YAMAHA XVZ1300A 2000 Owner's Manual

Manufacturer: YAMAHA, Model Year: 2000, Model line: XVZ1300A, Model: YAMAHA XVZ1300A 2000Pages: 91, PDF Size: 15.45 MB

Page 21 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-7

3

EAU02917

Fuel tank capTo remove

Slide the lock cover open, insert the

key and turn it 1/4 turn clockwise. The

lock will be released and the cap can

be removed.

To install

Make sure the arrow mark on the tank

cap is facing forward, then push the

tank cap into position. Turn the key

counterclockwise to the original posi-

tion and remove it. Close the lock cov-

er.

NOTE:@ This tank cap cannot be closed unless

the key is in the lock. The key cannot

be removed if the cap is not locked

properly. @

EW000023

WARNING

@ Be sure the cap is properly installed

and locked in place before riding the

motorcycle. @

EAU01183

FuelMake sure there is sufficient fuel in the

tank. Fill the fuel tank to the bottom of

the filler tube as shown in the illustra-

tion.

EW000130

WARNING

@ Do not overfill the fuel tank. Avoid

spilling fuel on the hot engine. Do

not fill the fuel tank above the bot-

tom of the filler tube or it may over-

flow when the fuel heats up later and

expands. @1. Filler tube

2. Fuel level

E_4YP_Functions.fm Page 7 Wednesday, October 6, 1999 10:03 AM

Page 22 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-8

3

EAU00185

CAUTION:@ Always wipe off spilled fuel immedi-

ately with a dry and clean soft cloth.

Fuel may deteriorate painted surfac-

es or plastic parts. @

EAU00191

NOTE:@ If knocking or pinging occurs, use a dif-

ferent brand of gasoline or higher oc-

tane grade. @

EAU02969

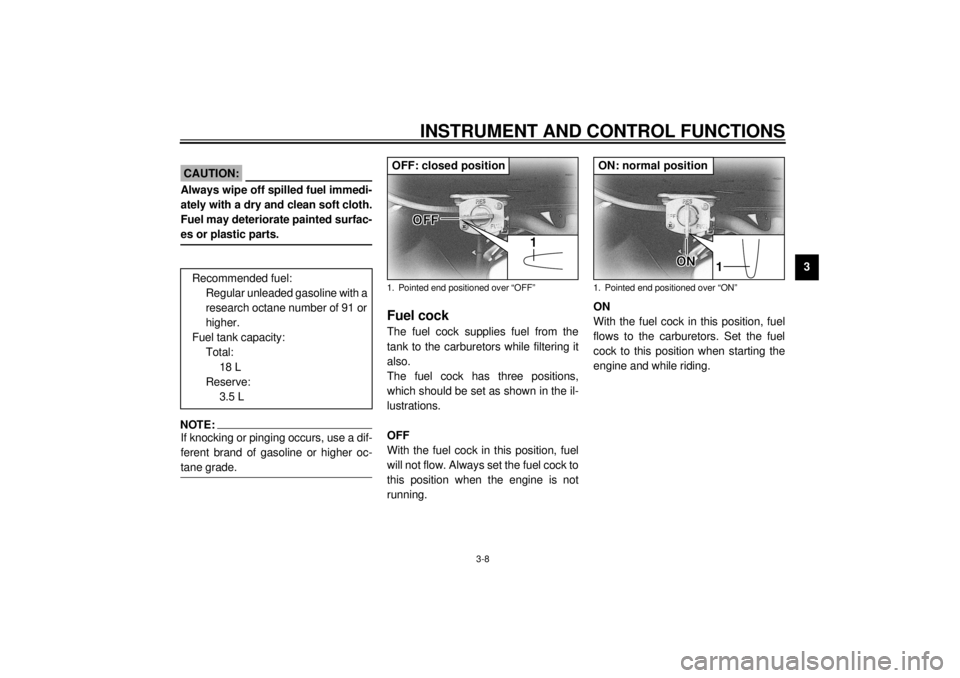

Fuel cockThe fuel cock supplies fuel from the

tank to the carburetors while filtering it

also.

The fuel cock has three positions,

which should be set as shown in the il-

lustrations.

