window YAMAHA YZ250F 2009 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 11 of 190

1-1

DESCRIPTION

GENERAL INFORMATION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Front brake lever

4. Throttle grip

5. Radiator cap

6. Fuel tank cap

7. Engine stop switch

8. Kickstarter crank

9. Fuel tank

10. Radiator

11. Coolant drain bolt

12. Rear brake pedal

13. Valve joint14. Fuel cock

15. Cold starter knob

16. Drive chain

17. Air filter

18. Oil level check window

19. Shift pedal

20. Front fork

1

Page 33 of 190

2-11

TIGHTENING TORQUES

Radiator pipe M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 1.7 0.17 1.2

Oil pump M6 × 1.0 3 10 1.0 7.2

Oil filter element drain bolt M6 × 1.0 1 10 1.0 7.2

Oil filter element cover M6 × 1.0 2 10 1.0 7.2

Oil strainer (crankcase) M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 × 1.25 1 20 2.0 14

Oil delivery pipe 1 (M8) M8 × 1.25 2 18 1.8 13

Oil hose M6 × 1.0 2 8 0.8 5.8

△Oil hose clamp — 1 2 0.2 1.4

Oil strainer (oil tank) M6 × 1.0 1 9 0.9 6.5

Oil tank drain bolt M8 × 1.25 1 18 1.8 13

Oil tank (upper) M6 × 1.0 1 7 0.7 5.1

Oil tank and frame M6 × 1.0 3 9 0.9 6.5

Carburetor joint clamp M4 × 0.7 2 3 0.3 2.2

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Throttle cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Throttle cable (return) M12 × 1.0 1 11 1.1 8.0

Throttle cable cover M5 × 0.8 2 4 0.4 2.9

Hot starter plunger M12 × 1.0 1 2 0.2 1.4

Hot starter cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

△Air filter case M6 × 1.0 2 8 0.8 5.8

Air filter joint and air filter case M5 × 0.8 1 4 0.4 2.9

Air filter element M6 × 1.0 1 2 0.2 1.4

Exhaust pipe M8 × 1.25 2 20 2.0 14

△Exhaust pipe protector M6 × 1.0 3 10 1.0 7.2

△Silencer M8 × 1.25 2 30 3.0 22

Silencer clamp M8 × 1.25 1 16 1.6 11

Crankcase M6 × 1.0 11 12 1.2 8.7

Crankcase bearing stopper M6 × 1.0 11 10 1.0 7.2

Crankcase bearing stopper (crankshaft) M6 × 1.0 4 14 1.4 10

Oil level check window holder M6 × 1.0 1 10 1.0 7.2

Left crankcase cover M6 × 1.0 8 10 1.0 7.2

Right crankcase cover M6 × 1.0 8 10 1.0 7.2

Clutch cover M6 × 1.0 7 10 1.0 7.2

Crankcase oil drain bolt M10 × 1.25 1 20 2.0 14

△Crankshaft end accessing screw M32 × 1.5 1 — — —

△Timing mark accessing screw M14 × 1.5 1 — — —

Drive chain sprocket cover M6 × 1.0 2 8 0.8 5.8

Kick shaft ratchet wheel guide M6 × 1.0 2 12 1.2 8.7

Kickstarter crank M8 × 1.25 1 33 3.3 24

Primary drive gear M18 × 1.0 1 75 7.5 54

Clutch spring M6 × 1.0 5 10 1.0 7.2Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 55 of 190

3-9

ENGINE

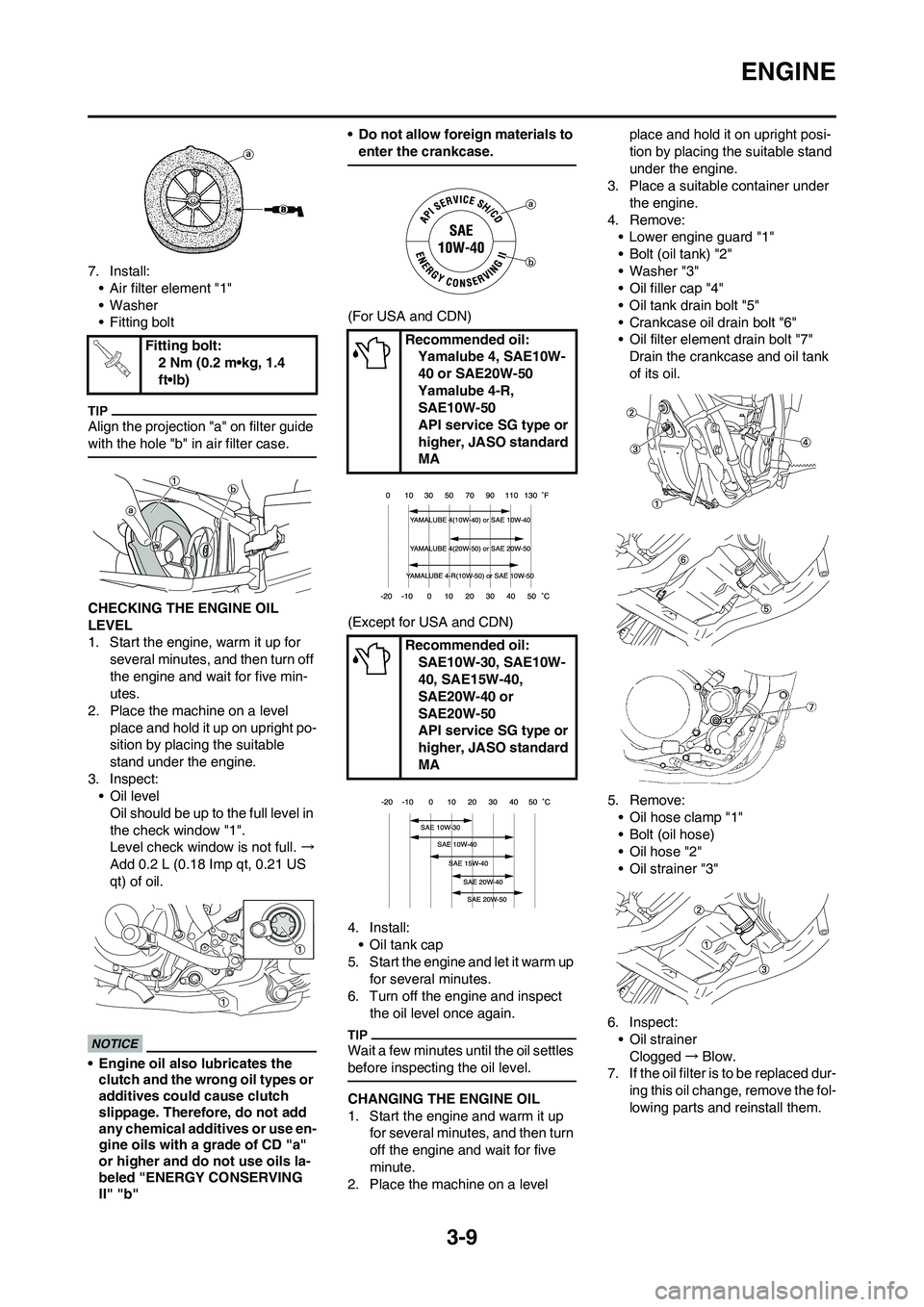

7. Install:

• Air filter element "1"

• Washer

• Fitting bolt

Align the projection "a" on filter guide

with the hole "b" in air filter case.

CHECKING THE ENGINE OIL

LEVEL

1. Start the engine, warm it up for

several minutes, and then turn off

the engine and wait for five min-

utes.

2. Place the machine on a level

place and hold it up on upright po-

sition by placing the suitable

stand under the engine.

3. Inspect:

• Oil level

Oil should be up to the full level in

the check window "1".

Level check window is not full. →

Add 0.2 L (0.18 Imp qt, 0.21 US

qt) of oil.

• Engine oil also lubricates the

clutch and the wrong oil types or

additives could cause clutch

slippage. Therefore, do not add

any chemical additives or use en-

gine oils with a grade of CD "a"

or higher and do not use oils la-

beled "ENERGY CONSERVING

II" "b"• Do not allow foreign materials to

enter the crankcase.

(For USA and CDN)

(Except for USA and CDN)

4. Install:

• Oil tank cap

5. Start the engine and let it warm up

for several minutes.

6. Turn off the engine and inspect

the oil level once again.

Wait a few minutes until the oil settles

before inspecting the oil level.

CHANGING THE ENGINE OIL

1. Start the engine and warm it up

for several minutes, and then turn

off the engine and wait for five

minute.

2. Place the machine on a level place and hold it on upright posi-

tion by placing the suitable stand

under the engine.

3. Place a suitable container under

the engine.

4. Remove:

• Lower engine guard "1"

• Bolt (oil tank) "2"

• Washer "3"

• Oil filler cap "4"

• Oil tank drain bolt "5"

• Crankcase oil drain bolt "6"

• Oil filter element drain bolt "7"

Drain the crankcase and oil tank

of its oil.

5. Remove:

• Oil hose clamp "1"

• Bolt (oil hose)

•Oil hose "2"

• Oil strainer "3"

6. Inspect:

• Oil strainer

Clogged→Blow.

7. If the oil filter is to be replaced dur-

ing this oil change, remove the fol-

lowing parts and reinstall them. Fitting bolt:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended oil:

Yamalube 4, SAE10W-

40 or SAE20W-50

Yamalube 4-R,

SAE10W-50

API service SG type or

higher, JASO standard

MA

Recommended oil:

SAE10W-30, SAE10W-

40, SAE15W-40,

SAE20W-40 or

SAE20W-50

API service SG type or

higher, JASO standard

MA

4