YAMAHA XENTER 150 2012 Service Manual

Manufacturer: YAMAHA, Model Year: 2012, Model line: XENTER 150, Model: YAMAHA XENTER 150 2012Pages: 84, PDF Size: 1.33 MB

Page 41 of 84

1

2

3

4

5

6

7

8

9

6-4

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU17717

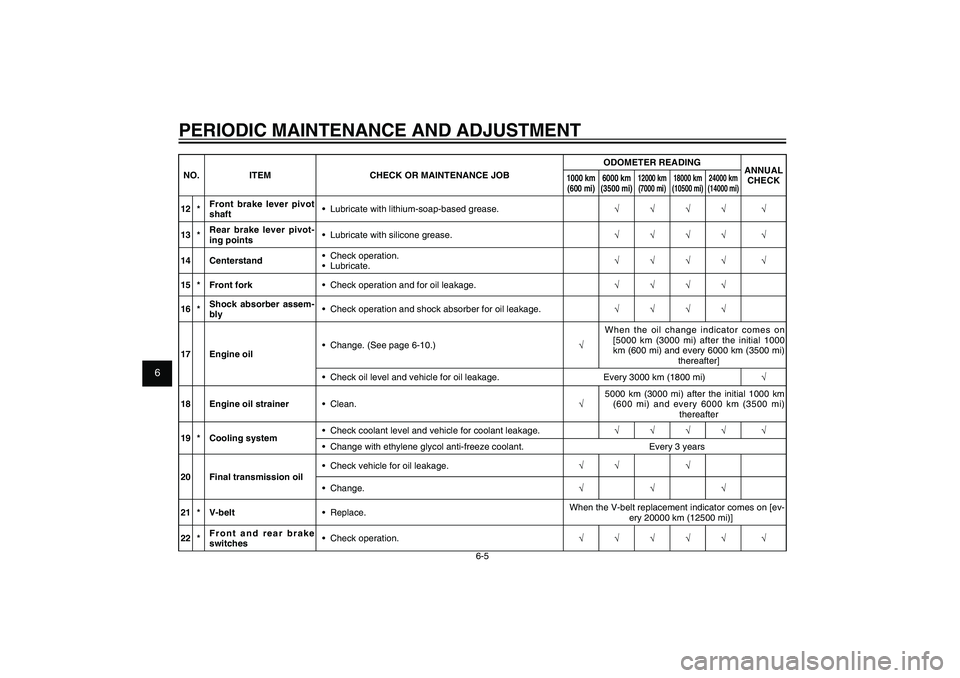

General maintenance and lubrication chartNO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)

12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

1 Air � lter element• Replace. Every 20000 km (12500 mi)

2 Air � lter check hose• Clean.

√√√√√

3V-belt case air � lter ele-

ment• Clean.

√√√√

• Replace. Every 20000 km (12500 mi)

4 * Front brake• Check operation, fl uid level and vehicle for fl uid leakage.

√√√√√ √

• Replace brake pads. Whenever worn to the limit

5 * Rear brake• Check operation and adjust brake lever free play.

√√√√√ √

• Replace brake shoes. Whenever worn to the limit

6 * Brake hose• Check for cracks or damage.

• Check for correct routing and clamping.√√√√ √

• Replace. Every 4 years

7 * Wheels• Check runout and for damage.

√√√√

8 * Tires• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.√√√√ √

9 * Wheel bearings• Check bearing for looseness or damage.

√√√√

10 * Steering bearings• Check bearing play and steering for roughness.

√√√√√

• Lubricate with lithium-soap-based grease. Every 50000 km (30000 mi)

11 * Chassis fasteners• Make sure that all nuts, bolts and screws are properly

tightened.√√√√ √

52S-F8199-E0_CS.indd 6-452S-F8199-E0_CS.indd 6-4

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 42 of 84

1

2

3

4

5

6

7

8

9

6-5

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENTNO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)

12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

12 *Front brake lever pivot

shaft• Lubricate with lithium-soap-based grease.

√√√√ √

13 *Rear brake lever pivot-

ing points• Lubricate with silicone grease.

√√√√ √

14 Centerstand• Check operation.

• Lubricate.√√√√ √

15 * Front fork• Check operation and for oil leakage.

