maintenance YAMAHA YFZ50 2018 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: YFZ50, Model: YAMAHA YFZ50 2018Pages: 132, PDF Size: 4.84 MB

Page 87 of 132

8-5

8

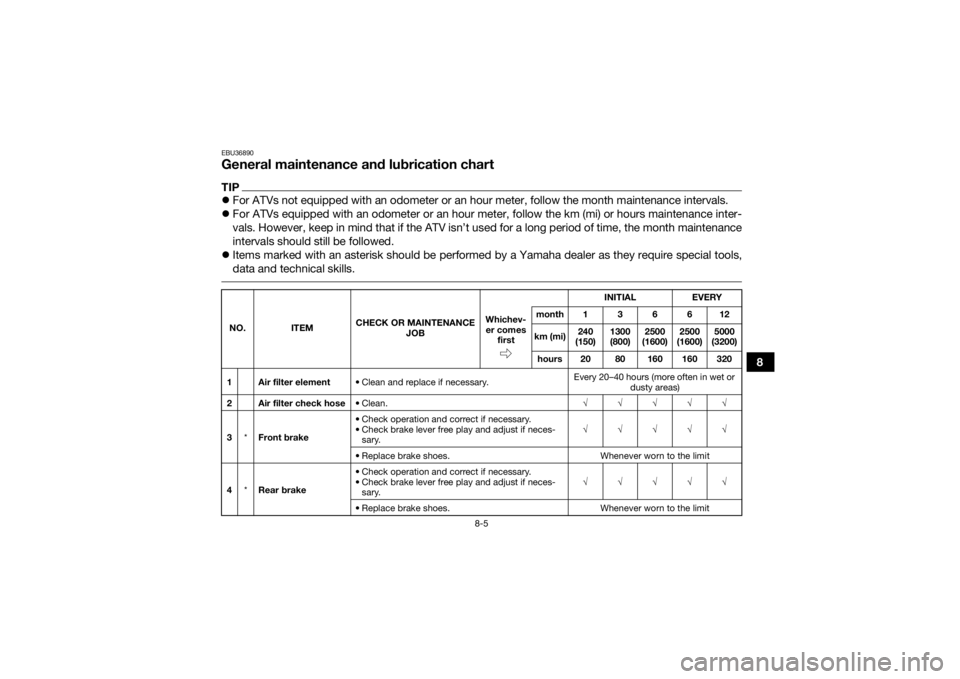

EBU36890General maintenance and lubrication chartTIPFor ATVs not equipped with an odometer or an hour meter, follow the month maintenance intervals.

For ATVs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance inter-

vals. However, keep in mind that if the ATV isn’t used for a long period of time, the month maintenance

intervals should still be followed.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools,

data and technical skills. NO. ITEM CHECK OR MAINTENANCE

JOB INITIAL

EVERY

Whichev- er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 20 80 160 160 320

1 Air filter element • Clean and replace if necessary. Every 20–40 hours (more often in wet or

dusty areas)

2 Air filter check hose • Clean. √√√√√

3 *Front brake • Check operation and correct if necessary.

• Check brake lever free play and adjust if neces-

sary. √√√√√

• Replace brake shoes. Whenever worn to the limit

4 *Rear brake • Check operation and correct if necessary.

