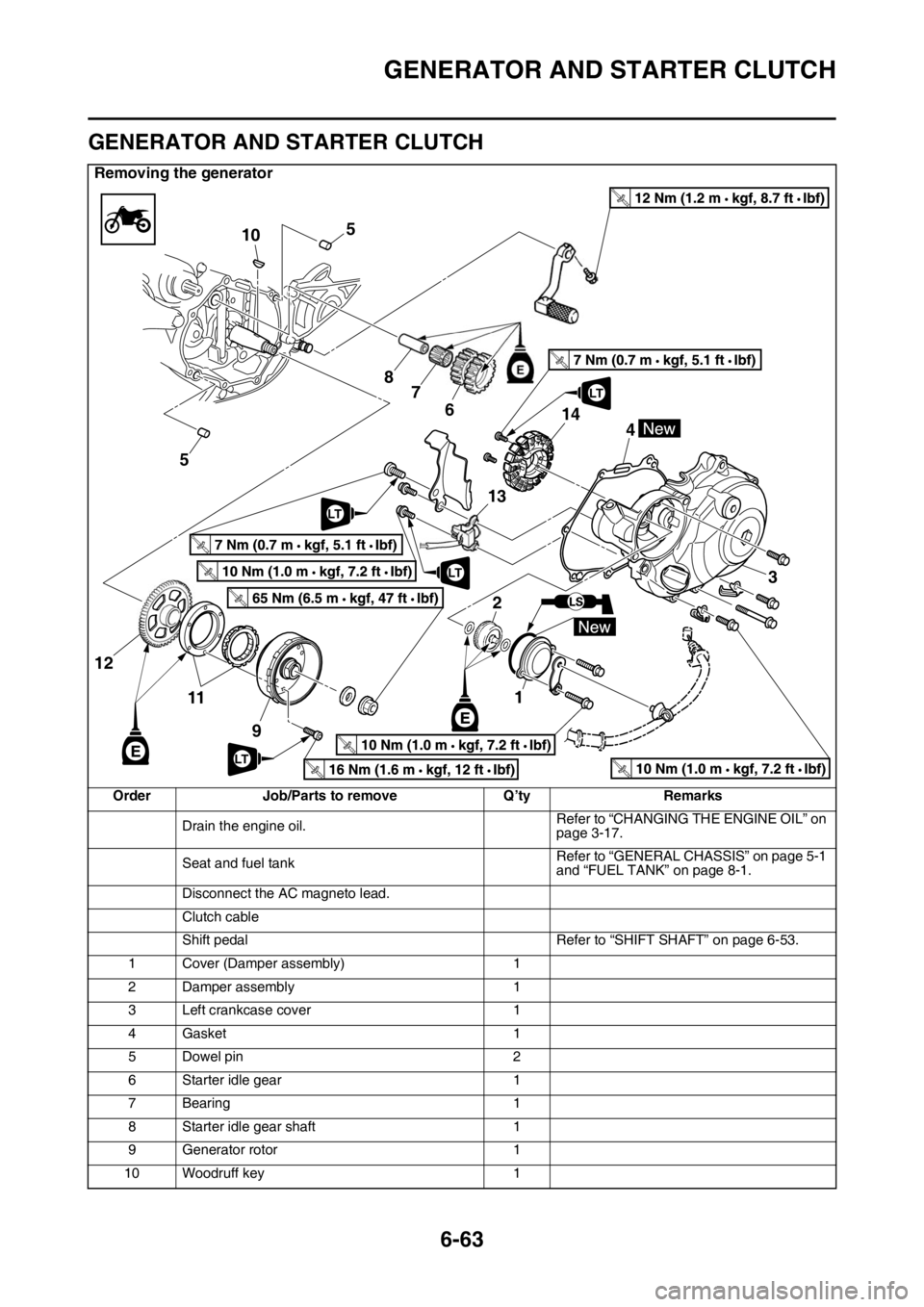

EAS2GC1305

GENERATOR AND STARTER CLUTCH

Removing the generator

Order Job/Parts to remove Q’tyRemarks

Drain the engine oil. Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

Seat and fuel tank Refer to “GENERAL CHASSIS” on page 5-1

and “FUEL TANK” on page 8-1.

