tire pressure YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 50 of 426

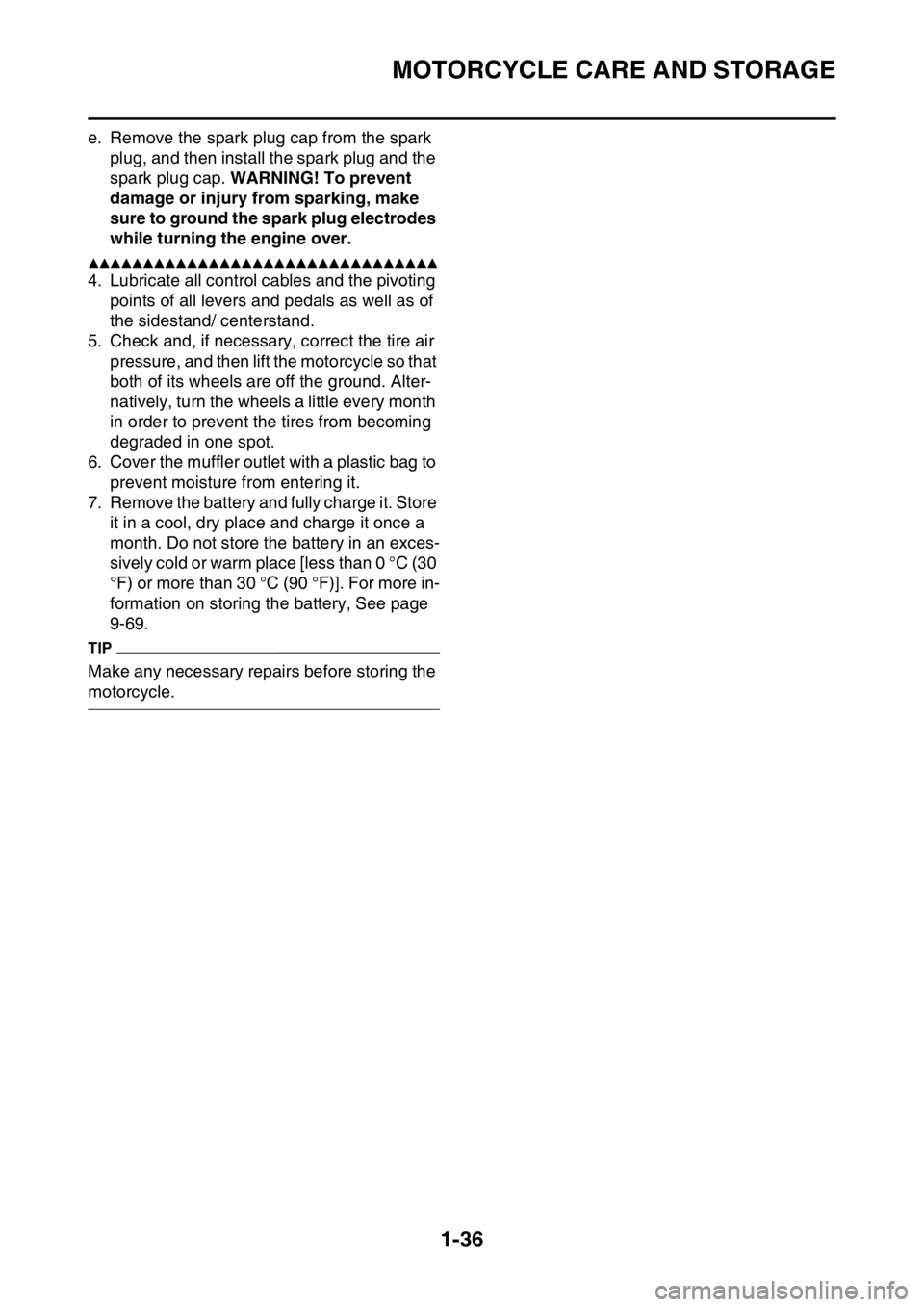

MOTORCYCLE CARE AND STORAGE

1-36

e. Remove the spark plug cap from the spark plug, and then install the spark plug and the

spark plug cap. WARNING! To prevent

damage or injury from sparking, make

sure to ground the spark plug electrodes

while turning the engine over.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Lubricate all control cables and the pivoting points of all levers and pedals as well as of

the sidestand/ centerstand.

5. Check and, if necessary, correct the tire air

pressure, and then lift the motorcycle so that

both of its wheels are off the ground. Alter-

natively, turn the wheels a little every month

in order to prevent the tires from becoming

degraded in one spot.

6. Cover the muffler outlet with a plastic bag to

prevent moisture from entering it.

7. Remove the battery and fully charge it. Store it in a cool, dry place and charge it once a

month. Do not store the battery in an exces-

sively cold or warm place [less than 0 °C (30

°F) or more than 30 °C (90 °F)]. For more in-

formation on storing the battery, See page

9-69.

TIP

Make any necessary repairs before storing the

motorcycle.