• Check brake lever free play and adjust if neces-

sary. √√√√√

• Replace brake shoes. Whenever worn to the limit

UBW461E0.book Page 5 Tuesday, January 31, 2017 5:13 PM

Page 88 of 132

8-6

8

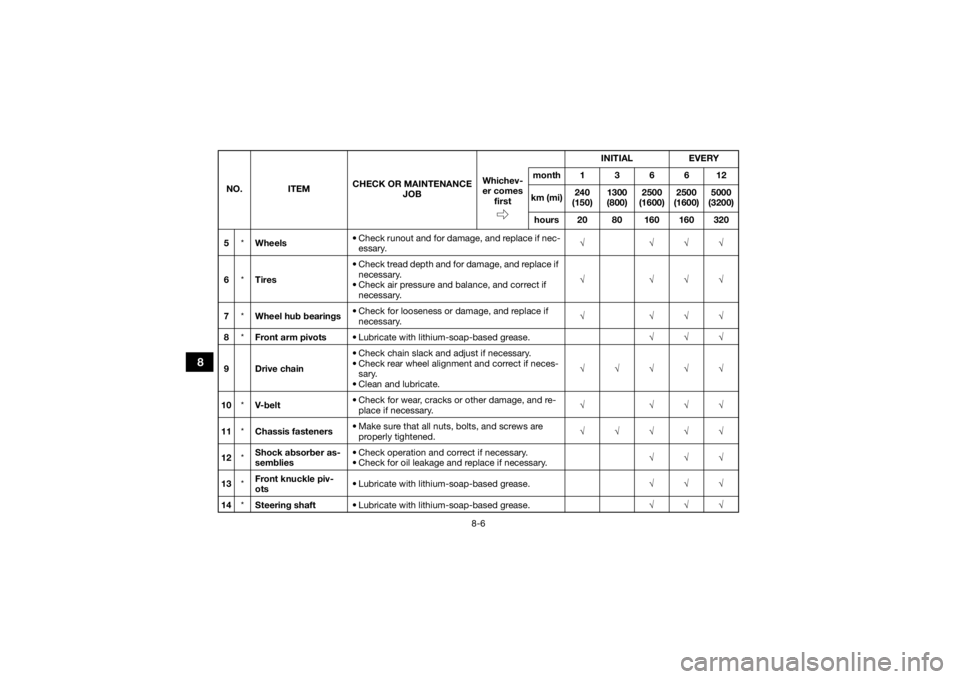

5*Wheels • Check runout and for damage, and replace if nec-

essary. √ √√√

6 *Tires • Check tread depth and for damage, and replace if

necessary.

• Check air pressure and balance, and correct if necessary. √ √√√

7 *Wheel hub bearings • Check for looseness or damage, and replace if

necessary. √ √√√

8 *Front arm pivots • Lubricate with lithium-soap-based grease. √√√

9Drive chain • Check chain slack and adjust if necessary.

• Check rear wheel alignment and correct if neces-

sary.

• Clean and lubricate. √√√√√

10 *V- b e l t • Check for wear, cracks or other damage, and re-

place if necessary. √ √√√

11 *Chassis fasteners • Make sure that all nuts, bolts, and screws are

properly tightened. √√√√√

12 *Shock absorber as-

semblies • Check operation and correct if necessary.

• Check for oil leakage and replace if necessary.

√√√

13 *Front knuckle piv-

ots • Lubricate with lithium-soap-based grease.

√√√

14 *Steering shaft • Lubricate with lithium-soap-based grease. √√√

NO. ITEM

CHECK OR MAINTENANCE

JOB INITIAL EVERY

Whichev-

er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 20 80 160 160 320UBW461E0.book Page 6 Tuesda y, January 31, 2017 5:13 PM

