YAMAHA XJR 1300 2015 Repair Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: XJR 1300, Model: YAMAHA XJR 1300 2015Pages: 98, PDF Size: 2.6 MB

Page 61 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-16

6

wei

ght of ri der, passen ger, car-

g o, an d accessories approve d

for this mo del.

WARNING

EWA10512

Never overload your vehicle. Opera-

tion of an overloa ded vehicle coul d

cause an acci dent.

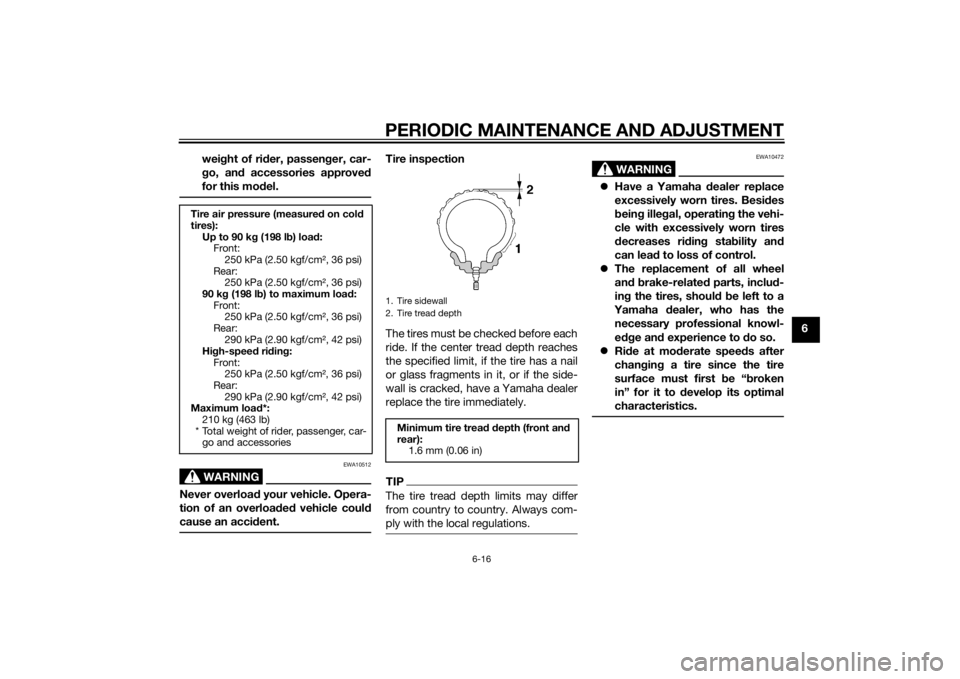

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.TIPThe tire tread depth limits may differ

from country to country. Always com-

ply with the local regulations.

WARNING

EWA10472

Have a Yamaha dealer replace

excessively worn tires. Besi des

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases ri din g sta bility an d

can lead to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dg e an d experience to d o so.

Ride at mo derate spee ds after

chan gin g a tire since the tire

surface must first b e “broken

in” for it to d evelop its optimal

characteristics.

Tire air pressure (measure d on col d

tires): Up to 90 k g (198 l b) loa d:

Front:

250 kPa (2.50 kgf/cm², 36 psi)

Rear: 250 kPa (2.50 kgf/cm², 36 psi)

90 k g (198 l b) to maximum load :

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Hi gh-spee d ri din g:

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear:

290 kPa (2.90 kgf/cm², 42 psi)

Maximum loa d*:

210 kg (463 lb)

* Total weight of rider, passenger, car- go and accessories

1. Tire sidewall

2. Tire tread depth

Minimum tire trea d d epth (front an d

rear): 1.6 mm (0.06 in)