√√√√

16 *Shock absorber assem-

bly• Check operation and shock absorber for oil leakage.

√√√√

17 Engine oil• Change. (See page 6-10.)

√When the oil change indicator comes on

[5000 km (3000 mi) after the initial 1000

km (600 mi) and every 6000 km (3500 mi)

thereafter]

• Check oil level and vehicle for oil leakage. Every 3000 km (1800 mi)

√

18 Engine oil strainer• Clean.

√5000 km (3000 mi) after the initial 1000 km

(600 mi) and every 6000 km (3500 mi)

thereafter

19 * Cooling system• Check coolant level and vehicle for coolant leakage.

√√√√ √

• Change with ethylene glycol anti-freeze coolant. Every 3 years

20 Final transmission oil• Check vehicle for oil leakage.

√√ √

• Change.

√√√

21 * V-belt• Replace.When the V-belt replacement indicator comes on [ev-

ery 20000 km (12500 mi)]

22 *Front and rear brake

switches• Check operation.

√√√√√ √

52S-F8199-E0_CS.indd 6-552S-F8199-E0_CS.indd 6-5

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 43 of 84

1

2

3

4

5

6

7

8

9

6-6

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAUT2710

TIP● Air fi lter and V-belt fi lter

• This model’s air fi lter is equipped with a disposable oil-coated paper element, which must not be cleaned with

compressed air to avoid damaging it.

• The air fi lter element needs to be replaced and V-belt fi lter needs to be serviced more frequently when riding in

unusually wet or dusty areas.● Hydraulic brake service

• After disassembling the brake master cylinder and caliper, always change the fl uid. Regularly check the brake

fl uid level and fi ll the reservoir as required.

• Every two years replace the internal components of the brake master cylinder and caliper, and change the brake

fl uid.

• Replace the brake hose every four years and if cracked or damaged.NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)

12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

23Moving parts and ca-

bles• Lubricate.

√√√√ √

24 * Throttle grip• Check operation.

• Check throttle grip free play, and adjust if necessary.

• Lubricate cable and grip housing.√√√√ √

25 *Lights, signals and

switches• Check operation.

• Adjust headlight beam.√√√√√ √

52S-F8199-E0_CS.indd 6-652S-F8199-E0_CS.indd 6-6

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 44 of 84

1

2

3

4

5

6

7

8

9

6-7

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU18722

Removing and installing the

cowling and panelsThe cowling and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each

time the cowling or a panel needs to

be removed and installed.

1

2

3

4

1. Cowling A

2. Panel A

3. Panel B

4. Panel C

EAUT3560

Cowling A

To remove the cowling

1. Remove the cowling screws and

bolts.

1

1. Cowling A2. Disconnect the coupler shown,

and then take the cowling off.

1

1. Coupler

To install the cowling

1. Connect the coupler.

2. Place the cowling in the original

position.

3. Install the cowling screws and

bolts.

EAUT3600

Panel A

To remove the panel

2

1

1. Luggage holder

2. Panel A1. Remove the luggage holder by

removing the screws.

2. Remove the screws, and then

pull the panel outward.

52S-F8199-E0_CS.indd 6-752S-F8199-E0_CS.indd 6-7

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 45 of 84

1

2

3

4

5

6

7

8

9

6-8

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

To install the panel

1. Place the panel in the original po-

sition, and then install the screws.

2. Install the luggage holder by

installing the screws, and then

tighten the screws to the speci-

fi ed torque.Tightening torque:

Luggage holder screws:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

EAUT3610

Panel B

To remove the panel

Remove the screws and quick fas-

tener, and then take the panel off.

1

2

1. Panel B

2. Quick fastener

To install the panel

Place the panel in the original posi-

tion, and then install the quick fasten-

er and screws.

EAUT3620

Panel C

To remove the panel

1. Open the seat. (See page 3-11.)

2. Remove the screws, and then

pull the panel off as shown.

1

1. Panel C

To install the panel

1

1. Projection1. Insert the projections on the pan-

el into the slots as shown, and

then install the screws.

