YAMAHA XJR 1300 2015 Owner's Guide

Manufacturer: YAMAHA, Model Year: 2015, Model line: XJR 1300, Model: YAMAHA XJR 1300 2015Pages: 98, PDF Size: 2.6 MB

Page 31 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

2. Push the rear of the seat down to lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

EAU14744

A djustin g the front fork

WARNING

EWA10181

Always a djust both fork leg s equally,

otherwise poor han dlin g an d loss of

sta bility may result.This front fork is equipped with spring

preload adjusting bolts, rebound

damping force adjusting screws and

compression damping force adjusting

screws.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

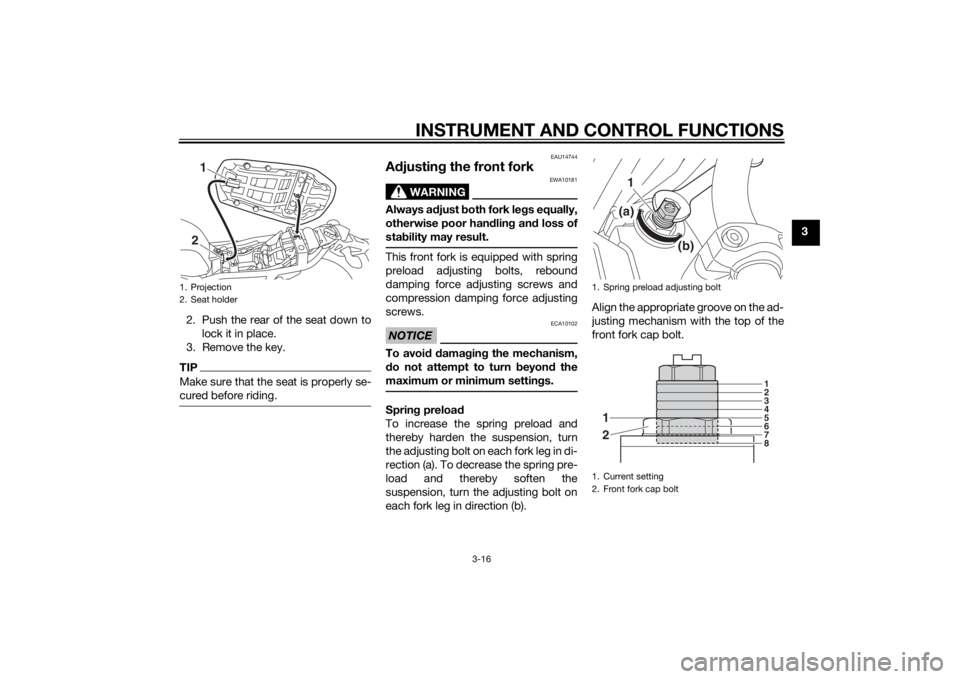

maximum or minimum settin gs.Sprin g preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b). Align the appropriate groove on the ad-

justing mechanism with the top of the

front fork cap bolt.

1. Projection

2. Seat holder

12

1. Spring preload adjusting bolt

1. Current setting

2. Front fork cap bolt

1(a)

(b)