U2PNE0E0.book Page 16 Tuesda y, September 16, 2014 4:15 PM

Page 62 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-17

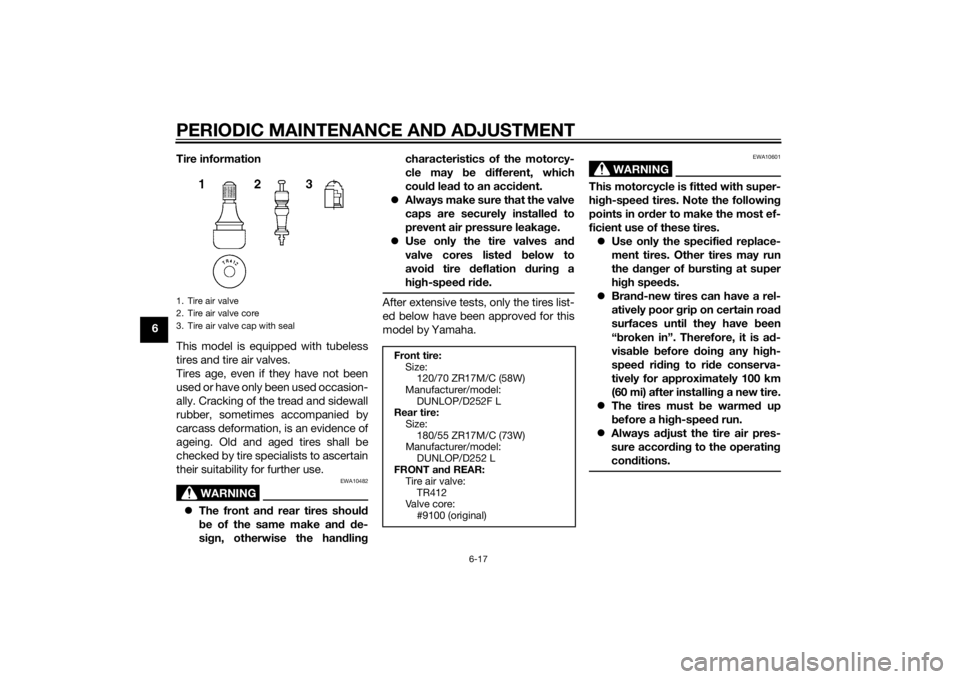

6Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10482

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g characteristics of the motorcy-

cle may

be different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installed to

prevent air pressure leakag e.

Use only the tire valves an d

valve cores listed below to

avoi d tire deflation durin g a

hi gh-spee d ri de.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA10601

This motorcycle is fitte d with super-

hi gh-spee d tires. Note the followin g

points in or der to make the most ef-

ficient use of these tires. Use only the specified replace-

ment tires. Other tires may run

the dan ger of burstin g at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor grip on certain roa d

surfaces until they have been

“ b roken in”. Therefore, it is a d-

visa ble before doin g any hi gh-

speed ridin g to ri de conserva-

tively for approximately 100 km

(60 mi) after installin g a new tire.

The tires must be warme d up

b efore a hi gh-spee d run.

Always a djust the tire air pres-

sure accor din g to the operatin g

con ditions.

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

Front tire:

Size:120/70 ZR17M/C (58W)

Manufacturer/model: DUNLOP/D252F L

Rear tire:

Size:180/55 ZR17M/C (73W)

Manufacturer/model:

DUNLOP/D252 L

FRONT and REAR:

Tire air valve:

TR412

Valve core: #9100 (original)

U2PNE0E0.book Page 17 Tuesda y, September 16, 2014 4:15 PM

Page 63 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-18

6

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels. The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

EAU22074

Clutch leverSince this model is equipped with a hy-

draulic clutch, adjusting the clutch le-

ver free play is not needed. However, it

is necessary to check the clutch fluid

level and check the hydraulic system

for leakage before each ride. (See page

6-20.) If the clutch lever free play does

become excessive, and shifting be-

comes rough or clutch slippage oc-

curs, causing poor acceleration, there

may be air in the clutch system. If there

is air in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the motorcycle.

EAU37914

Checkin g the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the1. No brake lever free play

1

U2PNE0E0.book Page 18 Tuesda y, September 16, 2014 4:15 PM

Page 64 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

6b

rakin g performance, which may re-

sult in loss of control and an acci-

d ent.