Page 89 of 132

8-7

8

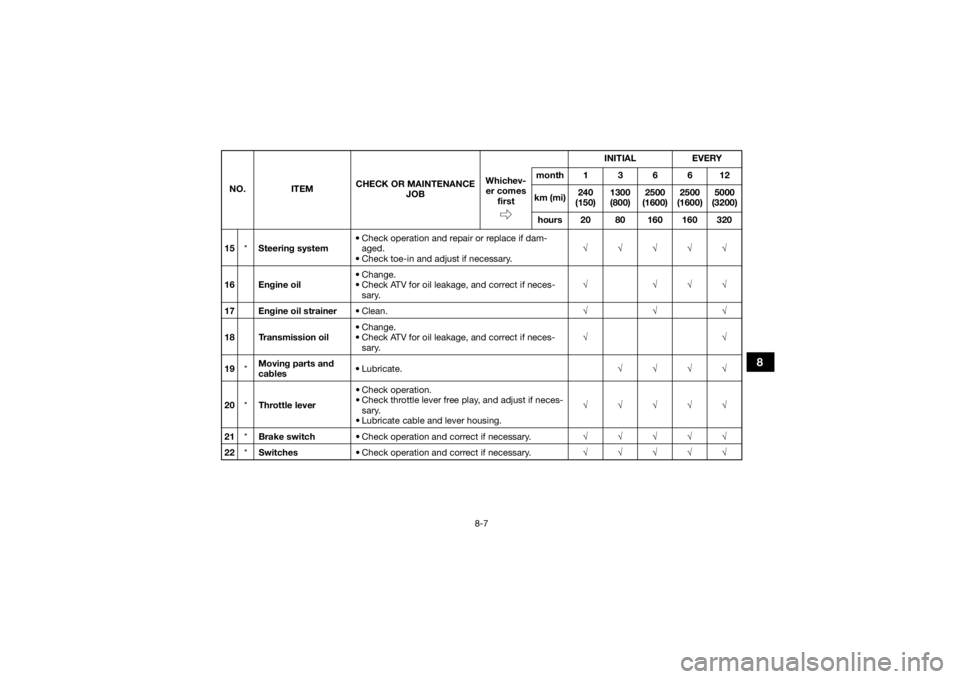

15*Steering system • Check operation and repair or replace if dam-

aged.

• Check toe-in and adjust if necessary. √√√√√

16 Engine oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √ √√√

17 Engine oil strainer • Clean. √√√

18 Transmission oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √√

19 *Moving parts and

cables

•Lubricate.

√√√√

20 *Throttle lever • Check operation.

• Check throttle lever free play, and adjust if neces-

sary.

• Lubricate cable and lever housing. √√√√√

21 *Brake switch • Check operation and correct if necessary. √√√√√

22 *Switches • Check operation and correct if necessary. √√√√√

NO. ITEM

CHECK OR MAINTENANCE

JOB INITIAL EVERY

Whichev- er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 20 80 160 160 320UBW461E0.book Page 7 Tuesda y, January 31, 2017 5:13 PM

Page 90 of 132

8-8

8

EBU23062TIPSome maintenance items need more frequent service if you are riding in unusually wet, dusty, sandy or

muddy areas, or at full-throttle. UBW461E0.book Page 8 Tuesday, January 31, 2017 5:13 PM

Page 91 of 132

8-9

8

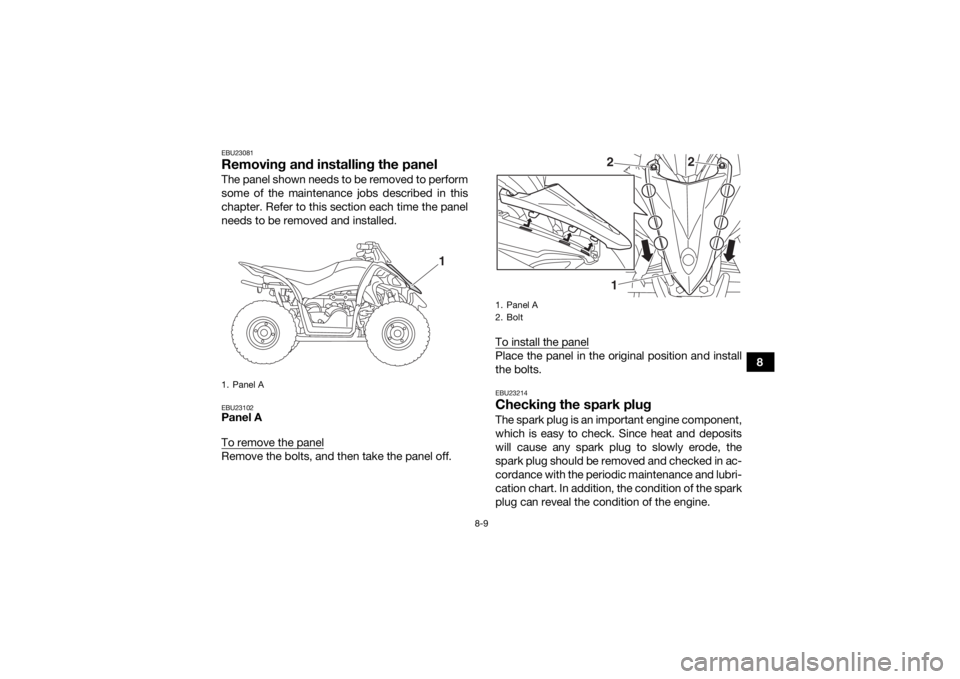

EBU23081Removing and installing the panelThe panel shown needs to be removed to perform

some of the maintenance jobs described in this

chapter. Refer to this section each time the panel

needs to be removed and installed.EBU23102Panel A

To remove the panelRemove the bolts, and then take the panel off.To install the panel

