YAMAHA XT1200ZE 2019 Manual PDF

Manufacturer: YAMAHA, Model Year: 2019, Model line: XT1200ZE, Model: YAMAHA XT1200ZE 2019Pages: 122, PDF Size: 3.88 MB

Page 71 of 122

Periodic maintenance an d a djustment

6-5

6

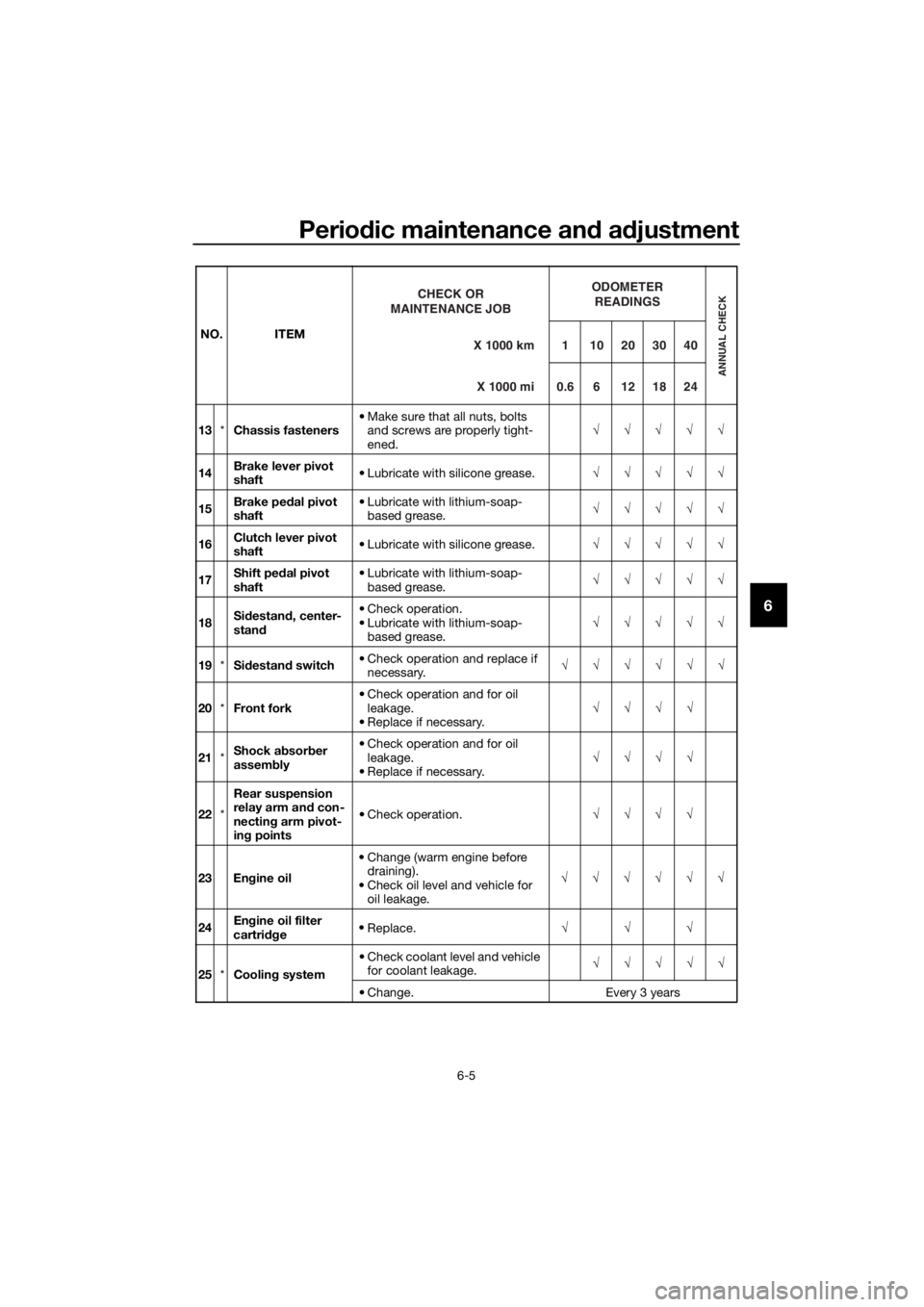

13 *Chassis fasteners • Make sure that all nuts, bolts

and screws are properly tight-

ened. √√√√√

14 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

15 Brake ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

16 Clutch lever pivot

shaft • Lubricate with silicone grease.

√√√√√

17 Shift pe

dal pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Si

destan d, center-

stan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

19 *Sidestan d switch • Check operation and replace if

necessary. √√√√√√

20 *Front fork • Check operation and for oil

leakage.

• Replace if necessary. √√√√

21 *Shock a

bsor ber

assem bly • Check operation and for oil

leakage.

• Replace if necessary. √√√√

22 *Rear suspension

relay arm an

d con-

nectin g arm pivot-

in g points • Check operation.

√√√√

23 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. √√√√√√

24 En

gine oil filter

cartri dge •

Replace.

√√√

25 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change. Every 3 years

NO. ITEM

X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER READINGS

ANNUAL CHECK

110203040

0.66121824

UBP9E1E0.book Page 5 Friday, September 7, 2018 10:01 AM

Page 72 of 122

Periodic maintenance an d a djustment

6-6

6

EAU72841

TIP

Air filter

This model’s air filter uses a disposable oil-coated paper element, which

must be replaced. Do not clean with compressed air, doing so will only dam-

age it.

The air filter element needs to be replaced more frequently if you often ride in

the rain or dusty areas.

Hydraulic brake and clutch service Regularly check the brake fluid and clutch fluid reservoirs. Replenish as nec-

essary.