2 1

1

2

3

4

5

6

7

8

U2PNE0E0.book Page 16 Tuesda

y, September 16, 2014 4:15 PM

Page 32 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-17

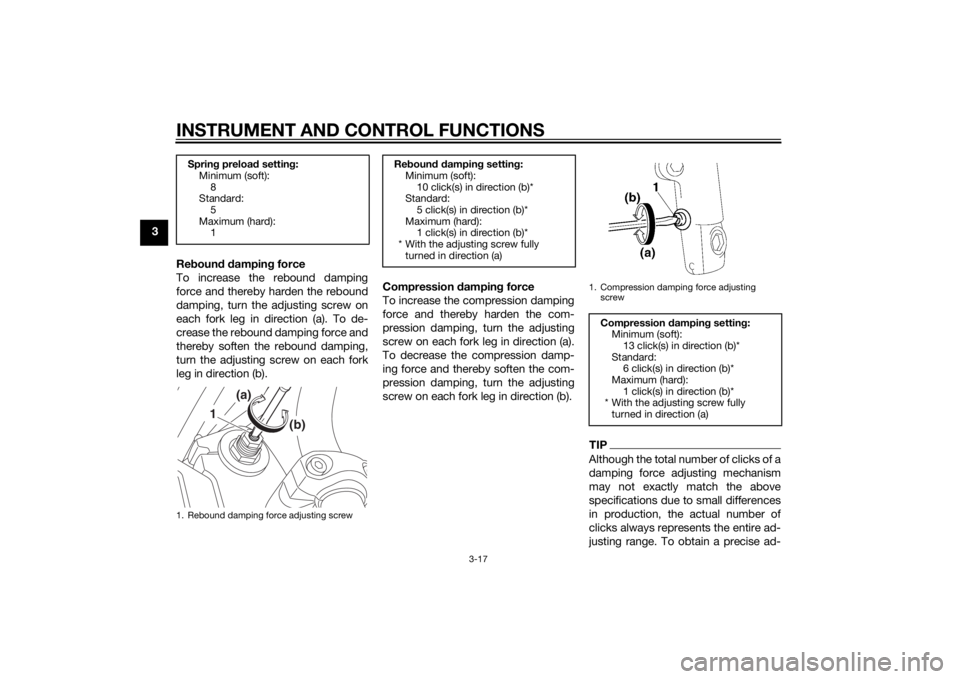

3Reboun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw on

each fork leg in direction (a). To de-

crease the rebound damping force and

thereby soften the rebound damping,

turn the adjusting screw on each fork

leg in direction (b). Compression

dampin g force

To increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

screw on each fork leg in direction (a).

To decrease the compression damp-

ing force and thereby soften the com-

pression damping, turn the adjusting

screw on each fork leg in direction (b).

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-

Sprin g preloa d setting :

Minimum (soft):

8

Standard:

5

Maximum (hard): 11. Rebound damping force adjusting screw

1

(a)

(b)

Re boun d d ampin g setting :

Minimum (soft):

10 click(s) in direction (b)*

Standard:

5 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

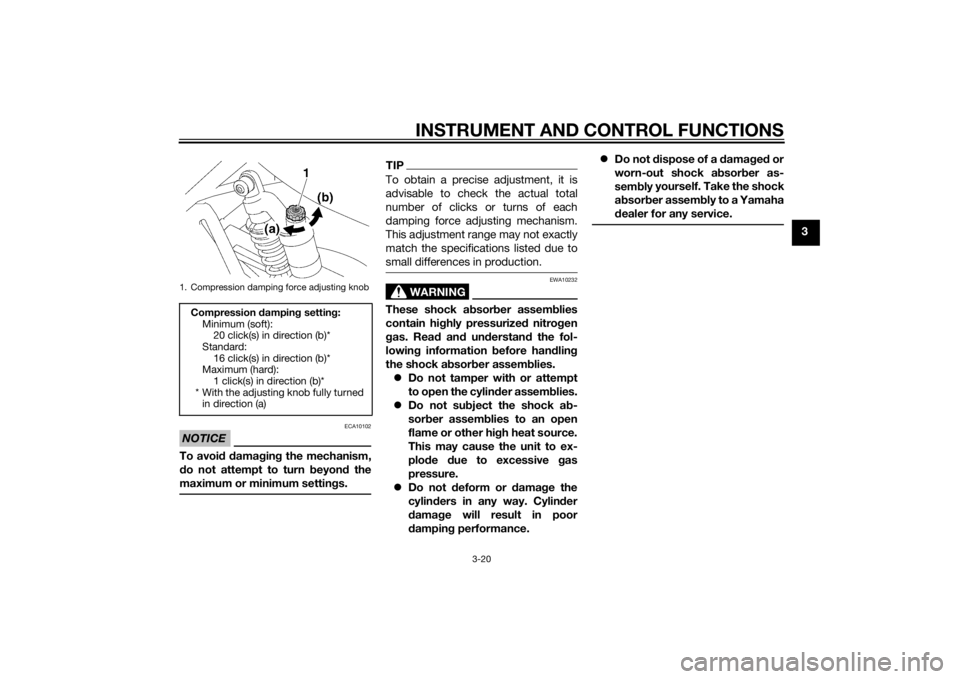

1. Compression damping force adjusting

screwCompression dampin g settin g:

Minimum (soft): 13 click(s) in direction (b)*

Standard: 6 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U2PNE0E0.book Page 17 Tuesda y, September 16, 2014 4:15 PM

Page 33 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-18

3

justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

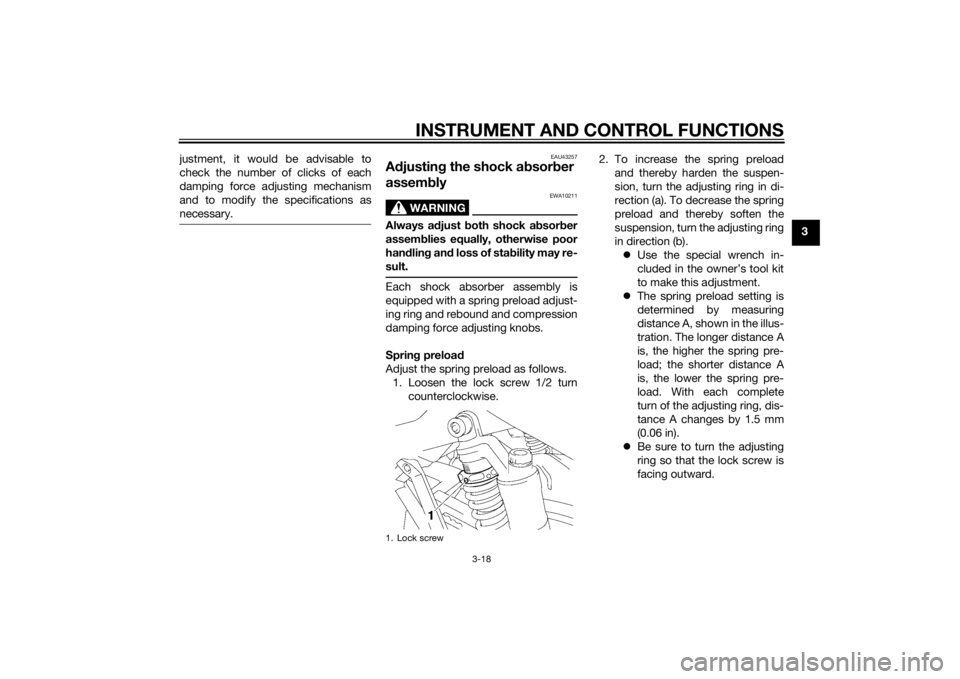

EAU43257

A

djustin g the shock a bsor ber

assemb ly

WARNING

EWA10211

Always a djust both shock ab sorber

assem blies equally, otherwise poor

han dlin g an d loss of stab ility may re-

sult.Each shock absorber assembly is

equipped with a spring preload adjust-

ing ring and rebound and compression

damping force adjusting knobs.

Sprin g preloa d

Adjust the spring preload as follows. 1. Loosen the lock screw 1/2 turn counterclockwise. 2. To increase the spring preload

and thereby harden the suspen-

sion, turn the adjusting ring in di-

rection (a). To decrease the spring

preload and thereby soften the

suspension, turn the adjusting ring

in direction (b). Use the special wrench in-

cluded in the owner’s tool kit

to make this adjustment.

The spring preload setting is

determined by measuring

distance A, shown in the illus-

tration. The longer distance A

is, the higher the spring pre-

load; the shorter distance A

is, the lower the spring pre-

load. With each complete

turn of the adjusting ring, dis-

tance A changes by 1.5 mm

(0.06 in).

