valve YAMAHA YZ250F 2009 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 83 of 190

4-13

CARBURETOR

18. Install:

• Carburetor breather hose "1"

Install the carburetor breather hoses

to the carburetor so that the hoses do

not bend near where they are in-

stalled.

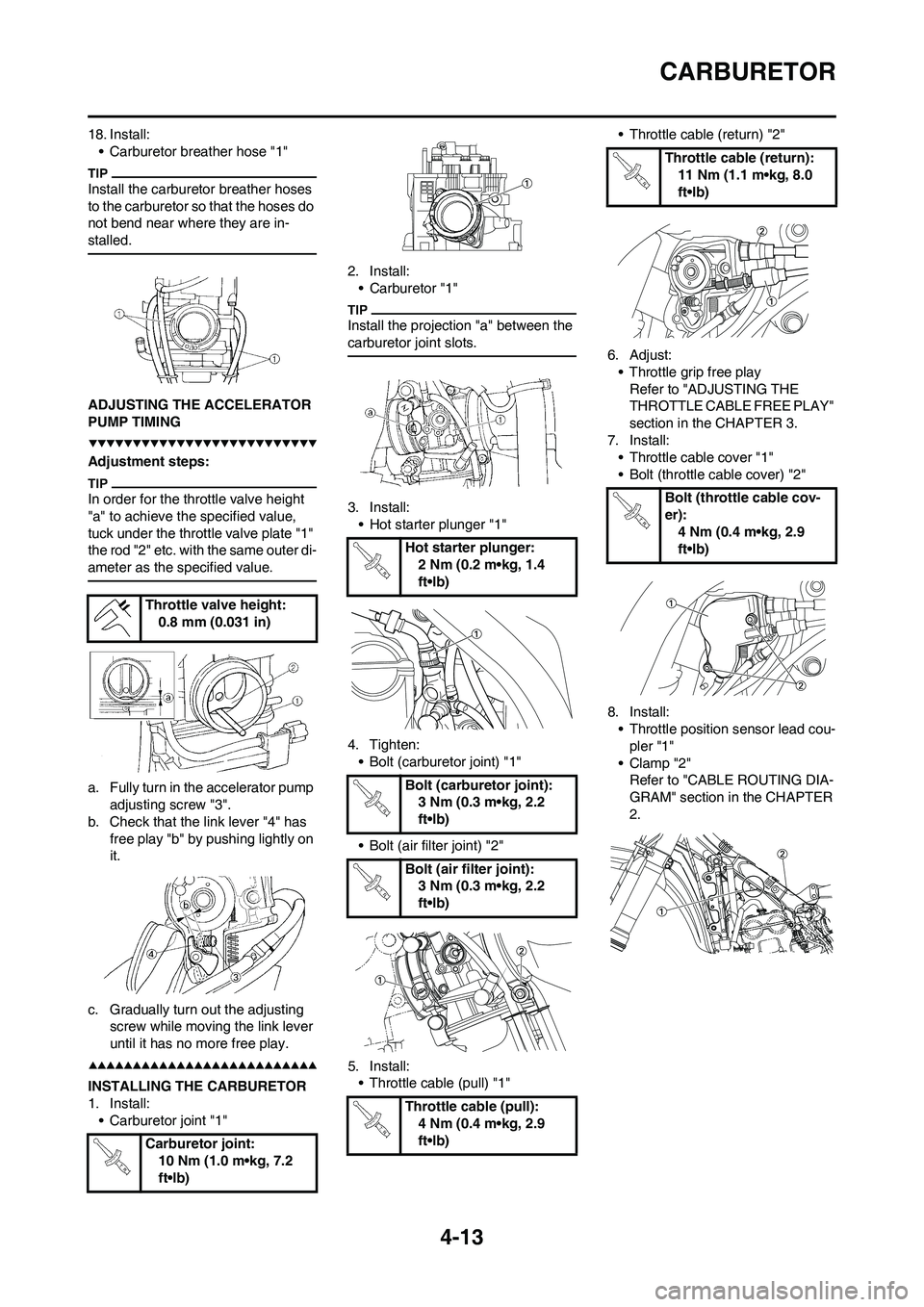

ADJUSTING THE ACCELERATOR

PUMP TIMING

Adjustment steps:

In order for the throttle valve height

"a" to achieve the specified value,

tuck under the throttle valve plate "1"

the rod "2" etc. with the same outer di-

ameter as the specified value.

a. Fully turn in the accelerator pump

adjusting screw "3".

b. Check that the link lever "4" has

free play "b" by pushing lightly on

it.

c. Gradually turn out the adjusting

screw while moving the link lever

until it has no more free play.

INSTALLING THE CARBURETOR

1. Install:

• Carburetor joint "1"2. Install:

• Carburetor "1"

Install the projection "a" between the

carburetor joint slots.

3. Install:

• Hot starter plunger "1"

4. Tighten:

• Bolt (carburetor joint) "1"

• Bolt (air filter joint) "2"

5. Install:

• Throttle cable (pull) "1"• Throttle cable (return) "2"

6. Adjust:

• Throttle grip free play

Refer to "ADJUSTING THE

THROTTLE CABLE FREE PLAY"

section in the CHAPTER 3.