2. Close the seat.

52S-F8199-E0_CS.indd 6-852S-F8199-E0_CS.indd 6-8

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 46 of 84

1

2

3

4

5

6

7

8

9

6-9

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

1

1. Spark plug wrenchTo check the spark plug

1. Check that the porcelain insula-

tor around the center electrode

of the spark plug is a medium-to-

light tan (the ideal color when the

vehicle is ridden normally).TIPIf the spark plug shows a distinctly

different color, the engine could be

operating improperly. Do not attempt

to diagnose such problems yourself.

Instead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for elec-trode erosion and excessive

carbon or other deposits, and re-

place it if necessary.

Speci� ed spark plug:

CPR9EA-9 (NGK)To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specifi cation.Spark plug gap:

0.8 ~ 0.9 mm (0.031 ~ 0.035 in)2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specifi ed torque.Tightening torque:

Spark plug:

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

EAUT1835

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause

any spark plug to slowly erode, the

spark plug should be removed and

checked in accordance with the pe-

riodic maintenance and lubrication

chart. In addition, the condition of the

spark plug can reveal the condition of

the engine.

To remove the spark plug

1. Place the vehicle on the center-

stand.

2. Remove panel C. (See page 6-8.)

3. Remove the spark plug cap.

4. Remove the spark plug as

shown, with the spark plug

wrench included in the owner’s

tool kit.

52S-F8199-E0_CS.indd 6-952S-F8199-E0_CS.indd 6-9

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 47 of 84

1

2

3

4

5

6

7

8

9

6-10

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAUT3700

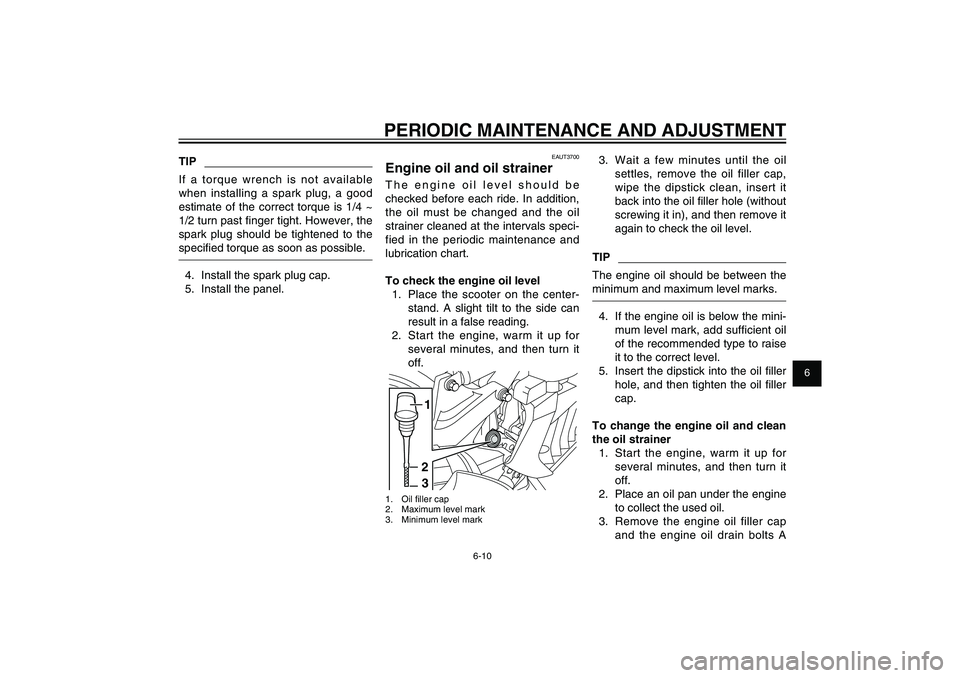

Engine oil and oil strainerThe engine oil level should be

checked before each ride. In addition,

the oil must be changed and the oil

strainer cleaned at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the scooter on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

231

1. Oil fi ller cap

2. Maximum level mark

3. Minimum level mark

3. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, insert it

back into the oil fi ller hole (without

screwing it in), and then remove it

again to check the oil level.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add suffi cient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil fi ller

hole, and then tighten the oil fi ller

cap.

To change the engine oil and clean

the oil strainer

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the engine

to collect the used oil.

