YAMAHA YFM700R 2018 Service Manual

Manufacturer: YAMAHA, Model Year: 2018, Model line: YFM700R, Model: YAMAHA YFM700R 2018Pages: 158, PDF Size: 3.7 MB

Page 41 of 158

4-15

4

would be advisable to check the number of clicks

or turns of each damping force adjusting mecha-

nism and to modify the specifications as neces-

sary.

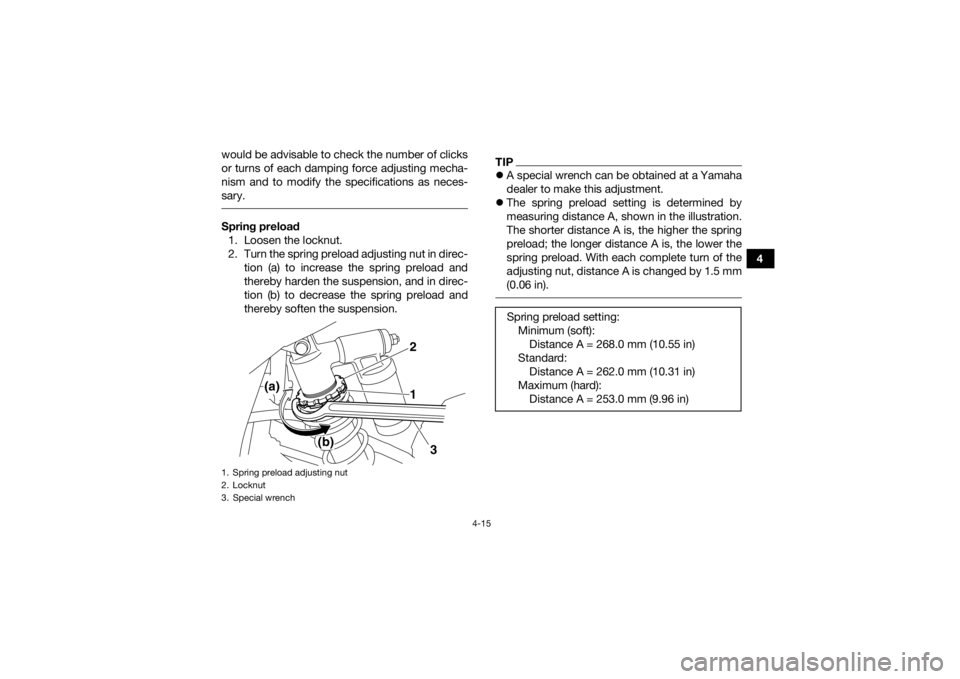

Spring preload

1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

TIPA special wrench can be obtained at a Yamaha

dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the higher the spring

preload; the longer distance A is, the lower the

spring preload. With each complete turn of the

adjusting nut, distance A is changed by 1.5 mm

(0.06 in).

1. Spring preload adjusting nut

2. Locknut

3. Special wrench

2

1

3

(a)

(b)

Spring preload setting:Minimum (soft):Distance A = 268.0 mm (10.55 in)

Standard: Distance A = 262.0 mm (10.31 in)

Maximum (hard): Distance A = 253.0 mm (9.96 in)

U2LS63E0.book Page 15 Friday, March 31, 2017 8:42 AM

Page 42 of 158

![YAMAHA YFM700R 2018 Service Manual 4-16

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

Rebound damping force

Turn YAMAHA YFM700R 2018 Service Manual 4-16

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

Rebound damping force

Turn](/img/51/53750/w960_53750-41.png)

4-16

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

Rebound damping force

Turn the rebound damping force adjusting screw

in direction (a) to increase the rebound damping

force and thereby harden the damping, and in di-

rection (b) to decrease the rebound damping force

and thereby soften the damping.

