torque YAMAHA YXZ1000R SS 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: YXZ1000R SS, Model: YAMAHA YXZ1000R SS 2020Pages: 212, PDF Size: 9.36 MB

Page 152 of 212

9-25

9

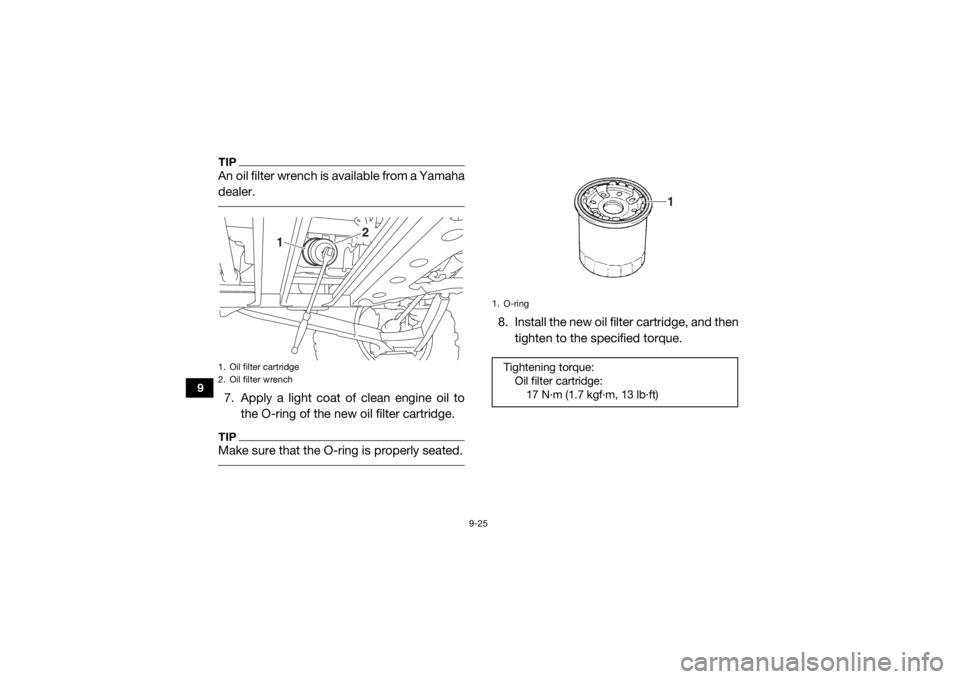

TIPAn oil filter wrench is available from a Yamaha

dealer. 7. Apply a light coat of clean engine oil to

the O-ring of the new oil filter cartridge.TIPMake sure that the O-ring is properly seated.

8. Install the new oil filter cartridge, and thentighten to the specified torque.

1. Oil filter cartridge

2. Oil filter wrench

2

1

1. O-ringTightening torque:Oil filter cartridge:17 N·m (1.7 kgf·m, 13 lb·ft)

1

UBAS7AE0.book Page 25 Wednesday, June 19, 2019 11:51 AM

Page 153 of 212

9-26

9

9. Follow steps 10–20 of the “To change theengine oil” section for the oil filling proce-

dure.

10. Slide the front portion of the center bot- tom panel into place as shown, and then

hook the left and right sides of the center

bottom panel into place.

11. Install the center bottom panel bolts, andthen tighten them to the specified torque.1. Torque wrench

1

1. Center bottom panel

1. Center bottom panel

1

1

UBAS7AE0.book Page 26 Wednesday, June 19, 2019 11:51 AM

Page 154 of 212

9-27

9

12. Install the rear bottom panel by installingthe bolts, and then tightening them to the

specified torque.