Page 58 of 426

CHASSIS SPECIFICATIONS

2-7

EAS2GC1063

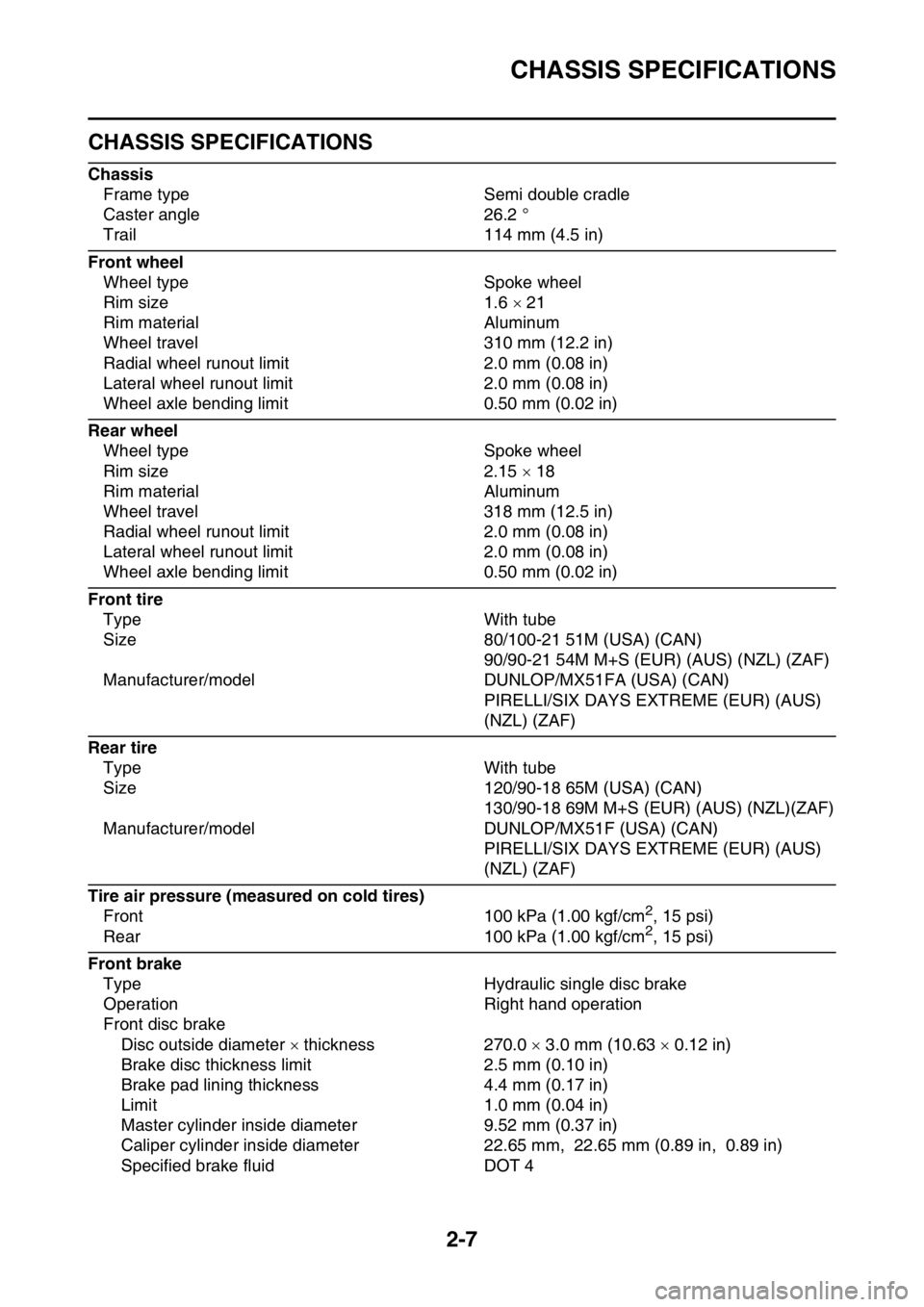

CHASSIS SPECIFICATIONS

ChassisFrame type Semi double cradle

Caster angle 26.2 °

Trail 114 mm (4.5 in)

Front wheelWheel type Spoke wheel

Rim size 1.6 21

Rim material Aluminum

Wheel travel 310 mm (12.2 in)

Radial wheel runout limit 2.0 mm (0.08 in)

Lateral wheel runout limit 2.0 mm (0.08 in)

Wheel axle bending limit 0.50 mm (0.02 in)

Rear wheel

Wheel type Spoke wheel

Rim size 2.15 18

Rim material Aluminum

Wheel travel 318 mm (12.5 in)

Radial wheel runout limit 2.0 mm (0.08 in)

Lateral wheel runout limit 2.0 mm (0.08 in)

Wheel axle bending limit 0.50 mm (0.02 in)

Front tire

Type With tube

Size 80/100-21 51M (USA) (CAN) 90/90-21 54M M+S (EUR) (AUS) (NZL) (ZAF)

Manufacturer/model DUNLOP/MX51FA (USA) (CAN) PIRELLI/SIX DAYS EXTREME (EUR) (AUS)

(NZL) (ZAF)

Rear tireType With tube

Size 120/90-18 65M (USA) (CAN) 130/90-18 69M M+S (EUR) (AUS) (NZL)(ZAF)

Manufacturer/model DUNLOP/MX51F (USA) (CAN) PIRELLI/SIX DAYS EXTREME (EUR) (AUS)

(NZL) (ZAF)

Tire air pressure (measured on cold tires)Front 100 kPa (1.00 kgf/cm2, 15 psi)

Rear 100 kPa (1.00 kgf/cm2, 15 psi)

Front brake Type Hydraulic single disc brake

Operation Right hand operation

Front disc brake Disc outside diameter thickness 270.0 3.0 mm (10.63 0.12 in)

Brake disc thickness limit 2.5 mm (0.10 in)

Brake pad lining thickness 4.4 mm (0.17 in)

Limit 1.0 mm (0.04 in)

Master cylinder inside diameter 9.52 mm (0.37 in)

Caliper cylinder inside diameter 22.65 mm, 22.65 mm (0.89 in, 0.89 in)

