torque YAMAHA WR 450F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 147 of 426

CHASSIS

4-6

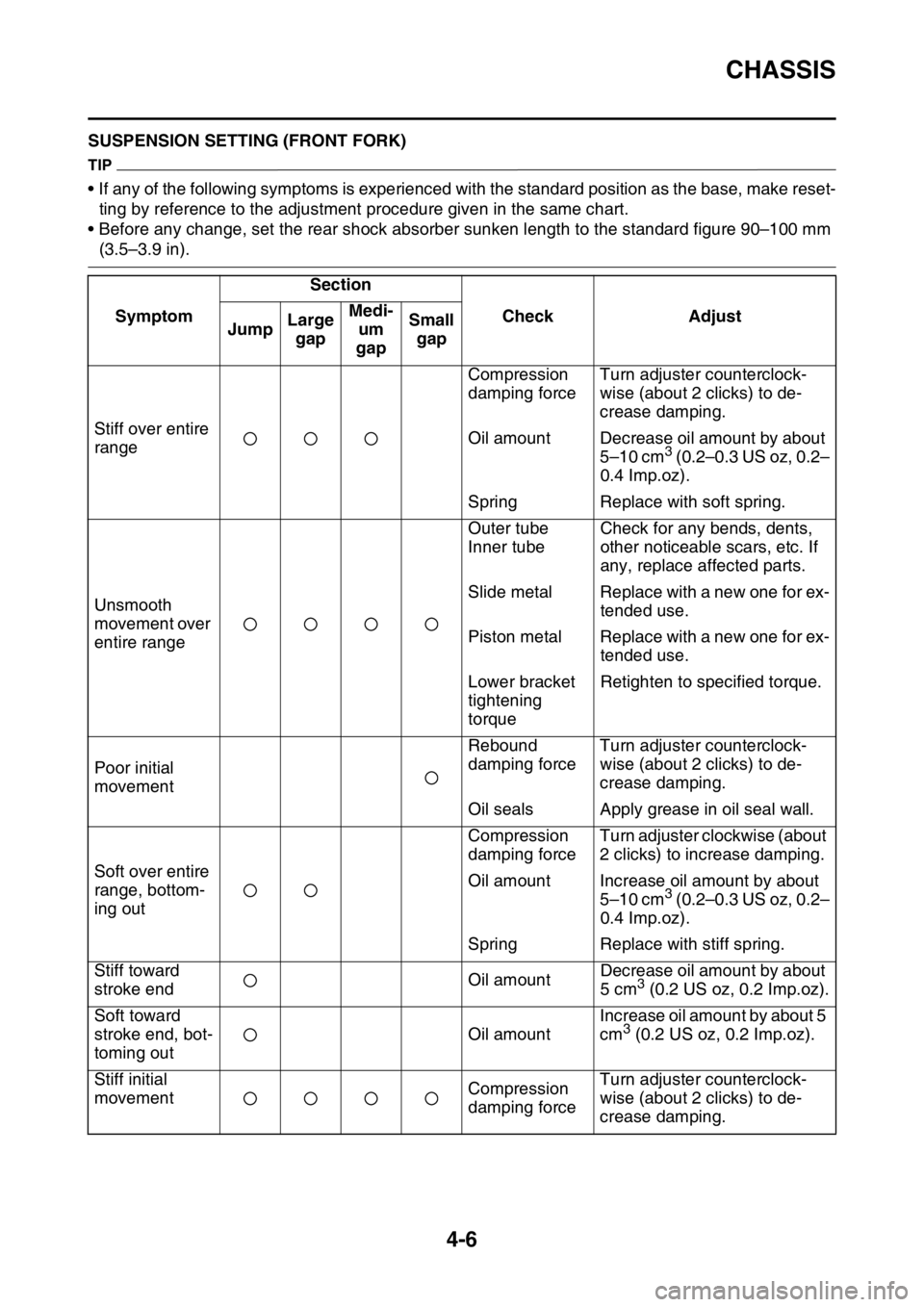

EAS2GC1148SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absor ber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

Symptom Section

CheckAdjust

Jump Large

gap Medi-

um

gap Small

gap

Stiff over entire

range Compression

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire range Outer tube

Inner tube

Check for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex- tended use.