Every two years replace the internal components of the brake master cylin-

ders and calipers as well as clutch master and release cylinders, and change

the brake and clutch fluids.

Replace the brake and clutch hoses every four years or sooner if cracked or

damaged.

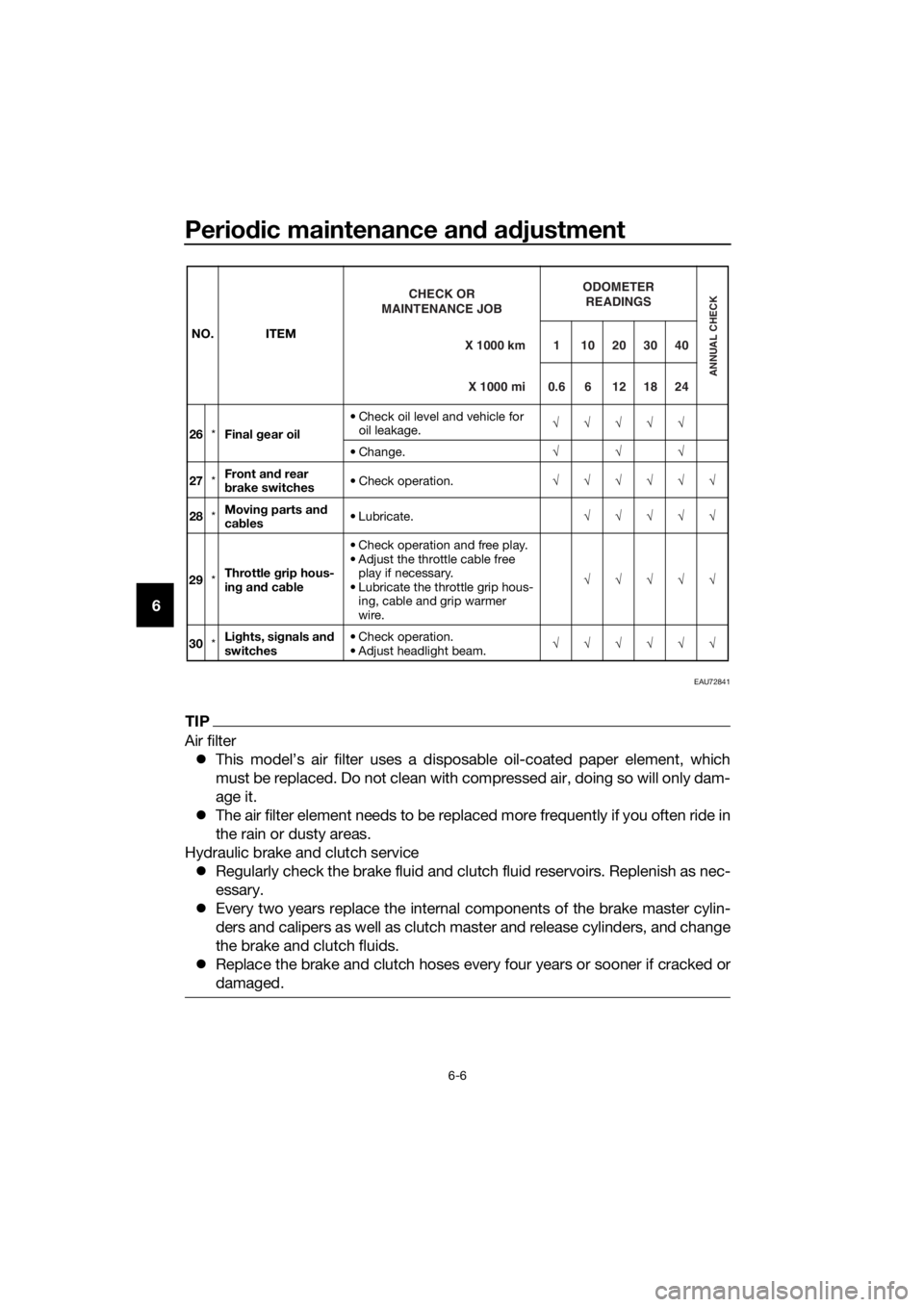

26 *Final gear oil • Check oil level and vehicle for

oil leakage. √√√√√

• Change. √√√

27 *Front an

d rear

b rake switches • Check operation.

√√√√√√

28 *Movin

g parts an d

cab les • Lubricate.

√√√√√

29 *Throttle

grip hous-

in g an d ca ble • Check operation and free play.

• Adjust the throttle cable free

play if necessary.