Specified brake fluid DOT 4

Page 100 of 426

PERIODIC MAINTENANCE

3-2

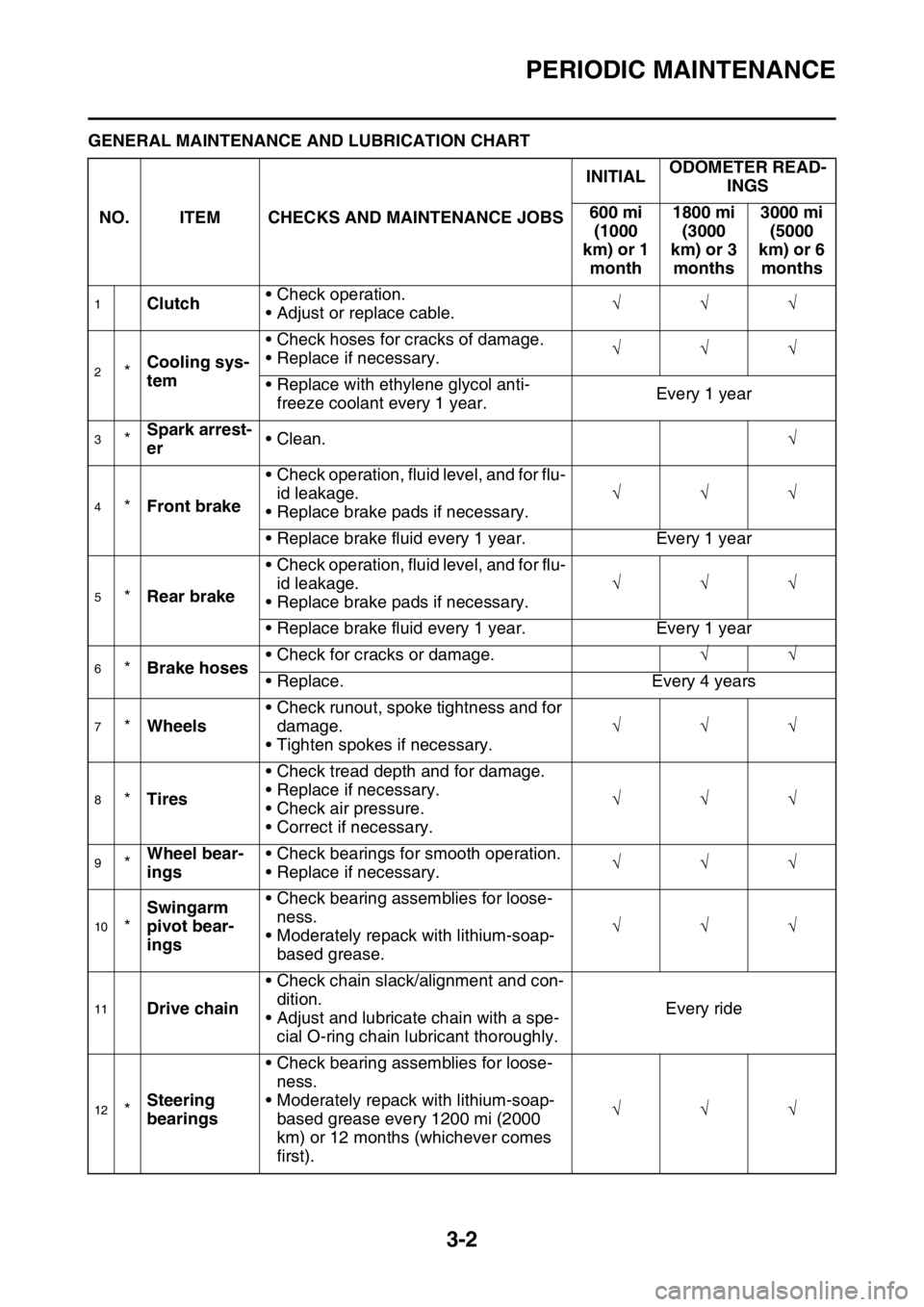

EAS2GC1077GENERAL MAINTENANCE AND LUBRICATION CHARTNO. ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER READ-

INGS

600 mi (1000

km) or 1 month 1800 mi

(3000

km) or 3 months 3000 mi

(5000

km) or 6 months

1Clutch • Check operation.

• Adjust or replace cable.

2*Cooling sys-

tem • Check hoses for cracks of damage.

• Replace if necessary.

• Replace with ethylene glycol anti- freeze coolant every 1 year. Every 1 year

3*Spark arrest-

er • Clean.

4*Front brake • Check operation, fluid level, and for flu-

id leakage.

• Replace brake pads if necessary.

• Replace brake fluid every 1 year. Every 1 year

5* Rear brake • Check operation, fluid level, and for flu-

id leakage.

• Replace brake pads if necessary.

• Replace brake fluid every 1 year. Every 1 year

6* Brake hoses • Check for cracks or damage.

• Replace. Every 4 years

7*Wheels • Check runout, spoke tightness and for

damage.

• Tighten spokes if necessary.

8*

Tires • Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.

9*

Wheel bear-

ings • Check bearings for smooth operation.

• Replace if necessary.

10*Swingarm

pivot bear-

ings • Check bearing assemblies for loose-

ness.

• Moderately repack with lithium-soap- based grease.

11Drive chain• Check chain slack/alignment and con-

dition.

• Adjust and lubricate chain with a spe- cial O-ring chain lubricant thoroughly. Every ride

12*

Steering

bearings • Check bearing assemblies for loose-

ness.

• Moderately repack with lithium-soap- based grease every 1200 mi (2000

km) or 12 months (whichever comes

first).