Disconnect the AC magneto lead.

Clutch cable

Shift pedal Refer to “SHIFT SHAFT” on page 6-53.

1 Cover (Damper assembly) 1

2 Damper assembly 1

3 Left crankcase cover 1

4Gasket 1

5 Dowel pin 2

6 Starter idle gear 1

7 Bearing 1

8 Starter idle gear shaft 1

9 Generator rotor 1

10 Woodruff key 1

T R..

T R..

T R..

5

5 10

87

6

21

13 3

4

11 9

12

T R..

T R..

T R..LT

LT

T R..

T R..

14

LT

LT

Page 293 of 426

GENERATOR AND STARTER CLUTCH

6-66

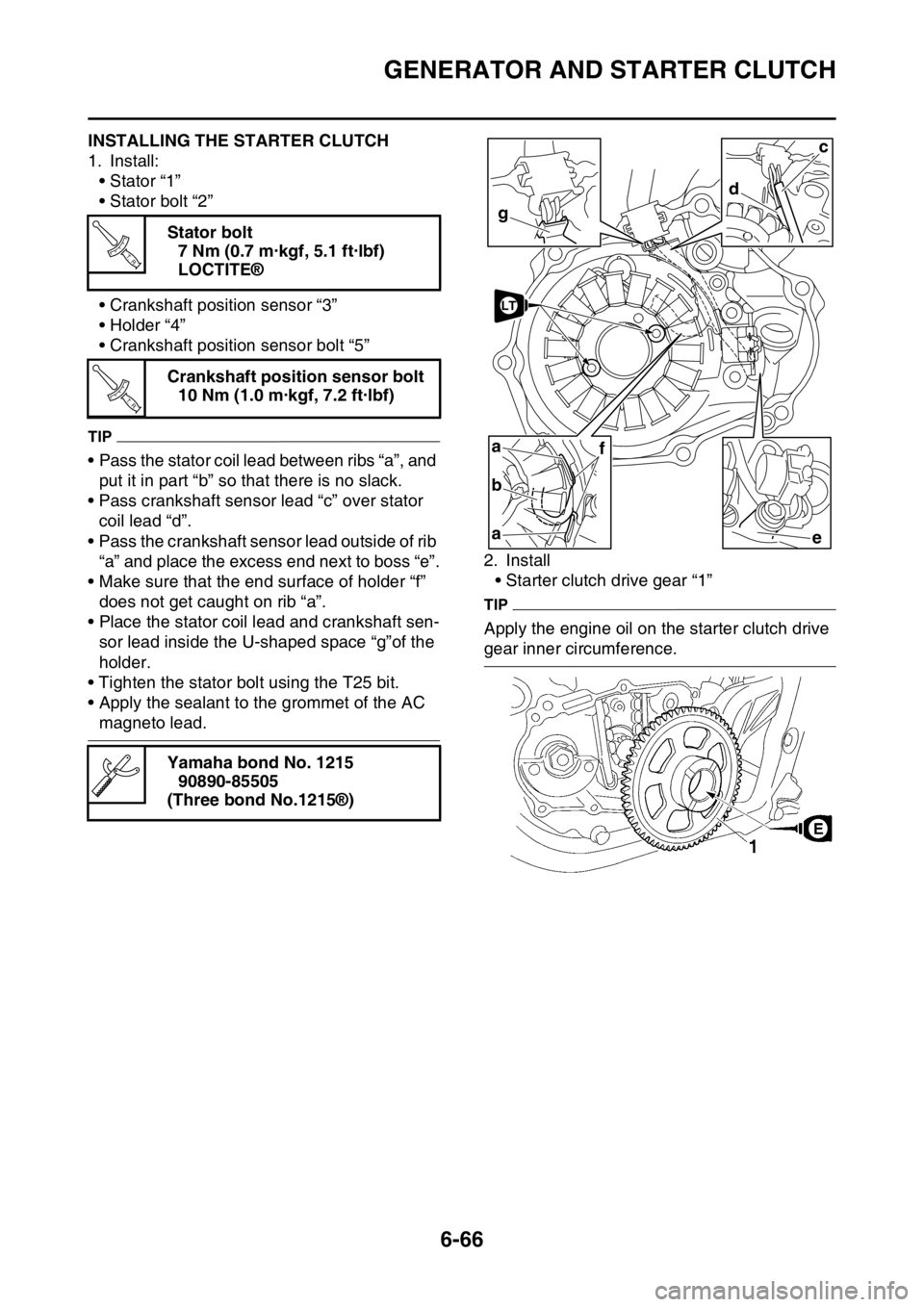

EAS2GC1308INSTALLING THE STARTER CLUTCH

1. Install:• Stator “1”

• Stator bolt “2”