OFF

With the fuel cock in this position, fuel

will not flow. Always set the fuel cock to

this position when the engine is not

running.ON

With the fuel cock in this position, fuel

flows to the carburetors. Set the fuel

cock to this position when starting the

engine and while riding. Recommended fuel:

Regular unleaded gasoline with a

research octane number of 91 or

higher.

Fuel tank capacity:

Total:

18 L

Reserve:

3.5 L1. Pointed end positioned over “OFF”OFF: closed position

1. Pointed end positioned over “ON”ON: normal position

E_4YP_Functions.fm Page 8 Wednesday, October 6, 1999 10:03 AM

Page 23 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-9

3

RES

This indicates reserve. If you run out of

fuel while riding, set the fuel cock to this

position. Fill the tank at the first oppor-

tunity. Be sure to set the fuel cock back

to “ON” after refueling!

EAU03032

Starter (choke) knobStarting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the knob in direction

a to turn on

the starter (choke).

Move the knob in direction

b to turn off

the starter (choke).

EAU01214

Steering lockThe steering lock is located on the left

side of the head pipe.

To lock the steering

1. Turn the handlebars all the way to

the right.

2. Open the steering lock cover.

3. Insert the key and turn it counter-

clockwise 1/8 turn.

4. Push the key in and turn it back

1/8 turn clockwise.

5. Check that the steering is locked.

6. Remove the key and close the

steering lock cover.

1. Pointed end positioned over “RES”RES: reserve position

1. Steering lock

E_4YP_Functions.fm Page 9 Wednesday, October 6, 1999 10:03 AM

Page 24 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-10

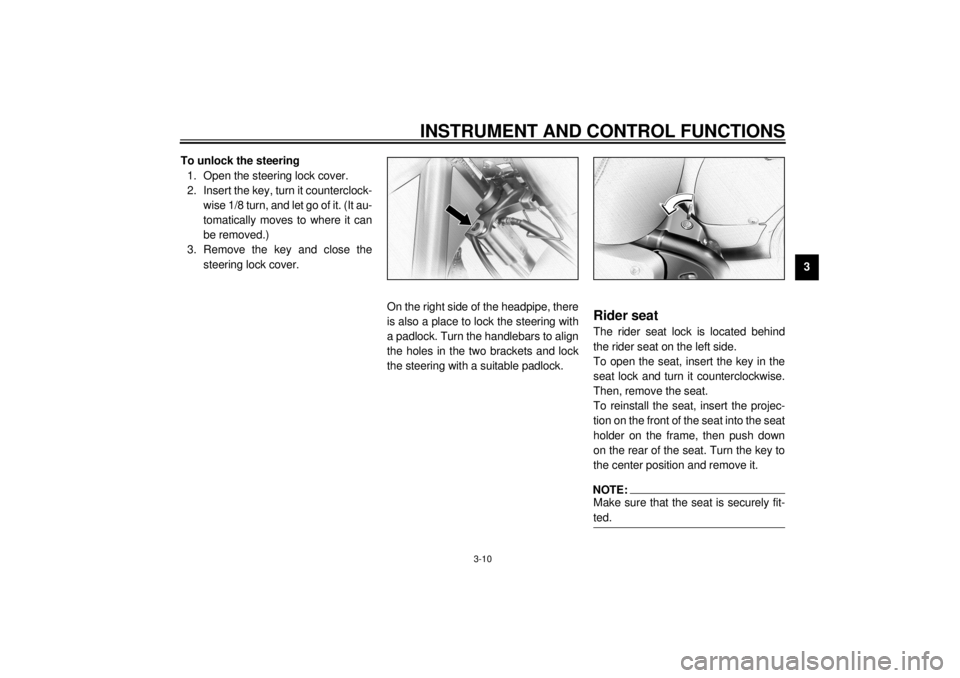

3 To unlock the steering

1. Open the steering lock cover.

2. Insert the key, turn it counterclock-

wise 1/8 turn, and let go of it. (It au-

tomatically moves to where it can

be removed.)

3. Remove the key and close the

steering lock cover.

On the right side of the headpipe, there

is also a place to lock the steering with

a padlock. Turn the handlebars to align

the holes in the two brackets and lock

the steering with a suitable padlock.

EAU01604

Rider seatThe rider seat lock is located behind

the rider seat on the left side.

