check oil YAMAHA YZ250F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 194 of 668

3 - 18

INSP

ADJ

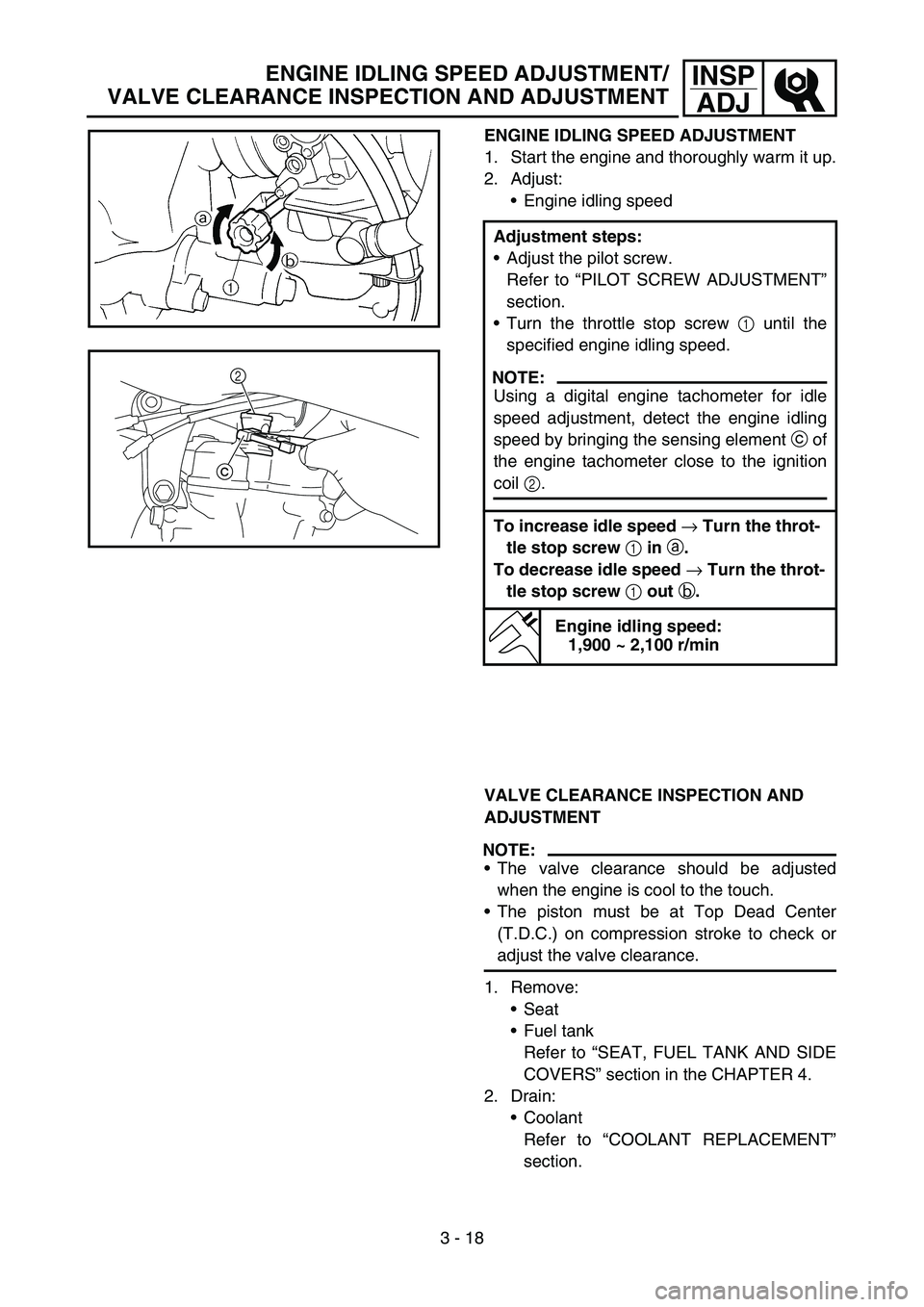

ENGINE IDLING SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

Engine idling speed

Adjustment steps:

Adjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

Turn the throttle stop screw 1 until the

specified engine idling speed.

NOTE:

Using a digital engine tachometer for idle

speed adjustment, detect the engine idling

speed by bringing the sensing element c of

the engine tachometer close to the ignition

coil 2.