1. Bolt A

2. Bolt B

3. Bolt C

1

2

3

1. Bolt A

2. Bolt B

3. Bolt CTightening torques:Bolt A:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt B: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt C: 7 N·m (0.7 kgf·m, 5.2 lb·ft)1

3

2

3

UBAS7AE0.book Page 27 Wednesday, June 19, 2019 11:51 AM

Page 155 of 212

9-28

9

13. Install the side panel bolts, and then tight-en them to the specified torque.

EBU38630Why YamalubeYAMALUBE oil is a Genuine YAMAHA Partborn of the engineers’ passion and belief that

engine oil is an important liquid engine com-

ponent. We form teams of specialists in the

fields of mechanical engineering, chemistry,

electronics and track testing, and have them

develop the engine together with the oil it will

1. Rear bottom panel

2. Bolt A

3. Bolt BTightening torques: Bolt A:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt B: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

3

1

2

2

1. Bolt BTightening torque: Bolt B:7 N·m (0.7 kgf·m, 5.2 lb·ft)

1

1

UBAS7AE0.book Page 28 Wednesday, June 19, 2019 11:51 AM

Page 158 of 212

9-31

9

TIPOil will flow out immediately when the drain

bolt is loosened. Take care not to lose the

bolt. 4. After draining the oil, install the transmis-sion oil drain bolt with a new gasket.

5. Tighten the drain bolt to the specified torque. 6. Check the O-ring for damage, and re-

place it if necessary.

7. Refill the transmission with the specified amount of the recommended oil.

8. Install the transmission oil filler cap.

9. Start the engine and let it idle while checking for oil leakage.

10. Stop the engine and check the oil level one last time.

EBU36054Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the periodic

maintenance chart.

1. Transmission oil drain bolt

2. Gasket2

1

Tightening torque:Transmission oil drain bolt:20 N·m (2.0 kgf·m, 15 lb·ft)

UBAS7AE0.book Page 31 Wednesday, June 19, 2019 11:51 AM

Page 160 of 212

9-33

9

5. Install the oil filler bolt and its gasket, andthen tighten the bolt to the specified

torque.

Changing the final gear oil 1. Park the vehicle on a level surface.

2. Place an oil pan under the final gear case

to collect the used oil.

3. Remove the final gear oil filler bolt, the fi-

nal gear oil drain bolt and their gasket to

drain the oil. 4. Install the drain bolt and its new gasket,

and then tighten the bolt to the specified

torque.

5. Refill with the recommended final gear oil up to the brim of the filler hole.

6. Check the oil filler bolt gasket for dam- age, and replace it if necessary.Tightening torque:Final gear oil filler bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

1. Final gear oil drain bolt

2. GasketTightening torque:Final gear oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

21

UBAS7AE0.book Page 33 Wednesday, June 19, 2019 11:51 AM

Page 161 of 212

9-34

9

7. Install the oil filler bolt and its gasket, andthen tighten the bolt to the specified

torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.EBU36064Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the period-

ic maintenance chart.NOTICEECB03600When checking or changing the differen-

tial gear oil, make sure that no foreign ma-

terial enters the differential gear case. If

necessary, clean the differential gear oil

filler bolt and surrounding area.

TIPIf the recommended gear oil is not available,

SAE 80W-90 API GL-4 or GL-5 hypoid gear

oil may be used instead. Checking the differential gear oil level 1. Park the vehicle on a level surface.

2. Remove the differential gear oil filler bolt and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole.

Tightening torque:Final gear oil filler bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

UBAS7AE0.book Page 34 Wednesday, June 19, 2019 11:51 AM

Page 162 of 212

9-35

9

3. If the level is low, add sufficient oil of therecommended type to raise it to the

specified level.

4. Check the gasket for damage, and re- place it if necessary.

5. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque. Changing the differential gear oil

1. Park the vehicle on a level surface.

2. Place an oil pan under the differential

gear case to collect the used oil.

3. Remove the differential gear oil filler bolt,

the differential gear oil drain bolt and their

gasket to drain the oil.1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

Tightening torque:Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)1. Differential gear oil drain bolt

2. Gasket

1 2

UBAS7AE0.book Page 35 Wednesday, June 19, 2019 11:51 AM

Page 163 of 212

9-36

9

4. Install the differential gear oil drain boltand its new gasket, and then tighten the

bolt to the specified torque.

5. Refill the differential gear case with the recommended oil.

6. Check the oil filler bolt gasket for dam- age, and replace it if necessary.

7. Install the differential gear oil filler bolt and its gasket, and then tighten the bolt

to the specified torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.