To open the seat, insert the key in the

seat lock and turn it counterclockwise.

Then, remove the seat.

To reinstall the seat, insert the projec-

tion on the front of the seat into the seat

holder on the frame, then push down

on the rear of the seat. Turn the key to

the center position and remove it.NOTE:@ Make sure that the seat is securely fit-

ted. @

E_4YP_Functions.fm Page 10 Wednesday, October 6, 1999 10:03 AM

Page 25 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-11

3

EAU01636

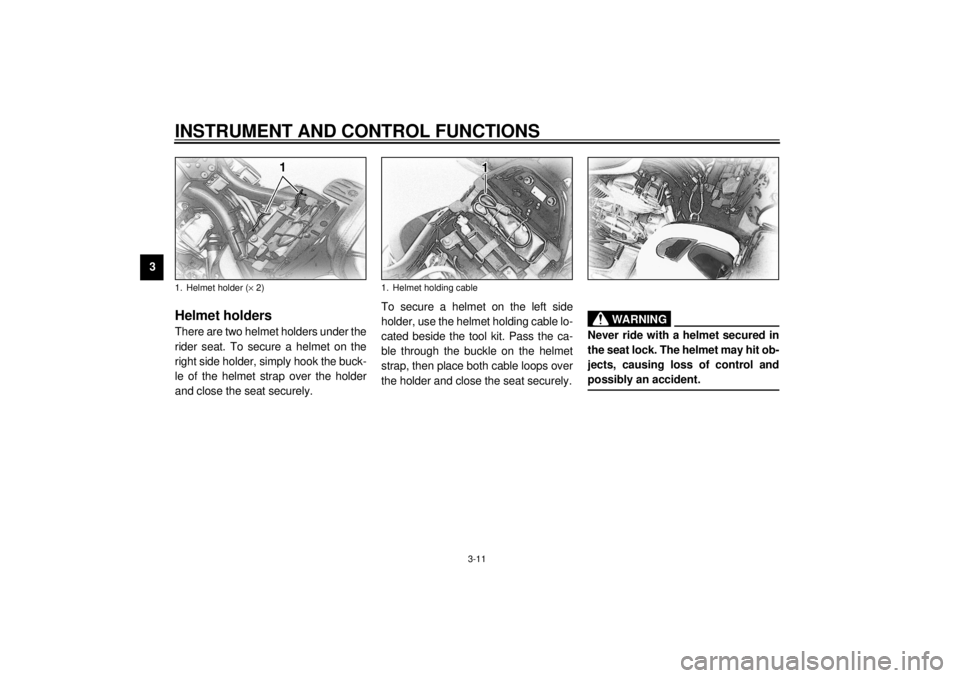

Helmet holdersThere are two helmet holders under the

rider seat. To secure a helmet on the

right side holder, simply hook the buck-

le of the helmet strap over the holder

and close the seat securely.To secure a helmet on the left side

holder, use the helmet holding cable lo-

cated beside the tool kit. Pass the ca-

ble through the buckle on the helmet

strap, then place both cable loops over

the holder and close the seat securely.