1. Distance ATightening torque: Locknut:42 N·m (4.2 kgf·m, 31 lb·ft)

1

1. Rebound damping force adjusting screw

1(a)

(b)

U2LS63E0.book Page 16 Friday, March 31, 2017 8:42 AM

Page 43 of 158

4-17

4

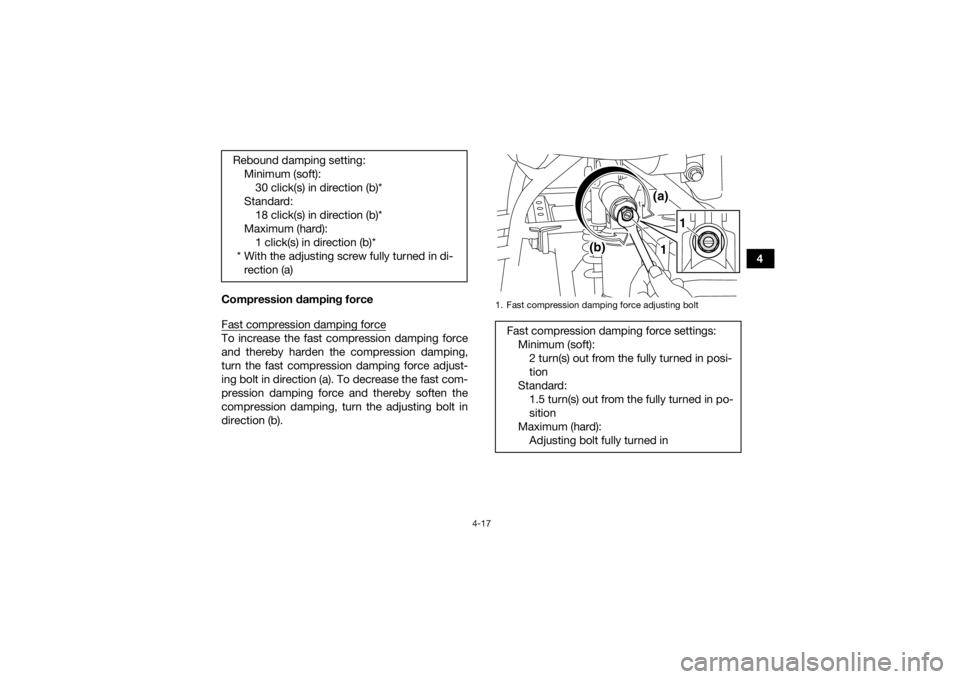

Compression damping force

Fast compression damping force

To increase the fast compression damping force

and thereby harden the compression damping,

turn the fast compression damping force adjust-

ing bolt in direction (a). To decrease the fast com-

pression damping force and thereby soften the

compression damping, turn the adjusting bolt in

direction (b). Rebound damping setting:

Minimum (soft):30 click(s) in direction (b)*

Standard: 18 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

1. Fast compression damping force adjusting boltFast compression damping force settings: Minimum (soft):2 turn(s) out from the fully turned in posi-

tion

Standard: 1.5 turn(s) out from the fully turned in po-

sition

Maximum (hard): Adjusting bolt fully turned in

1

(a)