• Lubricate the throttle grip hous- ing, cable and grip warmer

wire. √√√√√

30 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM

X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi ODOMETER

READINGS

ANNUAL CHECK

110203040

0.6 6 12 18 24

UBP9E1E0.book Page 6 Friday, September 7, 2018 10:01 AM

Page 73 of 122

Periodic maintenance an d a djustment

6-7

6

EAU18782

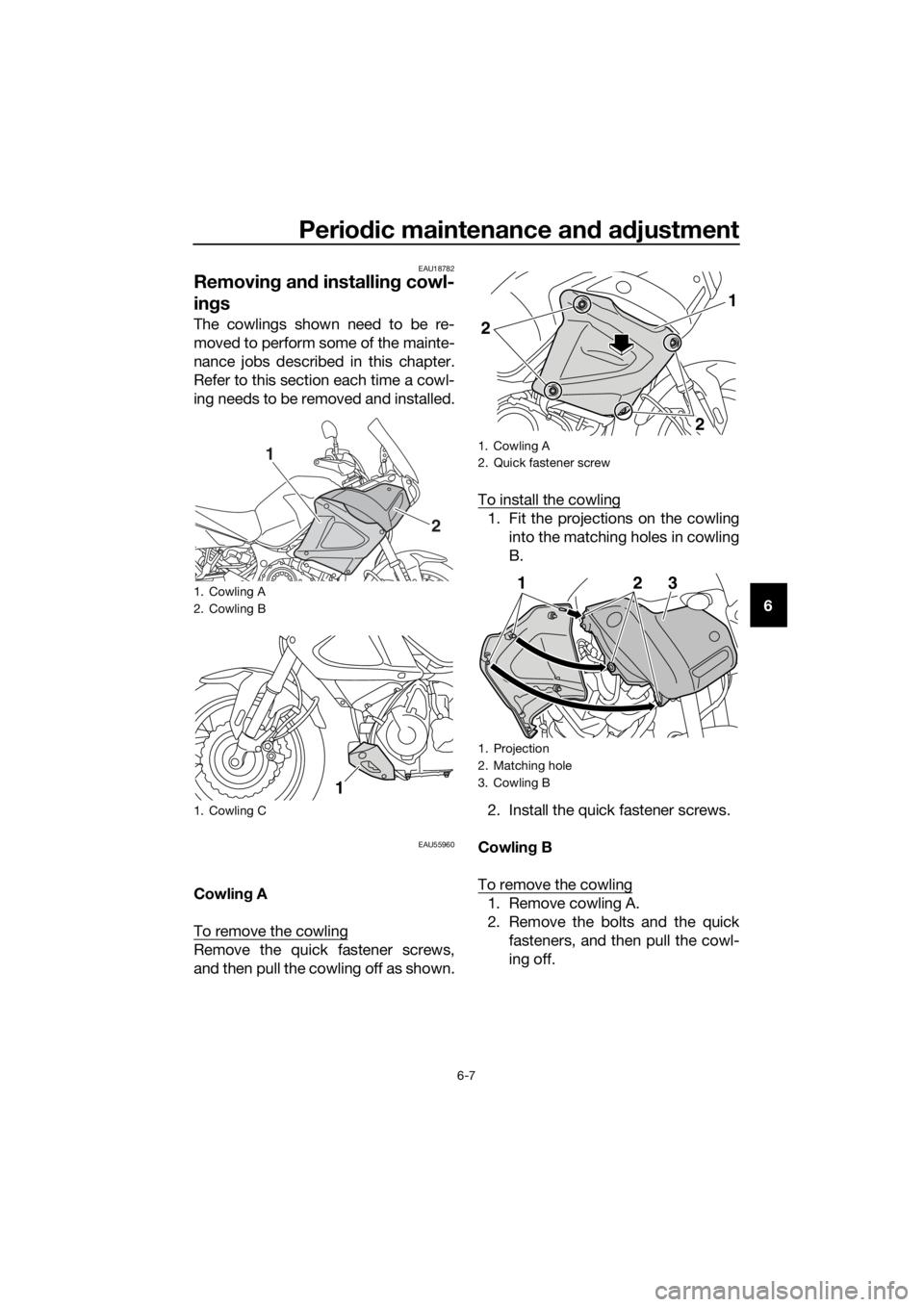

Removin g an d installin g cowl-

in gs

The cowlings shown need to be re-

moved to perform some of the mainte-

nance jobs described in this chapter.

Refer to this section each time a cowl-

ing needs to be removed and installed.

EAU55960

Cowlin g A

To remove the cowling

Remove the quick fastener screws,

and then pull the cowling off as shown. To install the cowling

1. Fit the projections on the cowling

into the matching holes in cowling

B.

2. Install the quick fastener screws.

Cowlin g B

To remove the cowling

1. Remove cowling A.

2. Remove the bolts and the quick fasteners, and then pull the cowl-

ing off.