Piston metal Replace with a new one for ex- tended use.

Lower bracket

tightening

torque Retighten to specified torque.

Poor initial

movement Rebound

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing out Compression

damping force

Turn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about 5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke end Oil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming out Oil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movement Compression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 203 of 426

FRONT FORK

5-51

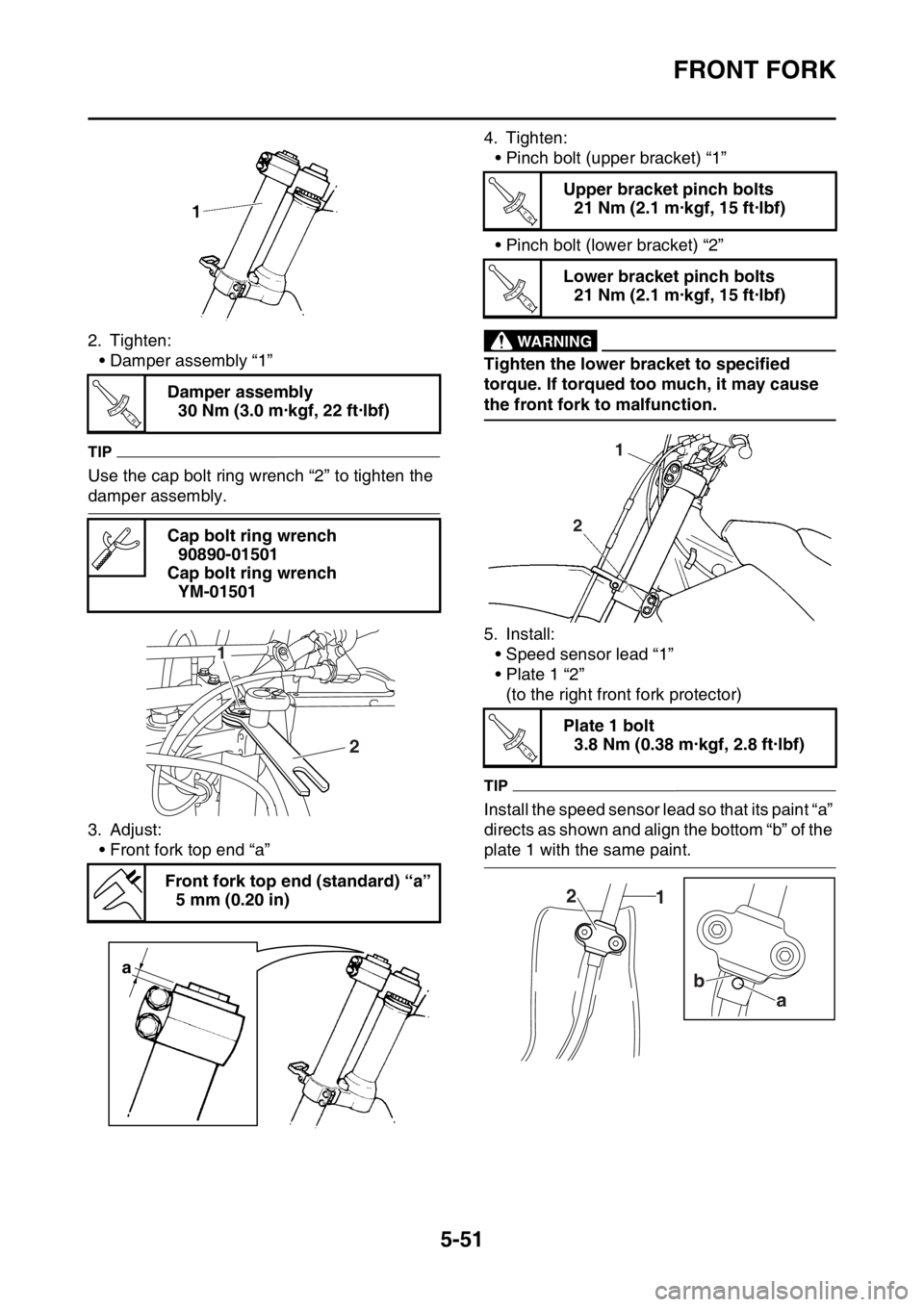

2. Tighten:• Damper assembly “1”

TIP

Use the cap bolt ring wrench “2” to tighten the

damper assembly.