• Crankshaft position sensor “3”

• Holder “4”

• Crankshaft position sensor bolt “5”

TIP

• Pass the stator coil lead between ribs “a”, and put it in part “b” so that there is no slack.

• Pass crankshaft sensor lead “c” over stator

coil lead “d”.

• Pass the crankshaft sensor lead outside of rib “a” and place the excess end next to boss “e”.

• Make sure that the end surface of holder “f” does not get caught on rib “a”.

• Place the stator coil lead and crankshaft sen-

sor lead inside the U-shaped space “g”of the

holder.

• Tighten the stator bolt using the T25 bit.

• Apply the sealant to the grommet of the AC

magneto lead. 2. Install

• Starter clutch drive gear “1”

TIP

Apply the engine oil on the starter clutch drive

gear inner circumference.

Stator bolt

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LOCTITE®

Crankshaft position sensor bolt 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215 90890-85505

(Three bond No.1215®)

T R..

T R..

g

d

c

ea

a

b

f

LT

Page 294 of 426

GENERATOR AND STARTER CLUTCH

6-67

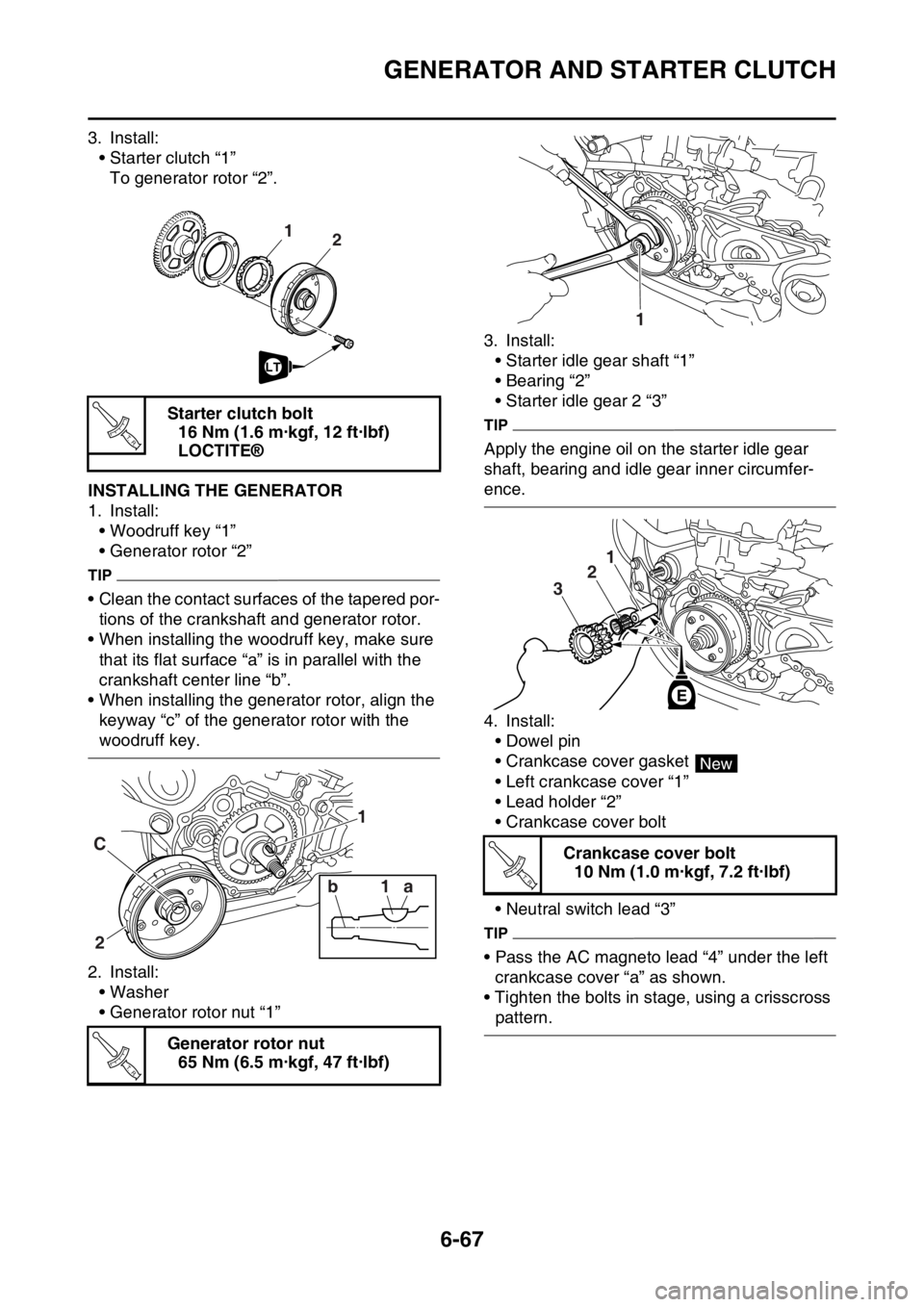

3. Install:• Starter clutch “1”To generator rotor “2”.