(b) 1

U2LS63E0.book Page 17 Friday, March 31, 2017 8:42 AM

Page 44 of 158

4-18

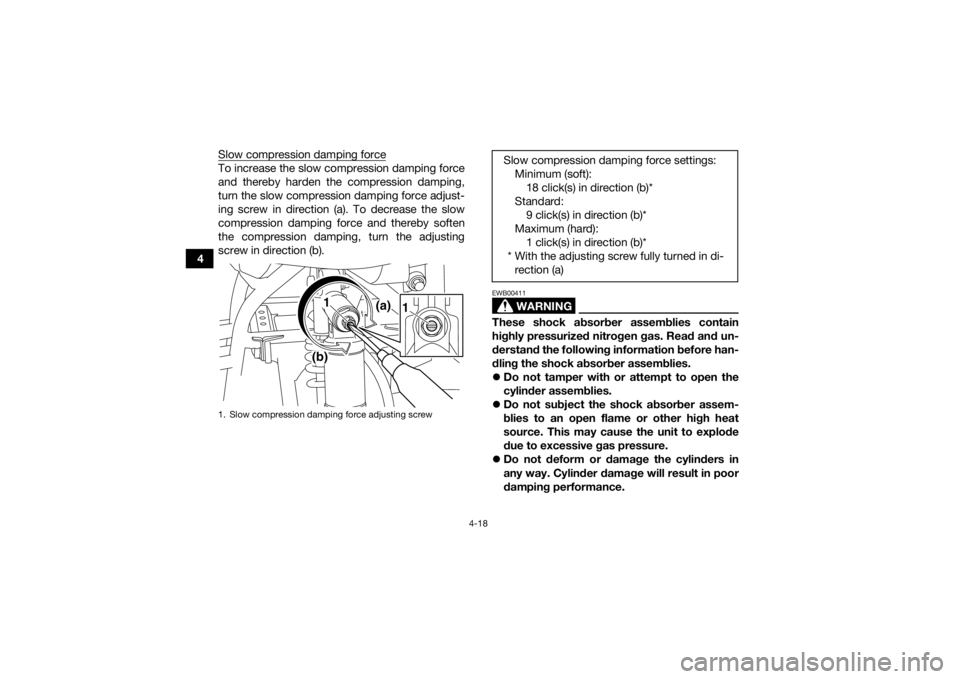

4Slow compression damping force

To increase the slow compression damping force

and thereby harden the compression damping,

turn the slow compression damping force adjust-

ing screw in direction (a). To decrease the slow

compression damping force and thereby soften

the compression damping, turn the adjusting

screw in direction (b).

WARNING

EWB00411These shock absorber assemblies contain

highly pressurized nitrogen gas. Read and un-

derstand the following information before han-

dling the shock absorber assemblies.

Do not tamper with or attempt to open the

cylinder assemblies.

Do not subject the shock absorber assem-

blies to an open flame or other high heat

source. This may cause the unit to explode

due to excessive gas pressure.

Do not deform or damage the cylinders in

any way. Cylinder damage will result in poor

damping performance.

1. Slow compression damping force adjusting screw

1

(a)

(b)

1

Slow compression damping force settings: Minimum (soft):18 click(s) in direction (b)*

Standard: 9 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

U2LS63E0.book Page 18 Friday, March 31, 2017 8:42 AM

Page 45 of 158

4-19

4

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service.

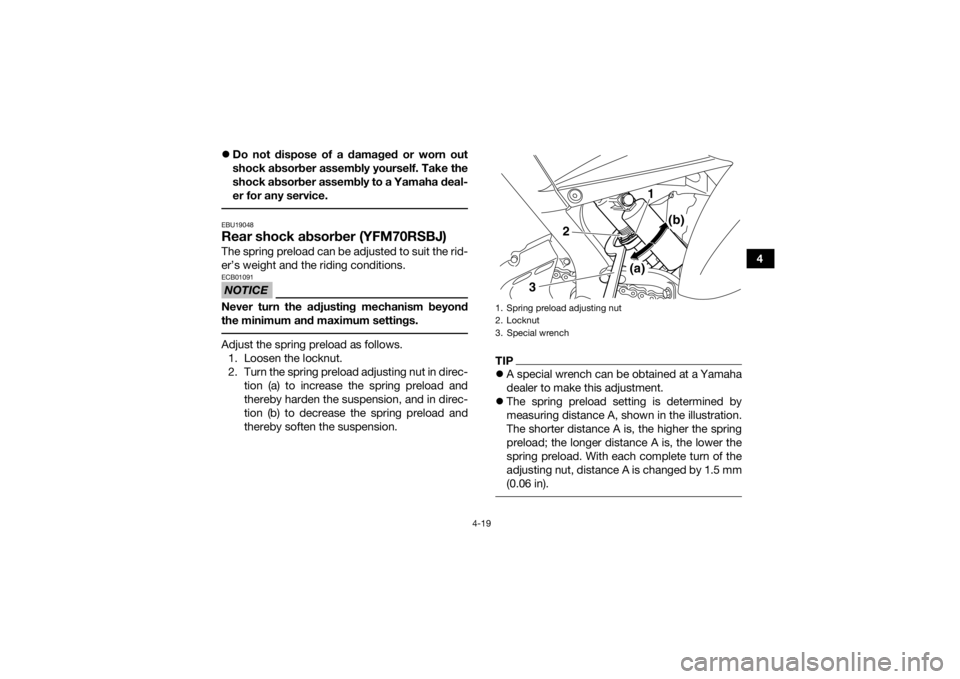

EBU19048Rear shock absorber (YFM70RSBJ)The spring preload can be adjusted to suit the rid-

er’s weight and the riding conditions.NOTICEECB01091Never turn the adjusting mechanism beyond

the minimum and maximum settings. Adjust the spring preload as follows.