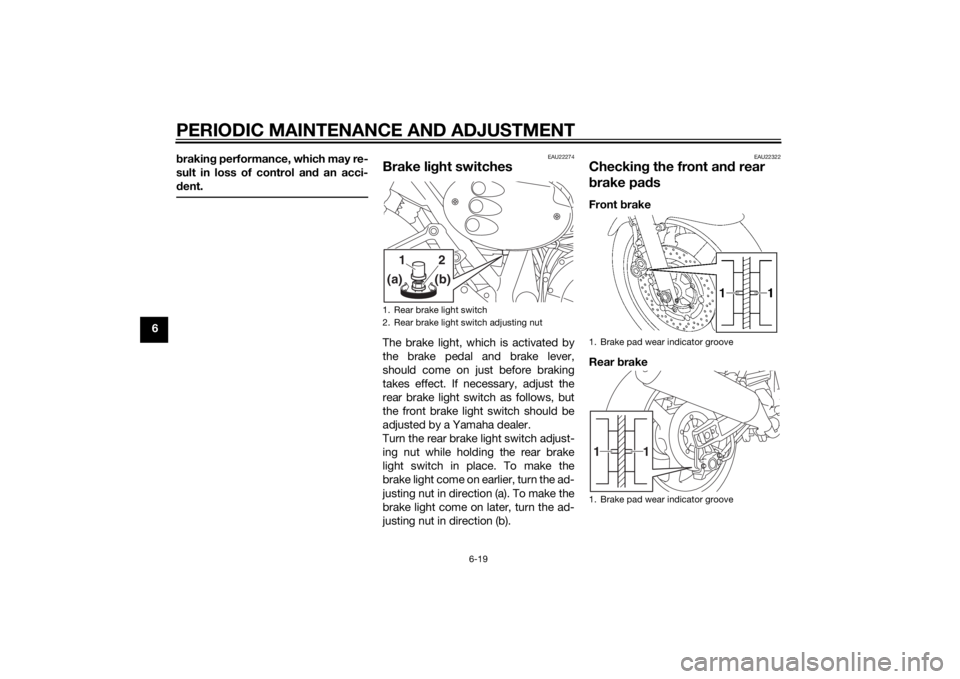

EAU22274

Brake li ght switchesThe brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

EAU22322

Checkin g the front an d rear

b rake pa dsFront brake

Rear brake

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2(b)

(a)

1. Brake pad wear indicator groove

1. Brake pad wear indicator groove1

1

U2PNE0E0.book Page 19 Tuesda y, September 16, 2014 4:15 PM

Page 65 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-20

6

The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart. Each brake pad is

provided with a wear indicator groove,

which allows you to check the brake

pad wear without having to disassem-

ble the brake. To check the brake pad

wear, check the wear indicator

grooves. If a brake pad has worn to the

point that the wear indicator groove

has almost disappeared, have a

Yamaha dealer replace the brake pads as a set.

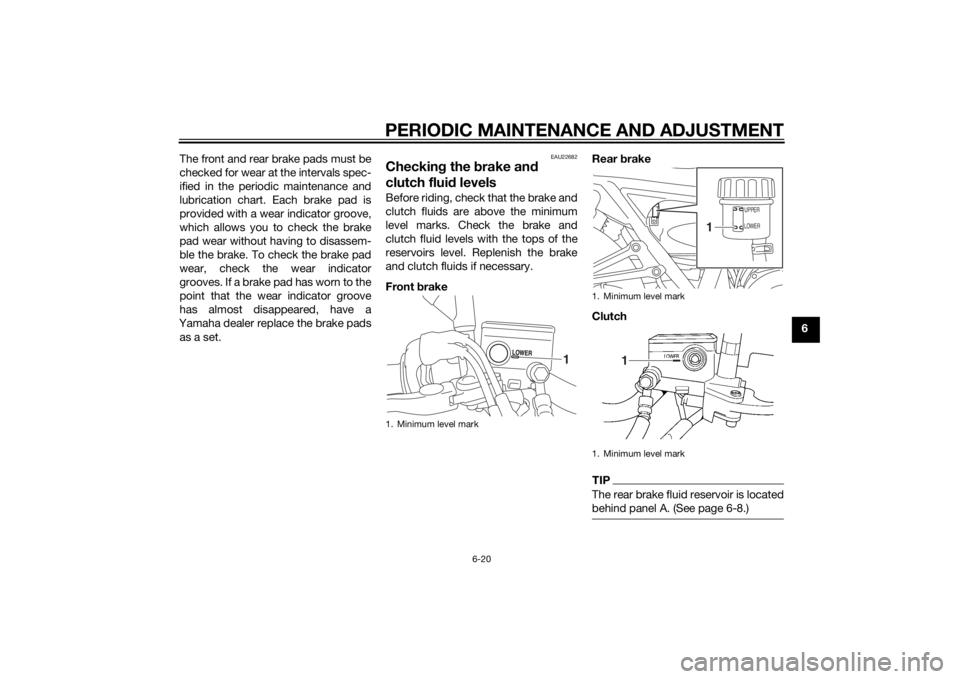

EAU22682

Checkin g the brake an d

clutch flui d levelsBefore riding, check that the brake and

clutch fluids are above the minimum

level marks. Check the brake and

clutch fluid levels with the tops of the

reservoirs level. Replenish the brake

and clutch fluids if necessary.