To increase idle speed → Turn the throt-

tle stop screw 1 in a.

To decrease idle speed → Turn the throt-

tle stop screw 1 out b.

Engine idling speed:

1,900 ~ 2,100 r/min

c2

VALVE CLEARANCE INSPECTION AND

ADJUSTMENT

NOTE:

The valve clearance should be adjusted

when the engine is cool to the touch.

The piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

Seat

Fuel tank

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

2. Drain:

Coolant

Refer to “COOLANT REPLACEMENT”

section.

ENGINE IDLING SPEED ADJUSTMENT/

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

Page 224 of 668

3 - 32

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

4. Check:

Drive chain stiffness a

Clean and oil the drive chain and hold as

illustrated.

Stiff → Replace drive chain.

5. Install:

Drive chain 1

Joint 2

Master link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction

6. Lubricate:

Drive chain

Drive chain lubricant:

SAE 10W-30 motor oil or

suitable chain lubricants

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

Drive chain slack a

Above the seal guard installation bolt.

Out of specification → Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust the drive chain

slack with the rear wheel in this “tight chain”

position.

Drive chain slack:

48 ~ 58 mm (1.9 ~ 2.3 in)

Page 254 of 668

3 - 47

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw 1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “ENGINE IDLING SPEED

ADJUSTMENT” section.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing mark accessing screw

Page 306 of 668

4 - 26

ENGCAMSHAFTS

Decompression system

1. Check:

Decompression system

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

Exhaust camshaft 1

Intake camshaft 2 Checking steps:

Check that the decompression mecha-

nism cam 1 moves smoothly.

Check that the decompression mecha-

nism cam lever pin 2 projects from the

camshaft.

Installation steps:

Turn the crankshaft counterclockwise with

a wrench.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Squeezing the decompression lever

allows the crankshaft to be turned easily.