EW000031

WARNING

@ Never ride with a helmet secured in

the seat lock. The helmet may hit ob-

jects, causing loss of control and

possibly an accident. @

1. Helmet holder (´ 2)

1. Helmet holding cable

E_4YP_Functions.fm Page 11 Wednesday, October 6, 1999 10:03 AM

Page 26 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

EAU01605

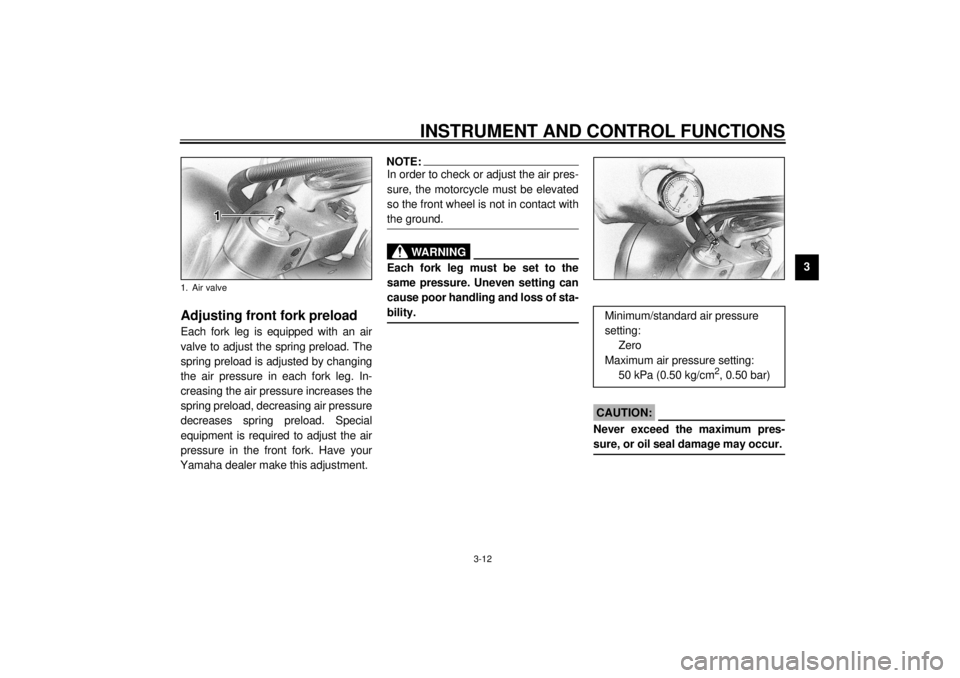

Adjusting front fork preloadEach fork leg is equipped with an air

valve to adjust the spring preload. The

spring preload is adjusted by changing

the air pressure in each fork leg. In-

creasing the air pressure increases the

spring preload, decreasing air pressure

decreases spring preload. Special

equipment is required to adjust the air

pressure in the front fork. Have your

Yamaha dealer make this adjustment.

NOTE:@ In order to check or adjust the air pres-

sure, the motorcycle must be elevated

so the front wheel is not in contact with

the ground. @

EW000037

WARNING

@ Each fork leg must be set to the

same pressure. Uneven setting can

cause poor handling and loss of sta-

bility. @

EC000012

CAUTION:@ Never exceed the maximum pres-

sure, or oil seal damage may occur. @

1. Air valve

Minimum/standard air pressure

setting:

Zero

Maximum air pressure setting:

50 kPa (0.50 kg/cm

2, 0.50 bar)