Front brake Rear

brake

Clutch

TIPThe rear brake fluid reservoir is located

behind panel A. (See page 6-8.)

1. Minimum level mark

1

1. Minimum level mark

1. Minimum level mark

UPPER

LOWER

1

1

U2PNE0E0.book Page 20 Tuesda y, September 16, 2014 4:15 PM

Page 66 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

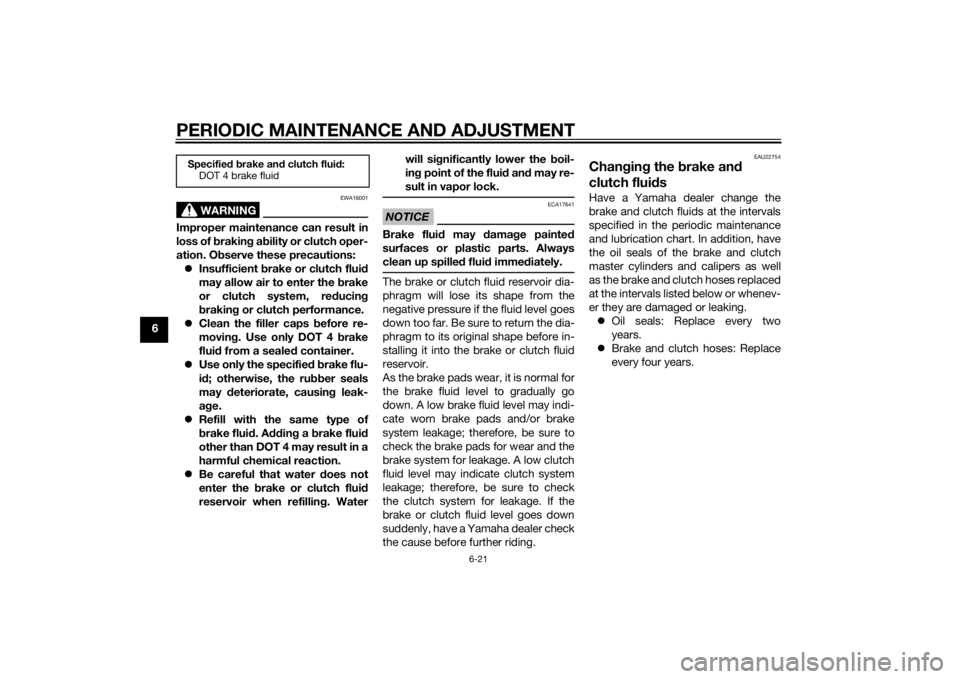

WARNING

EWA16001

Improper maintenance can result in

loss of braking a bility or clutch oper-

ation. O bserve these precautions:

Insufficient brake or clutch flui d

may allow air to enter the brake

or clutch system, re ducing

b rakin g or clutch performance.

Clean the filler caps before re-

moving . Use only DOT 4 b rake

flui d from a seale d container.

Use only the specified b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water does not

enter the brake or clutch flui d

reservoir when refillin g. Water will si

gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock.

NOTICE

ECA17641

Brake fluid may damag e painted

surfaces or plastic parts. Always

clean up spille d flui d imme diately.The brake or clutch fluid reservoir dia-

phragm will lose its shape from the

negative pressure if the fluid level goes

down too far. Be sure to return the dia-

phragm to its original shape before in-

stalling it into the brake or clutch fluid

reservoir.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. A low clutch

fluid level may indicate clutch system

leakage; therefore, be sure to check

the clutch system for leakage. If the

brake or clutch fluid level goes down

suddenly, have a Yamaha dealer check

the cause before further riding.

EAU22754

Chan gin g the brake an d

clutch flui dsHave a Yamaha dealer change the

brake and clutch fluids at the intervals

specified in the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the brake and clutch

master cylinders and calipers as well

as the brake and clutch hoses replaced

at the intervals listed below or whenev-

er they are damaged or leaking.

Oil seals: Replace every two

years.

Brake and clutch hoses: Replace

every four years.