Align the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

Page 390 of 668

4 - 68

ENGOIL PUMP

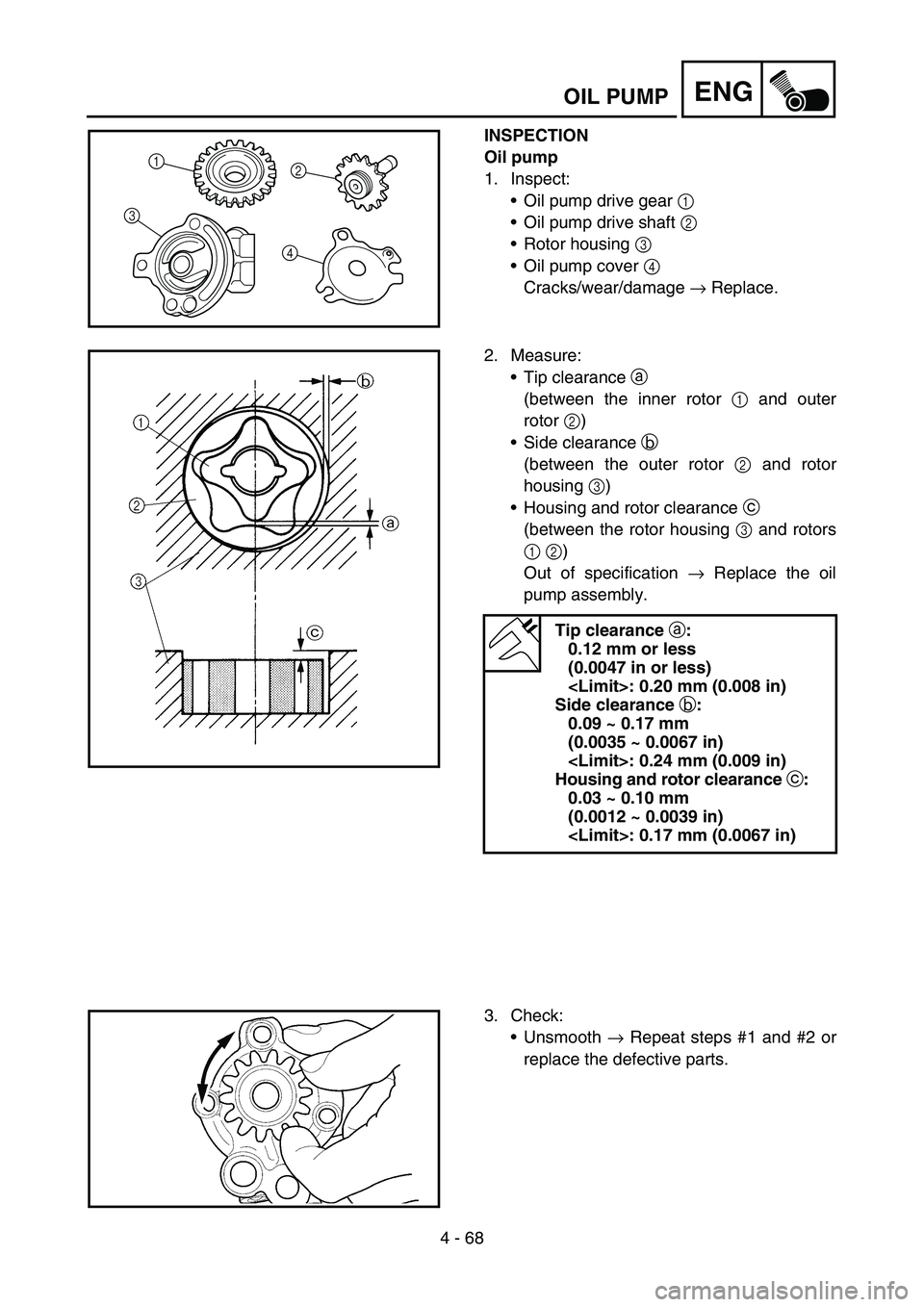

INSPECTION

Oil pump

1. Inspect:

Oil pump drive gear 1

Oil pump drive shaft 2

Rotor housing 3

Oil pump cover 4

Cracks/wear/damage → Replace.

1

32

4

2. Measure:

Tip clearance a

(between the inner rotor 1 and outer

rotor 2)

Side clearance b

(between the outer rotor 2 and rotor

housing 3)

Housing and rotor clearance c

(between the rotor housing 3 and rotors

1 2)

Out of specification → Replace the oil

pump assembly.

Tip clearance a:

0.12 mm or less

(0.0047 in or less)

Side clearance b:

0.09 ~ 0.17 mm

(0.0035 ~ 0.0067 in)

Housing and rotor clearance c:

0.03 ~ 0.10 mm

(0.0012 ~ 0.0039 in)

3. Check:

Unsmooth → Repeat steps #1 and #2 or

replace the defective parts.