1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

TIPA special wrench can be obtained at a Yamaha

dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the higher the spring

preload; the longer distance A is, the lower the

spring preload. With each complete turn of the

adjusting nut, distance A is changed by 1.5 mm

(0.06 in). 1. Spring preload adjusting nut

2. Locknut

3. Special wrench

1

(b)

(a)

2

3

U2LS63E0.book Page 19 Friday, March 31, 2017 8:42 AM

Page 46 of 158

![YAMAHA YFM700R 2018 Service Manual 4-20

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

WARNING

EWB00451This shock YAMAHA YFM700R 2018 Service Manual 4-20

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

WARNING

EWB00451This shock](/img/51/53750/w960_53750-45.png)

4-20

43. Tighten the locknut to the specified torque.NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

WARNING

EWB00451This shock absorber assembly contains highly

pressurized nitrogen gas. If the shock absorb-

er assembly is damaged, it could explode

causing injury or property damage. Shock ab-

sorber cylinder damage could also result in

poor handling which could cause an accident.

Do not tamper with or attempt to open the

cylinder assembly.

Do not subject the shock absorber assembly

to an open flame or other high heat.

Do not deform or damage the cylinder in any

way.

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service.

Spring preload setting:

Minimum (soft):Distance A = 238.5 mm (9.39 in)

Standard: Distance A = 228.5 mm (9.00 in)

Maximum (hard): Distance A = 223.5 mm (8.80 in)1. Distance A

1

Tightening torque:Locknut:42 N·m (4.2 kgf·m, 31 lb·ft)

U2LS63E0.book Page 20 Friday, March 31, 2017 8:42 AM

Page 47 of 158

4-21

4

EBU30992Rear shock absorber (YFM70RSXJ)This shock absorber assembly is equipped with a

spring preload adjusting nut, a rebound damping

force adjusting screw, with a compression damp-

ing force adjusting bolt (for fast compression

damping), and a compression damping force ad-

justing screw (for slow compression damping).

WARNING

EWB02681Suspension components become hot during

operation. Never touch the compression

damping force adjusting bolt and screw, the

rebound damping force adjusting screw or the

oil reservoir with your bare hand or skin until

the suspension components have cooled. NOTICEECB00091Never turn an adjusting mechanism beyond

the minimum and maximum settings. TIPAlthough the total number of clicks or turns of a

damping force adjusting mechanism may not ex-

actly match the following specifications due to

small differences in production, the actual number of clicks or turns always represents the entire ad-

justing range. To obtain a precise adjustment, it

would be advisable to check the number of clicks

or turns of each damping force adjusting mecha-

nism and to modify the specifications as neces-

sary.