Page 107 of 426

PRE-OPERATION INSPECTION AND MAINTENANCE

3-9

EAS2GC1079

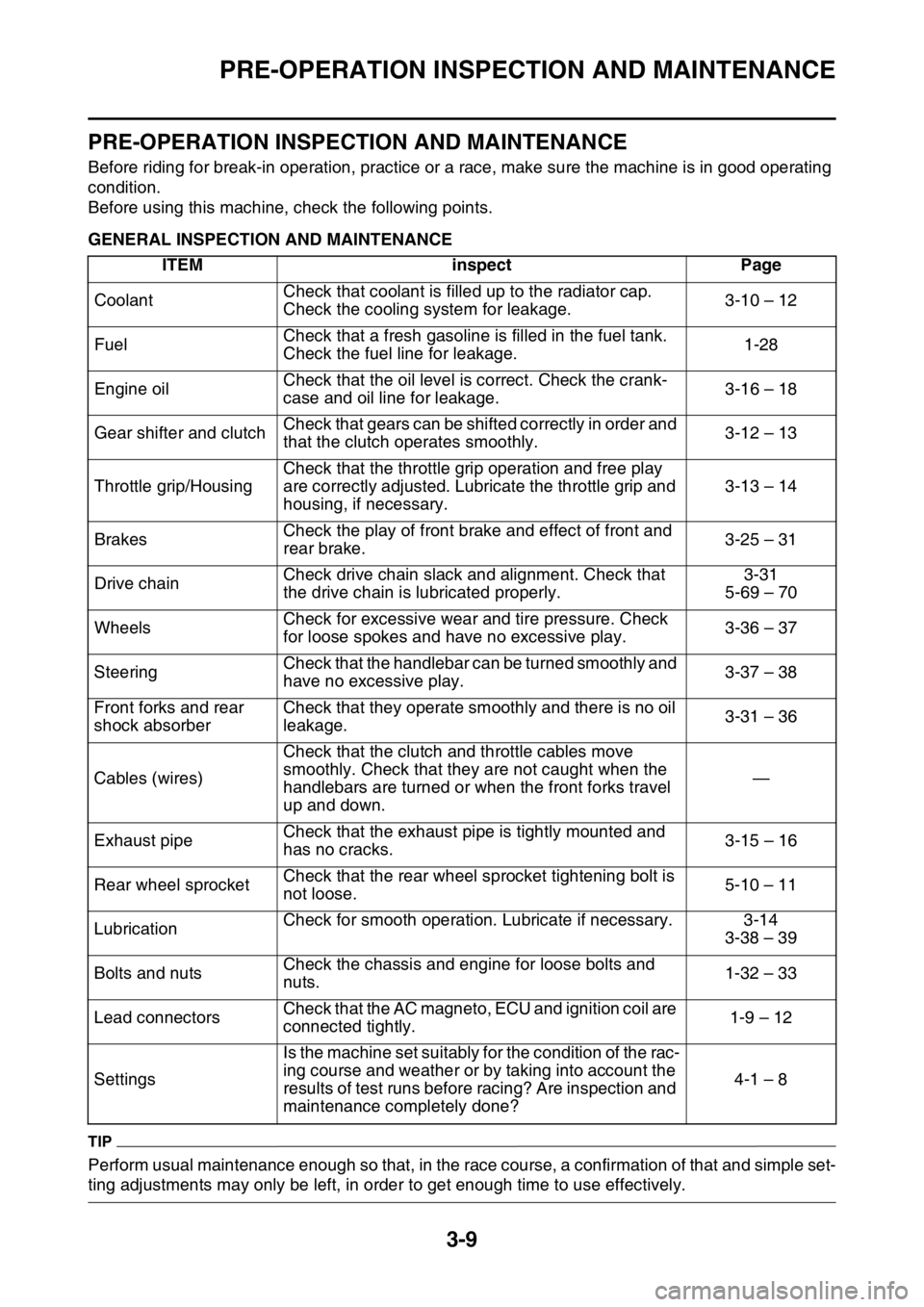

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS2GC1080GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

Coolant Check that coolant is filled up to the radiator cap.

Check the cooling system for leakage. 3-10 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage. 1-28

Engine oil Check that the oil level is correct. Check the crank-

case and oil line for leakage. 3-16 – 18

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly. 3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary. 3-13 – 14

Brakes Check the play of front brake and effect of front and

rear brake. 3-25 – 31

Drive chain Check drive chain slack and alignment. Check that

the drive chain is lubricated properly. 3-31

5-69 – 70

Wheels Check for excessive wear and tire pressure. Check

for loose spokes and have no excessive play. 3-36 – 37

Steering Check that the handlebar can be turned smoothly and

have no excessive play. 3-37 – 38

Front forks and rear

shock absorber Check that they operate smoothly and there is no oil

leakage.

3-31 – 36

Cables (wires) Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and

has no cracks. 3-15 – 16

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is

not loose. 5-10 – 11

Lubrication Check for smooth operation. Lubricate if necessary. 3-14

3-38 – 39

Bolts and nuts Check the chassis and engine for loose bolts and

nuts. 1-32 – 33

Lead connectors Check that the AC magneto, ECU and ignition coil are

connected tightly. 1-9 – 12

Settings Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?

4-1 – 8

Page 123 of 426

CHASSIS

3-25

EAS2GC1101

CHASSIS

EAS2GC1102BLEEDING THE BRAKE SYSTEMEWA

WARNING

Bleed the brake system whenever:

• The system is disassembled.

• A brake hose is loosened, disconnected, or replaced.

• The brake fluid level is very low.

• Brake operation is faulty.

1. Remove: • Brake master cylinder cap

• Reservoir diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

TIP

• Be careful not to spill any brake fluid or allow the reservoir to overflow.

• Make sure that there is enough brake fluid be-

fore applying the brake. Ignoring this precau-

tion could allow air to enter the brake system,

considerably lengthening the bleeding proce-

dure.

• If bleeding is difficult, it may be necessary to let the brake fluid settle for a few hours. Re-

peat the bleeding procedure when the tiny

bubbles in the hose have disappeared.

2. Bleed the brake system.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Fill the reservoir to the proper level with the recommended brake fluid.

b. Install the reservoir diaphragm.