EAS2GC1309INSTALLING THE GENERATOR

1. Install:

• Woodruff key “1”

• Generator rotor “2”

TIP

• Clean the contact surfaces of the tapered por-tions of the crankshaft and generator rotor.

• When installing the woodruff key, make sure that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the generator rotor, align the keyway “c” of the generator rotor with the

woodruff key.

2. Install: • Washer

• Generator rotor nut “1” 3. Install:

• Starter idle gear shaft “1”

• Bearing “2”

• Starter idle gear 2 “3”

TIP

Apply the engine oil on the starter idle gear

shaft, bearing and idle gear inner circumfer-

ence.

4. Install:

• Dowel pin

• Crankcase cover gasket

• Left crankcase cover “1”

• Lead holder “2”

• Crankcase cover bolt

• Neutral switch lead “3”

TIP

• Pass the AC magneto lead “4” under the left crankcase cover “a” as shown.

• Tighten the bolts in stage, using a crisscross

pattern.

Starter clutch bolt

16 Nm (1.6 m·kgf, 12 ft·lbf)

LOCTITE®

Generator rotor nut 65 Nm (6.5 m·kgf, 47 ft·lbf)

21

LT

T R..

2

C

1 1

1a

b

T R..

Crankcase cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

1

2 1

2

3

New

T R..