Place the panel in the original position and install

the bolts.EBU23214Checking the spark plugThe spark plug is an important engine component,

which is easy to check. Since heat and deposits

will cause any spark plug to slowly erode, the

spark plug should be removed and checked in ac-

cordance with the periodic maintenance and lubri-

cation chart. In addition, the condition of the spark

plug can reveal the condition of the engine.

1. Panel A

1

1. Panel A

2. Bolt

2

2

1

UBW461E0.book Page 9 Tuesda

y, January 31, 2017 5:13 PM

Page 93 of 132

8-11

8

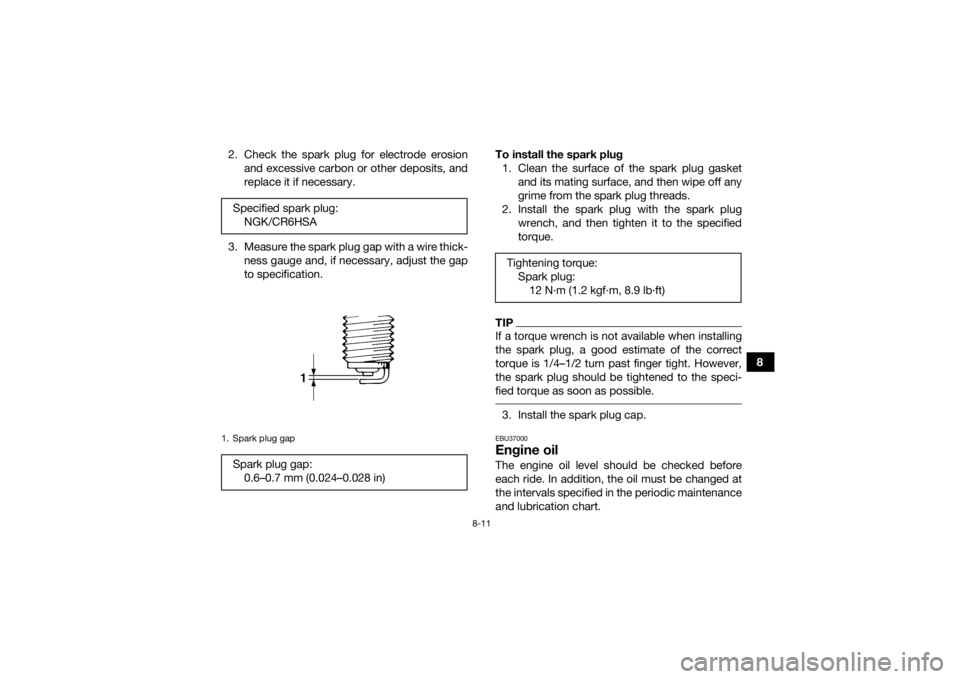

2. Check the spark plug for electrode erosion

and excessive carbon or other deposits, and

replace it if necessary.

3. Measure the spark plug gap with a wire thick- ness gauge and, if necessary, adjust the gap

to specification. To install the spark plug

1. Clean the surface of the spark plug gasket and its mating surface, and then wipe off any

grime from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tighten it to the specified

torque.

TIPIf a torque wrench is not available when installing

the spark plug, a good estimate of the correct

torque is 1/4–1/2 turn past finger tight. However,

the spark plug should be tightened to the speci-

fied torque as soon as possible. 3. Install the spark plug cap.EBU37000Engine oilThe engine oil level should be checked before

each ride. In addition, the oil must be changed at

the intervals specified in the periodic maintenance

and lubrication chart.