Be sure to turn the adjusting

ring so that the lock screw is

facing outward.1. Lock screw

U2PNE0E0.book Page 18 Tuesda y, September 16, 2014 4:15 PM

Page 34 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-19

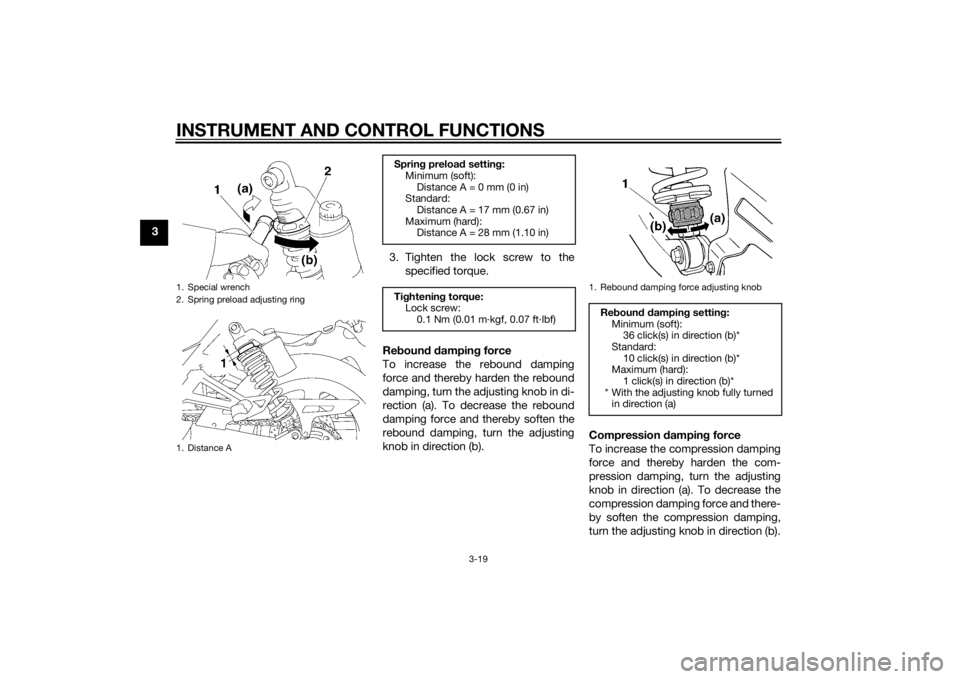

33. Tighten the lock screw to thespecified torque.

Re boun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting knob in di-

rection (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

knob in direction (b). Compression

dampin g force

To increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

knob in direction (a). To decrease the

compression damping force and there-

by soften the compression damping,

turn the adjusting knob in direction (b).

1. Special wrench

2. Spring preload adjusting ring

1. Distance A

Sprin g preloa d setting :

Minimum (soft):

Distance A = 0 mm (0 in)

Standard:

Distance A = 17 mm (0.67 in)

Maximum (hard): Distance A = 28 mm (1.10 in)

Ti ghtenin g torque:

Lock screw:

0.1 Nm (0.01 m·kgf, 0.07 ft·lbf)

1. Rebound damping force adjusting knobRe boun d d ampin g setting :

Minimum (soft): 36 click(s) in direction (b)*

Standard: 10 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

U2PNE0E0.book Page 19 Tuesda y, September 16, 2014 4:15 PM

Page 35 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-20

3

NOTICE

ECA10102

To avoid d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of clicks or turns of each

damping force adjusting mechanism.

This adjustment range may not exactly

match the specifications listed due to

small differences in production.

WARNING

EWA10232

These shock ab sorber assem blies

contain hi ghly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock ab sorber assem blies.

Do not tamper with or attempt

to open the cylin der assem blies.

Do not su bject the shock a b-

sor ber assem blies to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plod e due to excessive gas

pressure.

Do not deform or damag e the

cylin ders in any way. Cylin der

d amag e will result in poor

d ampin g performance.