3. Adjust:

• Front fork top end “a” 4. Tighten:

• Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:• Speed sensor lead “1”

• Plate 1 “2”(to the right front fork protector)

TIP

Install the speed sensor lead so that its paint “a”

directs as shown and align the bottom “b” of the

plate 1 with the same paint.

Damper assembly

30 Nm (3.0 m·kgf, 22 ft·lbf)

Cap bolt ring wrench 90890-01501

Cap bolt ring wrench YM-01501

Front fork top end (standard) “a” 5 mm (0.20 in)

T R..

2

1

a

Upper bracket pinch bolts21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Plate 1 bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

T R..

2 1

T R..

1

2

a

b

Page 209 of 426

STEERING HEAD

5-57

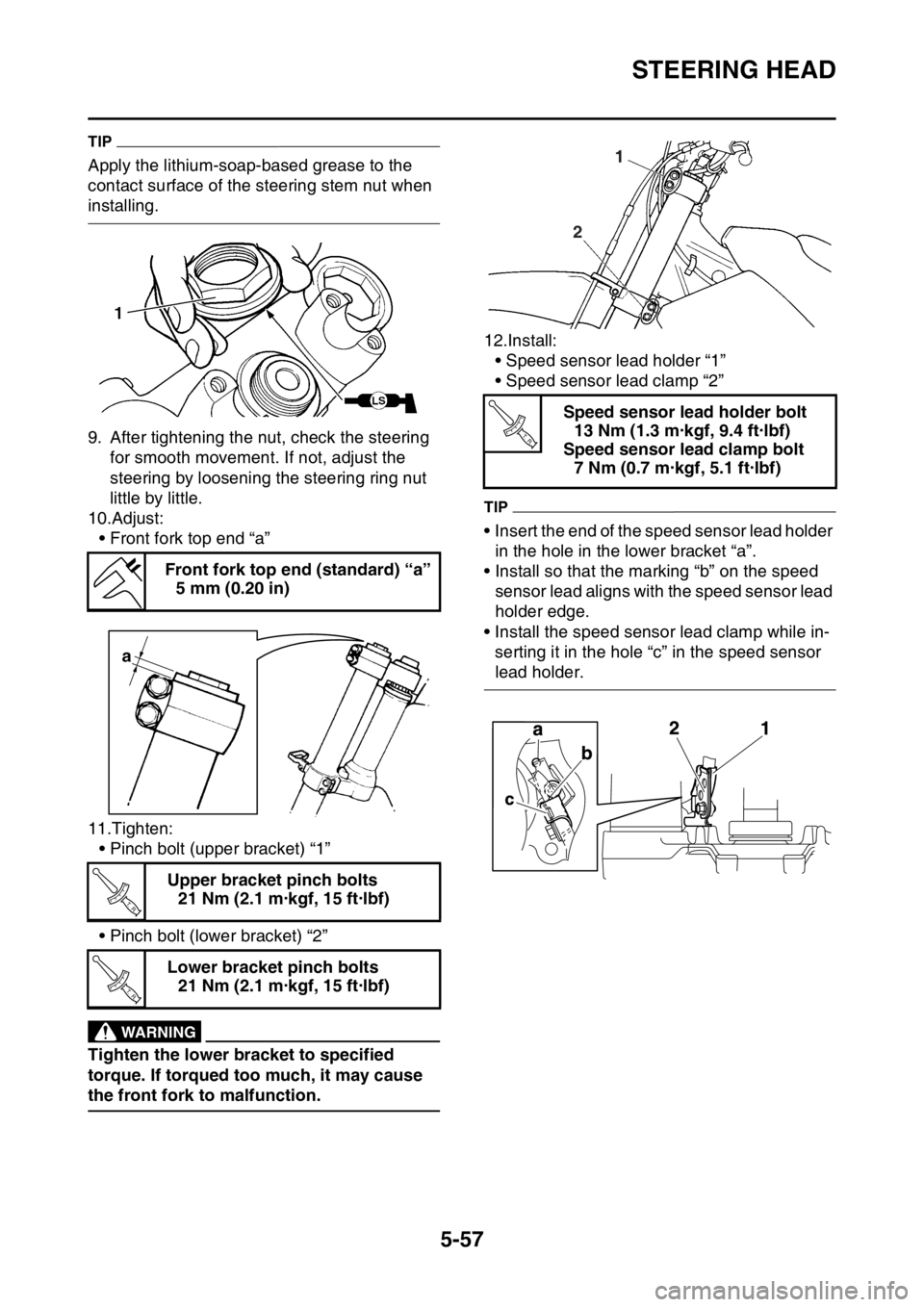

TIP

Apply the lithium-soap-based grease to the

contact surface of the steering stem nut when

installing.

9. After tightening the nut, check the steering for smooth movement. If not, adjust the

steering by loosening the steering ring nut

little by little.

10.Adjust:

• Front fork top end “a”

11.Tighten: • Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction. 12.Install:

• Speed sensor lead holder “1”

• Speed sensor lead clamp “2”

TIP

• Insert the end of the speed sensor lead holder

in the hole in the lower bracket “a”.

• Install so that the marking “b” on the speed sensor lead aligns with the speed sensor lead

holder edge.

• Install the speed sens or lead clamp while in-

serting it in the hole “c” in the speed sensor

lead holder.

Front fork top end (standard) “a”

5 mm (0.20 in)

Upper bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

a

T R..

T R..

Speed sensor lead holder bolt13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Speed sensor lead clamp bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

2 1

T R..

