valve YAMAHA YZ250F 2009 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 151 of 190

5-20

FRONT FORK

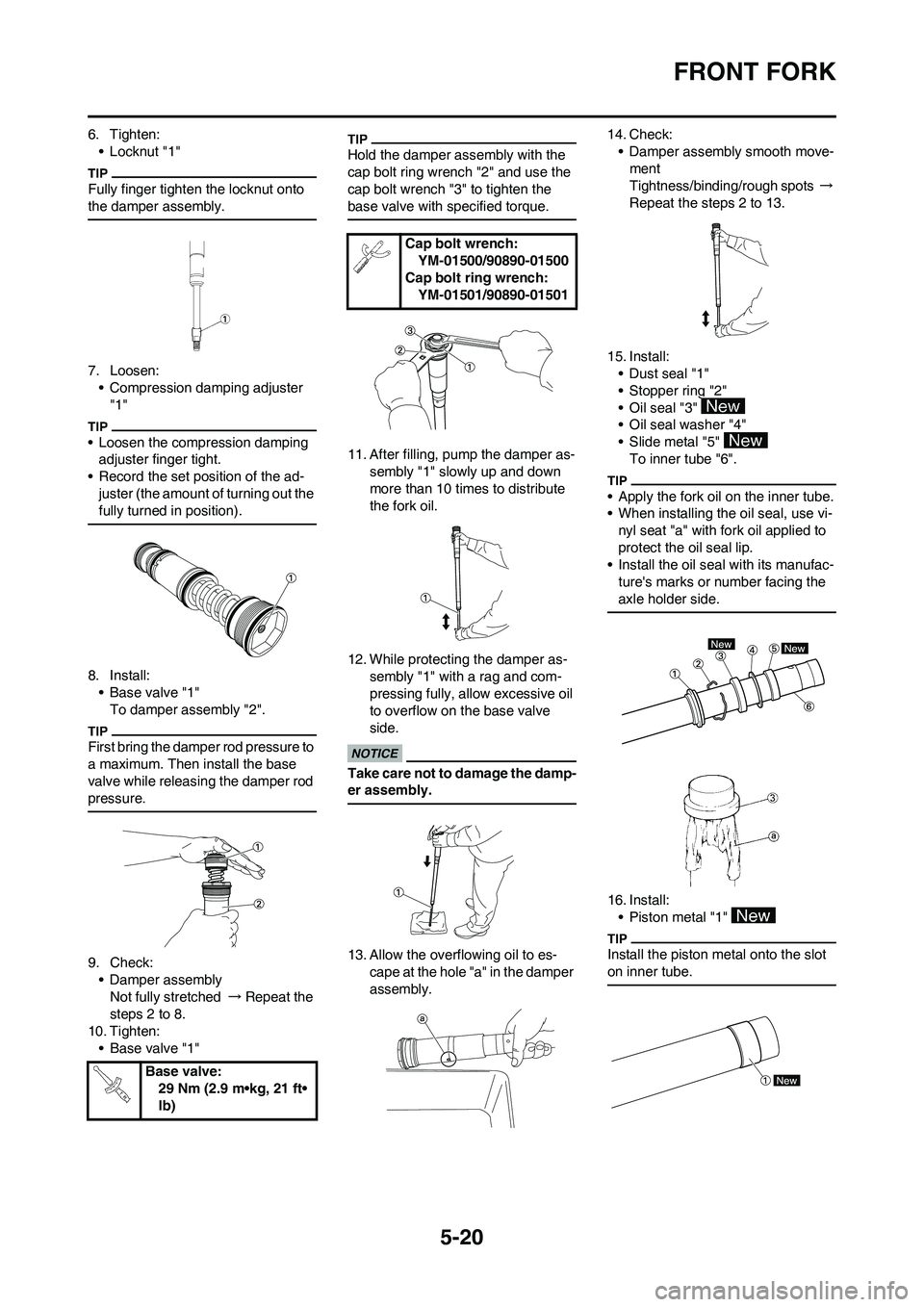

6. Tighten:

• Locknut "1"

Fully finger tighten the locknut onto

the damper assembly.