Do not dispose of a d amaged or

worn-out shock a bsor ber as-

sem bly y

ourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

1. Compression damping force adjusting knobCompression dampin g setting :

Minimum (soft): 20 click(s) in direction (b)*

Standard: 16 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

U2PNE0E0.book Page 20 Tuesda y, September 16, 2014 4:15 PM

Page 36 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-21

3

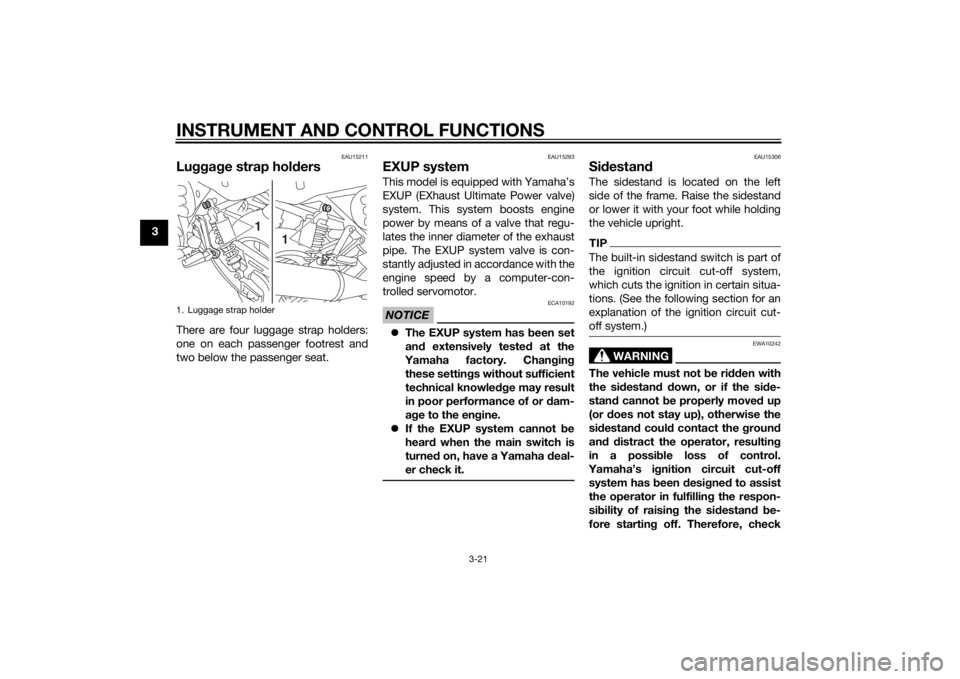

EAU15211

Luggage strap hol dersThere are four luggage strap holders:

one on each passenger footrest and

two below the passenger seat.

EAU15283

EXUP systemThis model is equipped with Yamaha’s

EXUP (EXhaust Ultimate Power valve)

system. This system boosts engine

power by means of a valve that regu-

lates the inner diameter of the exhaust

pipe. The EXUP system valve is con-

stantly adjusted in accordance with the

engine speed by a computer-con-

trolled servomotor.NOTICE

ECA10192

The EXUP system has been set

an d extensively teste d at the

Yamaha factory. Chan gin g

these settin gs without sufficient

technical knowledg e may result

in poor performance of or dam-

a g e to the en gine.

If the EXUP system cannot be

hear d when the main switch is

turne d on, have a Yamaha d eal-

er check it.

EAU15306

Si destan dThe sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

WARNING

EWA10242

The vehicle must not be ri dden with

the si destan d d own, or if the si de-

stan d cannot b e properly moved up

(or does not stay up), otherwise the

si destan d coul d contact the groun d

an d d istract the operator, resultin g

in a possi ble loss of control.

Yamaha’s i gnition circuit cut-off

system has been desi gne d to assist

the operator in fulfillin g the respon-

si bility of raisin g the si destan d b e-

fore startin g off. Therefore, check

1. Luggage strap holder

1

1

U2PNE0E0.book Page 21 Tuesda y, September 16, 2014 4:15 PM

Page 37 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-22

3

this system re

gularly an d have a

Yamaha dealer repair it if it does not

function properly.

EAU44893

I g nition circuit cut-off systemThe ignition circuit cut-off system

(comprising the sidestand switch,

clutch switch and neutral switch) has

the following functions.

It prevents starting when the

transmission is in gear and the

sidestand is up, but the clutch le-

ver is not pulled.

It prevents starting when the

transmission is in gear and the

clutch lever is pulled, but the side-

stand is still down.

It cuts the running engine when

the transmission is in gear and the

sidestand is moved down.

Periodically check the operation of the

ignition circuit cut-off system accord-

ing to the following procedure.