E_4YP_Functions.fm Page 12 Wednesday, October 6, 1999 10:03 AM

Page 27 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-13

3

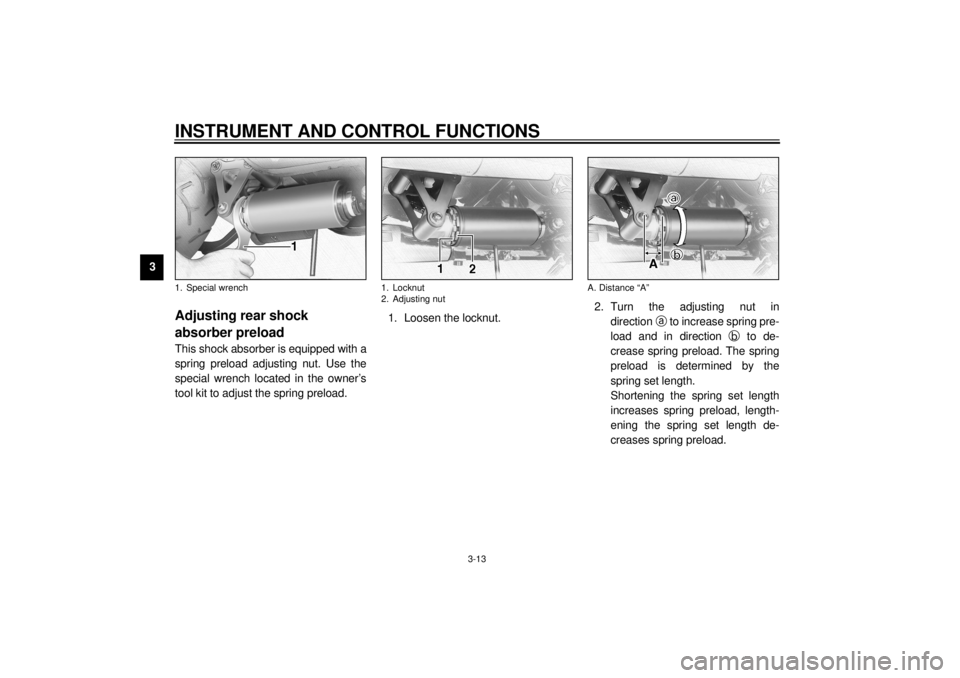

EAU01694

Adjusting rear shock

absorber preloadThis shock absorber is equipped with a

spring preload adjusting nut. Use the

special wrench located in the owner’s

tool kit to adjust the spring preload.1. Loosen the locknut.2. Turn the adjusting nut in

direction

a to increase spring pre-

load and in direction

b to de-

crease spring preload. The spring

preload is determined by the

spring set length.

Shortening the spring set length

increases spring preload, length-

ening the spring set length de-

creases spring preload.1. Special wrench

1. Locknut

2. Adjusting nut

A. Distance “A”

E_4YP_Functions.fm Page 13 Wednesday, October 6, 1999 10:03 AM

Page 28 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3

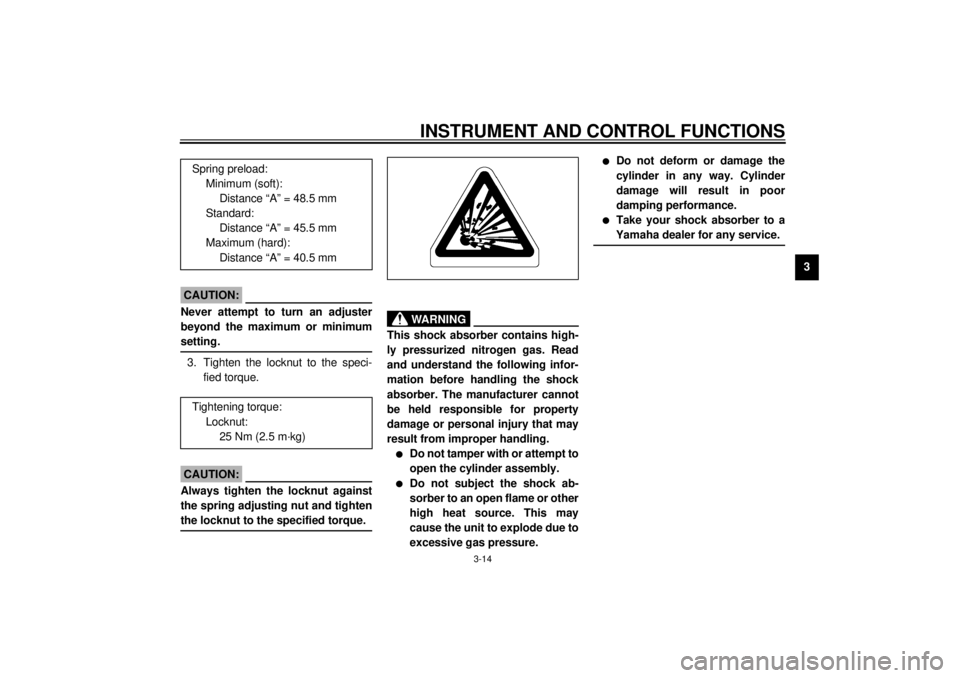

EC000015

CAUTION:@ Never attempt to turn an adjuster

beyond the maximum or minimum

setting. @3. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:@ Always tighten the locknut against

the spring adjusting nut and tighten

the locknut to the specified torque. @

EAU00315

WARNING

@ This shock absorber contains high-

ly pressurized nitrogen gas. Read

and understand the following infor-

mation before handling the shock

absorber. The manufacturer cannot

be held responsible for property

damage or personal injury that may

result from improper handling.l

Do not tamper with or attempt to

open the cylinder assembly.

l

Do not subject the shock ab-

sorber to an open flame or other

high heat source. This may

cause the unit to explode due to

excessive gas pressure.

l

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

l

Take your shock absorber to a

Yamaha dealer for any service.