3. Remove the engine oil filler cap

and the engine oil drain bolts A

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4 ~

1/2 turn past fi nger tight. However, the

spark plug should be tightened to the

specifi ed torque as soon as possible.

4. Install the spark plug cap.

5. Install the panel.

52S-F8199-E0_CS.indd 6-1052S-F8199-E0_CS.indd 6-10

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 48 of 84

1

2

3

4

5

6

7

8

9

6-11

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

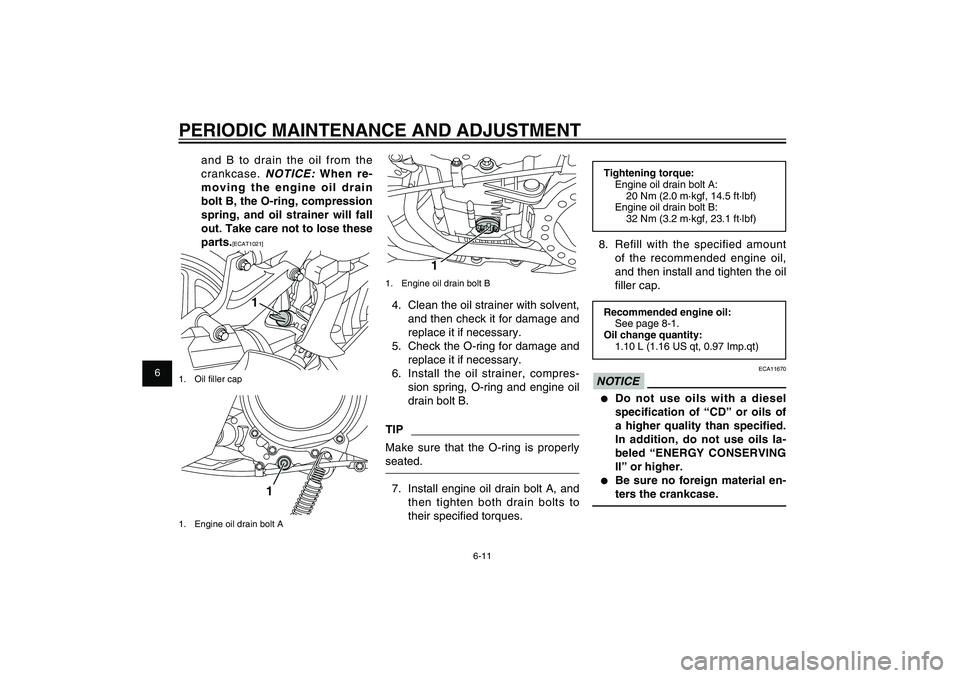

1

1. Engine oil drain bolt B4. Clean the oil strainer with solvent,

and then check it for damage and

replace it if necessary.

5. Check the O-ring for damage and

replace it if necessary.

6. Install the oil strainer, compres-

sion spring, O-ring and engine oil

drain bolt B.TIPMake sure that the O-ring is properly

seated.

7. Install engine oil drain bolt A, and

then tighten both drain bolts to

their specifi ed torques.

Tightening torque:

Engine oil drain bolt A:

20 Nm (2.0 m·kgf, 14.5 ft·lbf)

Engine oil drain bolt B:

32 Nm (3.2 m·kgf, 23.1 ft·lbf)8. Refill with the specified amount

of the recommended engine oil,

and then install and tighten the oil

fi ller cap.Recommended engine oil:

See page 8-1.

Oil change quantity:

1.10 L (1.16 US qt, 0.97 Imp.qt)

ECA11670

NOTICE● Do not use oils with a diesel

speci� cation of “CD” or oils of

a higher quality than speci� ed.

In addition, do not use oils la-

beled “ENERGY CONSERVING

II” or higher.● Be sure no foreign material en-

ters the crankcase. and B to drain the oil from the

crankcase.

NOTICE:

When re-

moving the engine oil drain

bolt B, the O-ring, compression

spring, and oil strainer will fall

out. Take care not to lose these

parts.