Specified spark plug:

NGK/CR6HSA

1. Spark plug gapSpark plug gap:0.6–0.7 mm (0.024–0.028 in)

Tightening torque:Spark plug:12 N·m (1.2 kgf·m, 8.9 lb·ft)

UBW461E0.book Page 11 Tuesday, January 31, 2017 5:13 PM

Page 98 of 132

8-16

87. Check the oil filler cap O-ring for damage,

and replace it if necessary.

8. Install and tighten the oil filler cap.

9. Check the transmission case for oil leakage. If oil is leaking, check for the cause.

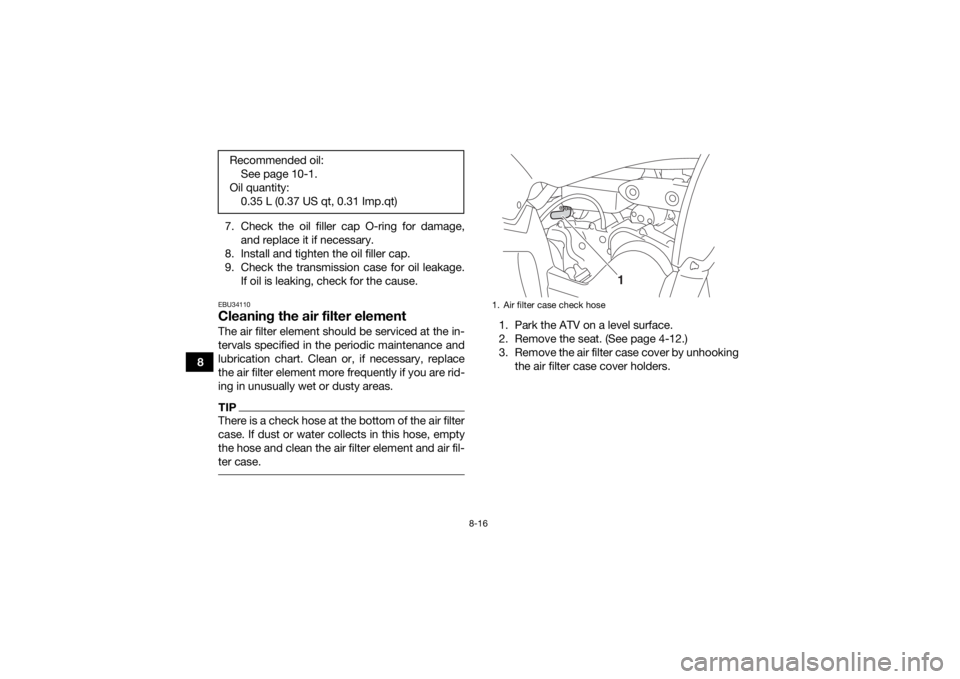

EBU34110Cleaning the air filter elementThe air filter element should be serviced at the in-

tervals specified in the periodic maintenance and

lubrication chart. Clean or, if necessary, replace

the air filter element more frequently if you are rid-

ing in unusually wet or dusty areas.TIPThere is a check hose at the bottom of the air filter

case. If dust or water collects in this hose, empty

the hose and clean the air filter element and air fil-

ter case.

1. Park the ATV on a level surface.

2. Remove the seat. (See page 4-12.)

3. Remove the air filter case cover by unhookingthe air filter case cover holders.

Recommended oil:

See page 10-1.

Oil quantity: 0.35 L (0.37 US qt, 0.31 Imp.qt)1. Air filter case check hose

1

UBW461E0.book Page 16 Tuesday, January 31, 2017 5:13 PM

Page 102 of 132

8-20

8

WARNING

EWB02341Do not start the engine when cleaning the

spark arrester, otherwise it could cause injury

to the eyes, burns, carbon monoxide poison-

ing, possibly leading to death, and start a fire.