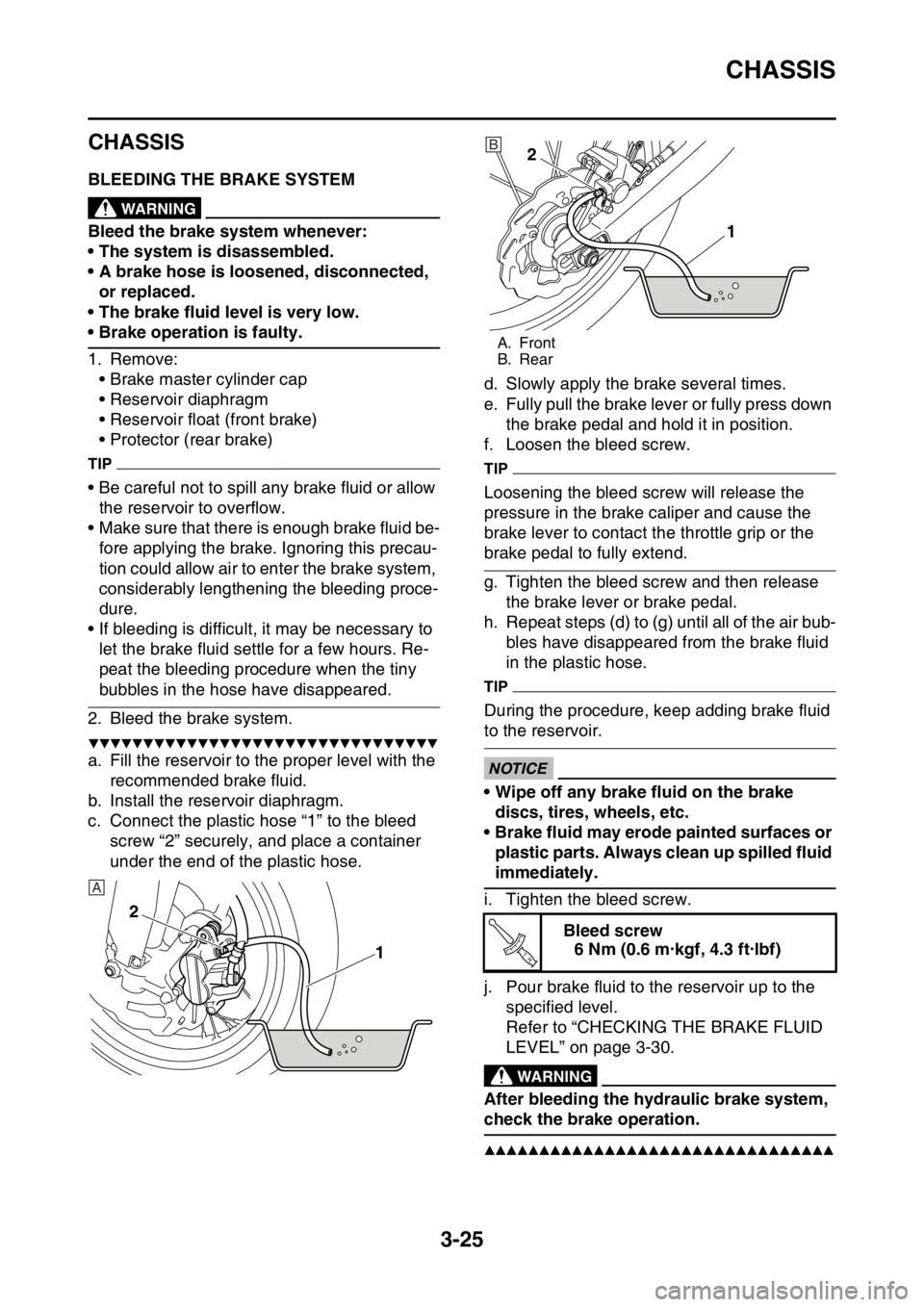

c. Connect the plastic hose “1” to the bleed screw “2” securely, and place a container

under the end of the plastic hose. d. Slowly apply the brake several times.

e. Fully pull the brake lever or fully press down

the brake pedal and hold it in position.

f. Loosen the bleed screw.

TIP

Loosening the bleed screw will release the

pressure in the brake caliper and cause the

brake lever to contact the throttle grip or the

brake pedal to fully extend.

g. Tighten the bleed screw and then release the brake lever or brake pedal.

h. Repeat steps (d) to (g) until all of the air bub- bles have disappeared from the brake fluid

in the plastic hose.

TIP

During the procedure, keep adding brake fluid

to the reservoir.

ECA

NOTICE

• Wipe off any brake fluid on the brake discs, tires, wheels, etc.

• Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

i. Tighten the bleed screw.

j. Pour brake fluid to the reservoir up to the specified level.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

EWA

WARNING

After bleeding the hydraulic brake system,

check the brake operation.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

1

2

A

A. Front

B. Rear

Bleed screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1B

T R..

Page 134 of 426

CHASSIS

3-36

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

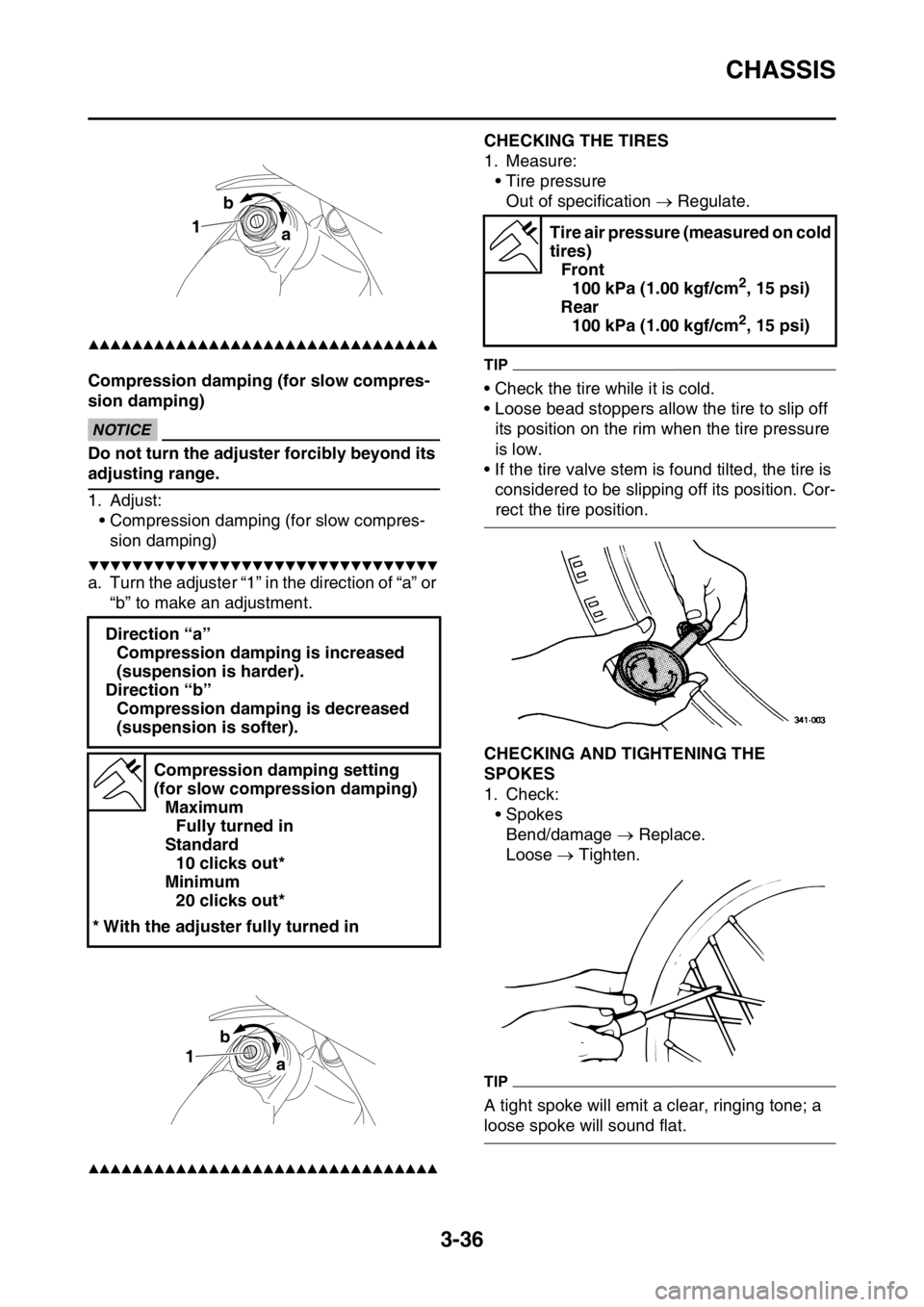

Compression damping (for slow compres-

sion damping)

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:• Compression damping (for slow compres-

sion damping)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1119CHECKING THE TIRES

1. Measure:

• Tire pressureOut of specification Regulate.