1. Cowling A

2. Cowling B

1. Cowling C

1

2

1

1. Cowling A

2. Quick fastener screw

1. Projection

2. Matching hole

3. Cowling B

2

2

1

123

UBP9E1E0.book Page 7 Friday, September 7, 2018 10:01 AM

Page 74 of 122

Periodic maintenance an d a djustment

6-8

6

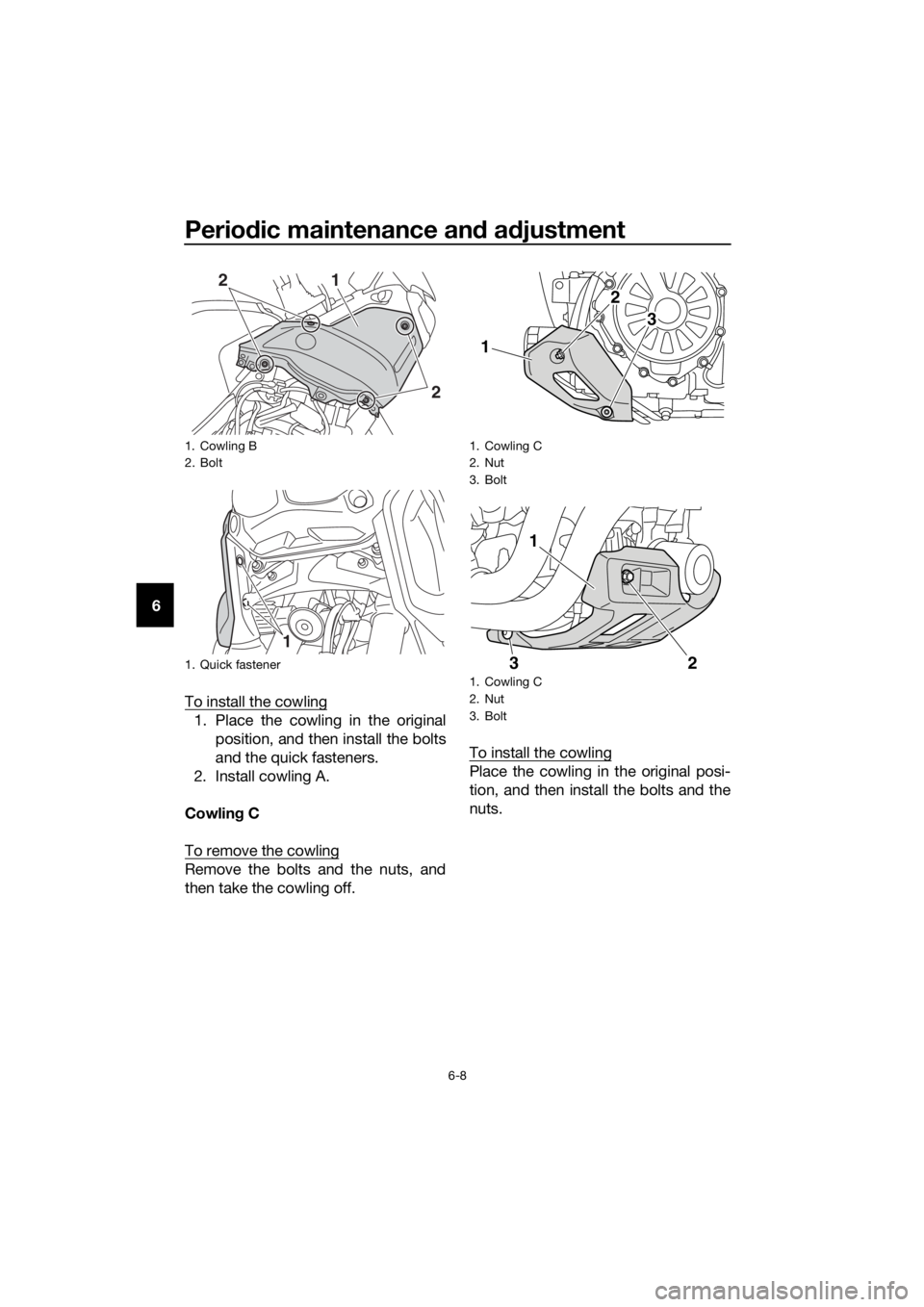

To install the cowling

1. Place the cowling in the originalposition, and then install the bolts

and the quick fasteners.

2. Install cowling A.

Cowlin g C

To remove the cowling

Remove the bolts and the nuts, and

then take the cowling off. To install the cowling

Place the cowling in the original posi-

tion, and then install the bolts and the

nuts.