Page 442 of 668

4 - 94

ENGCRANKCASE AND CRANKSHAFT

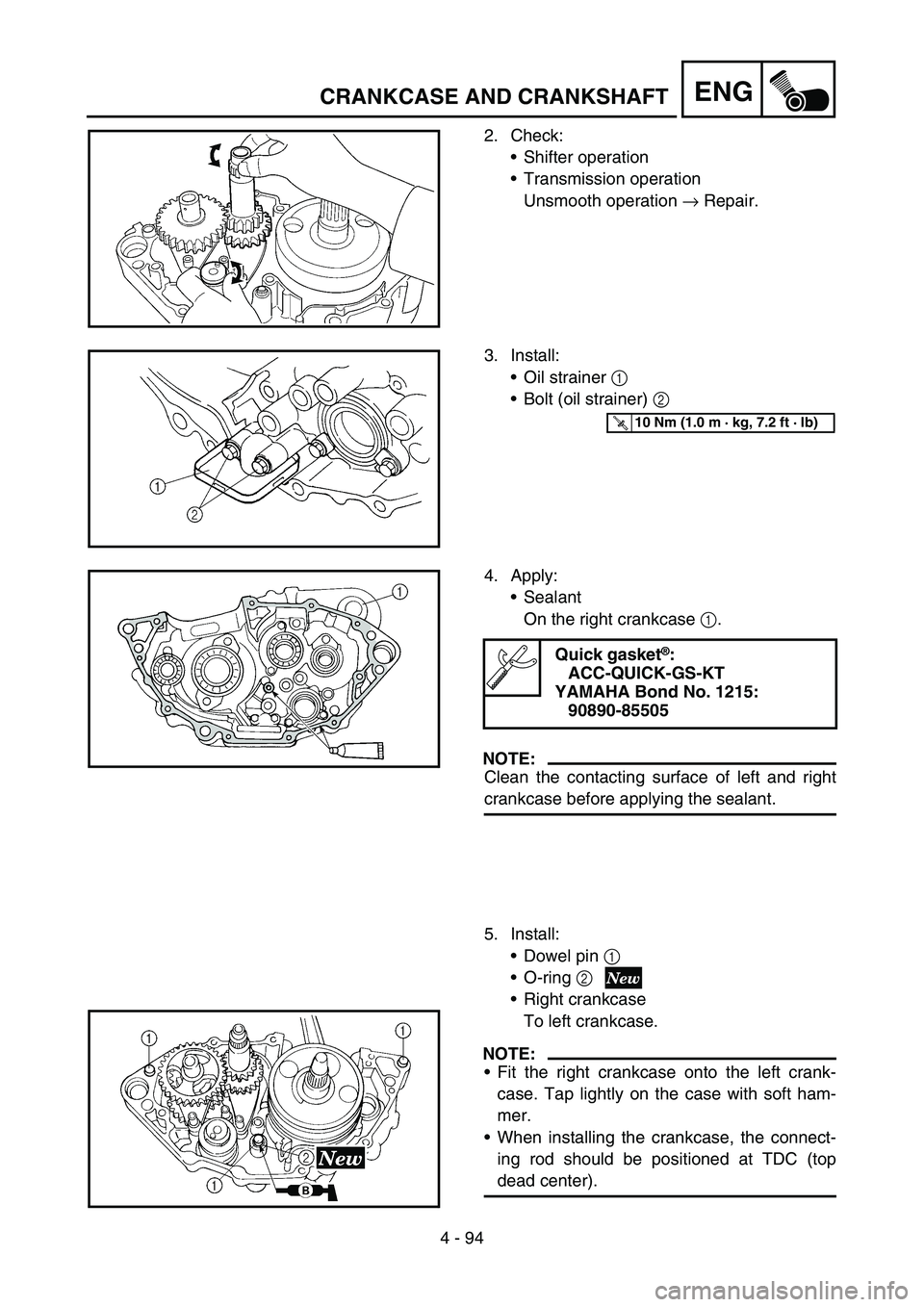

2. Check:

Shifter operation

Transmission operation

Unsmooth operation → Repair.

3. Install:

Oil strainer 1

Bolt (oil strainer) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

4. Apply:

Sealant

On the right crankcase 1.

NOTE:

Clean the contacting surface of left and right

crankcase before applying the sealant.

5. Install:

Dowel pin 1

O-ring 2

Right crankcase

To left crankcase.

NOTE:

Fit the right crankcase onto the left crank-

case. Tap lightly on the case with soft ham-

mer.

When installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

Page 444 of 668

4 - 95

ENGCRANKCASE AND CRANKSHAFT

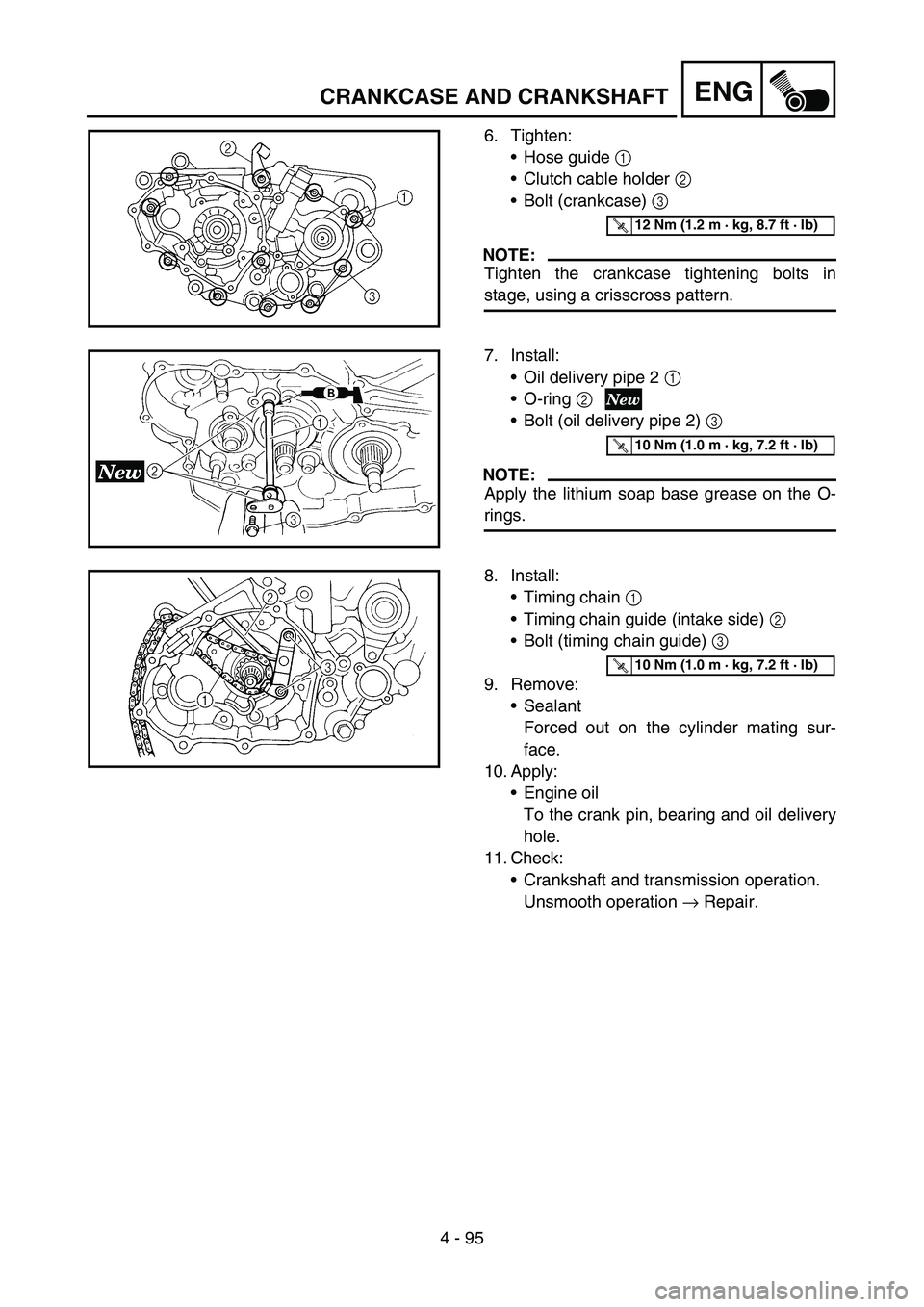

6. Tighten:

Hose guide 1

Clutch cable holder 2

Bolt (crankcase) 3

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

7. Install:

Oil delivery pipe 2 1

O-ring 2

Bolt (oil delivery pipe 2) 3

NOTE:

Apply the lithium soap base grease on the O-

rings.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

8. Install:

Timing chain 1

Timing chain guide (intake side) 2

Bolt (timing chain guide) 3

9. Remove:

Sealant

Forced out on the cylinder mating sur-

face.

10. Apply:

Engine oil

To the crank pin, bearing and oil delivery

hole.

11. Check:

Crankshaft and transmission operation.

Unsmooth operation → Repair.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 450 of 668