Page 218 of 426

SWINGARM

5-66

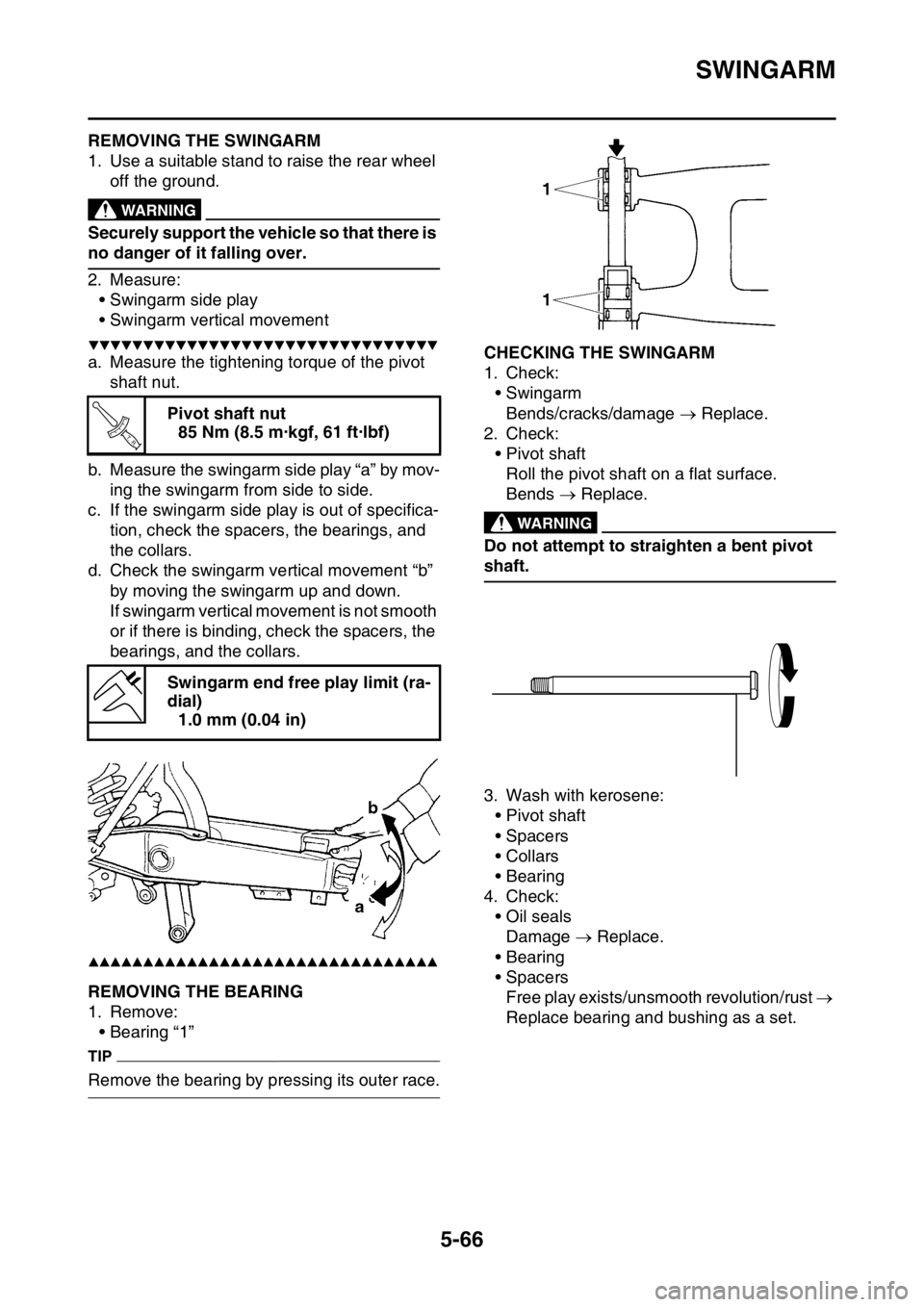

EAS2GC1217REMOVING THE SWINGARM

1. Use a suitable stand to raise the rear wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Measure:• Swingarm side play

• Swingarm vertical movement

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure the tightening torque of the pivot shaft nut.

b. Measure the swingarm side play “a” by mov- ing the swingarm from side to side.

c. If the swingarm side play is out of specifica- tion, check the spacers, the bearings, and

the collars.

d. Check the swingarm vertical movement “b” by moving the swingarm up and down.

If swingarm vertical movement is not smooth

or if there is binding, check the spacers, the

bearings, and the collars.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1218REMOVING THE BEARING

1. Remove:• Bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS2GC1219CHECKING THE SWINGARM

1. Check:• Swingarm

Bends/cracks/damage Replace.

2. Check: • Pivot shaft

Roll the pivot shaft on a flat surface.

Bends Replace.

EWA

WARNING

Do not attempt to straighten a bent pivot

shaft.

3. Wash with kerosene:

• Pivot shaft

• Spacers

•Collars

• Bearing

4. Check: • Oil seals

Damage Replace.

• Bearing

• Spacers Free play exists/unsmooth revolution/rust

Replace bearing and bushing as a set.

Pivot shaft nut

85 Nm (8.5 m·kgf, 61 ft·lbf)

Swingarm end free play limit (ra-

dial) 1.0 mm (0.04 in)

T R..