1. Cowling B

2. Bolt

1. Quick fastener

21

2

1

1. Cowling C

2. Nut

3. Bolt

1. Cowling C

2. Nut

3. Bolt

2

3

1

1

2

3

UBP9E1E0.book Page 8 Friday, September 7, 2018 10:01 AM

Page 75 of 122

Periodic maintenance an d a djustment

6-9

6

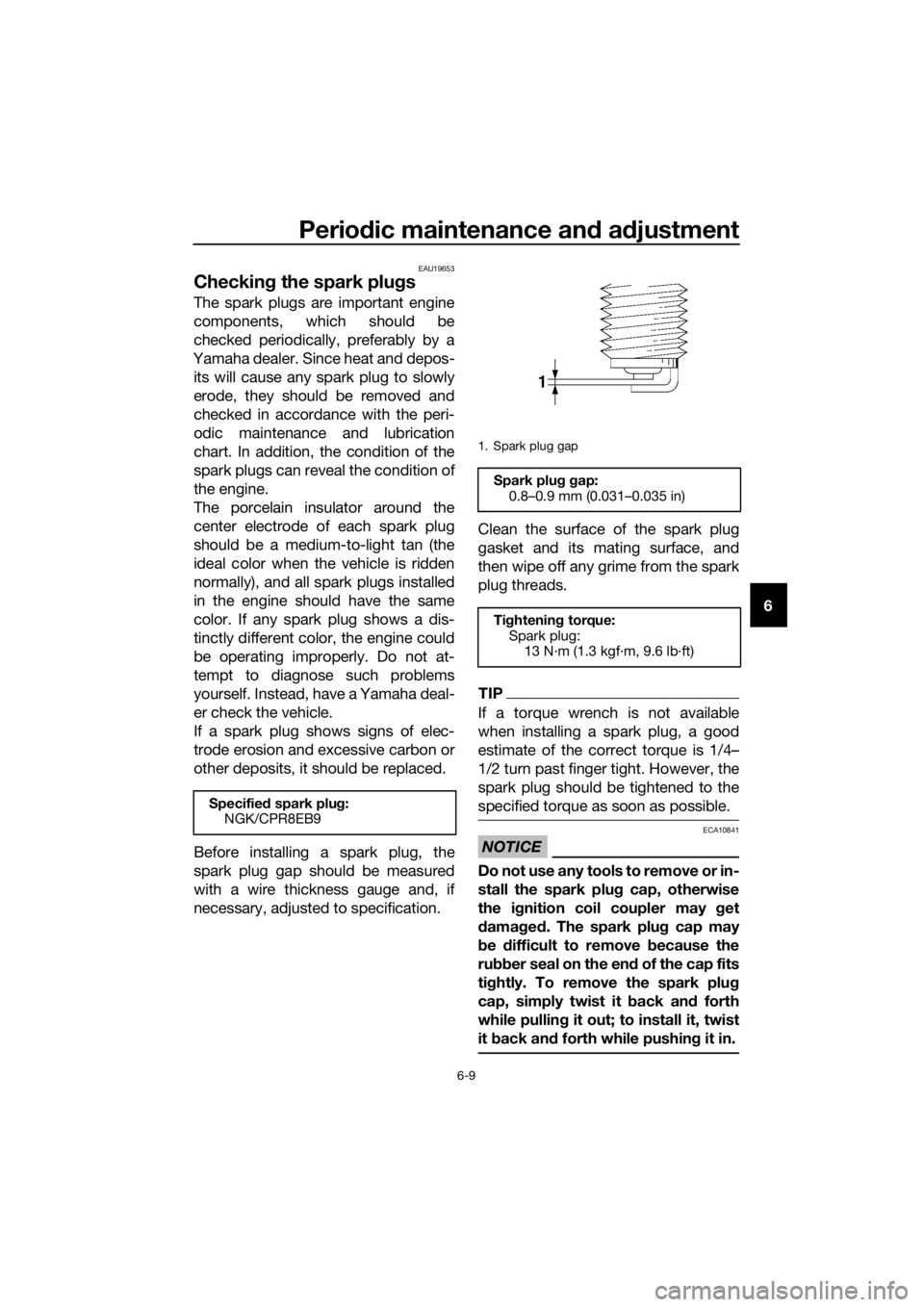

EAU19653

Checkin g the spark plu gs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it back an d forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/CPR8EB9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.6 lb·ft)

UBP9E1E0.book Page 9 Friday, September 7, 2018 10:01 AM

Page 76 of 122

Periodic maintenance an d a djustment

6-10

6

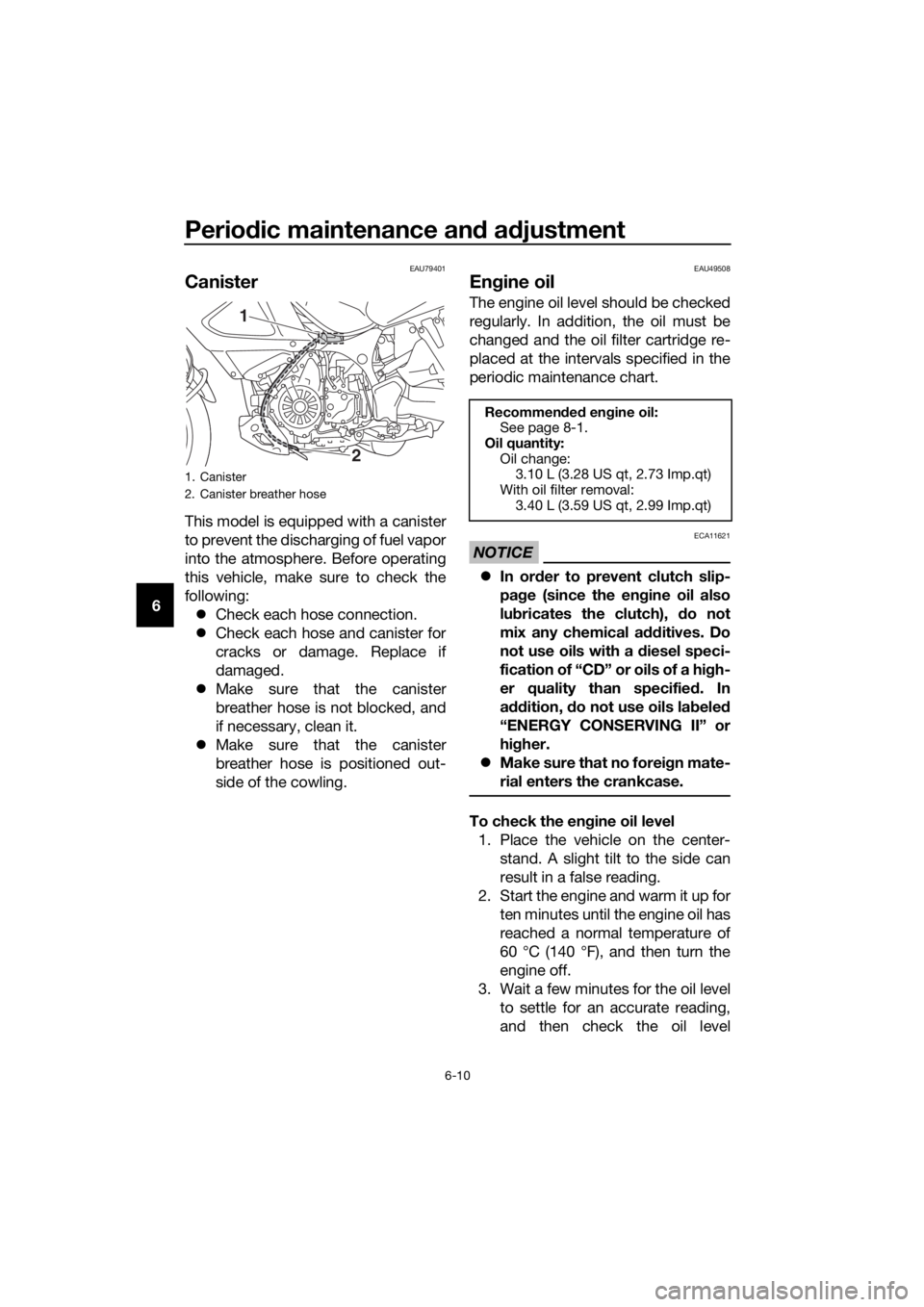

EAU79401

Canister

This model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather hose is not blocked, and

if necessary, clean it.

Make sure that the canister

breather hose is positioned out-

side of the cowling.