Always let the exhaust system cool prior to

touching exhaust components. EBU23941Adjusting the carburetorThe carburetor should be checked and, if neces-

sary, adjusted at the intervals specified in the pe-

riodic maintenance and lubrication chart. The

carburetor is an important part of the engine and

requires very sophisticated adjustment. There-

fore, most carburetor adjustments should be left

to a Yamaha dealer, who has the necessary pro-

fessional knowledge and experience. The adjust-

ment described in the following section, however,

may be performed by the owner as part of routine

maintenance.

NOTICEECB00481The carburetor has been set and extensively

tested at the Yamaha factory. Changing these

settings without sufficient technical knowl-

edge may result in poor performance of or

damage to the engine. EBU24001Adjusting the engine idling speedThe engine idling speed must be checked and, if

necessary, adjusted as follows at the intervals

specified in the periodic maintenance and lubrica-

tion chart.TIPA diagnostic tachometer is needed to make this

adjustment. 1. Start the engine and warm it up.TIPThe engine is warm when it quickly responds to

the throttle. 2. Attach the tachometer to the spark plug lead.

Tightening torque:

Tailpipe bolt:10 N·m (1.0 kgf·m, 7.4 lb·ft)

UBW461E0.book Page 20 Tuesday, January 31, 2017 5:13 PM

Page 103 of 132

8-21

8

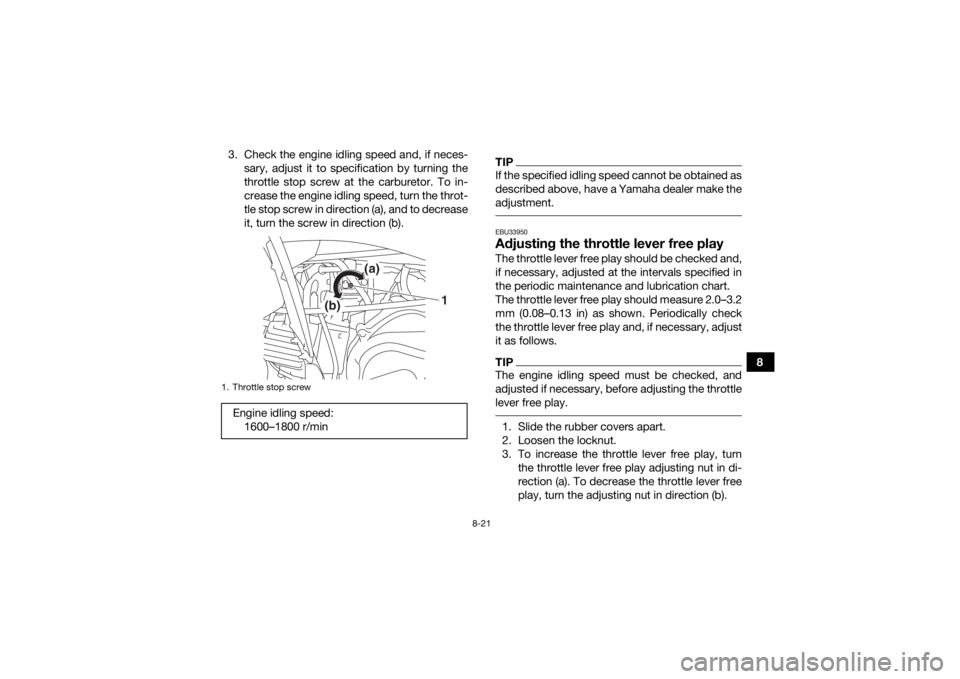

3. Check the engine idling speed and, if neces-

sary, adjust it to specification by turning the

throttle stop screw at the carburetor. To in-

crease the engine idling speed, turn the throt-

tle stop screw in direction (a), and to decrease

it, turn the screw in direction (b).