Spring preload

1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

U2LS63E0.book Page 21 Friday, March 31, 2017 8:42 AM

Page 48 of 158

4-22

4

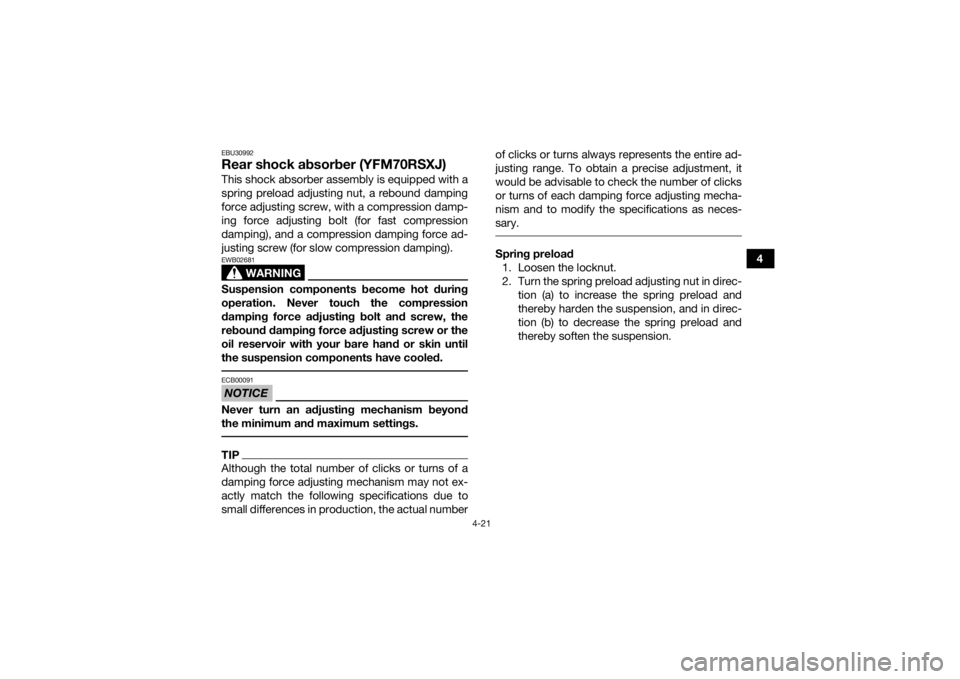

TIPA special wrench can be obtained at a Yamaha

dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the higher the spring

preload; the longer distance A is, the lower the

spring preload. With each complete turn of the

adjusting nut, distance A is changed by 1.5 mm

(0.06 in).

3. Tighten the locknut to the specified torque.

NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

1. Spring preload adjusting nut

2. Locknut

3. Special wrench

1

(b)

(a)

2

3

Spring preload setting: Minimum (soft):Distance A = 238.5 mm (9.39 in)

Standard: Distance A = 228.5 mm (9.00 in)

Maximum (hard): Distance A = 223.5 mm (8.80 in)1. Distance A

1

U2LS63E0.book Page 22 Friday, March 31, 2017 8:42 AM

Page 49 of 158

4-23

4

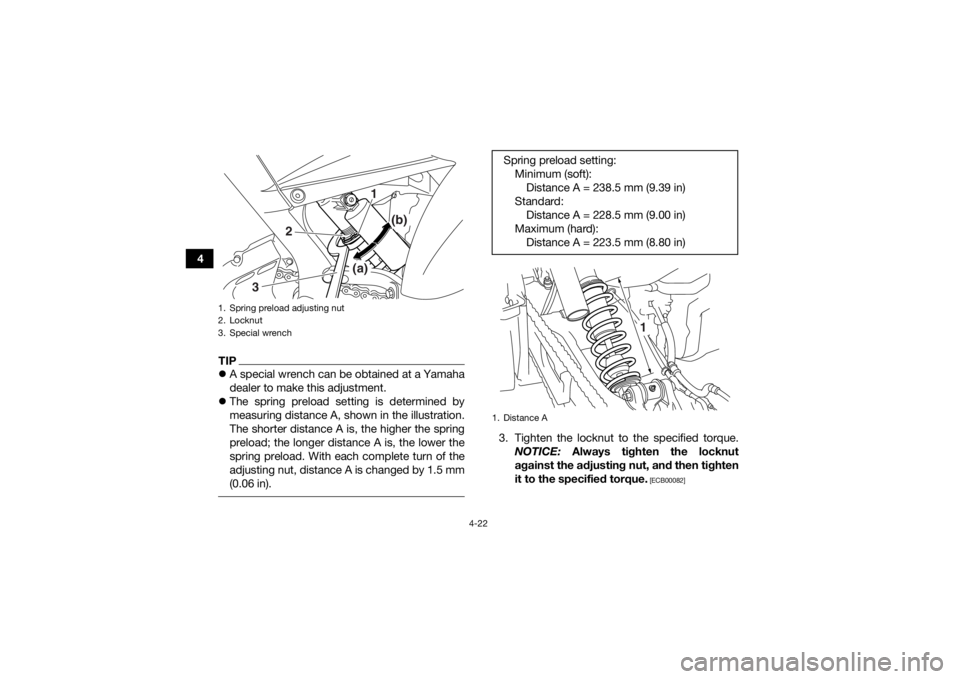

Rebound damping force

Turn the rebound damping force adjusting screw

in direction (a) to increase the rebound damping

force and thereby harden the damping, and in di-

rection (b) to decrease the rebound damping force

and thereby soften the damping.