7. Install:

• Throttle cable cover "1"

• Bolt (throttle cable cover) "2"

8. Install:

• Throttle position sensor lead cou-

pler "1"

•Clamp "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Throttle valve height:

0.8 mm (0.031 in)

Carburetor joint:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Hot starter plunger:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (air filter joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Throttle cable (pull):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Throttle cable (return):

11 Nm (1.1 m•kg, 8.0

ft•lb)

Bolt (throttle cable cov-

er):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 88 of 190

4-18

CAMSHAFTS

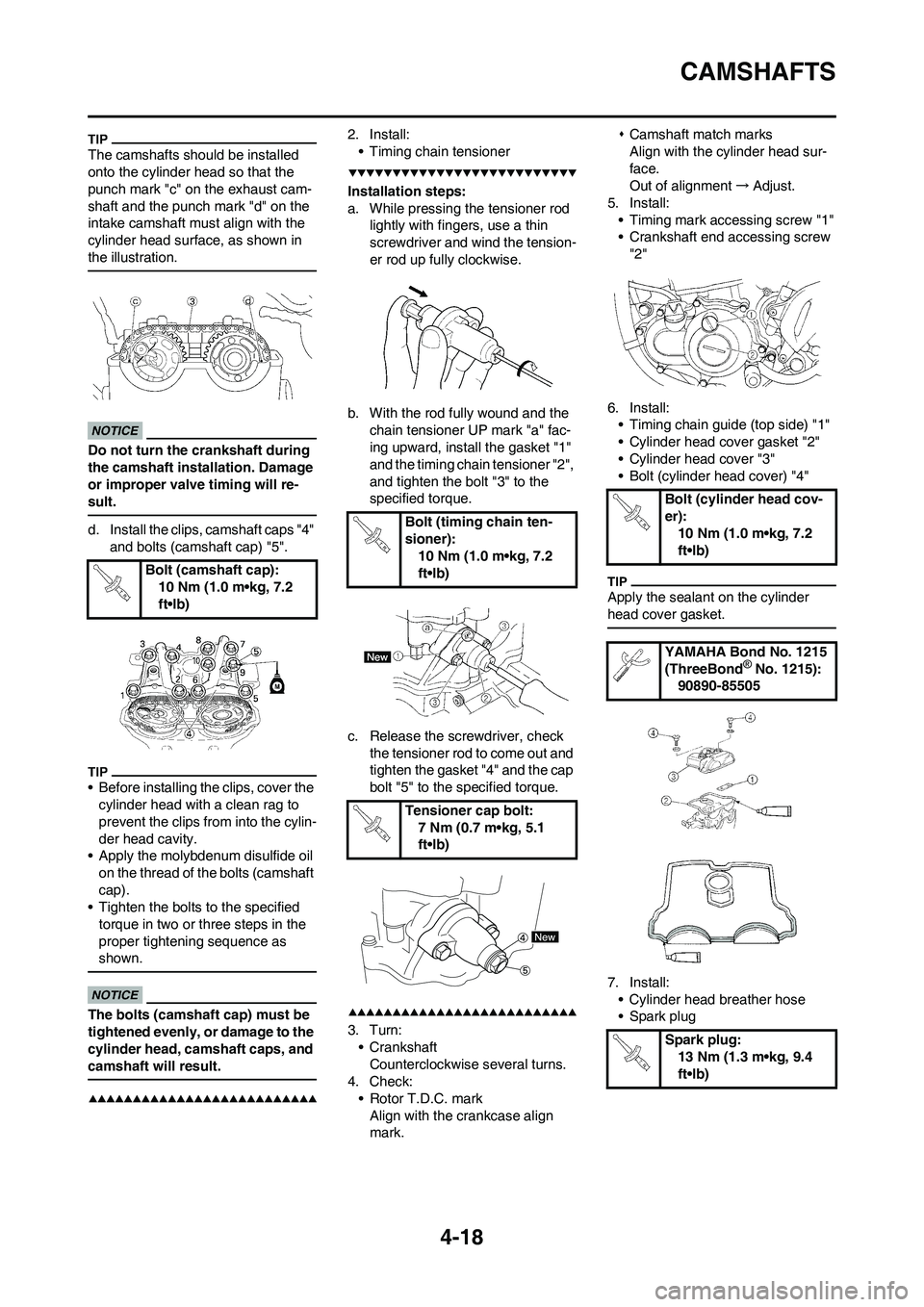

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the

cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil

on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:

• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the

chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check

the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Rotor T.D.C. mark

Align with the crankcase align

mark.�ŒCamshaft match marks

Align with the cylinder head sur-

face.

Out of alignment→Adjust.

5. Install:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

6. Install:

• Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:

• Cylinder head breather hose

• Spark plug Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er):

10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Page 90 of 190

4-20

CYLINDER HEAD

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

•Valve seats

2. Inspect:

• Cylinder head

Scratches/damage→Replace.

3. Measure:

• Cylinder head warpage

Out of specification→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Dowel pin "1"

• Cylinder head gasket "2"

• Timing chain guide (exhaust side)

"3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

•Washer "1"

• Cable guide "2"

• Bolts [L = 145 mm (5.71 in)] "3"

• Bolts [L = 135 mm (5.31 in)] "4"

•Nuts "5"

• Apply the molybdenum disulfide

grease on the thread and contact

surface of the bolts.

• Follow the numerical order shown

in the illustration. Tighten the bolts

and nuts in two stages.

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

4. Install:

• Radiator pipe "1"

• Bolt (radiator pipe) "2" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts [L = 145 mm (5.71

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolts [L = 135 mm (5.31

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Nuts:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 91 of 190

4-21

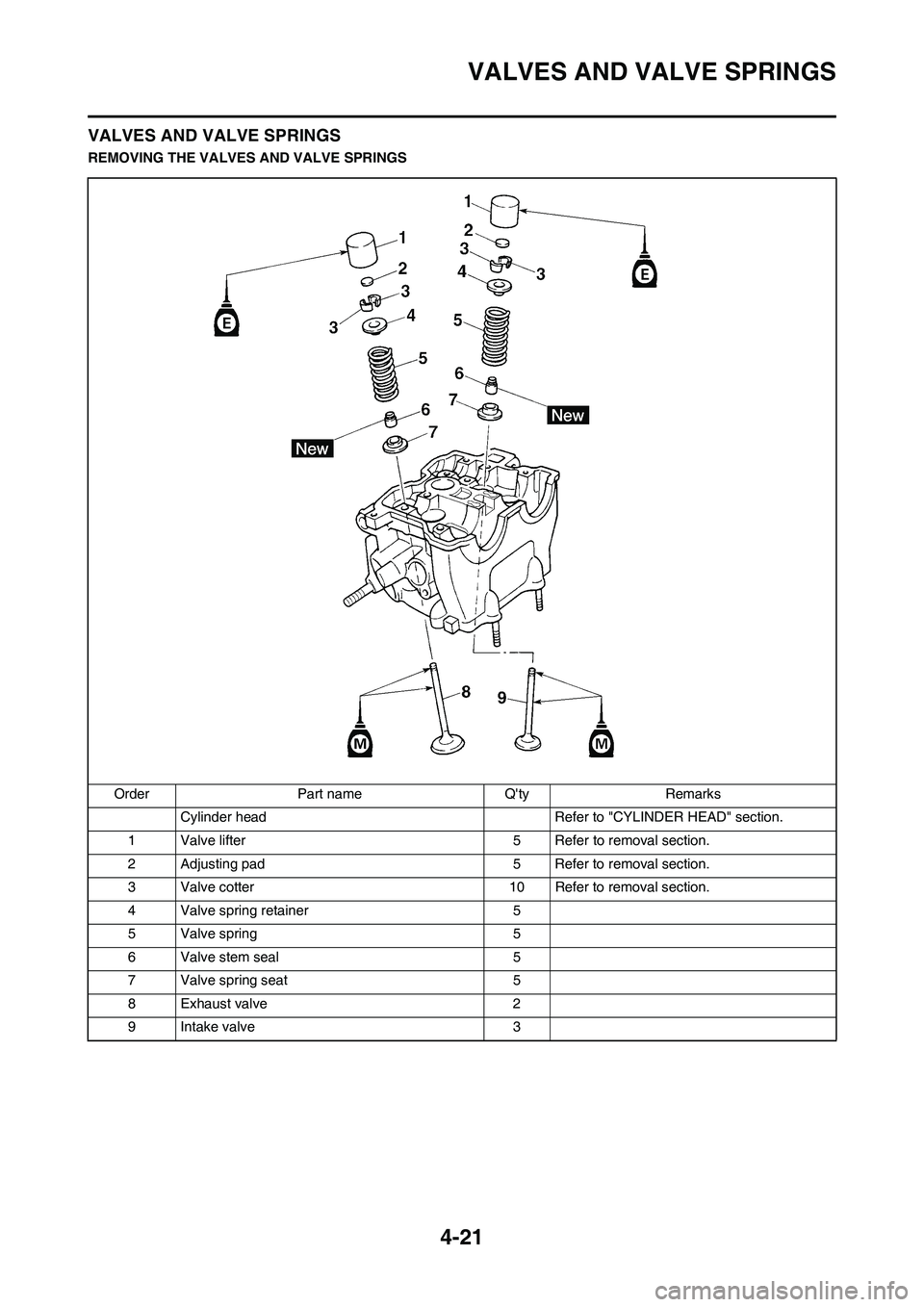

VALVES AND VALVE SPRINGS

VALVES AND VALVE SPRINGS

REMOVING THE VALVES AND VALVE SPRINGS

Order Part name Q'ty Remarks

Cylinder head Refer to "CYLINDER HEAD" section.

1 Valve lifter 5 Refer to removal section.

2 Adjusting pad 5 Refer to removal section.

3 Valve cotter 10 Refer to removal section.

4 Valve spring retainer 5

5 Valve spring 5

6 Valve stem seal 5

7 Valve spring seat 5

8 Exhaust valve 2

9 Intake valve 3

Page 92 of 190

4-22

VALVES AND VALVE SPRINGS

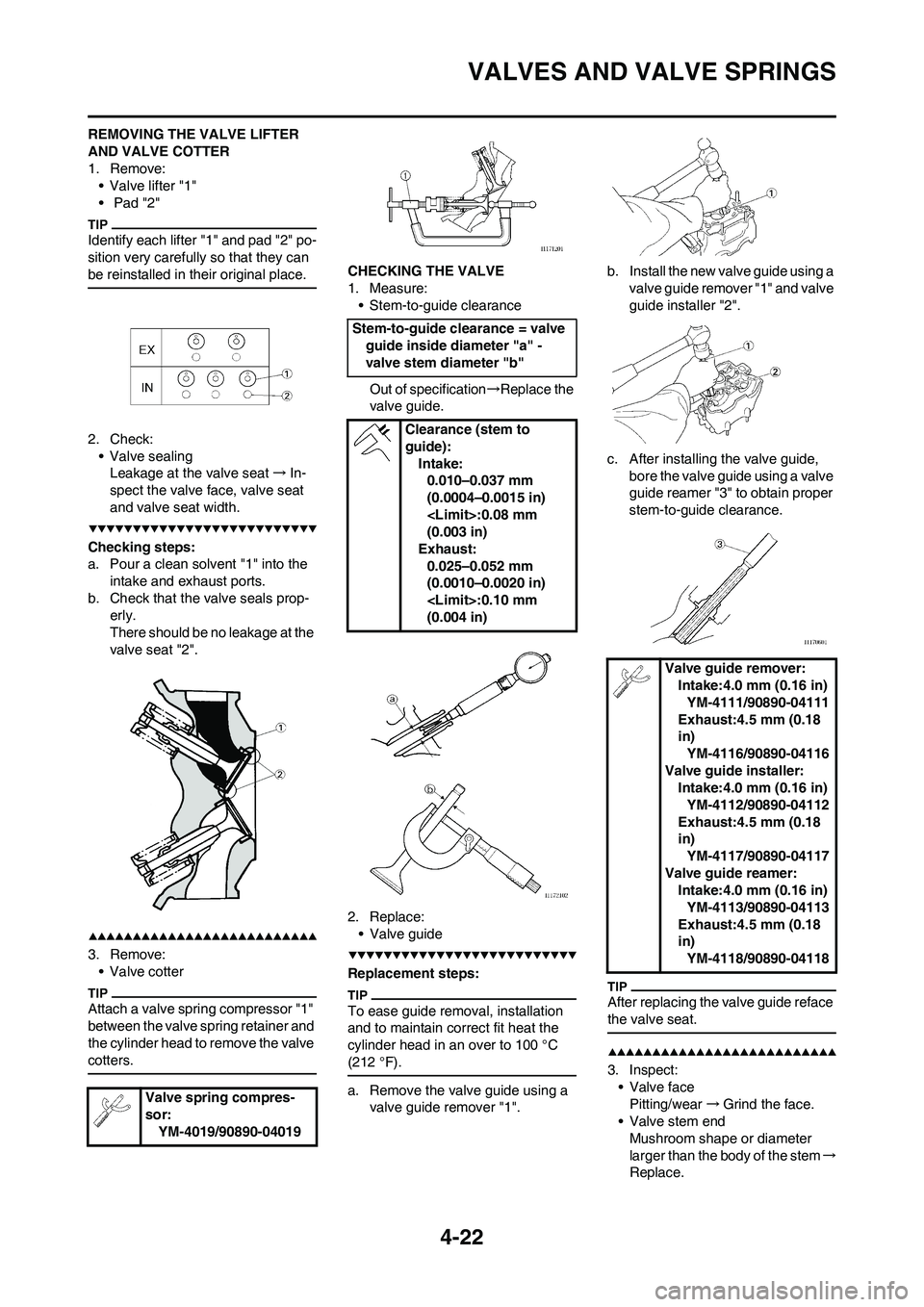

REMOVING THE VALVE LIFTER

AND VALVE COTTER

1. Remove:

• Valve lifter "1"

• Pad "2"

Identify each lifter "1" and pad "2" po-

sition very carefully so that they can

be reinstalled in their original place.

2. Check:

•Valve sealing

Leakage at the valve seat→In-

spect the valve face, valve seat

and valve seat width.

Checking steps:

a. Pour a clean solvent "1" into the

intake and exhaust ports.

b. Check that the valve seals prop-

erly.

There should be no leakage at the

valve seat "2".

3. Remove:

• Valve cotter

Attach a valve spring compressor "1"

between the valve spring retainer and

the cylinder head to remove the valve

cotters.

CHECKING THE VALVE

1. Measure:

• Stem-to-guide clearance

Out of specification→Replace the

valve guide.

2. Replace:

• Valve guide

Replacement steps:

To ease guide removal, installation

and to maintain correct fit heat the

cylinder head in an over to 100 °C

(212 °F).

a. Remove the valve guide using a

valve guide remover "1".b. Install the new valve guide using a

valve guide remover "1" and valve

guide installer "2".

c. After installing the valve guide,

bore the valve guide using a valve

guide reamer "3" to obtain proper

stem-to-guide clearance.

After replacing the valve guide reface

the valve seat.

3. Inspect:

• Valve face

Pitting/wear→Grind the face.

• Valve stem end

Mushroom shape or diameter

larger than the body of the stem→

Replace. Valve spring compres-

sor:

YM-4019/90890-04019

Stem-to-guide clearance = valve

guide inside diameter "a" -

valve stem diameter "b"

Clearance (stem to

guide):

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

(0.003 in)

Exhaust:

0.025–0.052 mm

(0.0010–0.0020 in)

(0.004 in)

Valve guide remover:

Intake:4.0 mm (0.16 in)

YM-4111/90890-04111

Exhaust:4.5 mm (0.18

in)

YM-4116/90890-04116

Valve guide installer:

Intake:4.0 mm (0.16 in)

YM-4112/90890-04112

Exhaust:4.5 mm (0.18

in)

YM-4117/90890-04117

Valve guide reamer:

Intake:4.0 mm (0.16 in)

YM-4113/90890-04113

Exhaust:4.5 mm (0.18

in)

YM-4118/90890-04118

Page 93 of 190

4-23

VALVES AND VALVE SPRINGS

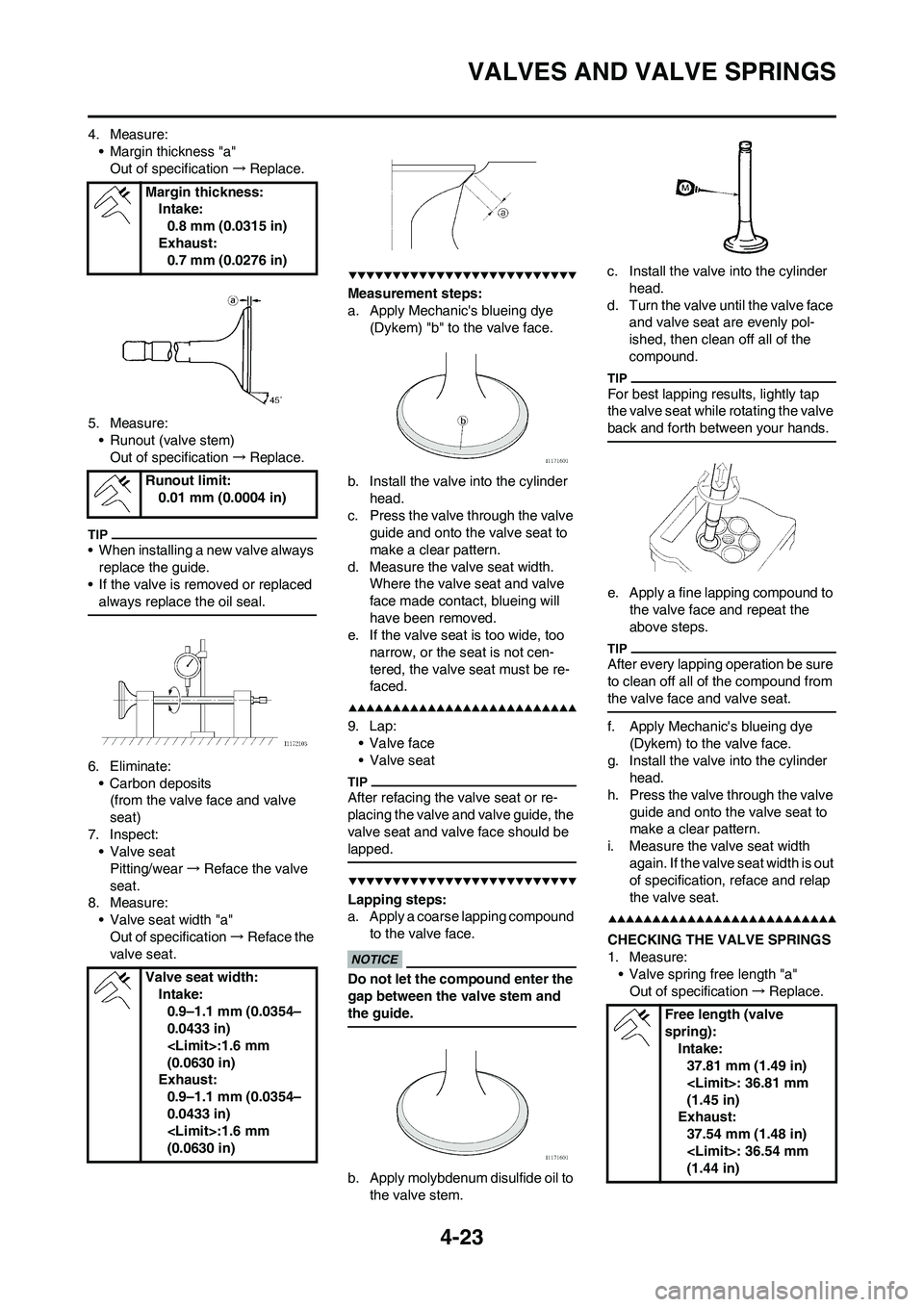

4. Measure:

• Margin thickness "a"

Out of specification→Replace.

5. Measure:

• Runout (valve stem)

Out of specification→Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

•Valve seat

Pitting/wear→Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification→Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be re-

faced.

9. Lap:

• Valve face

• Valve seat

After refacing the valve seat or re-

placing the valve and valve guide, the

valve seat and valve face should be

lapped.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace. Margin thickness:

Intake:

0.8 mm (0.0315 in)

Exhaust:

0.7 mm (0.0276 in)

Runout limit:

0.01 mm (0.0004 in)

Valve seat width:

Intake:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Exhaust:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Free length (valve

spring):

Intake:

37.81 mm (1.49 in)

(1.45 in)

Exhaust:

37.54 mm (1.48 in)

(1.44 in)

Page 94 of 190

4-24

VALVES AND VALVE SPRINGS

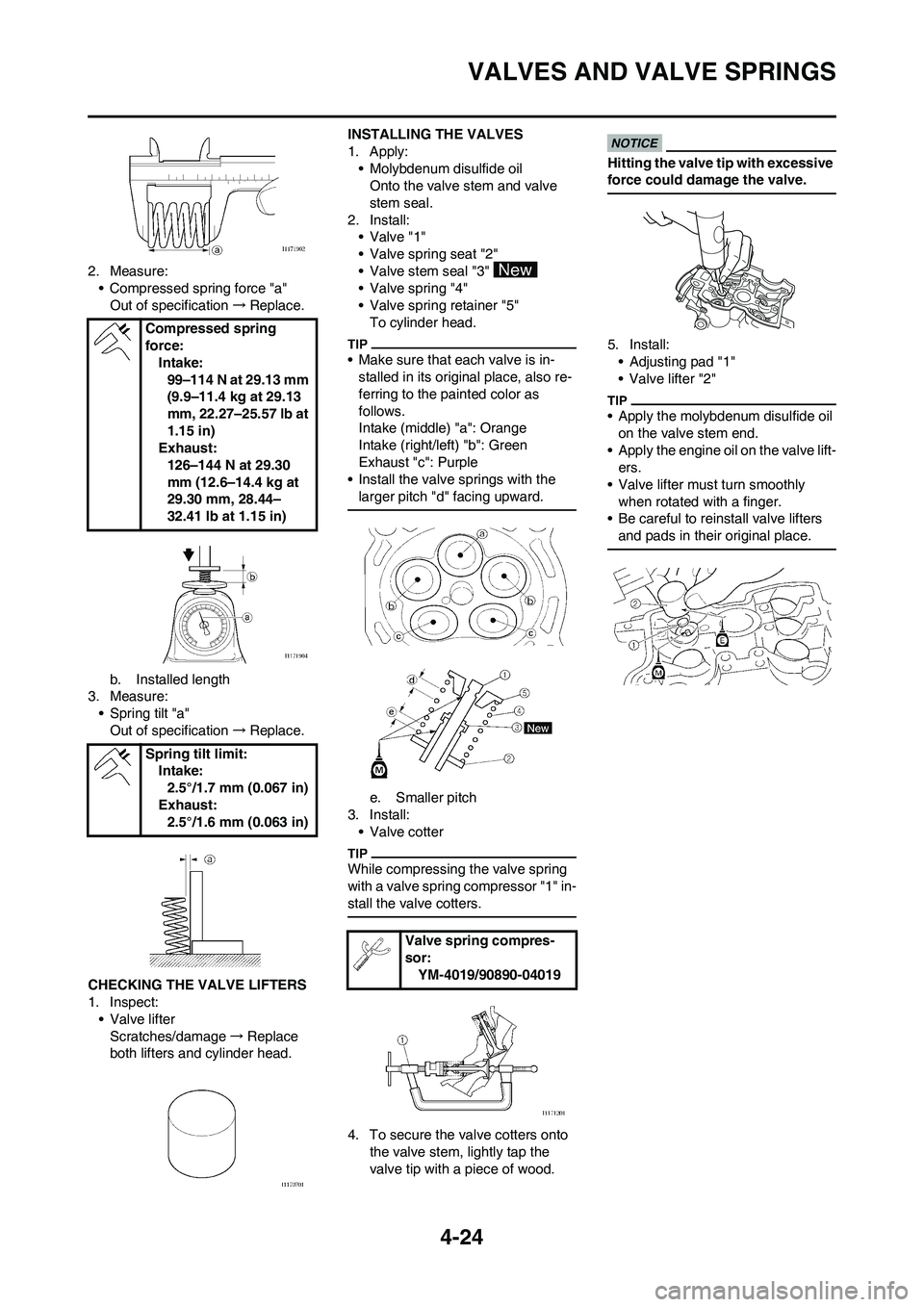

2. Measure:

• Compressed spring force "a"

Out of specification→Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification→Replace.

CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

•Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"

To cylinder head.

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch

3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Compressed spring

force:

Intake:

99–114 N at 29.13 mm

(9.9–11.4 kg at 29.13

mm, 22.27–25.57 lb at

1.15 in)

Exhaust:

126–144 N at 29.30

mm (12.6–14.4 kg at

29.30 mm, 28.44–

32.41 lb at 1.15 in)

Spring tilt limit:

Intake:

2.5°/1.7 mm (0.067 in)

Exhaust:

2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 148 of 190

5-17

FRONT FORK

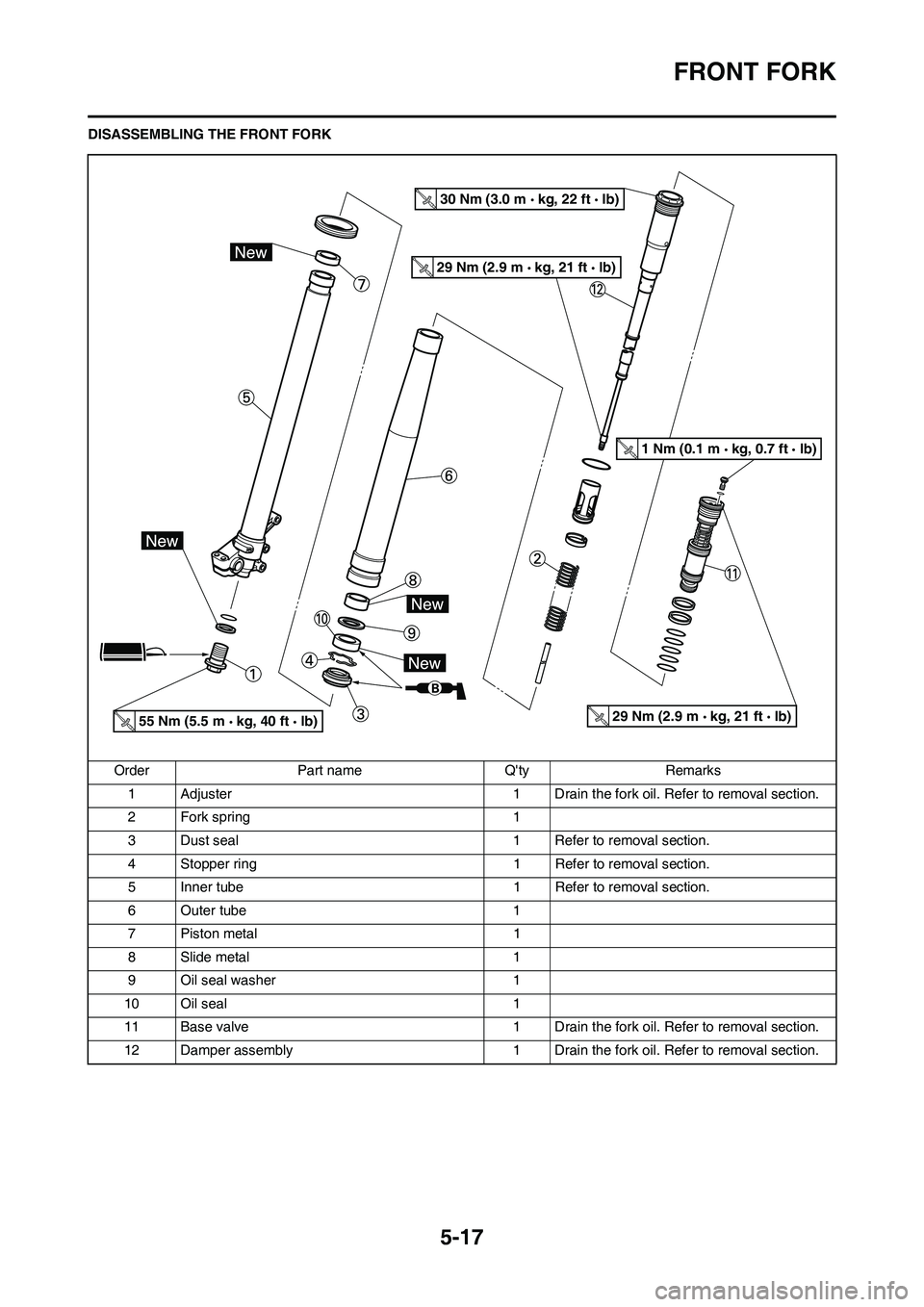

DISASSEMBLING THE FRONT FORK

Order Part name Q'ty Remarks

1 Adjuster 1 Drain the fork oil. Refer to removal section.

2 Fork spring 1

3 Dust seal 1 Refer to removal section.

4 Stopper ring 1 Refer to removal section.

5 Inner tube 1 Refer to removal section.

6 Outer tube 1

7 Piston metal 1

8 Slide metal 1

9 Oil seal washer 1

10 Oil seal 1

11 Base valve 1 Drain the fork oil. Refer to removal section.

12 Damper assembly 1 Drain the fork oil. Refer to removal section.

30 Nm (3.0 m kg, 22 ft lb)

29 Nm (2.9 m kg, 21 ft lb)

29 Nm (2.9 m kg, 21 ft lb)

1 Nm (0.1 m kg, 0.7 ft lb)

55 Nm (5.5 m kg, 40 ft lb)

Page 149 of 190

5-18

FRONT FORK

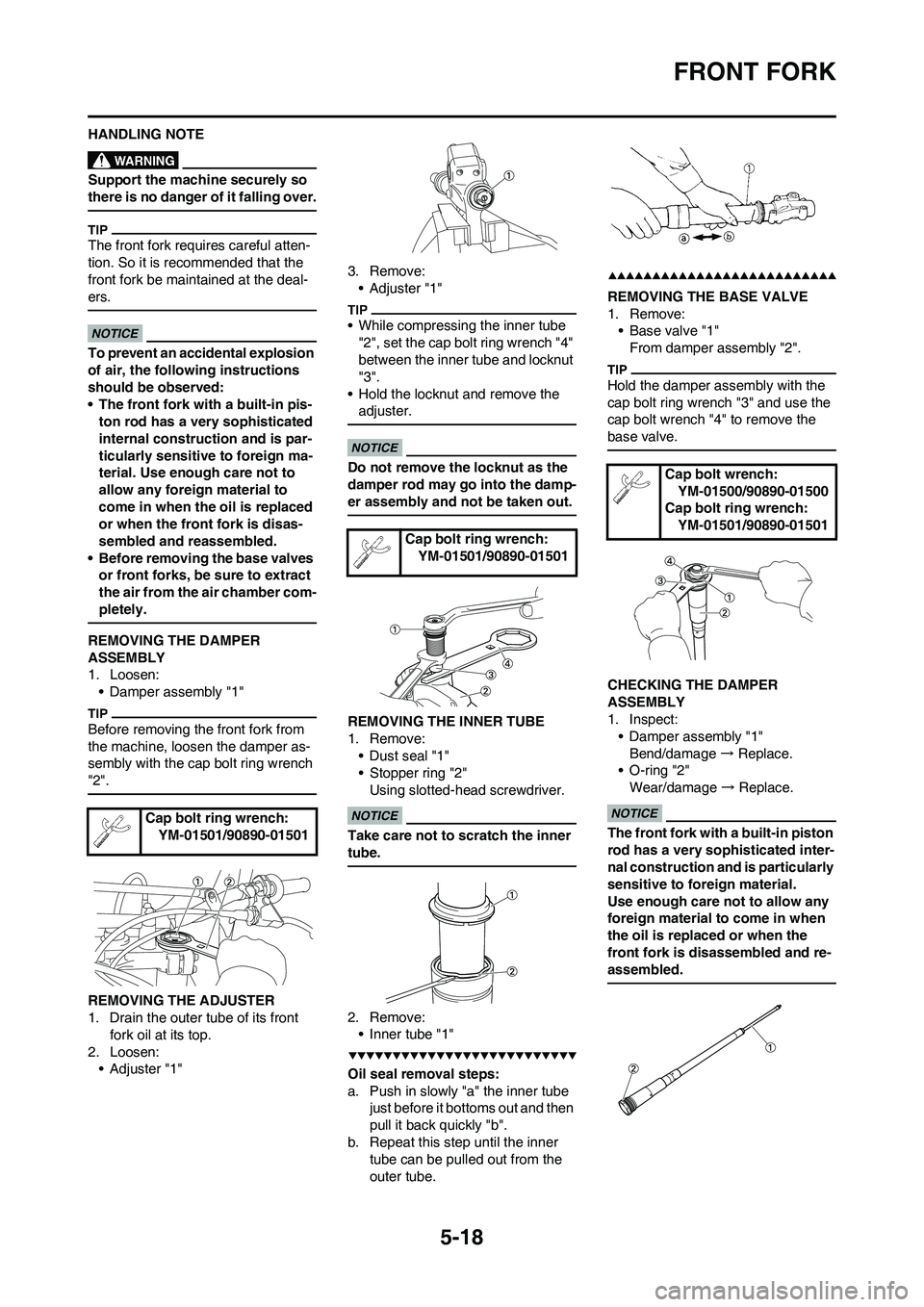

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

The front fork requires careful atten-

tion. So it is recommended that the

front fork be maintained at the deal-

ers.

To prevent an accidental explosion

of air, the following instructions

should be observed:

• The front fork with a built-in pis-

ton rod has a very sophisticated

internal construction and is par-

ticularly sensitive to foreign ma-

terial. Use enough care not to

allow any foreign material to

come in when the oil is replaced

or when the front fork is disas-

sembled and reassembled.

• Before removing the base valves

or front forks, be sure to extract

the air from the air chamber com-

pletely.

REMOVING THE DAMPER

ASSEMBLY

1. Loosen:

• Damper assembly "1"

Before removing the front fork from

the machine, loosen the damper as-

sembly with the cap bolt ring wrench

"2".

REMOVING THE ADJUSTER

1. Drain the outer tube of its front

fork oil at its top.

2. Loosen:

•Adjuster "1"3. Remove:

• Adjuster "1"

• While compressing the inner tube

"2", set the cap bolt ring wrench "4"

between the inner tube and locknut

"3".

• Hold the locknut and remove the

adjuster.

Do not remove the locknut as the

damper rod may go into the damp-

er assembly and not be taken out.

REMOVING THE INNER TUBE

1. Remove:

• Dust seal "1"

• Stopper ring "2"

Using slotted-head screwdriver.

Take care not to scratch the inner

tube.

2. Remove:

• Inner tube "1"

Oil seal removal steps:

a. Push in slowly "a" the inner tube

just before it bottoms out and then

pull it back quickly "b".

b. Repeat this step until the inner

tube can be pulled out from the

outer tube.

REMOVING THE BASE VALVE

1. Remove:

• Base valve "1"

From damper assembly "2".

Hold the damper assembly with the

cap bolt ring wrench "3" and use the

cap bolt wrench "4" to remove the

base valve.

CHECKING THE DAMPER

ASSEMBLY

1. Inspect:

• Damper assembly "1"

Bend/damage → Replace.

• O-ring "2"

Wear/damage → Replace.

The front fork with a built-in piston

rod has a very sophisticated inter-

nal construction and is particularly

sensitive to foreign material.

Use enough care not to allow any

foreign material to come in when

the oil is replaced or when the

front fork is disassembled and re-

assembled.Cap bolt ring wrench:

YM-01501/90890-01501

Cap bolt ring wrench:

YM-01501/90890-01501

Cap bolt wrench:

YM-01500/90890-01500

Cap bolt ring wrench:

YM-01501/90890-01501

Page 150 of 190

5-19

FRONT FORK

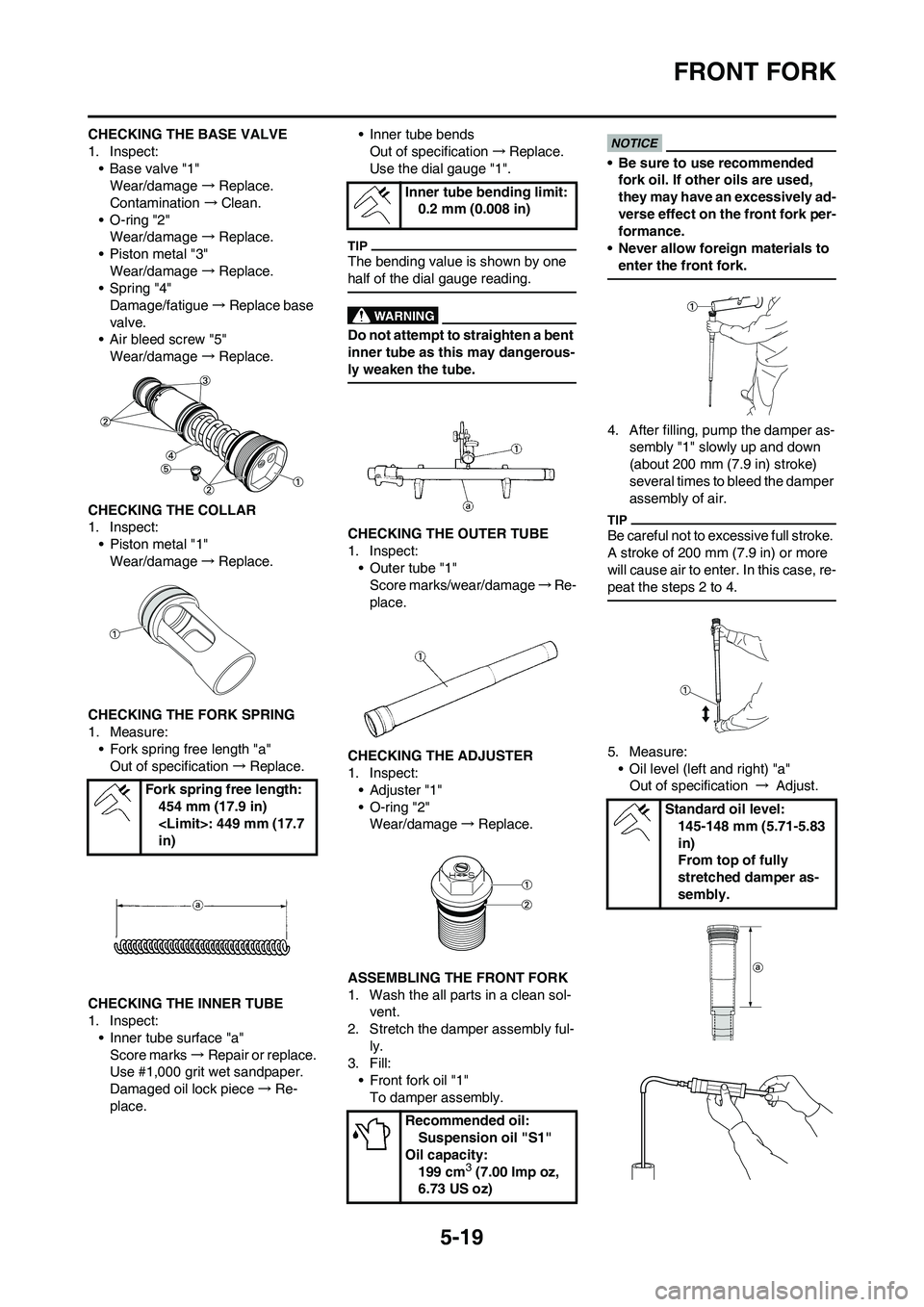

CHECKING THE BASE VALVE

1. Inspect:

• Base valve "1"

Wear/damage →Replace.

Contamination →Clean.

• O-ring "2"

Wear/damage →Replace.

• Piston metal "3"

Wear/damage →Replace.

• Spring "4"

Damage/fatigue →Replace base

valve.

• Air bleed screw "5"

Wear/damage →Replace.

CHECKING THE COLLAR

1. Inspect:

• Piston metal "1"

Wear/damage→Replace.

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification→Replace.

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks→Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece→Re-

place.• Inner tube bends

Out of specification→Replace.

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

inner tube as this may dangerous-

ly weaken the tube.

CHECKING THE OUTER TUBE

1. Inspect:

• Outer tube "1"

Score marks/wear/damage→Re-

place.

CHECKING THE ADJUSTER

1. Inspect:

• Adjuster "1"

• O-ring "2"

Wear/damage→Replace.

ASSEMBLING THE FRONT FORK

1. Wash the all parts in a clean sol-

vent.

2. Stretch the damper assembly ful-

ly.

3. Fill:

• Front fork oil "1"

To damper assembly.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

4. After filling, pump the damper as-

sembly "1" slowly up and down

(about 200 mm (7.9 in) stroke)

several times to bleed the damper

assembly of air.

Be careful not to excessive full stroke.

A stroke of 200 mm (7.9 in) or more

will cause air to enter. In this case, re-

peat the steps 2 to 4.

5. Measure:

• Oil level (left and right) "a"

Out of specification → Adjust.

Fork spring free length:

454 mm (17.9 in)

in)

Inner tube bending limit:

0.2 mm (0.008 in)

Recommended oil:

Suspension oil "S1"

Oil capacity:

199 cm

3 (7.00 Imp oz,

6.73 US oz)

Standard oil level:

145-148 mm (5.71-5.83

in)

From top of fully

stretched damper as-

sembly.