4 - 98

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

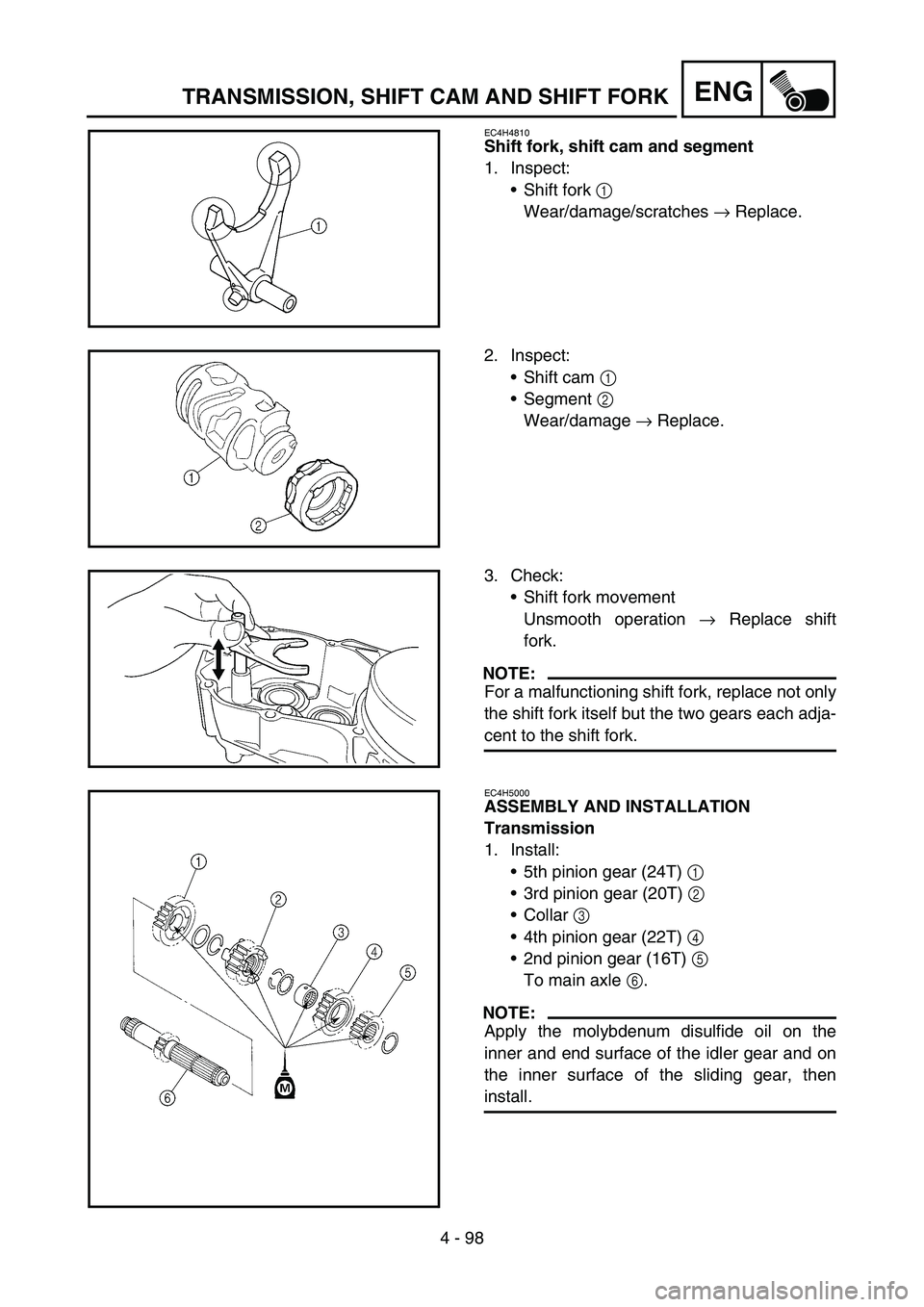

EC4H4810

Shift fork, shift cam and segment

1. Inspect:

Shift fork 1

Wear/damage/scratches → Replace.

2. Inspect:

Shift cam 1

Segment 2

Wear/damage → Replace.

3. Check:

Shift fork movement

Unsmooth operation → Replace shift

fork.

NOTE:

For a malfunctioning shift fork, replace not only

the shift fork itself but the two gears each adja-

cent to the shift fork.

EC4H5000

ASSEMBLY AND INSTALLATION

Transmission

1. Install:

5th pinion gear (24T) 1

3rd pinion gear (20T) 2

Collar 3

4th pinion gear (22T) 4

2nd pinion gear (16T) 5

To main axle 6.

NOTE:

Apply the molybdenum disulfide oil on the

inner and end surface of the idler gear and on

the inner surface of the sliding gear, then

install.