U2PNE0E0.book Page 22 Tuesda y, September 16, 2014 4:15 PM

Page 38 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-23

3

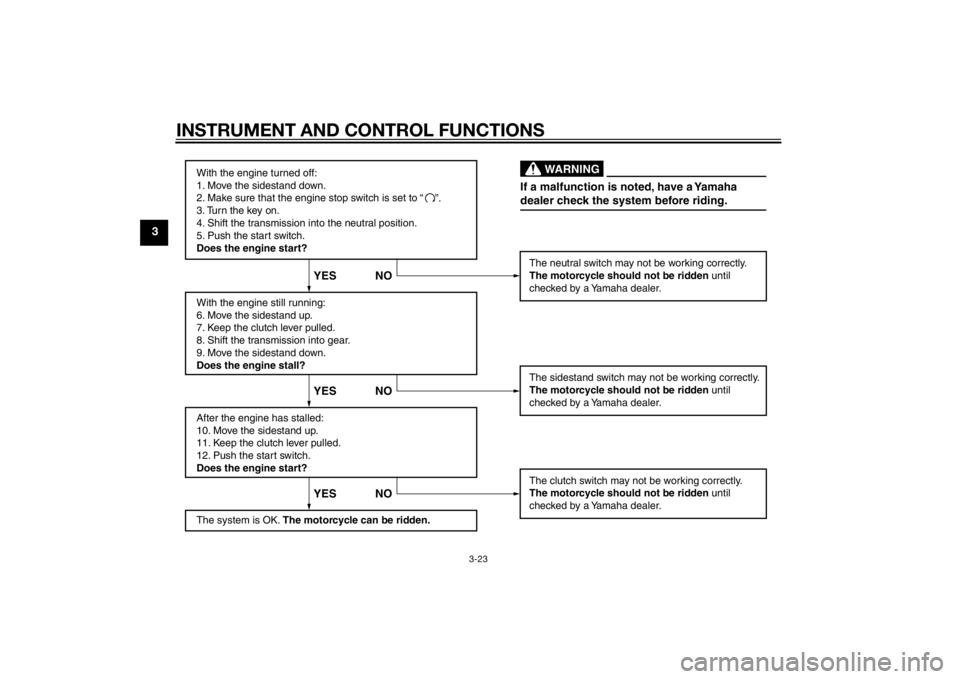

With the engine turned off:

1. Move the sidestand down.

2. Make sure that the engine stop switch is set to “

3. Turn the key on.

4. Shift the transmission into the neutral position.

5. Push the start switch.

Does the engine start?

With the engine still running:

6. Move the sidestand up.

7. Keep the clutch lever pulled.

8. Shift the transmission into gear.

9. Move the sidestand down.

Does the engine stall?

After the engine has stalled:

10. Move the sidestand up.

11. Keep the clutch lever pulled.

12. Push the start switch.

Does the engine start?

The system is OK. The motorcycle can be ridden. The neutral switch may not be working correctly.

The motorcycle should not be ridden

until

checked by a Yamaha dealer.

The sidestand switch may not be working correctly.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

The clutch switch may not be working correctly.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

YES NO YES NO YES NO

If a malfunction is noted, have a Yamaha

dealer check the system before riding.

WARNING

”.