Page 243 of 426

CAMSHAFT

6-16

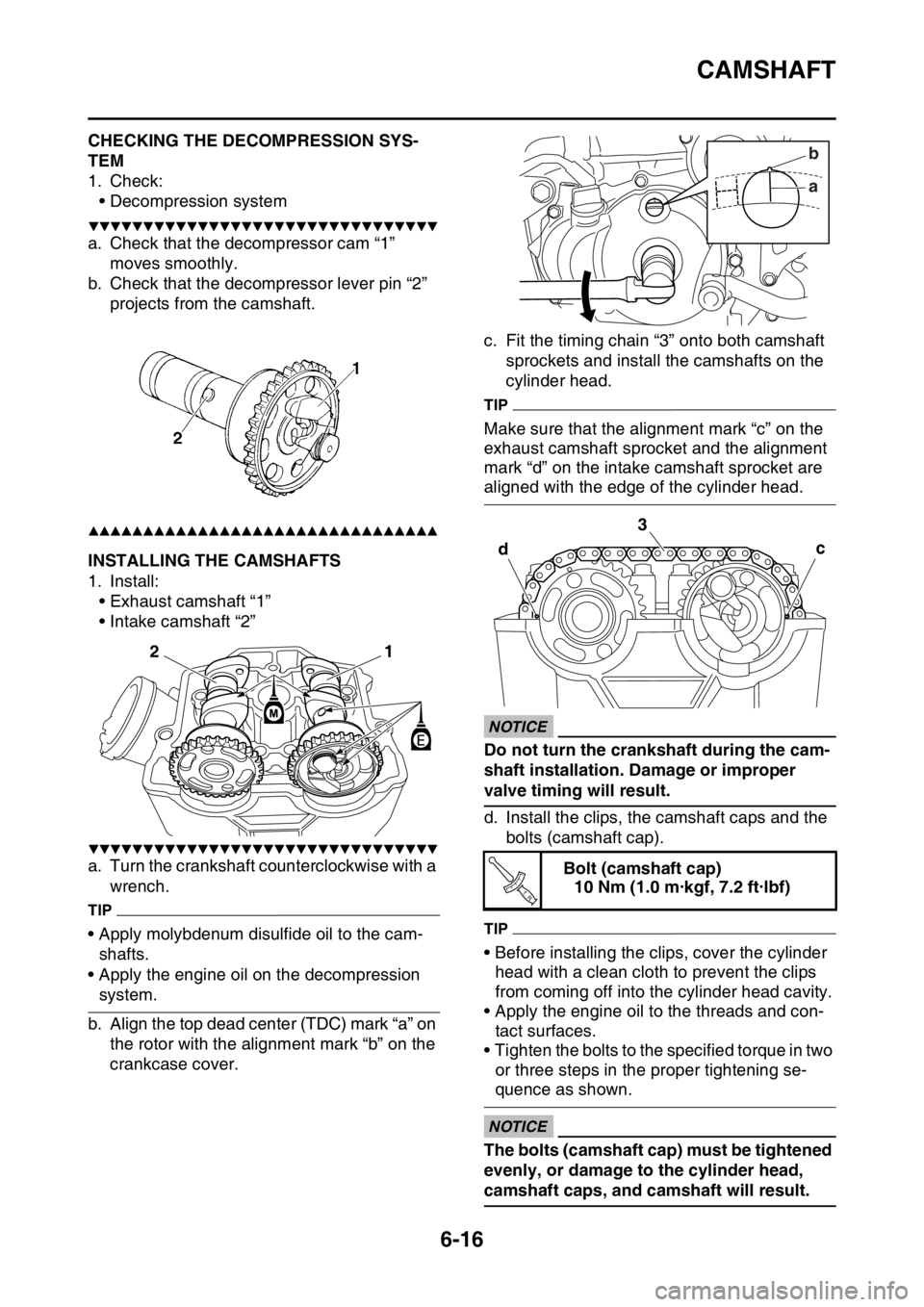

EAS2GC1242CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2” projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1243INSTALLING THE CAMSHAFTS

1. Install:• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on the rotor with the alignment mark “b” on the

crankcase cover. c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Apply the engine oil to the threads and con- tact surfaces.

• Tighten the bolts to the specified torque in two or three steps in the proper tightening se-

quence as shown.

ECA

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

ab

c

3

d

T R..