TIP

• Check the tire while it is cold.

• Loose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

• If the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Cor-

rect the tire position.

EAS2GC1120CHECKING AND TIGHTENING THE

SPOKES

1. Check:• SpokesBend/damage Replace.

Loose Tighten.

TIP

A tight spoke will emit a clear, ringing tone; a

loose spoke will sound flat.

Direction “a”

Compression damping is increased

(suspension is harder).

Direction “b” Compression damping is decreased

(suspension is softer).

Compression damping setting

(for slow compression damping)MaximumFully turned in

Standard 10 clicks out*

Minimum 20 clicks out*

* With the adjuster fully turned in

1 a

b

1

ba

Tire air pressure (measured on cold

tires)

Front 100 kPa (1.00 kgf/cm

2, 15 psi)

Rear 100 kPa (1.00 kgf/cm

2, 15 psi)

Page 141 of 426

4

TUNING

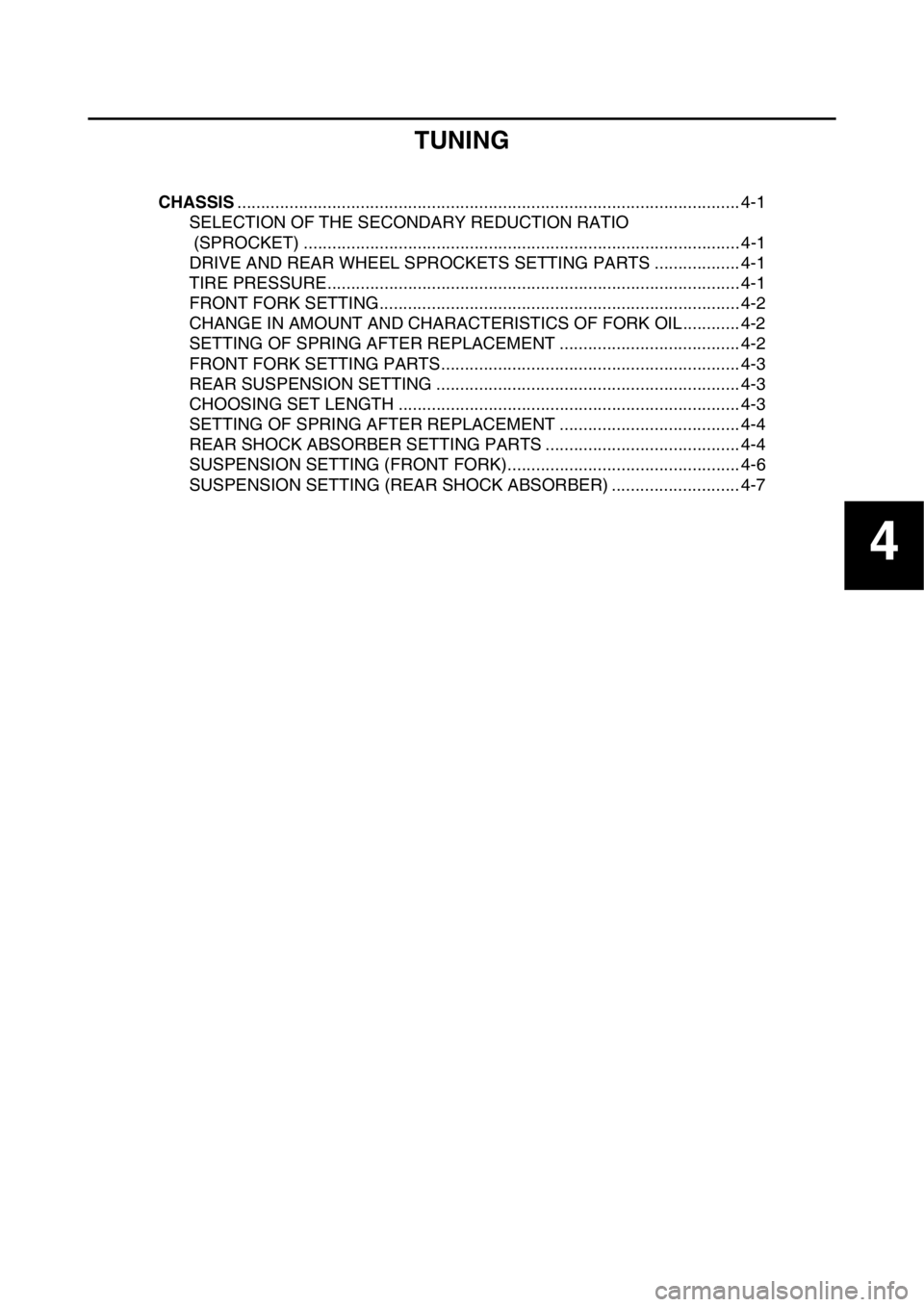

CHASSIS.......................................................................................................... 4-1

SELECTION OF THE SECONDARY REDUCTION RATIO

(SPROCKET) ............................................................................................ 4-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS .................. 4-1

TIRE PRESSURE............................. .......................................................... 4-1

FRONT FORK SETTING............................................................................ 4-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL............ 4-2

SETTING OF SPRING AFTER REPLACEMENT ...................................... 4-2

FRONT FORK SETTING PARTS............................................................... 4-3

REAR SUSPENSION SETTING ................................................................ 4-3

CHOOSING SET LENGTH ........................................................................ 4-3

SETTING OF SPRING AFTER REPLACEMENT ...................................... 4-4

REAR SHOCK ABSORBER SETT ING PARTS ......................................... 4-4

SUSPENSION SETTING (FRONT FORK)................................................. 4-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ........................... 4-7

Page 142 of 426

CHASSIS

4-1

EAS2GC1136

CHASSIS

EAS2GC1137SELECTION OF THE SECONDARY REDUC-

TION RATIO (SPROCKET)

• It is generally said that the secondary gear ra-tio should be reduced for a longer straight por-

tion of a speed course and should be

increased for a course with many corners. Ac-

tually, however, as the speed depends on the

ground condition of the day of the race, be

sure to run through the circuit to set the ma-

chine suitable for the entire course.