Page 295 of 426

GENERATOR AND STARTER CLUTCH

6-68

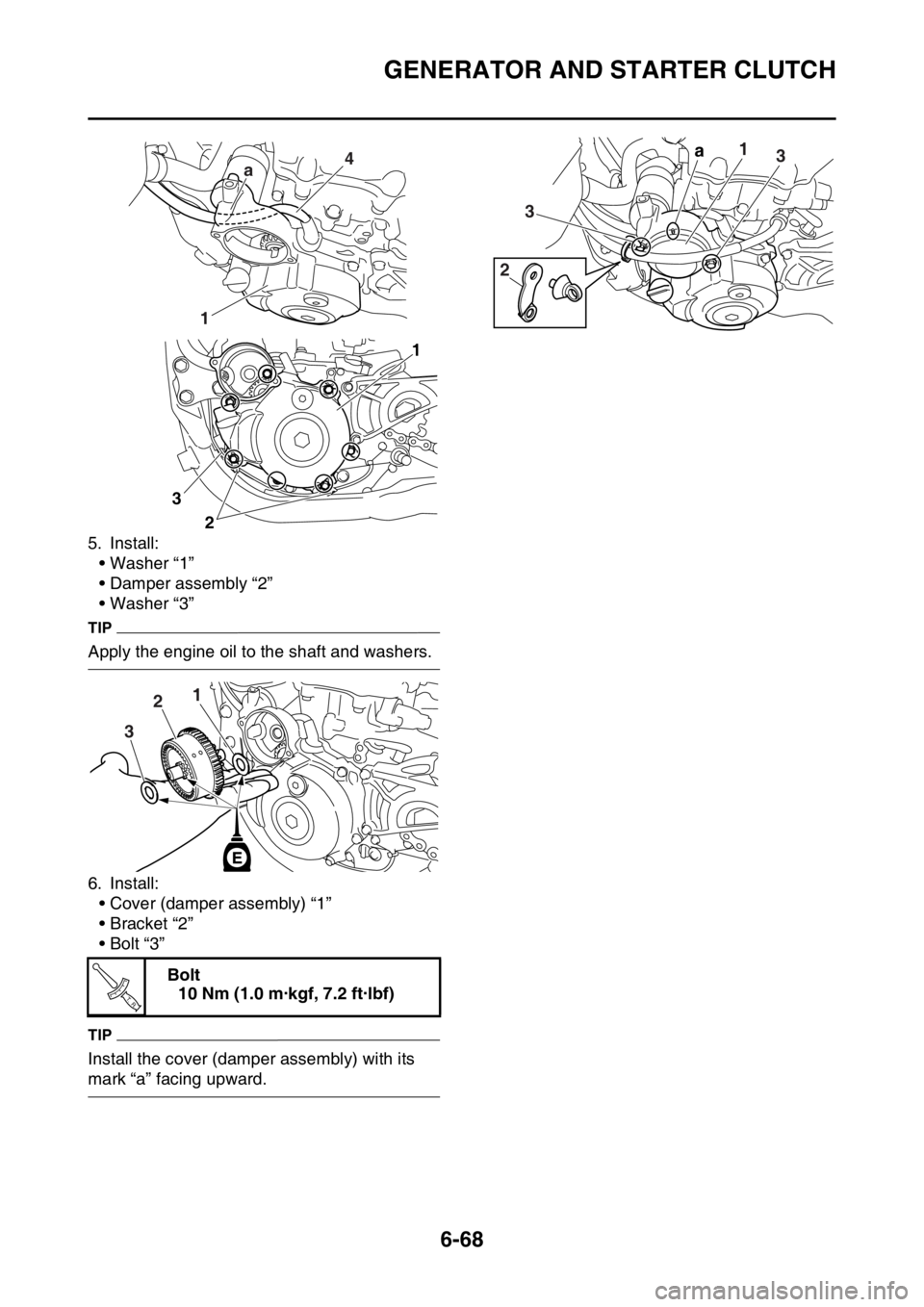

5. Install:• Washer “1”

• Damper assembly “2”

• Washer “3”

TIP

Apply the engine oil to the shaft and washers.

6. Install:• Cover (damper assembly) “1”

• Bracket “2”

•Bolt “3”

TIP

Install the cover (damper assembly) with its

mark “a” facing upward. Bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

4

1 a

1

2

3

2

1

2

3

T R..