U2PNE0E0.book Page 23 Tuesda y, September 16, 2014 4:15 PM

Page 39 of 98

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-1

4

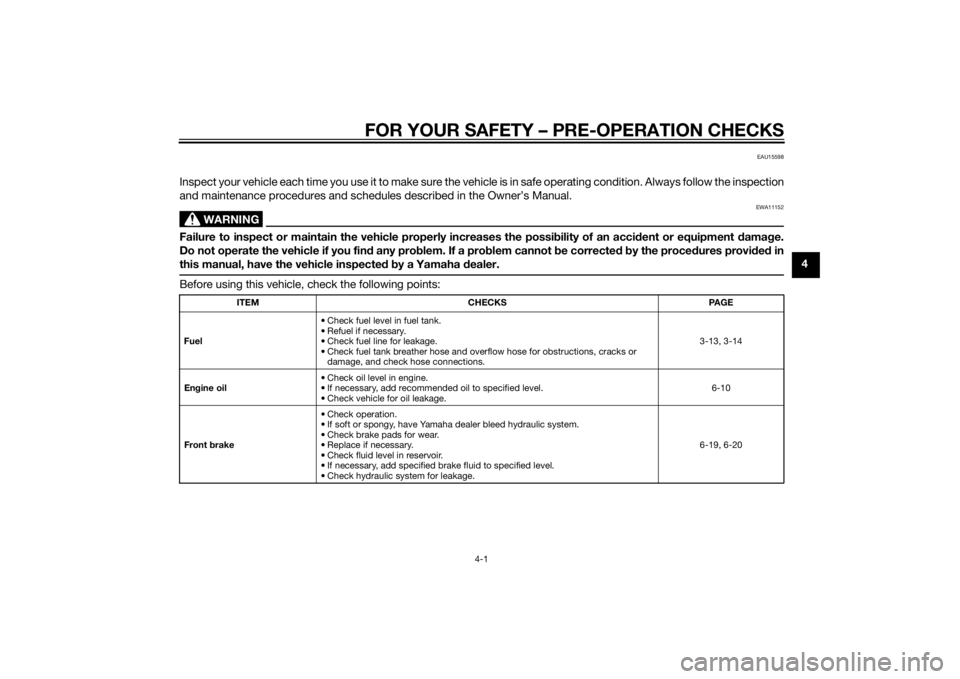

EAU15598

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment d amage.

Do not operate the vehicle if you fin d any pro blem. If a pro blem cannot b e corrected b y the proce dures provi ded in

this manual, have the vehicle inspecte d b y a Yamaha dealer.Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel • Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank breather hose and overflow hose for obstructions, cracks or

damage, and check hose connections. 3-13, 3-14

En gine oil • Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage. 6-10

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-19, 6-20

U2PNE0E0.book Page 1 Tuesday, September 16, 2014 4:15 PM

Page 40 of 98

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-2

4

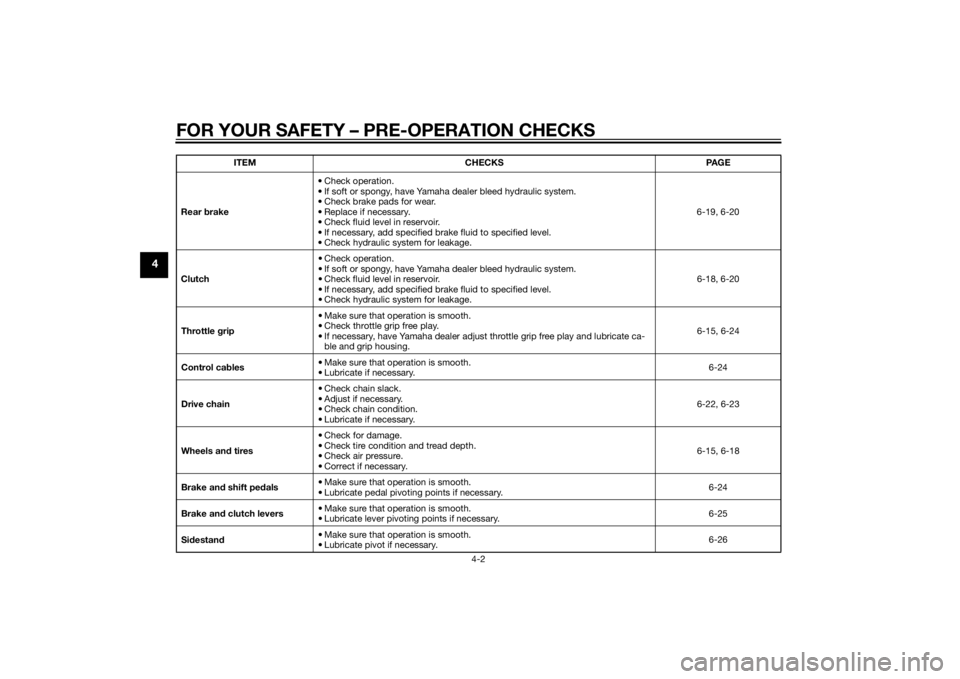

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-19, 6-20

Clutch • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-18, 6-20

Throttle g rip • Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, have Yamaha dealer adjust throttle grip free play and lubricate ca-

ble and grip housing. 6-15, 6-24

Control ca bles • Make sure that operation is smooth.

• Lubricate if necessary. 6-24

Drive chain • Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary.

6-22, 6-23

Wheels an d tires •Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.

6-15, 6-18

Brake an d shift pe dals • Make sure that operation is smooth.

• Lubricate pedal pivoting points if necessary. 6-24

Brake an d clutch levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

6-25

Si destan d • Make sure that operation is smooth.

• Lubricate pivot if necessary.

6-26

ITEM

CHECKS PAGE

U2PNE0E0.book Page 2 Tuesday, September 16, 2014 4:15 PM