@

Spring preload:

Minimum (soft):

Distance “A” = 48.5 mm

Standard:

Distance “A” = 45.5 mm

Maximum (hard):

Distance “A” = 40.5 mm

Tightening torque:

Locknut:

25 Nm (2.5 m·kg)

E_4YP_Functions.fm Page 14 Wednesday, October 6, 1999 10:03 AM

Page 29 of 91

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

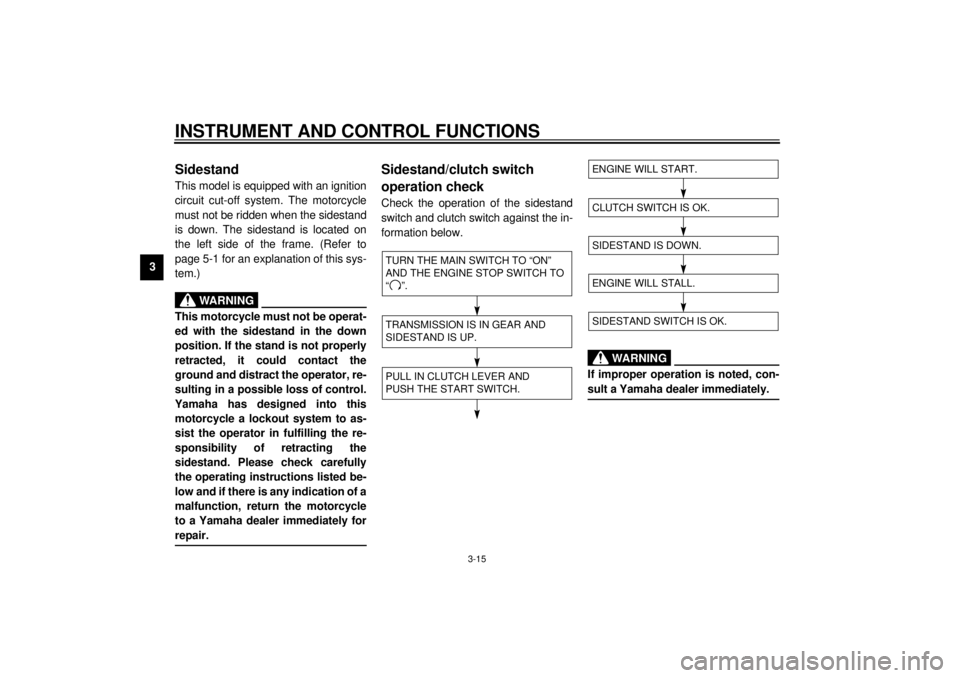

EAU00330

SidestandThis model is equipped with an ignition

circuit cut-off system. The motorcycle

must not be ridden when the sidestand

is down. The sidestand is located on

the left side of the frame. (Refer to

page 5-1 for an explanation of this sys-

tem.)

EW000044

WARNING

@ This motorcycle must not be operat-

ed with the sidestand in the down

position. If the stand is not properly

retracted, it could contact the

ground and distract the operator, re-

sulting in a possible loss of control.

Yamaha has designed into this

motorcycle a lockout system to as-

sist the operator in fulfilling the re-

sponsibility of retracting the

sidestand. Please check carefully

the operating instructions listed be-

low and if there is any indication of a

malfunction, return the motorcycle

to a Yamaha dealer immediately for

repair. @

EAU00331

Sidestand/clutch switch

operation checkCheck the operation of the sidestand

switch and clutch switch against the in-

formation below.CD-11E

CD-11E

EW000045

WARNING

@ If improper operation is noted, con-

sult a Yamaha dealer immediately. @

TURN THE MAIN SWITCH TO “ON”

AND THE ENGINE STOP SWITCH TO

“”.TRANSMISSION IS IN GEAR AND

SIDESTAND IS UP.PULL IN CLUTCH LEVER AND

PUSH THE START SWITCH.

ENGINE WILL START.SIDESTAND IS DOWN.ENGINE WILL STALL.SIDESTAND SWITCH IS OK.CLUTCH SWITCH IS OK.

E_4YP_Functions.fm Page 15 Wednesday, October 6, 1999 10:03 AM

Page 30 of 91

4

PRE-OPERATION CHECKS

Pre-operation check list ...................................................................... 4-1

E_4YP_PreopTOC.fm Page 1 Wednesday, October 6, 1999 10:04 AM