1a3

3

2

Page 296 of 426

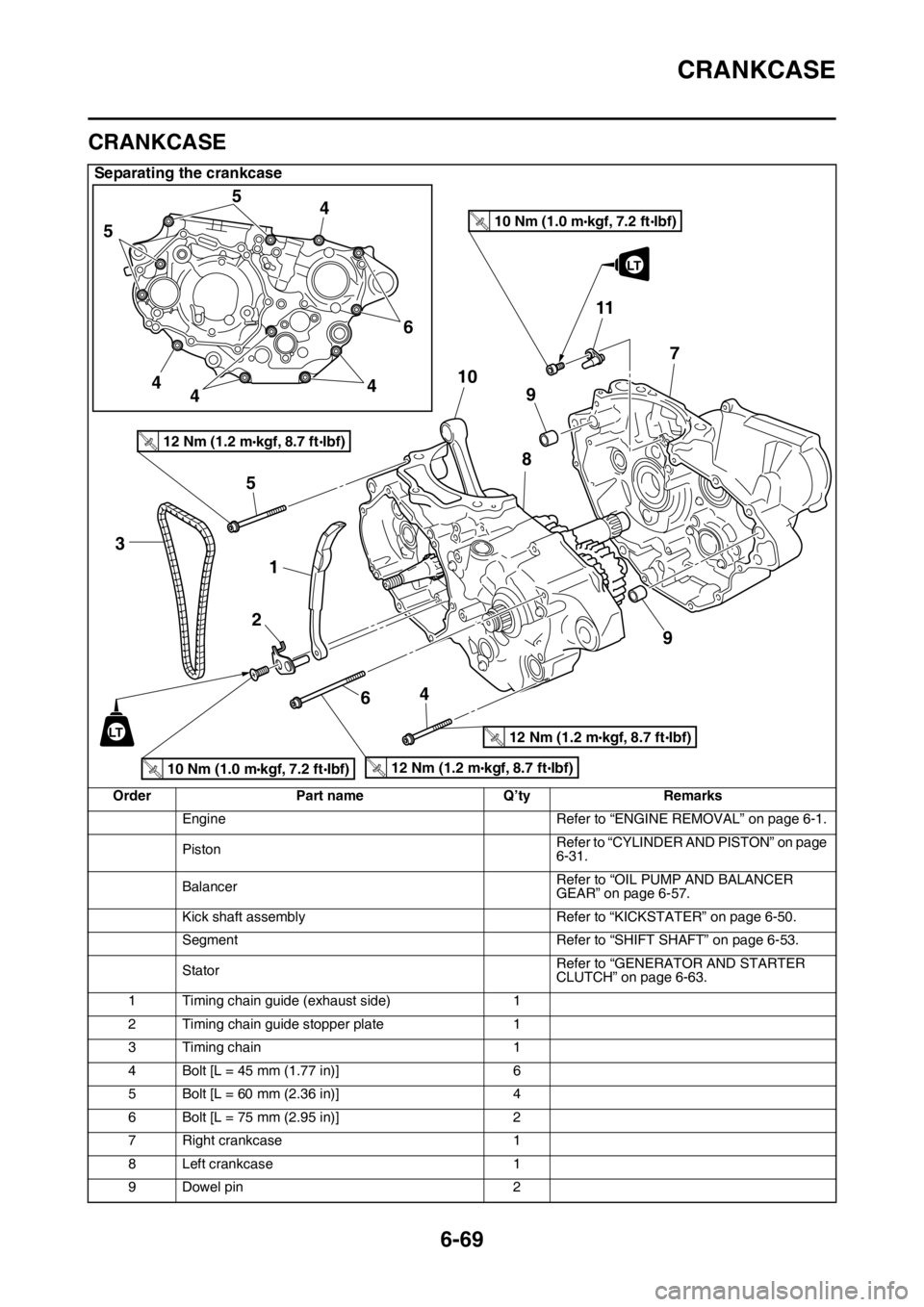

CRANKCASE

6-69

EAS2GC1310

CRANKCASE

Separating the crankcase

OrderPart name Q’tyRemarks

Engine Refer to “ENGINE REMOVAL” on page 6-1.

Piston Refer to “CYLINDER AND PISTON” on page

6-31.

Balancer Refer to “OIL PUMP AND BALANCER

GEAR” on page 6-57.

Kick shaft assembly Refer to “KICKSTATER” on page 6-50.

Segment Refer to “SHIFT SHAFT” on page 6-53.

Stator Refer to “GENERATOR AND STARTER

CLUTCH” on page 6-63.

1 Timing chain guide (exhaust side) 1

2 Timing chain guide stopper plate 1

3 Timing chain 1

4 Bolt [L = 45 mm (1.77 in)] 6

5 Bolt [L = 60 mm (2.36 in)] 4

6 Bolt [L = 75 mm (2.95 in)] 2

7 Right crankcase 1

8 Left crankcase 1

9 Dowel pin 2

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

3

1

5

2 6410

5

5

4

4 4 46

9 7

8

11

9

LT

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

LT

Page 299 of 426

CRANKCASE

6-72

EAS2GC1311DISASSEMBLING THE CRANKCASE

1. Separate:• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1”.

TIP

• Place the crankcase with its left side down-ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA33DD041

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force. c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1312REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by pressing its inner race.

• Do not use the removed bearing.

EAS2GC1313CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:• Timing chainStiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check: • Timing chain guide

Damage/wear Replace

EAS2GC1314CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

2. Check: • CrankcaseCrack/damage Replace.

1

a