Page 248 of 426

CYLINDER HEAD

6-21

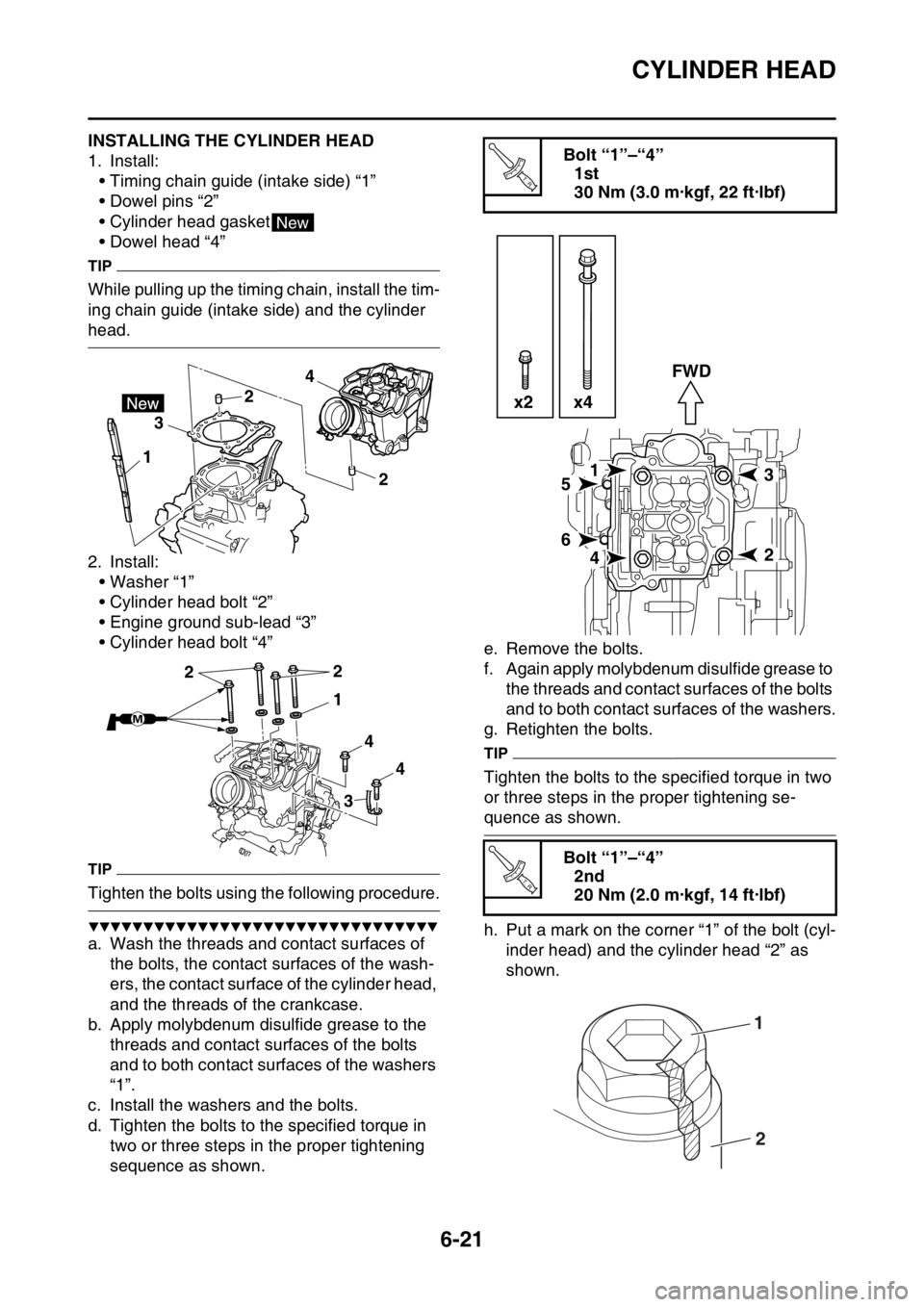

EAS2GC1248INSTALLING THE CYLINDER HEAD

1. Install:• Timing chain guide (intake side) “1”

• Dowel pins “2”

• Cylinder head gasket

• Dowel head “4”

TIP

While pulling up the timing chain, install the tim-

ing chain guide (intake side) and the cylinder

head.

2. Install:• Washer “1”

• Cylinder head bolt “2”

• Engine ground sub-lead “3”

• Cylinder head bolt “4”

TIP

Tighten the bolts using the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Wash the threads and contact surfaces of the bolts, the contact surfaces of the wash-

ers, the contact surface of the cylinder head,

and the threads of the crankcase.

b. Apply molybdenum disulfide grease to the threads and contact surfaces of the bolts

and to both contact surfaces of the washers

“1”.

c. Install the washers and the bolts.

d. Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown. e. Remove the bolts.

f. Again apply molybdenum disulfide grease to

the threads and contact surfaces of the bolts

and to both contact surfaces of the washers.

g. Retighten the bolts.

TIP

Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

h. Put a mark on the corner “1” of the bolt (cyl- inder head) and the cylinder head “2” as

shown.

New

1 2

2

4

3

1

3 4

2

2

4

Bolt “1”–“4”

1st

30 Nm (3.0 m·kgf, 22 ft·lbf)

Bolt “1”–“4” 2nd

20 Nm (2.0 m·kgf, 14 ft·lbf)

T R..

15

6

42

3

FWD

x2 x4

T R..