Page 454 of 668

4 - 100

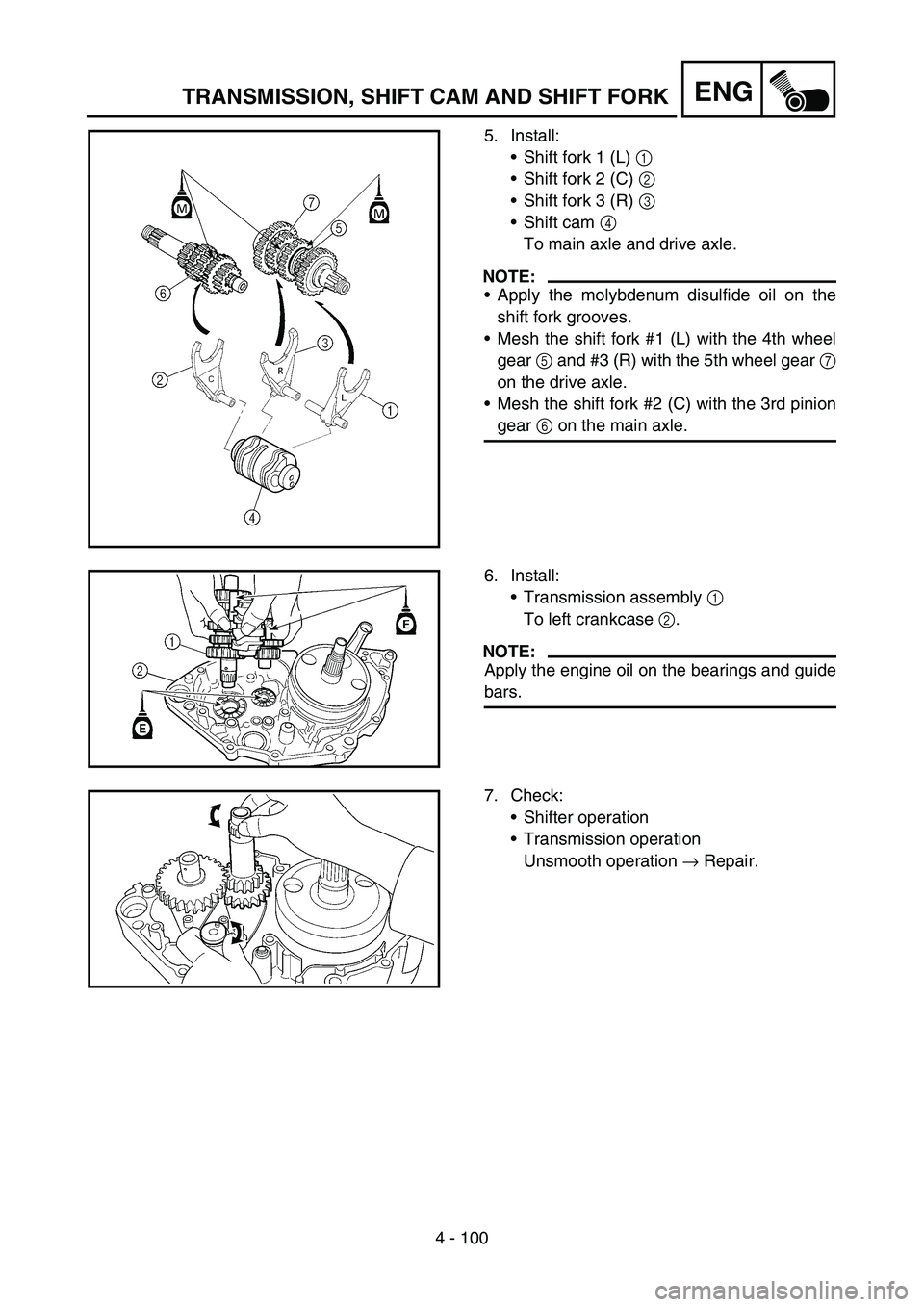

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

5. Install:

Shift fork 1 (L) 1

Shift fork 2 (C) 2

Shift fork 3 (R) 3

Shift cam 4

To main axle and drive axle.

NOTE:

Apply the molybdenum disulfide oil on the

shift fork grooves.

Mesh the shift fork #1 (L) with the 4th wheel

gear 5 and #3 (R) with the 5th wheel gear 7

on the drive axle.

Mesh the shift fork #2 (C) with the 3rd pinion

gear 6 on the main axle.

6. Install:

Transmission assembly 1

To left crankcase 2.

NOTE:

Apply the engine oil on the bearings and guide

bars.

7. Check:

Shifter operation

Transmission operation

Unsmooth operation → Repair.

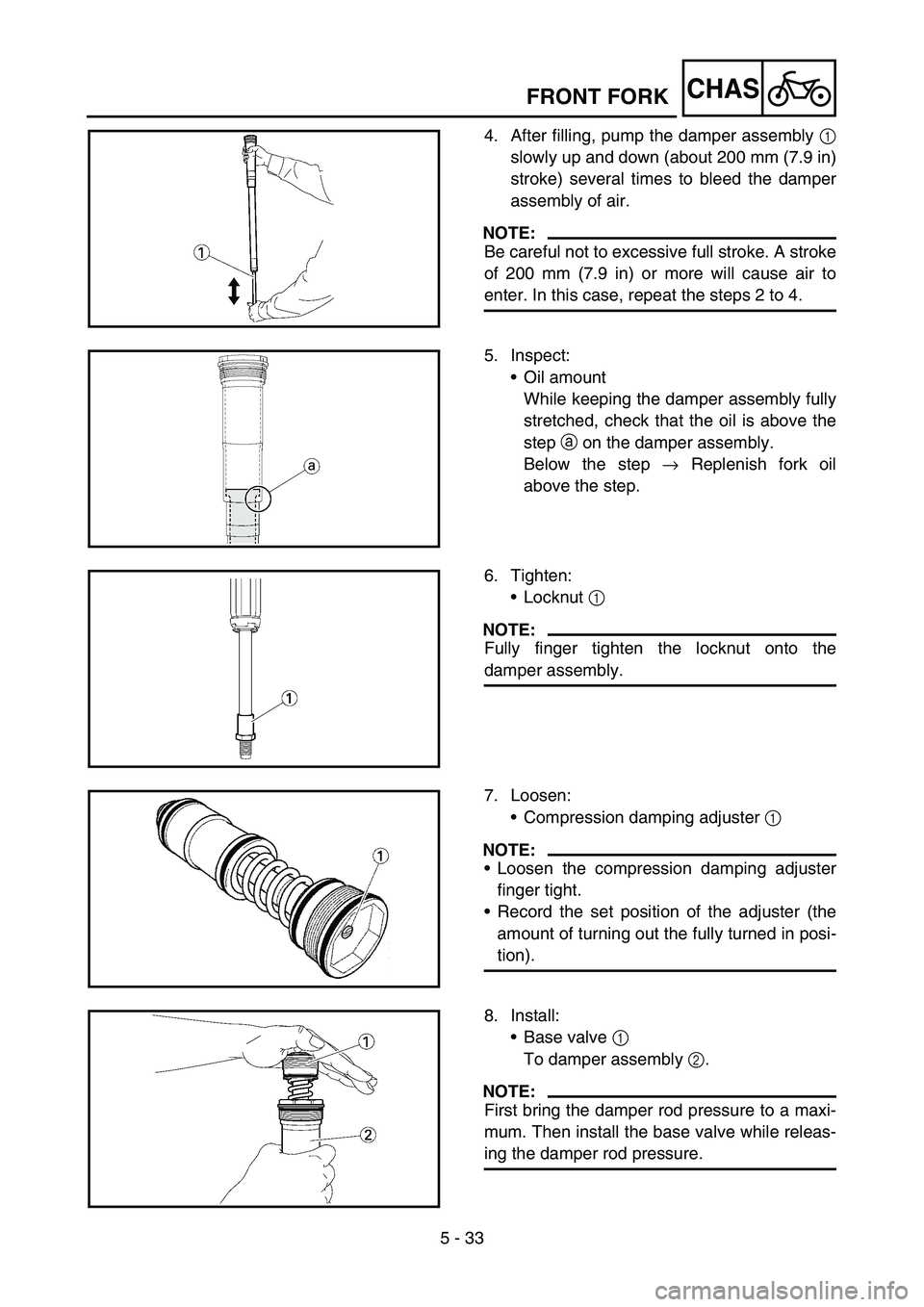

Page 520 of 668

5 - 33

CHASFRONT FORK

4. After filling, pump the damper assembly 1

slowly up and down (about 200 mm (7.9 in)

stroke) several times to bleed the damper

assembly of air.

NOTE:

Be careful not to excessive full stroke. A stroke

of 200 mm (7.9 in) or more will cause air to

enter. In this case, repeat the steps 2 to 4.

5. Inspect:

Oil amount

While keeping the damper assembly fully

stretched, check that the oil is above the

step a on the damper assembly.

Below the step → Replenish fork oil

above the step.

6. Tighten:

Locknut 1

NOTE:

Fully finger tighten the locknut onto the

damper assembly.

7. Loosen:

Compression damping adjuster 1

NOTE:

Loosen the compression damping adjuster

finger tight.

Record the set position of the adjuster (the

amount of turning out the fully turned in posi-

tion).

8. Install:

Base valve 1

To damper assembly 2.

NOTE:

First bring the damper rod pressure to a maxi-

mum. Then install the base valve while releas-

ing the damper rod pressure.