• In actuality, it is very difficult to achieve set- tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the race

result. In such a case, run through the entire

course while making notes of lap times to find

the best balance; then, determine the second-

ary reduction ratio.

• If a course has a long straight portion where a machine can run at maximum speed, the ma-

chine is generally set such that it can develop

its maximum revolutions toward the end of the

straight line, with care taken to avoid the en-

gine over-revving.

TIP

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider’s settings from the beginning but

choose your own setting according to the level

of your riding technique.

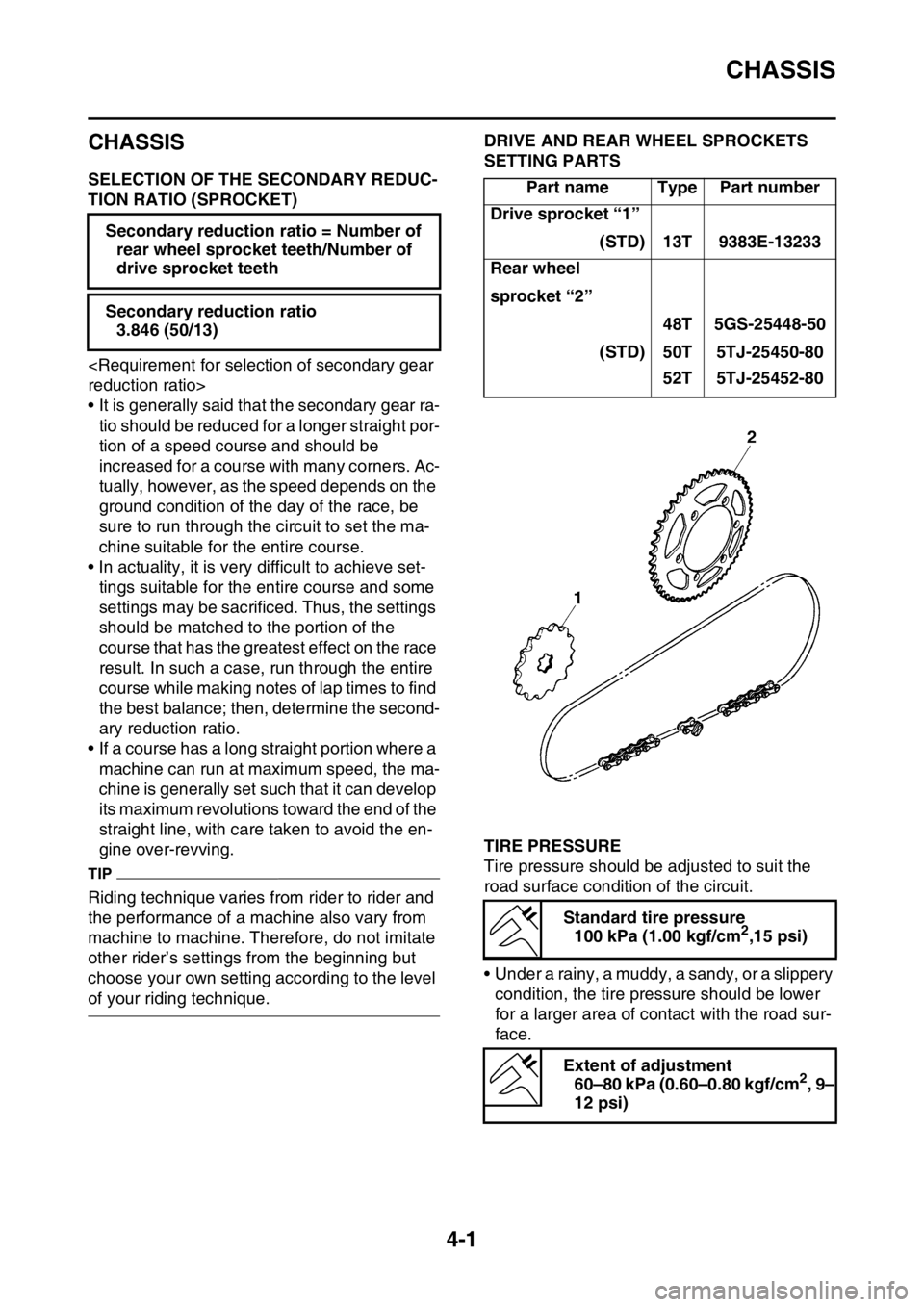

EAS2GC1138DRIVE AND REAR WHEEL SPROCKETS

SETTING PARTS

EAS2GC1139TIRE PRESSURE

Tire pressure should be adjusted to suit the

road surface condition of the circuit.

• Under a rainy, a muddy, a sandy, or a slippery condition, the tire pressure should be lower

for a larger area of contact with the road sur-

face.

Secondary reduction ratio = Number of

rear wheel sprocket teeth/Number of

drive sprocket teeth

Secondary reduction ratio 3.846 (50/13)

Part name Type Part number

Drive sprocket “1”

(STD) 13T 9383E-13233

Rear wheel

sprocket “2”

48T 5GS-25448-50

(STD) 50T 5TJ-25450-80 52T 5TJ-25452-80

Standard tire pressure 100 kPa (1.00 kgf/cm

2,15 psi)

Extent of adjustment 60–80 kPa (0.60–0.80 kgf/cm

2, 9–

12 psi)

Page 143 of 426

CHASSIS

4-2

• Under a stony or a hard road condition, the tire pressure should be hi gher to prevent a flat

tire.