EAU49508

Engine oil

The engine oil level should be checked

regularly. In addition, the oil must be

changed and the oil filter cartridge re-

placed at the intervals specified in the

periodic maintenance chart.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical add itives. Do

not use oils with a d iesel speci-

fication of “CD” or oils of a hi gh-

er quality than specified . In

a ddition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

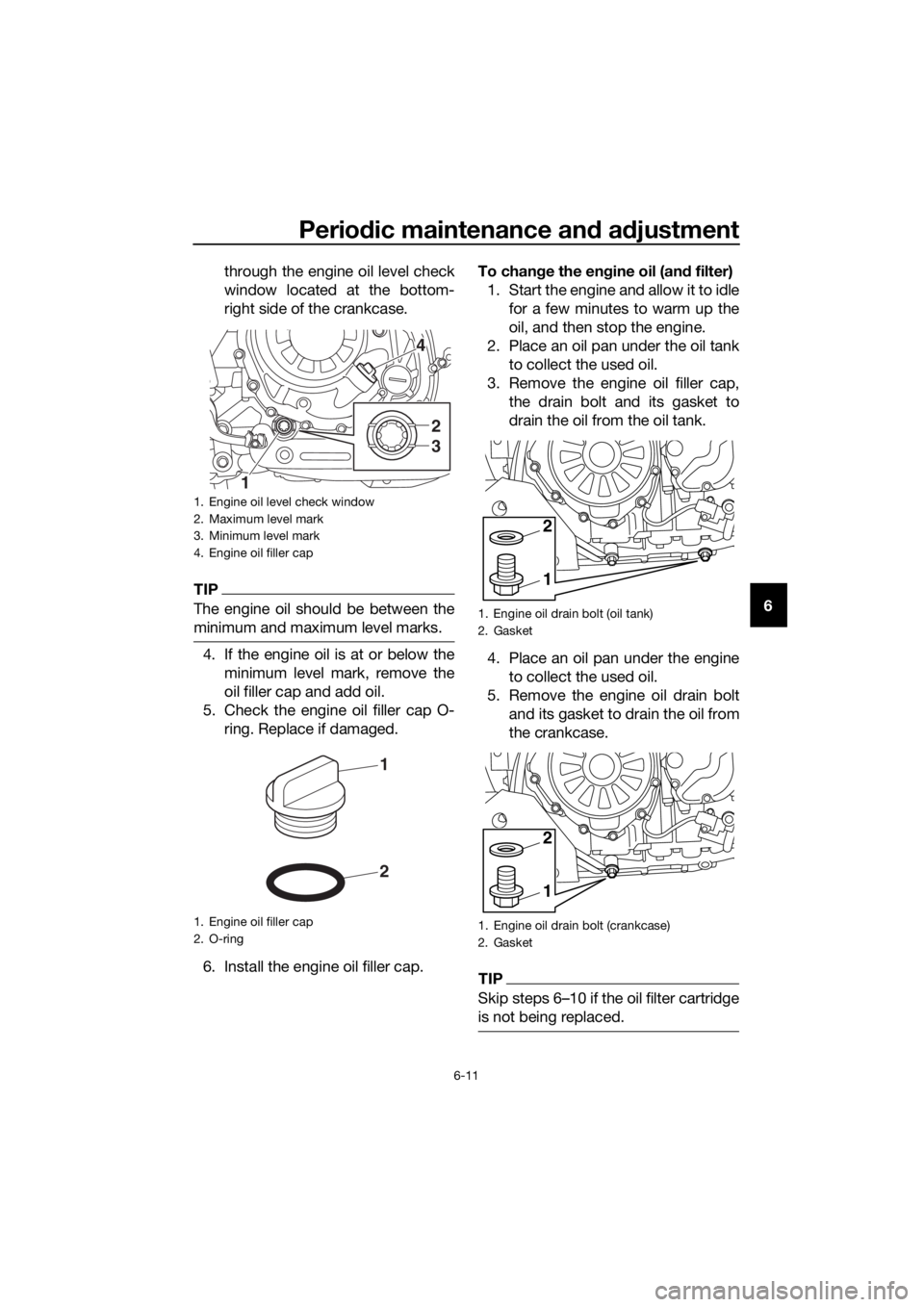

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine and warm it up for ten minutes until the engine oil has

reached a normal temperature of

60 °C (140 °F), and then turn the

engine off.

3. Wait a few minutes for the oil level to settle for an accurate reading,

and then check the oil level

1. Canister

2. Canister breather hose

2

1

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:3.10 L (3.28 US qt, 2.73 Imp.qt)

With oil filter removal: 3.40 L (3.59 US qt, 2.99 Imp.qt)

UBP9E1E0.book Page 10 Friday, September 7, 2018 10:01 AM

Page 77 of 122

Periodic maintenance an d a djustment

6-11

6

through the engine oil level check

window located at the bottom-

right side of the crankcase.

TIP

The engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is at or below the

minimum level mark, remove the

oil filler cap and add oil.

5. Check the engine oil filler cap O- ring. Replace if damaged.

6. Install the engine oil filler cap. To chan

ge the en gine oil (an d filter)

1. Start the engine and allow it to idle for a few minutes to warm up the

oil, and then stop the engine.

2. Place an oil pan under the oil tank to collect the used oil.

3. Remove the engine oil filler cap, the drain bolt and its gasket to

drain the oil from the oil tank.

4. Place an oil pan under the engine to collect the used oil.

5. Remove the engine oil drain bolt and its gasket to drain the oil from

the crankcase.

TIP

Skip steps 6–10 if the oil filter cartridge

is not being replaced.