TIPIf the specified idling speed cannot be obtained as

described above, have a Yamaha dealer make the

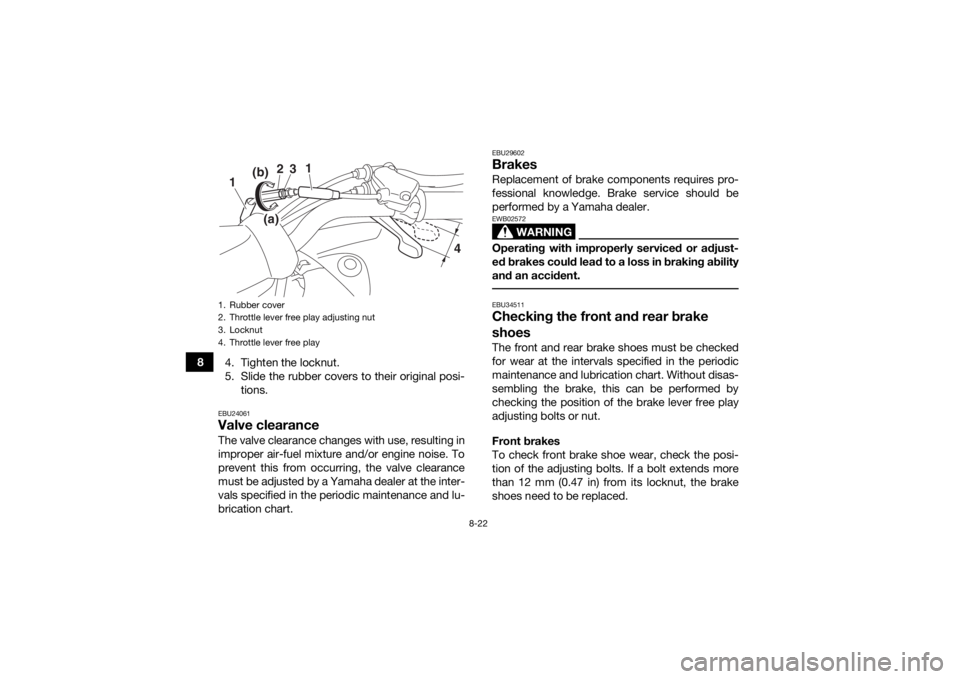

adjustment. EBU33950Adjusting the throttle lever free playThe throttle lever free play should be checked and,

if necessary, adjusted at the intervals specified in

the periodic maintenance and lubrication chart.

The throttle lever free play should measure 2.0–3.2

mm (0.08–0.13 in) as shown. Periodically check

the throttle lever free play and, if necessary, adjust

it as follows.TIPThe engine idling speed must be checked, and

adjusted if necessary, before adjusting the throttle

lever free play. 1. Slide the rubber covers apart.

2. Loosen the locknut.

3. To increase the throttle lever free play, turnthe throttle lever free play adjusting nut in di-

rection (a). To decrease the throttle lever free

play, turn the adjusting nut in direction (b).

1. Throttle stop screwEngine idling speed:1600–1800 r/min

(a)

(b)

1

UBW461E0.book Page 21 Tuesday, January 31, 2017 5:13 PM

Page 104 of 132

8-22

84. Tighten the locknut.

5. Slide the rubber covers to their original posi-

tions.

EBU24061Valve clearanceThe valve clearance changes with use, resulting in

improper air-fuel mixture and/or engine noise. To

prevent this from occurring, the valve clearance

must be adjusted by a Yamaha dealer at the inter-

vals specified in the periodic maintenance and lu-

brication chart.

EBU29602BrakesReplacement of brake components requires pro-

fessional knowledge. Brake service should be

performed by a Yamaha dealer.

WARNING

EWB02572Operating with improperly serviced or adjust-

ed brakes could lead to a loss in braking ability

and an accident. EBU34511Checking the front and rear brake

shoesThe front and rear brake shoes must be checked

for wear at the intervals specified in the periodic

maintenance and lubrication chart. Without disas-

sembling the brake, this can be performed by

checking the position of the brake lever free play

adjusting bolts or nut.

Front brakes

To check front brake shoe wear, check the posi-

tion of the adjusting bolts. If a bolt extends more

than 12 mm (0.47 in) from its locknut, the brake

shoes need to be replaced.

1. Rubber cover

2. Throttle lever free play adjusting nut

3. Locknut

4. Throttle lever free play

1

2

3

1

4

(a)(b)

UBW461E0.book Page 22 Tuesday, January 31, 2017 5:13 PM