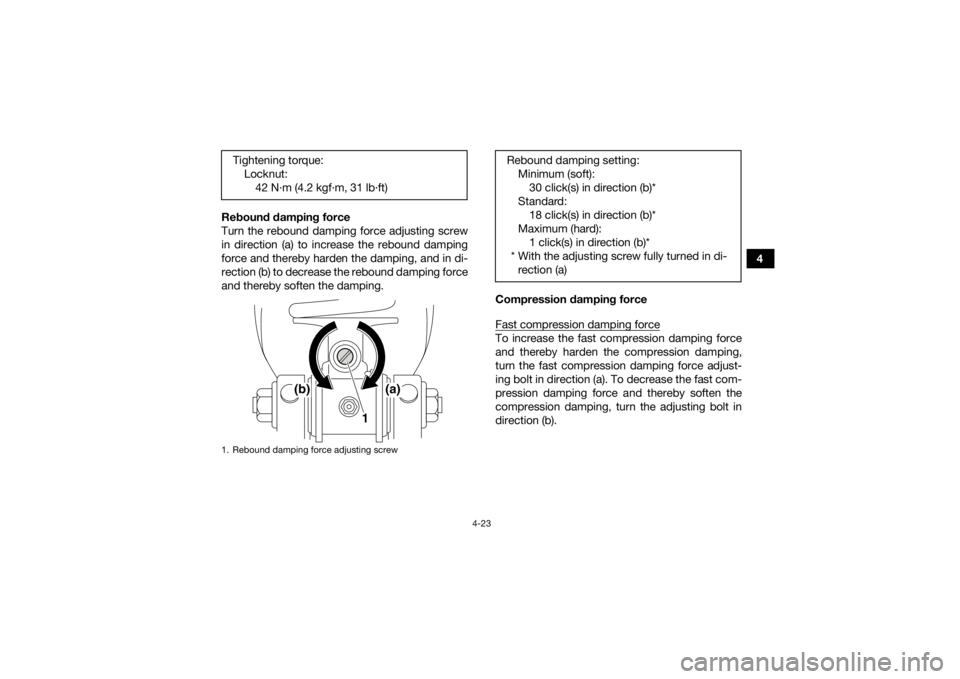

Compression damping force

Fast compression damping force

To increase the fast compression damping force

and thereby harden the compression damping,

turn the fast compression damping force adjust-

ing bolt in direction (a). To decrease the fast com-

pression damping force and thereby soften the

compression damping, turn the adjusting bolt in

direction (b).

Tightening torque:

Locknut:42 N·m (4.2 kgf·m, 31 lb·ft)

1. Rebound damping force adjusting screw

1

(b) (a)

Rebound damping setting:

Minimum (soft):30 click(s) in direction (b)*

Standard: 18 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

U2LS63E0.book Page 23 Friday, March 31, 2017 8:42 AM

Page 50 of 158

4-24

4Slow compression damping force

To increase the slow compression damping force

and thereby harden the compression damping,

turn the slow compression damping force adjust-

ing screw in direction (a). To decrease the slow compression damping force and thereby soften

the compression damping, turn the adjusting

screw in direction (b).1. Fast compression damping force adjusting boltFast compression damping force settings:

Minimum (soft):2 turn(s) out from the fully turned in posi-

tion

Standard: 1.25 turn(s) out from the fully turned in

position

Maximum (hard): Adjusting bolt fully turned in

1

(b)

(a)

1

1. Slow compression damping force adjusting screwSlow compression damping settings: Minimum (soft):18 click(s) in direction (b)*

Standard: 10 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

1

(b)

(a)

1

U2LS63E0.book Page 24 Friday, March 31, 2017 8:42 AM