1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

4. Engine oil filler cap

1. Engine oil filler cap

2. O-ring

4

2

3

1

2

1

1. Engine oil drain bolt (oil tank)

2. Gasket

1. Engine oil drain bolt (crankcase)

2. Gasket

1

2

1

2

UBP9E1E0.book Page 11 Friday, September 7, 2018 10:01 AM

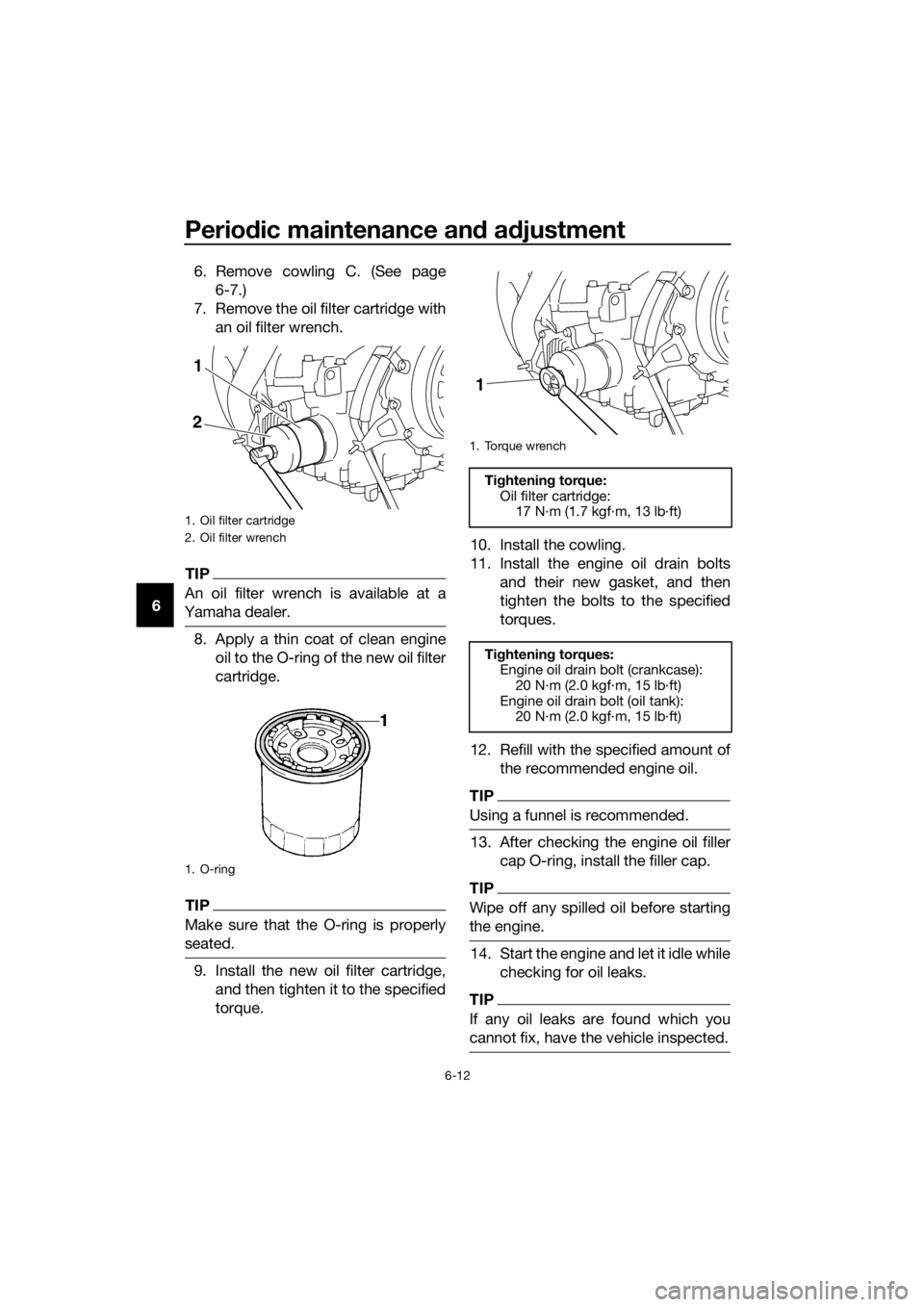

Page 78 of 122

Periodic maintenance an d a djustment

6-12

6 6. Remove cowling C. (See page

6-7.)

7. Remove the oil filter cartridge with an oil filter wrench.

TIP

An oil filter wrench is available at a

Yamaha dealer.

8. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.

TIP

Make sure that the O-ring is properly

seated.

9. Install the new oil filter cartridge,and then tighten it to the specified

torque. 10. Install the cowling.

11. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques.

12. Refill with the specified amount of the recommended engine oil.

TIP

Using a funnel is recommended.

13. After checking the engine oil fillercap O-ring, install the filler cap.

TIP

Wipe off any spilled oil before starting

the engine.

14. Start the engine and let it idle whilechecking for oil leaks.

TIP

If any oil leaks are found which you

cannot fix, have the vehicle inspected.

1. Oil filter cartridge

2. Oil filter wrench

1. O-ring

2

1

1. Torque wrench

Tightening torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 13 lb·ft)

Ti ghtening torques:

Engine oil drain bolt (crankcase):

20 N·m (2.0 kgf·m, 15 lb·ft)

Engine oil drain bolt (oil tank): 20 N·m (2.0 kgf·m, 15 lb·ft)

1

UBP9E1E0.book Page 12 Friday, September 7, 2018 10:01 AM

Page 79 of 122

Periodic maintenance an d a djustment

6-13

6

15. Stop the engine, wait a few minu-

tes for the oil level to settle, and

then check the oil level one last

time. NOTICE: Do not operate

the vehicle until you know that

the en gine oil level is sufficient.