[ECAT1021]

1

1. Oil fi ller cap

1

1. Engine oil drain bolt A

52S-F8199-E0_CS.indd 6-1152S-F8199-E0_CS.indd 6-11

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 49 of 84

1

2

3

4

5

6

7

8

9

6-12

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

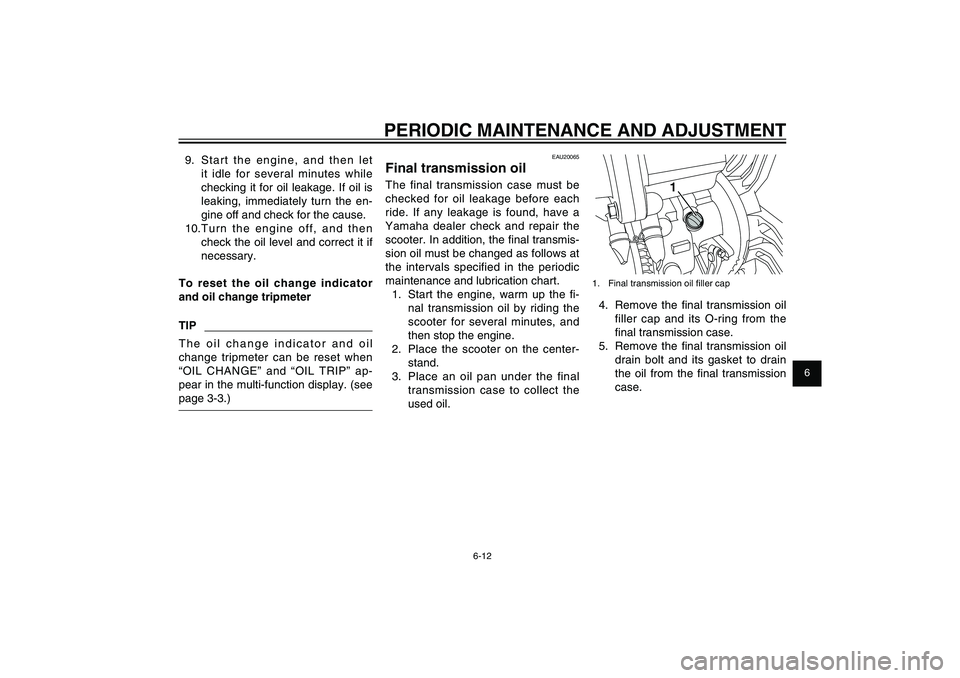

1

1. Final transmission oil fi ller cap4. Remove the fi nal transmission oil

filler cap and its O-ring from the

fi nal transmission case.

5. Remove the fi nal transmission oil

drain bolt and its gasket to drain

the oil from the fi nal transmission

case.

EAU20065

Final transmission oilThe final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the fi nal transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm up the fi -

nal transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center-

stand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

9. Start the engine, and then let

it idle for several minutes while

checking it for oil leakage. If oil is

leaking, immediately turn the en-

gine off and check for the cause.

10. Turn the engine off, and then

check the oil level and correct it if

necessary.

To reset the oil change indicator

and oil change tripmeterTIPThe oil change indicator and oil

change tripmeter can be reset when

“OIL CHANGE” and “OIL TRIP” ap-

pear in the multi-function display. (see

page 3-3.)

52S-F8199-E0_CS.indd 6-1252S-F8199-E0_CS.indd 6-12

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 50 of 84

1

2

3

4

5

6

7

8

9

6-13

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.2 L (0.21 US qt, 0.18 Imp.qt)8. Install the final transmission oil

fi ller cap and its new O-ring, and

then tighten the oil fi ller cap.

9. Check the fi nal transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20070

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specifi ed in the periodic maintenance

and lubrication chart.

EAUT3690

To check the coolant level

The coolant level should be checked

as follows before each ride. In addi-

tion, the coolant must be changed at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Place the vehicle on the center-

stand.TIP● The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.● Make sure that the vehicle is po-

sitioned straight up when check-

ing the coolant level. A slight tilt

to the side can result in a false

1

1. Final transmission oil drain bolt6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fi ed torque.Tightening torque:

Final transmission oil drain bolt:

20 Nm (2.0 m·kgf, 14.5 ft·lbf)7. Refi ll with the specifi ed amount of

the recommended fi nal transmis-

sion oil. WARNING! Make sure

that no foreign material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11311]

52S-F8199-E0_CS.indd 6-1352S-F8199-E0_CS.indd 6-13

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black