1

2

Page 249 of 426

CYLINDER HEAD

6-22

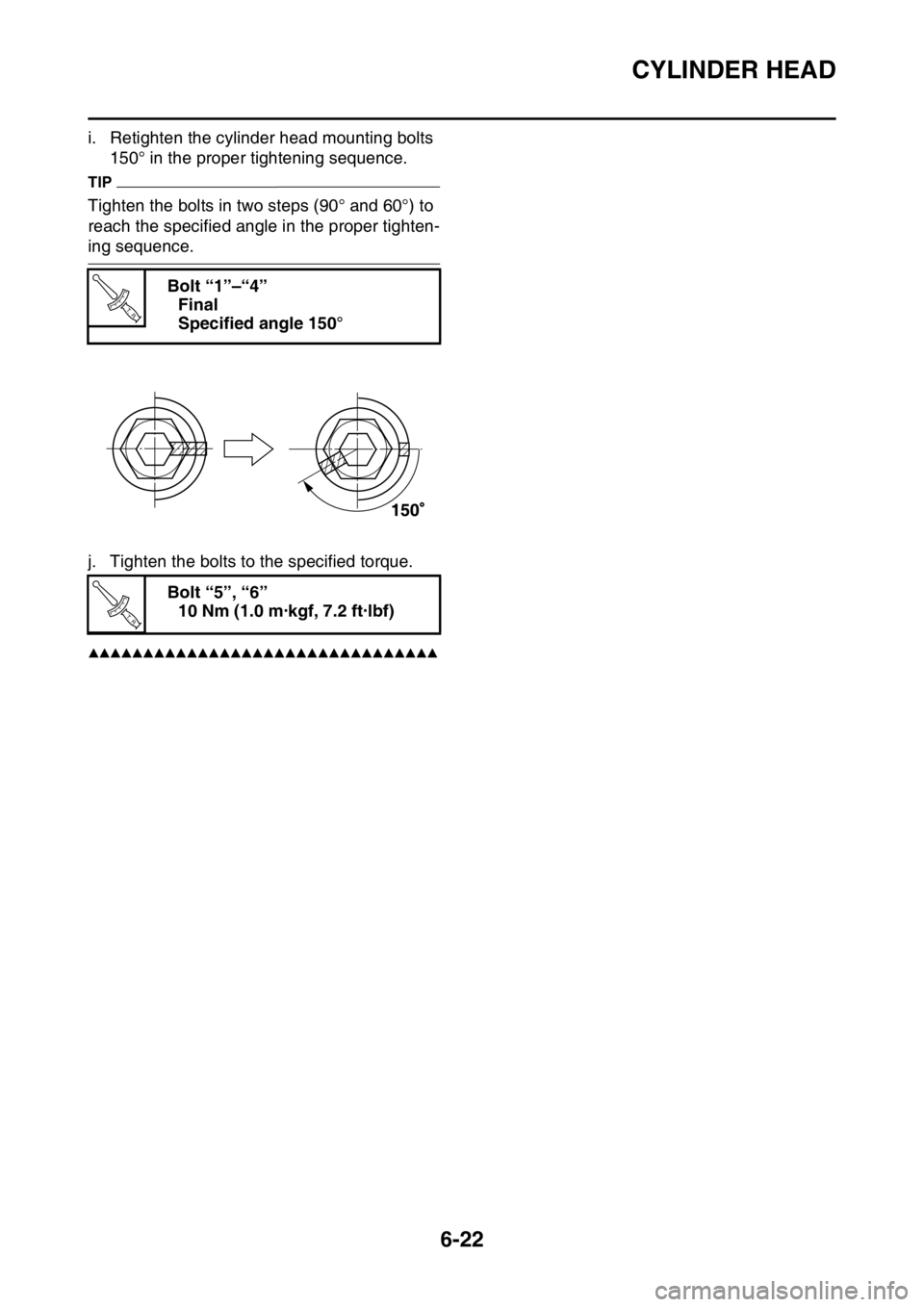

i. Retighten the cylinder head mounting bolts

150° in the proper tightening sequence.

TIP

Tighten the bolts in two steps (90° and 60°) to

reach the specified angle in the proper tighten-

ing sequence.

j. Tighten the bolts to the specified torque.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Bolt “1”–“4” Final

Specified angle 150°

Bolt “5”, “6” 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

T R..