EAS2GC1140FRONT FORK SETTING

The front fork setting should be made depend-

ing on the rider’s feeli ng of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics • Change the fork oil amount.

2. Setting of spring preload • Change the spring.

3. Setting of damping force

• Change the compression damping force.

• Change the rebound damping force.The spring acts on the load and the damping

force acts on the cushion travel speed.

EAS2GC1141CHANGE IN AMOUNT AND CHARACTERIS-

TICS OF FORK OIL

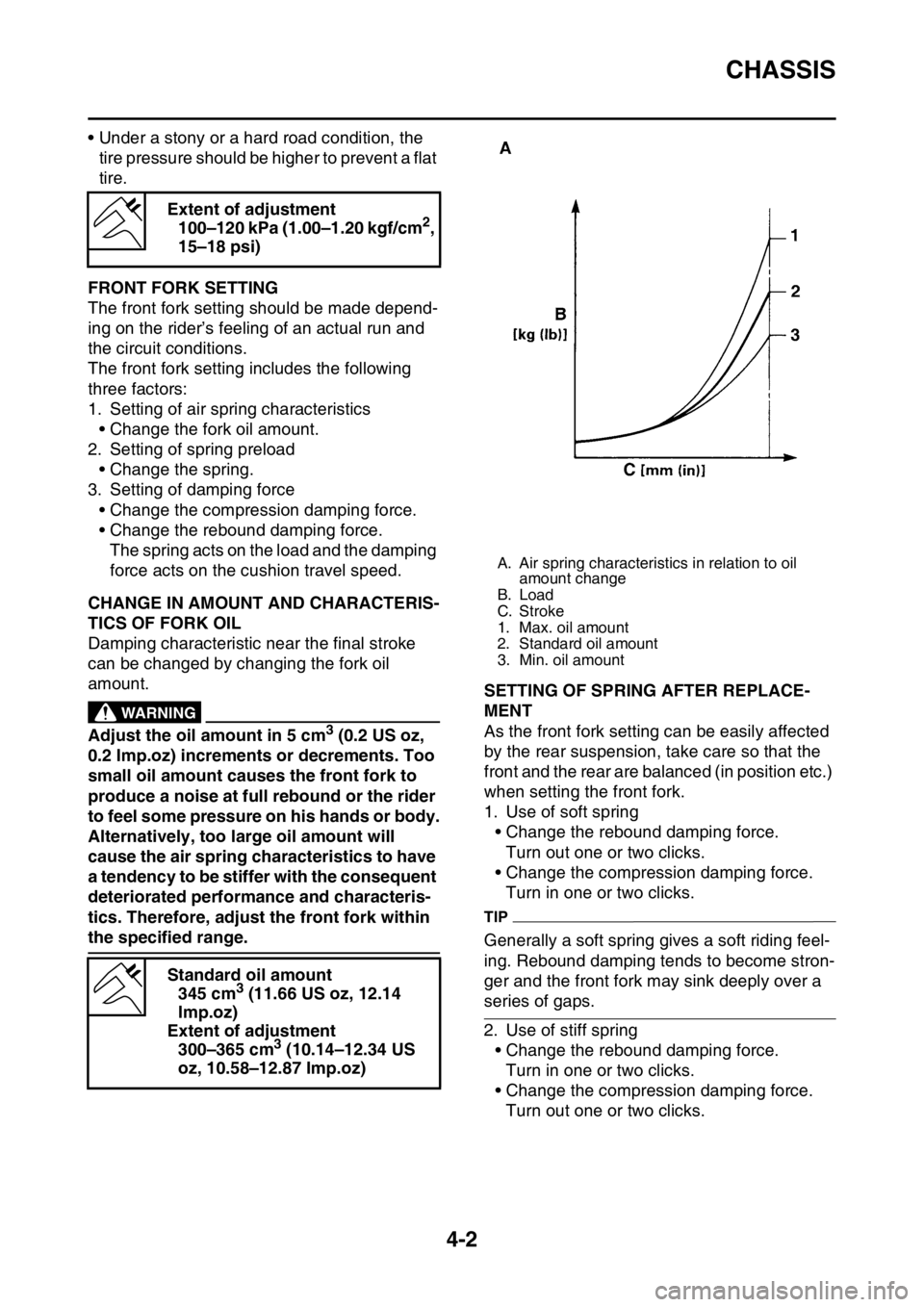

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

EWA

WARNING

Adjust the oil amount in 5 cm3 (0.2 US oz,

0.2 Imp.oz) increments or decrements. Too

small oil amount causes the front fork to

produce a noise at full rebound or the rider

to feel some pressure on his hands or body.

Alternatively, too large oil amount will

cause the air spring characteristics to have

a tendency to be stiffer with the consequent

deteriorated performance and characteris-

tics. Therefore, adjust the front fork within

the specified range.

EAS2GC1142SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force. Turn out one or two clicks.

Extent of adjustment

100–120 kPa (1.00–1.20 kgf/cm

2,

15–18 psi)

Standard oil amount 345 cm

3 (11.66 US oz, 12.14

lmp.oz)

Extent of adjustment 300–365 cm

3 (10.14–12.34 US

oz, 10.58–12.87 Imp.oz)

A. Air spring characteristics in relation to oil amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

Page 416 of 426

TROUBLESHOOTING

10-3

Cooling system

1. Coolant• Low coolant level

2. Radiator • Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump • Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Fuel system

1. Throttle body • Damaged or loose throttle body joint

2. Air filter • Clogged air filter element

Chassis

1. Brake(s) • Dragging brake

Electrical system

1. Spark plug • Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system • Faulty ECU

• Faulty coolant temperature sensor

EAS2GC1417OVERCOOLING

Cooling system

1. Coolant temperature sensor• Faulty coolant temperature sensor

EAS2GC1418POOR BRAKING PERFORMANCE

Chassis

1. Brake(s)• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS2GC1419FRONT FORK OIL LEAKING

Chassis

1. Front fork• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

EAS2GC1420FAULTY FRONT FORK LEGS

Chassis

1. Front fork • Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS2GC1421UNSTABLE HANDLING

Chassis

1. Handlebar• Bent or improperly installed handlebar

2. Steering head components • Improperly installed upper bracket

• Improperly installed lower bracket(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s) • Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm • Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies) • Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s) • Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear