length YAMAHA YZ250F 2009 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 86 of 190

4-16

CAMSHAFTS

REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

2. Align:

• T.D.C. mark

With align mark.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

3. Remove:

• Timing chain tensioner cap bolt

"1"

• Timing chain tensioner "2"

•Gasket4. Remove:

• Bolt (camshaft cap) "1"

• Camshaft cap "2"

•Clip

Remove the bolts (camshaft cap) in a

crisscross pattern, working from the

outside in.

The bolts (camshaft cap) must be

removed evenly to prevent dam-

age to the cylinder head, cam-

shafts or camshaft caps.

5. Remove:

• Exhaust camshaft "1"

• Intake camshaft "2"

Attach a wire "3" to the timing chain to

prevent it from falling into the crank-

case.

CHECKING THE CAMSHAFT

1. Inspect:

• Cam lobe

Pitting/scratches/blue discolora-

tion→Replace.

2. Measure:

• Cam lobe length "a" and "b"

Out of specification→Replace.3. Measure:

• Runout (camshaft)

Out of specification→Replace.

Cam lobes length:

Intake "a":

30.246–30.346 mm

(1.1908–1.1947 in)

30.146 mm (1.1869 in)

Intake "b":

22.45–22.55 mm

(0.8839–0.8878 in)

22.35 mm (0.8799 in)

Exhaust "a":

30.399–30.499 mm

(1.1968–1.2007 in)

30.299 mm (1.1929 in)

Exhaust "b":

22.45–22.55 mm

(0.8839–0.8878 in)

22.35 mm (0.8799 in)

Runout (camshaft):

Less than 0.03 mm

(0.0012 in)

Page 93 of 190

4-23

VALVES AND VALVE SPRINGS

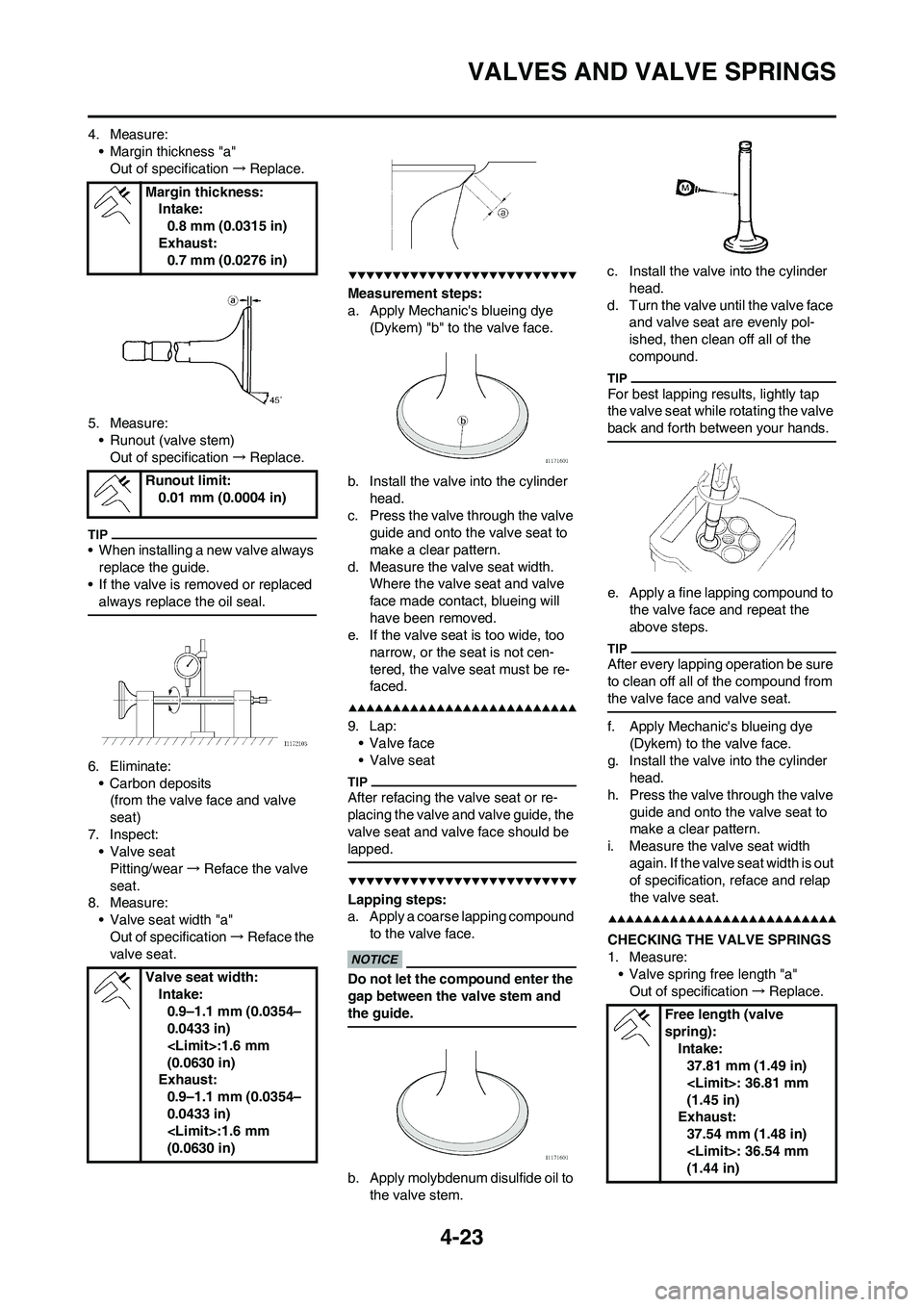

4. Measure:

• Margin thickness "a"

Out of specification→Replace.

5. Measure:

• Runout (valve stem)

Out of specification→Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

•Valve seat

Pitting/wear→Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification→Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be re-

faced.

9. Lap:

• Valve face

• Valve seat

After refacing the valve seat or re-

placing the valve and valve guide, the

valve seat and valve face should be

lapped.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace. Margin thickness:

Intake:

0.8 mm (0.0315 in)

Exhaust:

0.7 mm (0.0276 in)

Runout limit:

0.01 mm (0.0004 in)

Valve seat width:

Intake:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Exhaust:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Free length (valve

spring):

Intake:

37.81 mm (1.49 in)

(1.45 in)

Exhaust:

37.54 mm (1.48 in)

(1.44 in)

Page 94 of 190

4-24

VALVES AND VALVE SPRINGS

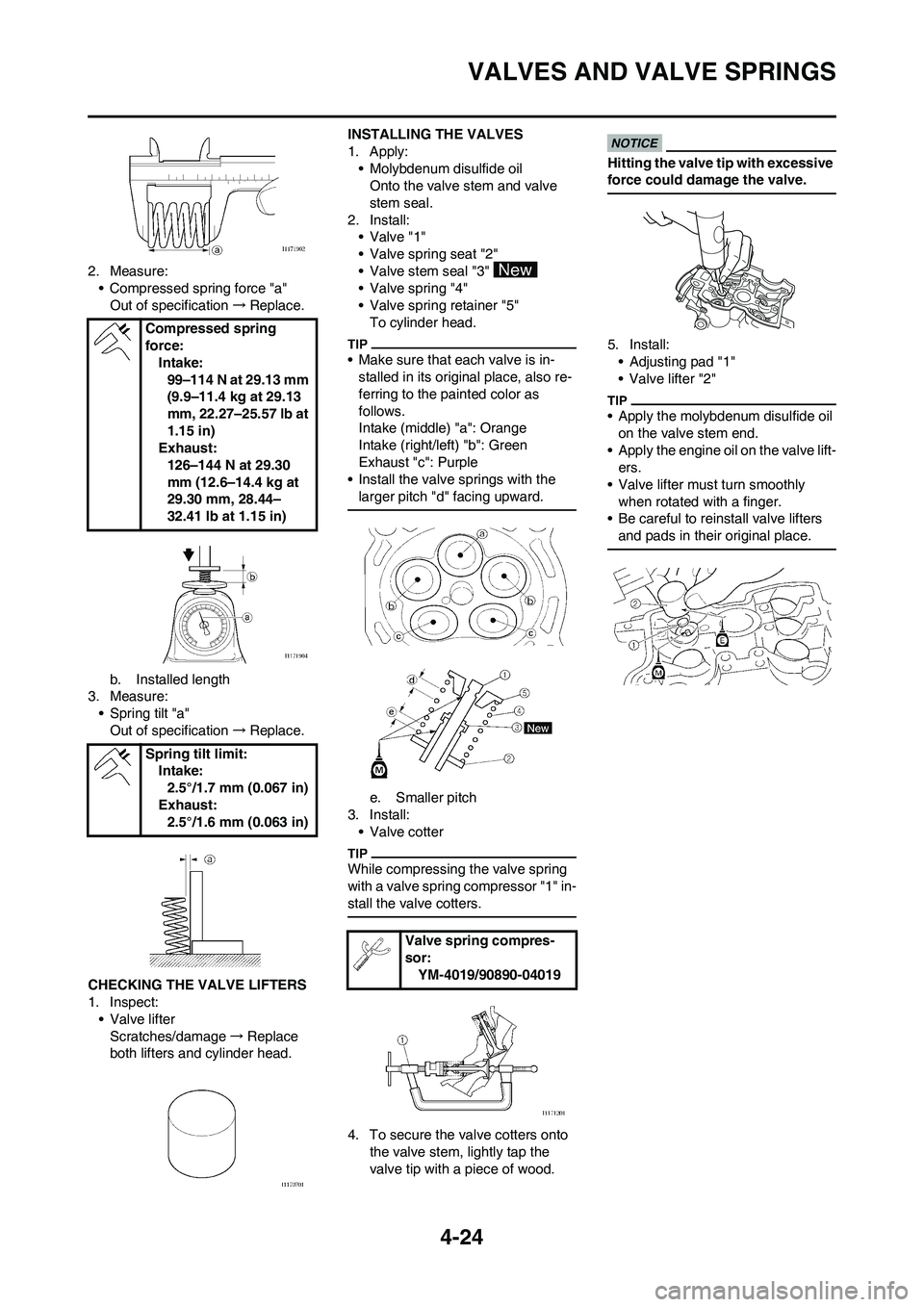

2. Measure:

• Compressed spring force "a"

Out of specification→Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification→Replace.

CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

•Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"

To cylinder head.

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch

3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Compressed spring

force:

Intake:

99–114 N at 29.13 mm

(9.9–11.4 kg at 29.13

mm, 22.27–25.57 lb at

1.15 in)

Exhaust:

126–144 N at 29.30

mm (12.6–14.4 kg at

29.30 mm, 28.44–

32.41 lb at 1.15 in)

Spring tilt limit:

Intake:

2.5°/1.7 mm (0.067 in)

Exhaust:

2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 101 of 190

4-31

CLUTCH

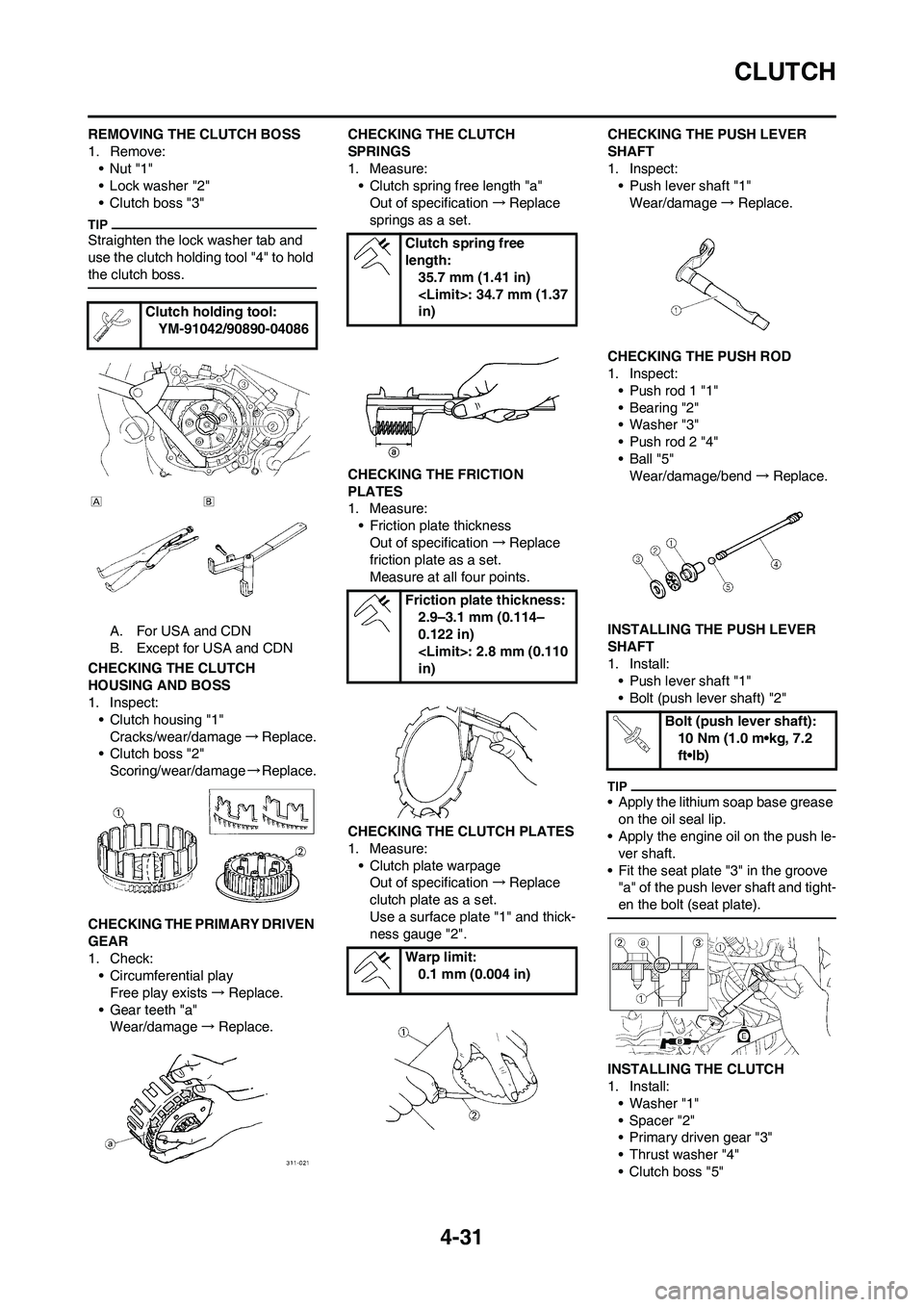

REMOVING THE CLUTCH BOSS

1. Remove:

•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect:

• Clutch housing "1"

Cracks/wear/damage→Replace.

• Clutch boss "2"

Scoring/wear/damage→Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check:

• Circumferential play

Free play exists→Replace.

• Gear teeth "a"

Wear/damage→Replace.CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification→Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure:

• Friction plate thickness

Out of specification→Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure:

• Clutch plate warpage

Out of specification→Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2".CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/damage→Replace.

CHECKING THE PUSH ROD

1. Inspect:

• Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

• Ball "5"

Wear/damage/bend→Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install:

• Push lever shaft "1"

• Bolt (push lever shaft) "2"

• Apply the lithium soap base grease

on the oil seal lip.

• Apply the engine oil on the push le-

ver shaft.

• Fit the seat plate "3" in the groove

"a" of the push lever shaft and tight-

en the bolt (seat plate).

INSTALLING THE CLUTCH

1. Install:

• Washer "1"

•Spacer "2"

• Primary driven gear "3"

• Thrust washer "4"

• Clutch boss "5" Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:

35.7 mm (1.41 in)

in)

Friction plate thickness:

2.9–3.1 mm (0.114–

0.122 in)

in)

Warp limit:

0.1 mm (0.004 in)

Bolt (push lever shaft):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 150 of 190

5-19

FRONT FORK

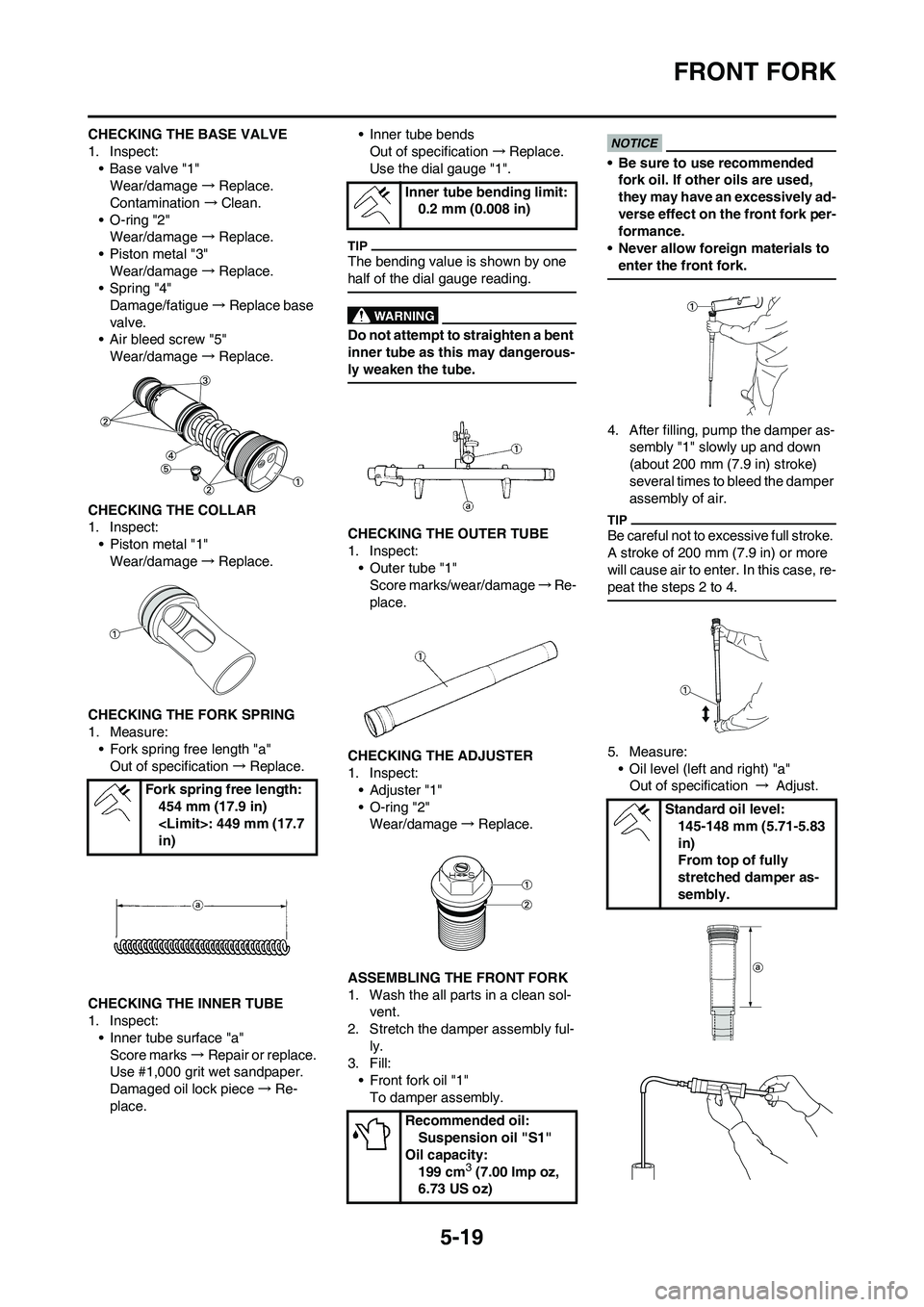

CHECKING THE BASE VALVE

1. Inspect:

• Base valve "1"

Wear/damage →Replace.

Contamination →Clean.

• O-ring "2"

Wear/damage →Replace.

• Piston metal "3"

Wear/damage →Replace.

• Spring "4"

Damage/fatigue →Replace base

valve.

• Air bleed screw "5"

Wear/damage →Replace.

CHECKING THE COLLAR

1. Inspect:

• Piston metal "1"

Wear/damage→Replace.

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification→Replace.

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks→Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece→Re-

place.• Inner tube bends

Out of specification→Replace.

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

inner tube as this may dangerous-

ly weaken the tube.

CHECKING THE OUTER TUBE

1. Inspect:

• Outer tube "1"

Score marks/wear/damage→Re-

place.

CHECKING THE ADJUSTER

1. Inspect:

• Adjuster "1"

• O-ring "2"

Wear/damage→Replace.

ASSEMBLING THE FRONT FORK

1. Wash the all parts in a clean sol-

vent.

2. Stretch the damper assembly ful-

ly.

3. Fill:

• Front fork oil "1"

To damper assembly.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

4. After filling, pump the damper as-

sembly "1" slowly up and down

(about 200 mm (7.9 in) stroke)

several times to bleed the damper

assembly of air.

Be careful not to excessive full stroke.

A stroke of 200 mm (7.9 in) or more

will cause air to enter. In this case, re-

peat the steps 2 to 4.

5. Measure:

• Oil level (left and right) "a"

Out of specification → Adjust.

Fork spring free length:

454 mm (17.9 in)

in)

Inner tube bending limit:

0.2 mm (0.008 in)

Recommended oil:

Suspension oil "S1"

Oil capacity:

199 cm

3 (7.00 Imp oz,

6.73 US oz)

Standard oil level:

145-148 mm (5.71-5.83

in)

From top of fully

stretched damper as-

sembly.

Page 169 of 190

5-38

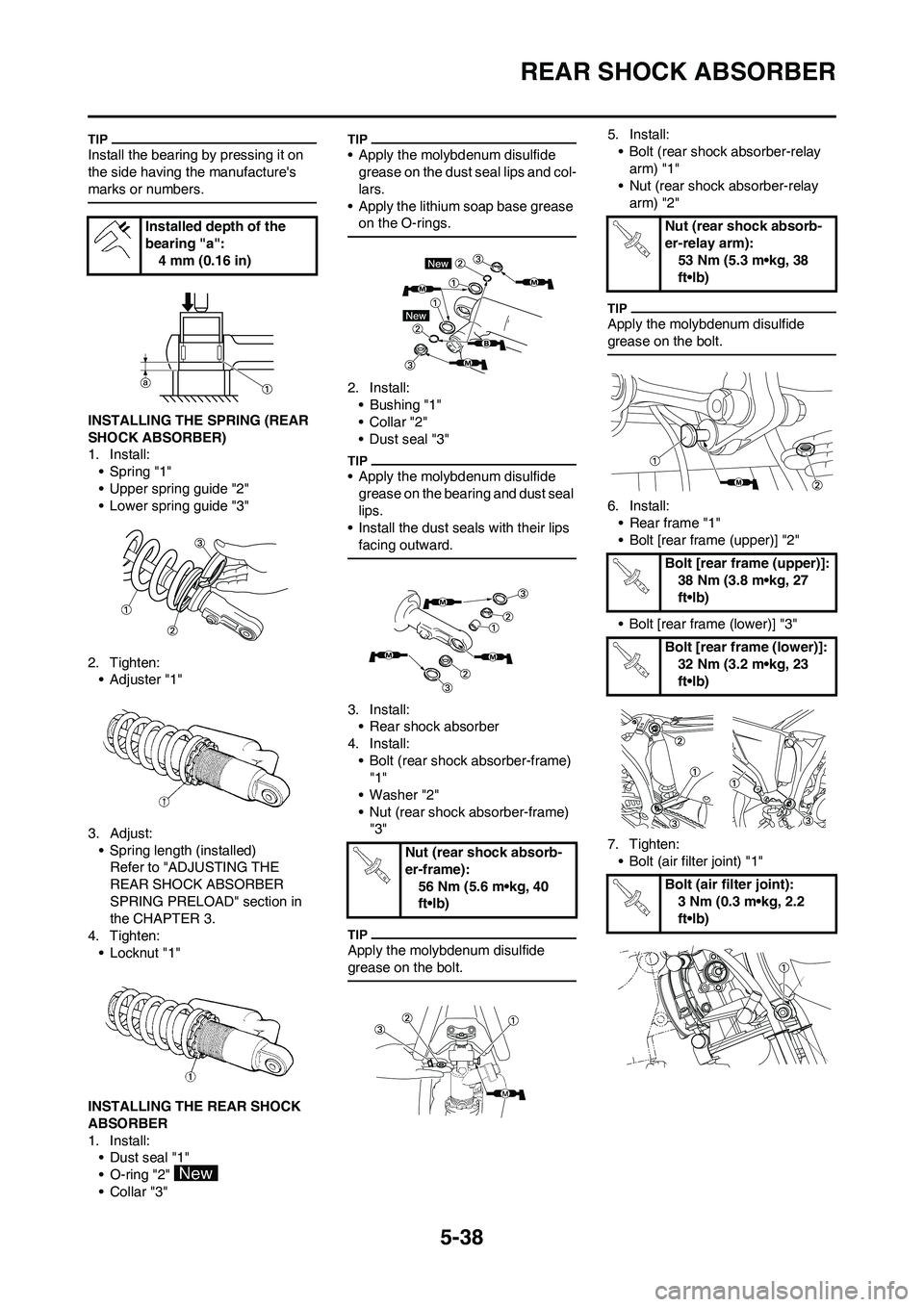

REAR SHOCK ABSORBER

Install the bearing by pressing it on

the side having the manufacture's

marks or numbers.

INSTALLING THE SPRING (REAR

SHOCK ABSORBER)

1. Install:

• Spring "1"

• Upper spring guide "2"

• Lower spring guide "3"

2. Tighten:

•Adjuster "1"

3. Adjust:

• Spring length (installed)

Refer to "ADJUSTING THE

REAR SHOCK ABSORBER

SPRING PRELOAD" section in

the CHAPTER 3.

4. Tighten:

• Locknut "1"

INSTALLING THE REAR SHOCK

ABSORBER

1. Install:

• Dust seal "1"

• O-ring "2"

•Collar "3"

• Apply the molybdenum disulfide

grease on the dust seal lips and col-

lars.

• Apply the lithium soap base grease

on the O-rings.

2. Install:

• Bushing "1"

•Collar "2"

• Dust seal "3"

• Apply the molybdenum disulfide

grease on the bearing and dust seal

lips.

• Install the dust seals with their lips

facing outward.

3. Install:

• Rear shock absorber

4. Install:

• Bolt (rear shock absorber-frame)

"1"

•Washer "2"

• Nut (rear shock absorber-frame)

"3"

Apply the molybdenum disulfide

grease on the bolt.

5. Install:

• Bolt (rear shock absorber-relay

arm) "1"

• Nut (rear shock absorber-relay

arm) "2"

Apply the molybdenum disulfide

grease on the bolt.

6. Install:

• Rear frame "1"

• Bolt [rear frame (upper)] "2"

• Bolt [rear frame (lower)] "3"

7. Tighten:

• Bolt (air filter joint) "1" Installed depth of the

bearing "a":

4 mm (0.16 in)

Nut (rear shock absorb-

er-frame):

56 Nm (5.6 m•kg, 40

ft•lb)

Nut (rear shock absorb-

er-relay arm):

53 Nm (5.3 m•kg, 38

ft•lb)

Bolt [rear frame (upper)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolt [rear frame (lower)]:

32 Nm (3.2 m•kg, 23

ft•lb)

Bolt (air filter joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Page 184 of 190

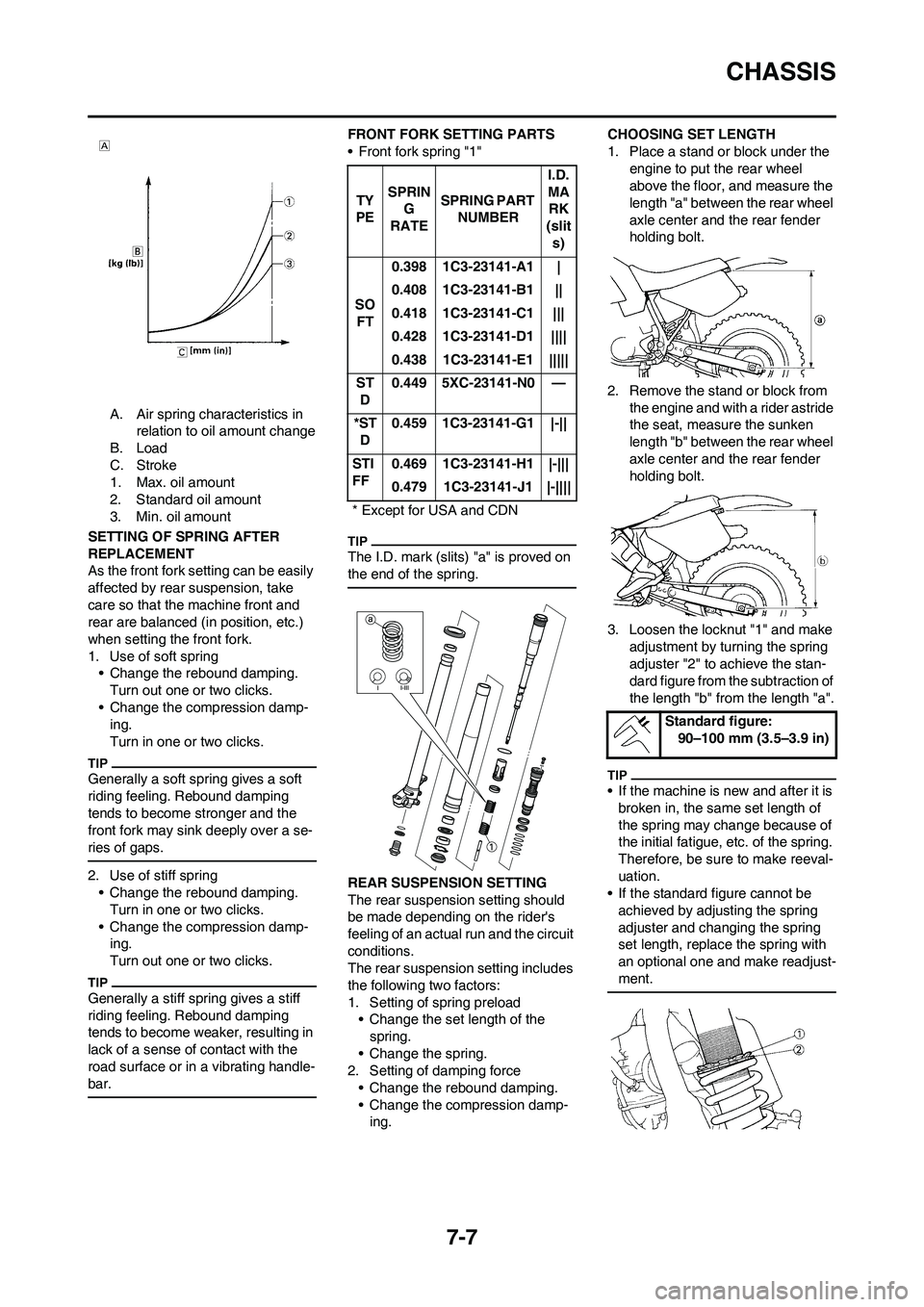

7-7

CHASSIS

A. Air spring characteristics in

relation to oil amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

SETTING OF SPRING AFTER

REPLACEMENT

As the front fork setting can be easily

affected by rear suspension, take

care so that the machine front and

rear are balanced (in position, etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping.

Turn out one or two clicks.

• Change the compression damp-

ing.

Turn in one or two clicks.

Generally a soft spring gives a soft

riding feeling. Rebound damping

tends to become stronger and the

front fork may sink deeply over a se-

ries of gaps.

2. Use of stiff spring

• Change the rebound damping.

Turn in one or two clicks.

• Change the compression damp-

ing.

Turn out one or two clicks.

Generally a stiff spring gives a stiff

riding feeling. Rebound damping

tends to become weaker, resulting in

lack of a sense of contact with the

road surface or in a vibrating handle-

bar.

FRONT FORK SETTING PARTS

• Front fork spring "1"

The I.D. mark (slits) "a" is proved on

the end of the spring.

REAR SUSPENSION SETTING

The rear suspension setting should

be made depending on the rider's

feeling of an actual run and the circuit

conditions.

The rear suspension setting includes

the following two factors:

1. Setting of spring preload

• Change the set length of the

spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping.

• Change the compression damp-

ing.CHOOSING SET LENGTH

1. Place a stand or block under the

engine to put the rear wheel

above the floor, and measure the

length "a" between the rear wheel

axle center and the rear fender

holding bolt.

2. Remove the stand or block from

the engine and with a rider astride

the seat, measure the sunken

length "b" between the rear wheel

axle center and the rear fender

holding bolt.

3. Loosen the locknut "1" and make

adjustment by turning the spring

adjuster "2" to achieve the stan-

dard figure from the subtraction of

the length "b" from the length "a".

• If the machine is new and after it is

broken in, the same set length of

the spring may change because of

the initial fatigue, etc. of the spring.

Therefore, be sure to make reeval-

uation.

• If the standard figure cannot be

achieved by adjusting the spring

adjuster and changing the spring

set length, replace the spring with

an optional one and make readjust-

ment.

TY

PESPRIN

G

RATESPRING PART

NUMBERI.D.

MA

RK

(slit

s)

SO

FT0.398 1C3-23141-A1 |

0.408 1C3-23141-B1 ||

0.418 1C3-23141-C1 |||

0.428 1C3-23141-D1 ||||

0.438 1C3-23141-E1 |||||

ST

D0.449 5XC-23141-N0 —

*ST

D0.459 1C3-23141-G1 |-||

STI

FF0.469 1C3-23141-H1 |-|||

0.479 1C3-23141-J1 |-||||

* Except for USA and CDN

Standard figure:

90–100 mm (3.5–3.9 in)

Page 185 of 190

![YAMAHA YZ250F 2009 User Guide 7-8

CHASSIS

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring

• S YAMAHA YZ250F 2009 User Guide 7-8

CHASSIS

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring

• S](/img/51/53949/w960_53949-184.png)

7-8

CHASSIS

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring

• Set the soft spring for less re-

bound damping to compensate

for its less spring load. Run with

the rebound damping adjuster

one or two clicks on the softer

side and readjust it to suit your

preference.

2. Use of stiff spring

• Set the soft spring for more re-

bound damping to compensate

for its greater spring load. Run

with the rebound damping adjust-

er one or two clicks on the stiffer

side and readjust it to suit your

preference.

Adjusting the rebound damping will

be followed more or less by a change

in the compression damping. For cor-

rection, turn the low compression

damping adjuster on the softer side.

When using a rear shock absorber

other than currently installed, use

the one whose overall length "a"

does not exceed the standard as it

may result in faulty performance.

Never use one whose overall

length is greater than standard.

REAR SHOCK ABSORBER

SETTING PARTS

• Rear shock spring "1"

[Equal-pitch steel spring]

[Unequal-pitch steel spring]

[Equal-pitch titanium spring]

Install the spring seat "2" to the ti-

tanium spring.

• The unequal-pitch spring is softer in

initial characteristic than the equal-

pitch spring and is difficult to bottom

out under full compression.

• The I.D. mark "a" is marked at the

end of the spring.

• Spring specification varies accord-

ing to the color and quantity of I.D.

marks.

• In case of using a titanium spring,

prepare 2cps. of the Yamaha genu-

ine parts, Spring sheet "2" (1C3-

22565-00), and attach them on top

and bottom of the spring.

• Install the spring seat with the pro-

jection "b" brought into contact with

the spring end, as shown.

Length "a" of standard

shock:

490 mm (19.29 in)

TYPESPRI

NG

RAT

ESPRING

PART

NUM-

B E R

(-22212-)I.D.

MARK/

Q'TY

SOFT 4.3 5UN-00 Brown/1

4.5 5UN-10 Green/1

4.7 5UN-20 Red/1

4.9 5UN-30 Black/1

5.1 5UN-40 Blue/1

STD5.35UN-50

(5UN-K0)Yellow/1

STIFF5.5 5UN-60 Pink/1

5.7 5UN-70 White/1

TYPESPRI

NG

RAT

E

(ap-

prox.

)SPRING

PART

NUM-

B E R

(-22212-)I.D.

MARK/

Q'TY

SOFT 4.5 5UN-A0 Green/2

4.7 5UN-B0 Red/2

4.9 5UN-C0 Black/2

5.1 5UN-D0 Blue/2

STIFF

5.3 5UN-E0 Yellow/2

5.5 5UN-F0 Pink/2

5.7 5UN-G0 White/2

TYPESPRI

NG

RAT

ESPRING

PART

NUM-

B E R

(-22212-)I.D.

MARK

Green/1

SOFT 4.5 1C3-00 Green/2

Green/3

Red/1

4.7 1C3-10 Red/2

Red/3

Black/1

4.9 1C3-20 Black/2

Black/3

Blue/1

5.1 1C3-30

Blue/2

Blue/3

Yellow/1

5.3 1C3-40

Yellow/2

Yellow/3

Pink/1

5.5 1C3-50

Pink/2

Pink/3

White/1

STIFF 5.7 1C3-60

White/2

White/3

TYPESPRI

NG

RAT

ESPRING

PART

NUM-

BER

(-22212-)I.D.

MARK

Page 186 of 190

7-9

CHASSIS

• Extent of adjustment (spring pre-

load)

• For the spring preload adjustment,

refer to "ADJUSTING THE REAR

SHOCK ABSORBER SPRING

PRELOAD" in the CHAPTER 3.

• Preload adjusting extent is the

same for the titanium and steel

springs.

Maximum Minimum

Position in

which the

spring is turned

in 13 mm (0.51

in) from its free

length.Position in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length.

Page 187 of 190

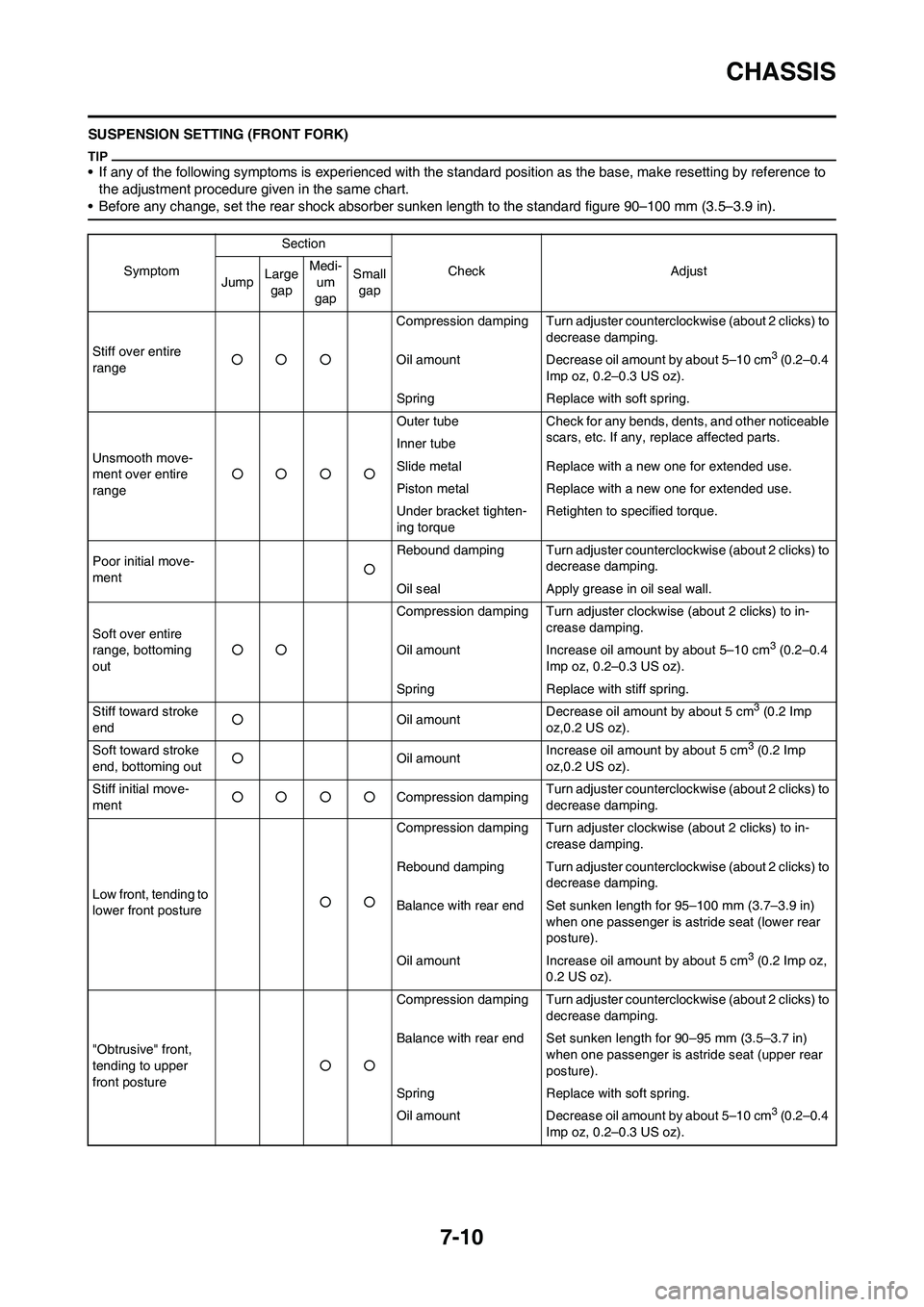

7-10

CHASSIS

SUSPENSION SETTING (FRONT FORK)

• If any of the following symptoms is experienced with the standard position as the base, make resetting by reference to

the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm (3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

range○○○Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).

Spring Replace with soft spring.

Unsmooth move-

ment over entire

range○○○○Outer tube Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Slide metal Replace with a new one for extended use.

Piston metal Replace with a new one for extended use.

Under bracket tighten-

ing torqueRetighten to specified torque.

Poor initial move-

ment○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming

out○○Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Oil amount Increase oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).

Spring Replace with stiff spring.

Stiff toward stroke

end○Oil amountDecrease oil amount by about 5 cm

3 (0.2 Imp

oz,0.2 US oz).

Soft toward stroke

end, bottoming out○Oil amountIncrease oil amount by about 5 cm

3 (0.2 Imp

oz,0.2 US oz).

Stiff initial move-

ment○○○○Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture○○Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95–100 mm (3.7–3.9 in)

when one passenger is astride seat (lower rear

posture).

Oil amount Increase oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

"Obtrusive" front,

tending to upper

front posture○○Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90–95 mm (3.5–3.7 in)

when one passenger is astride seat (upper rear

posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).