Specifie d b rake an d clutch flui d:

DOT 4 brake fluid

U2PNE0E0.book Page 21 Tuesda y, September 16, 2014 4:15 PM

Page 67 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

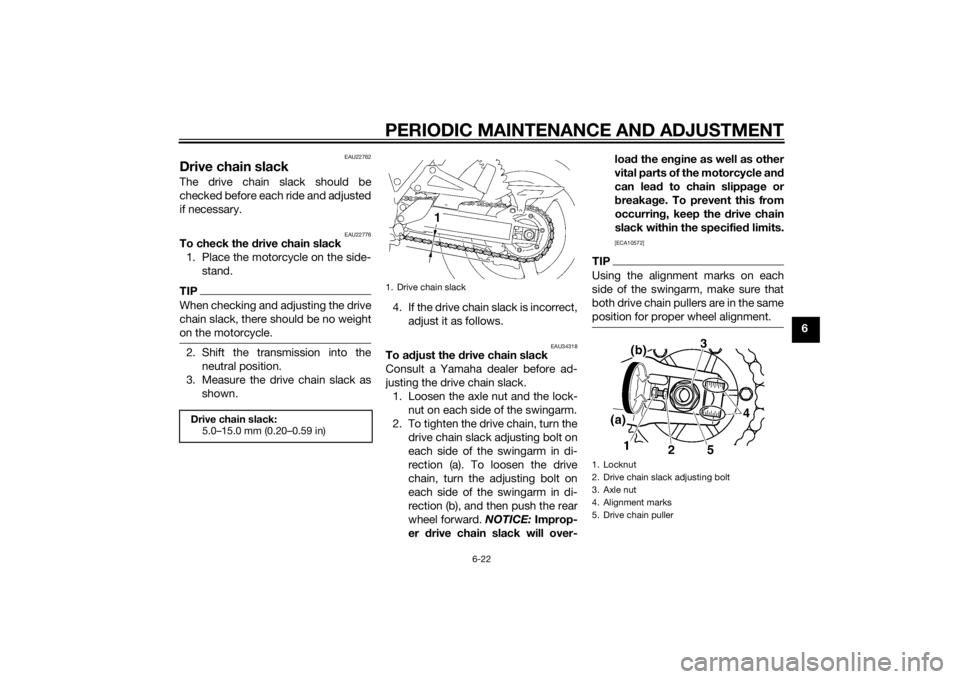

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22776

To check the drive chain slack

1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU34318

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over- loa

d the en gine as well as other

vital parts of the motorcycle and

can lead to chain slippa ge or

b reakag e. To prevent this from

occurrin g, keep the d rive chain

slack within the specified limits.

[ECA10572]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

Drive chain slack:

5.0–15.0 mm (0.20–0.59 in)

1. Drive chain slack

1

1. Locknut

2. Drive chain slack adjusting bolt

3. Axle nut

4. Alignment marks

5. Drive chain puller

U2PNE0E0.book Page 22 Tuesda y, September 16, 2014 4:15 PM

Page 68 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

63. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they may contain su

bstances that

coul d damag e the O-rin gs.

[ECA11112]

Ti ghtenin g torques:

Axle nut: 150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U2PNE0E0.book Page 23 Tuesda y, September 16, 2014 4:15 PM

Page 69 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

EAU23098

Checking an d lu bricatin g the

ca blesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or re-

place it. WARNING! Dama ge to the

outer housin g of cab les may result

in internal rustin g an d cause inter-

ference with ca ble movement. Re-

place damag ed cab les as soon as

possi ble to prevent unsafe con di-

tions.

[EWA10712] EAU23115

Checkin

g an d lu bricatin g the

throttle grip an d ca bleThe operation of the throttle grip

should be checked before each ride. In

addition, the cable should be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

chart.

The throttle cable is equipped with a

rubber cover. Make sure that the cover

is securely installed. Even though the

cover is installed correctly, it does not

completely protect the cable from wa-

ter entry. Therefore, use care not to

pour water directly onto the cover or

cable when washing the vehicle. If the

cable or cover becomes dirty, wipe

clean with a moist cloth.

EAU44275

Checkin g an d lu bricatin g the

b rake an d shift pe dalsThe operation of the brake and shift

pedals should be checked before each

ride, and the pedal pivots should be lu-

bricated if necessary.

Brake pe dal

Shift pe dal

Recommen ded lu bricant:

Yamaha cable lubricant or other

suitable cable lubricant

U2PNE0E0.book Page 24 Tuesda y, September 16, 2014 4:15 PM

Page 70 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-25

6

EAU43602

Checking an d lu bricatin g the

b rake an d clutch leversThe operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Brake lever

Clutch lever

Recommen ded lu bricant:

Lithium-soap-based grease

Recommen ded lu bricant:

Silicone grease

U2PNE0E0.book Page 25 Tuesda y, September 16, 2014 4:15 PM