EBU35112CoolantThe coolant level should be checked regular-

ly. In addition, the coolant must be changed

at the intervals specified in the periodic main-

tenance chart.TIPIf genuine Yamaha coolant is not available,

use an ethylene glycol antifreeze containing

corrosion inhibitors for aluminum engines and

mix with distilled water at a 1:1 ratio.

Tightening torque:Differential gear oil drain bolt:9.8 N·m (0.98 kgf·m, 7.2 lb·ft)

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

Recommended coolant:YAMALUBE coolant

Coolant quantity: Coolant reservoir (up to full level):0.56 L (0.59 US qt, 0.49 Imp.qt)

Radiator (including all routes): 3.78 L (4.00 US qt, 3.33 Imp.qt)

UBAS7AE0.book Page 36 Wednesday, June 19, 2019 11:51 AM

Page 167 of 212

9-40

9

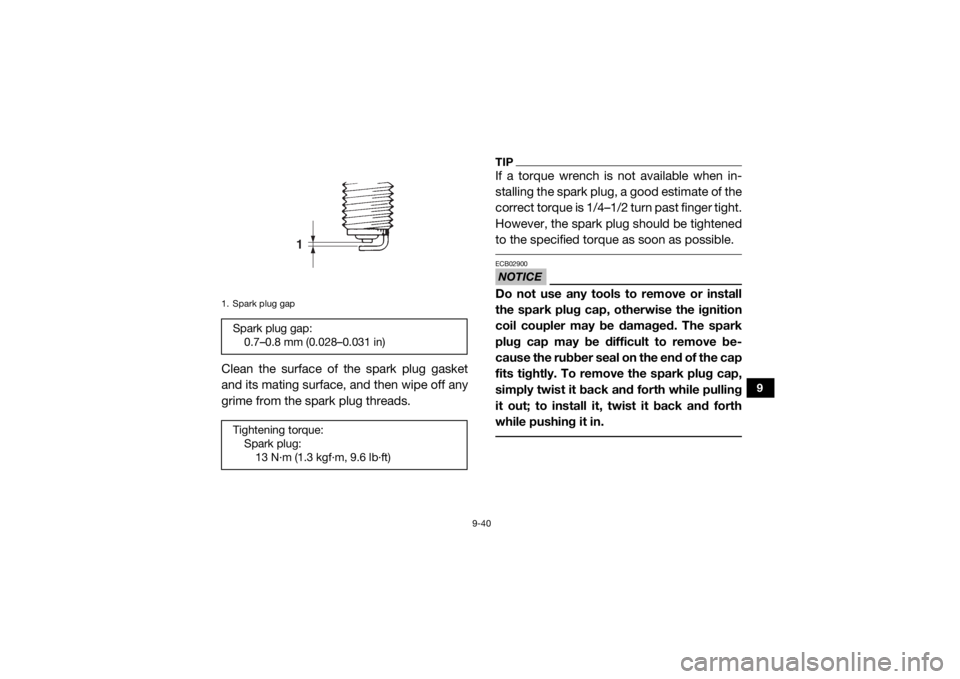

Clean the surface of the spark plug gasket

and its mating surface, and then wipe off any

grime from the spark plug threads.

TIPIf a torque wrench is not available when in-

stalling the spark plug, a good estimate of the

correct torque is 1/4–1/2 turn past finger tight.

However, the spark plug should be tightened

to the specified torque as soon as possible. NOTICEECB02900Do not use any tools to remove or install

the spark plug cap, otherwise the ignition

coil coupler may be damaged. The spark

plug cap may be difficult to remove be-

cause the rubber seal on the end of the cap

fits tightly. To remove the spark plug cap,

simply twist it back and forth while pulling

it out; to install it, twist it back and forth

while pushing it in.

1. Spark plug gapSpark plug gap: 0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug:13 N·m (1.3 kgf·m, 9.6 lb·ft)

1

UBAS7AE0.book Page 40 Wednesday, June 19, 2019 11:51 AM