[ECA10012] EAU85450

Why Yamalu

be

YAMALUBE oil is a Genuine YAMAHA

Part born of the engineers’ passion

and belief that engine oil is an impor-

tant liquid engine component. We form

teams of specialists in the fields of me-

chanical engineering, chemistry, elec-

tronics and track testing, and have

them develop the engine together with

the oil it will use. Yamalube oils take full

advantage of the base oil’s qualities

and blend in the ideal balance of addi-

tives to make sure the final oil clears

our performance standards. Thus,

Yamalube mineral, semisynthetic and synthetic oils have their own distinct

characters and value. Yamaha’s expe-

rience gained over many years of re-

search and development into oil since

the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

UBP9E1E0.book Page 13 Friday, September 7, 2018 10:01 AM

Page 80 of 122

Periodic maintenance an d a djustment

6-14

6

EAU20017

Final g ear oil

The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In ad-

dition, the final gear oil level must be

checked and the oil changed as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

WARNING

EWA10371

Make sure that no forei gn mate-

rial enters the final g ear case.

Make sure that no oil gets on

the tire or wheel.

To check the final gear oil level

1. Place the vehicle on the center- stand.

TIP

Make sure that the vehicle is posi-

tioned straight up when checking the

oil level. A slight tilt to the side can re-

sult in a false reading.

2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIP

The oil level should be at the brim of

the filler hole.

3. If the oil is below the brim of thefiller hole, add sufficient oil of the

recommended type to raise it to

the correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten

the bolt to the specified torque.

To chan ge the final gear oil

1. Place the vehicle on a level surfa- ce.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and

their gasket to drain the oil from

the final gear case.

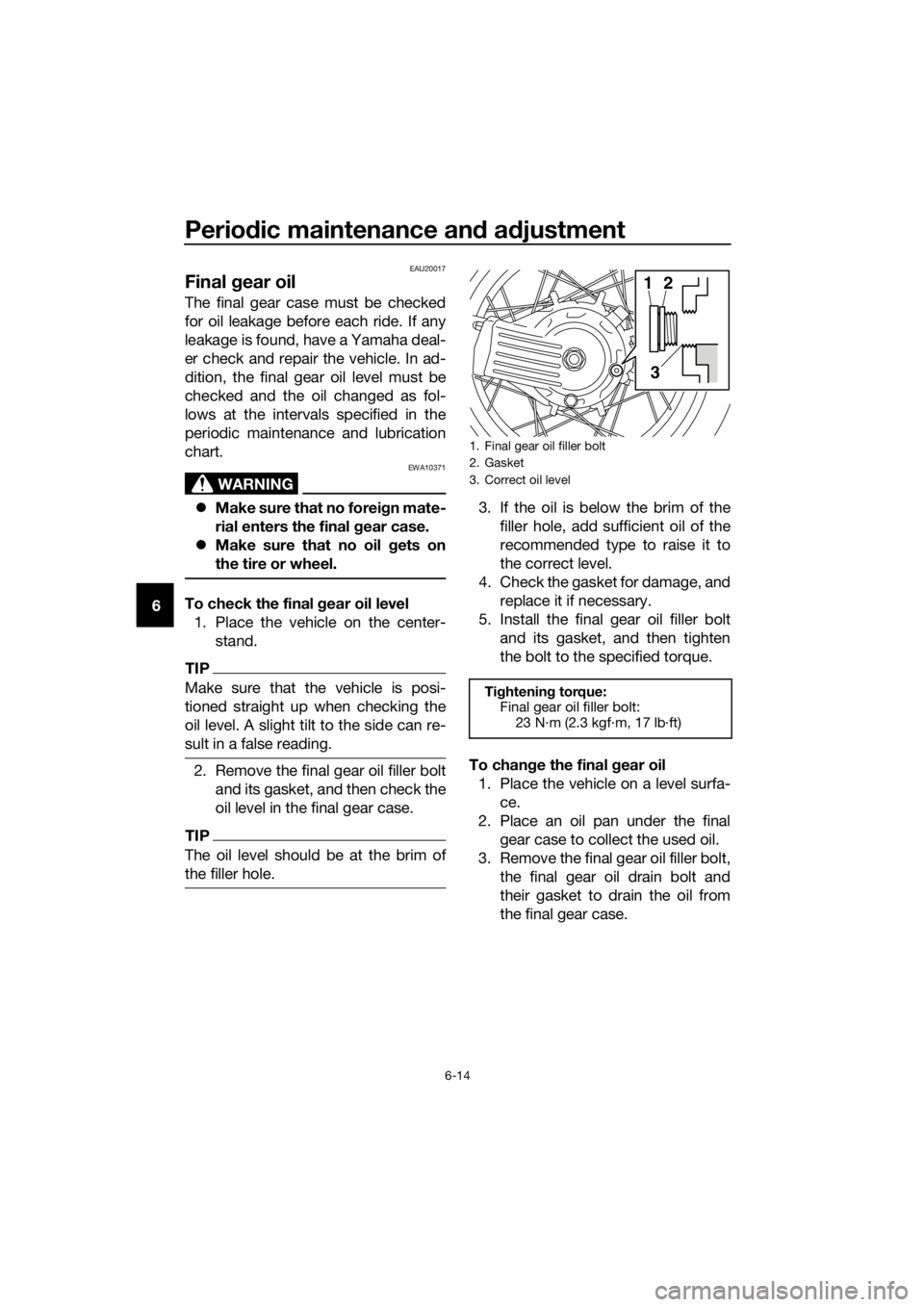

1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

Tightening torque:

Final gear oil filler bolt:

23 N·m (2.3 kgf·m, 17 lb·ft)

12

3

UBP9E1E0.book Page 14 Friday, September 7, 2018 10:01 AM