7. Loosen:

• Compression damping adjuster

"1"

• Loosen the compression damping

adjuster finger tight.

• Record the set position of the ad-

juster (the amount of turning out the

fully turned in position).

8. Install:

• Base valve "1"

To damper assembly "2".

First bring the damper rod pressure to

a maximum. Then install the base

valve while releasing the damper rod

pressure.

9. Check:

• Damper assembly

Not fully stretched → Repeat the

steps 2 to 8.

10. Tighten:

• Base valve "1"

Hold the damper assembly with the

cap bolt ring wrench "2" and use the

cap bolt wrench "3" to tighten the

base valve with specified torque.

11. After filling, pump the damper as-

sembly "1" slowly up and down

more than 10 times to distribute

the fork oil.

12. While protecting the damper as-

sembly "1" with a rag and com-

pressing fully, allow excessive oil

to overflow on the base valve

side.

Take care not to damage the damp-

er assembly.

13. Allow the overflowing oil to es-

cape at the hole "a" in the damper

assembly.14. Check:

• Damper assembly smooth move-

ment

Tightness/binding/rough spots →

Repeat the steps 2 to 13.

15. Install:

• Dust seal "1"

• Stopper ring "2"

•Oil seal "3"

• Oil seal washer "4"

• Slide metal "5"

To inner tube "6".

• Apply the fork oil on the inner tube.

• When installing the oil seal, use vi-

nyl seat "a" with fork oil applied to

protect the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or number facing the

axle holder side.

16. Install:

• Piston metal "1"

Install the piston metal onto the slot

on inner tube.

Base valve:

29 Nm (2.9 m•kg, 21 ft•

lb)

Cap bolt wrench:

YM-01500/90890-01500

Cap bolt ring wrench:

YM-01501/90890-01501

Page 152 of 190

5-21

FRONT FORK

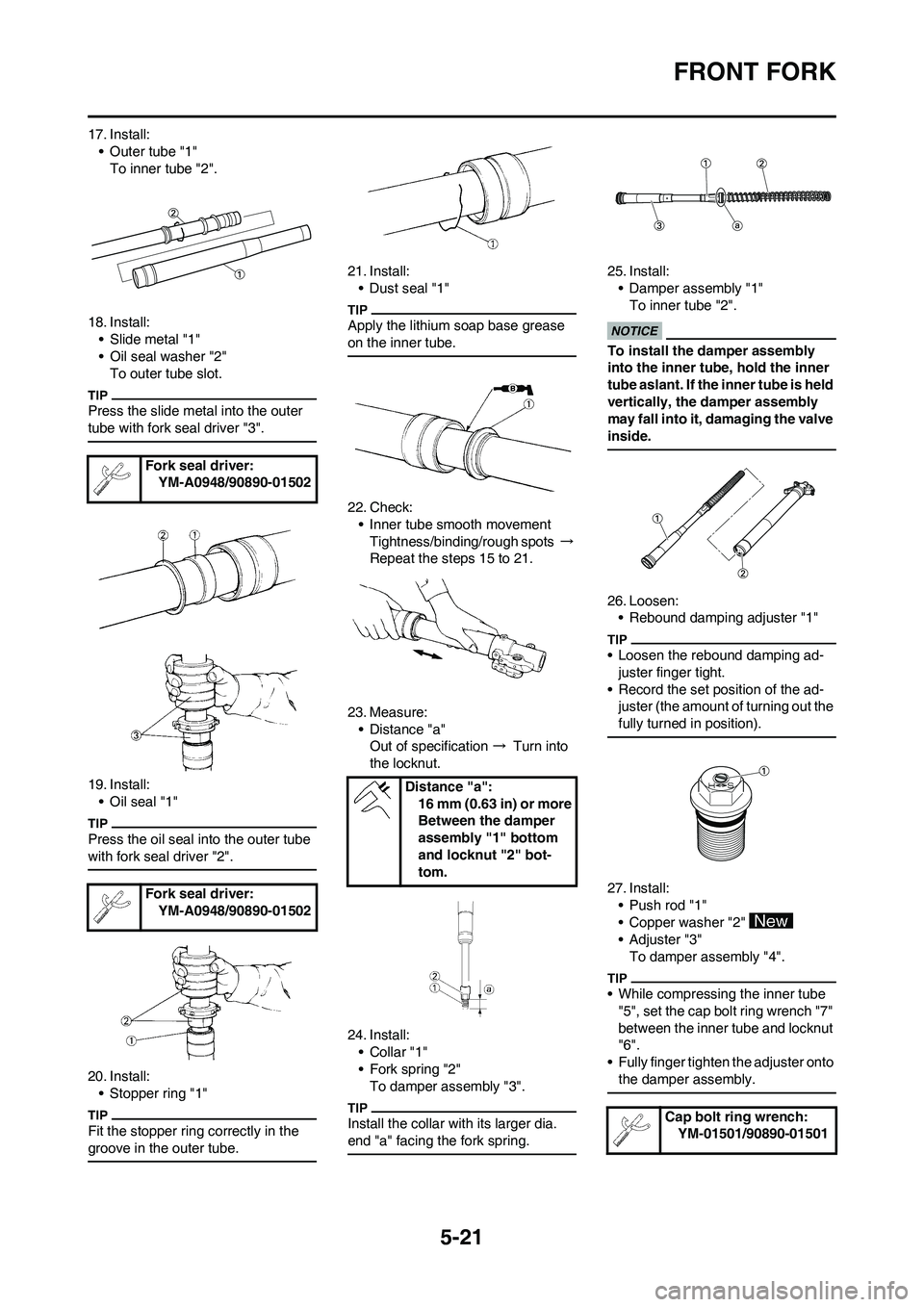

17. Install:

• Outer tube "1"

To inner tube "2".

18. Install:

• Slide metal "1"

• Oil seal washer "2"

To outer tube slot.

Press the slide metal into the outer

tube with fork seal driver "3".

19. Install:

•Oil seal "1"

Press the oil seal into the outer tube

with fork seal driver "2".

20. Install:

• Stopper ring "1"

Fit the stopper ring correctly in the

groove in the outer tube.

21. Install:

• Dust seal "1"

Apply the lithium soap base grease

on the inner tube.

22. Check:

• Inner tube smooth movement

Tightness/binding/rough spots →

Repeat the steps 15 to 21.

23. Measure:

• Distance "a"

Out of specification → Turn into

the locknut.

24. Install:

•Collar "1"

• Fork spring "2"

To damper assembly "3".

Install the collar with its larger dia.

end "a" facing the fork spring.

25. Install:

• Damper assembly "1"

To inner tube "2".

To install the damper assembly

into the inner tube, hold the inner

tube aslant. If the inner tube is held

vertically, the damper assembly

may fall into it, damaging the valve

inside.

26. Loosen:

• Rebound damping adjuster "1"

• Loosen the rebound damping ad-

juster finger tight.

• Record the set position of the ad-

juster (the amount of turning out the

fully turned in position).

27. Install:

• Push rod "1"

• Copper washer "2"

•Adjuster "3"

To damper assembly "4".

• While compressing the inner tube

"5", set the cap bolt ring wrench "7"

between the inner tube and locknut

"6".

• Fully finger tighten the adjuster onto

the damper assembly.

Fork seal driver:

YM-A0948/90890-01502

Fork seal driver:

YM-A0948/90890-01502

Distance "a":

16 mm (0.63 in) or more

Between the damper

assembly "1" bottom

and locknut "2" bot-

tom.

Cap bolt ring wrench:

YM-01501/90890-01501

Page 168 of 190

5-37

REAR SHOCK ABSORBER

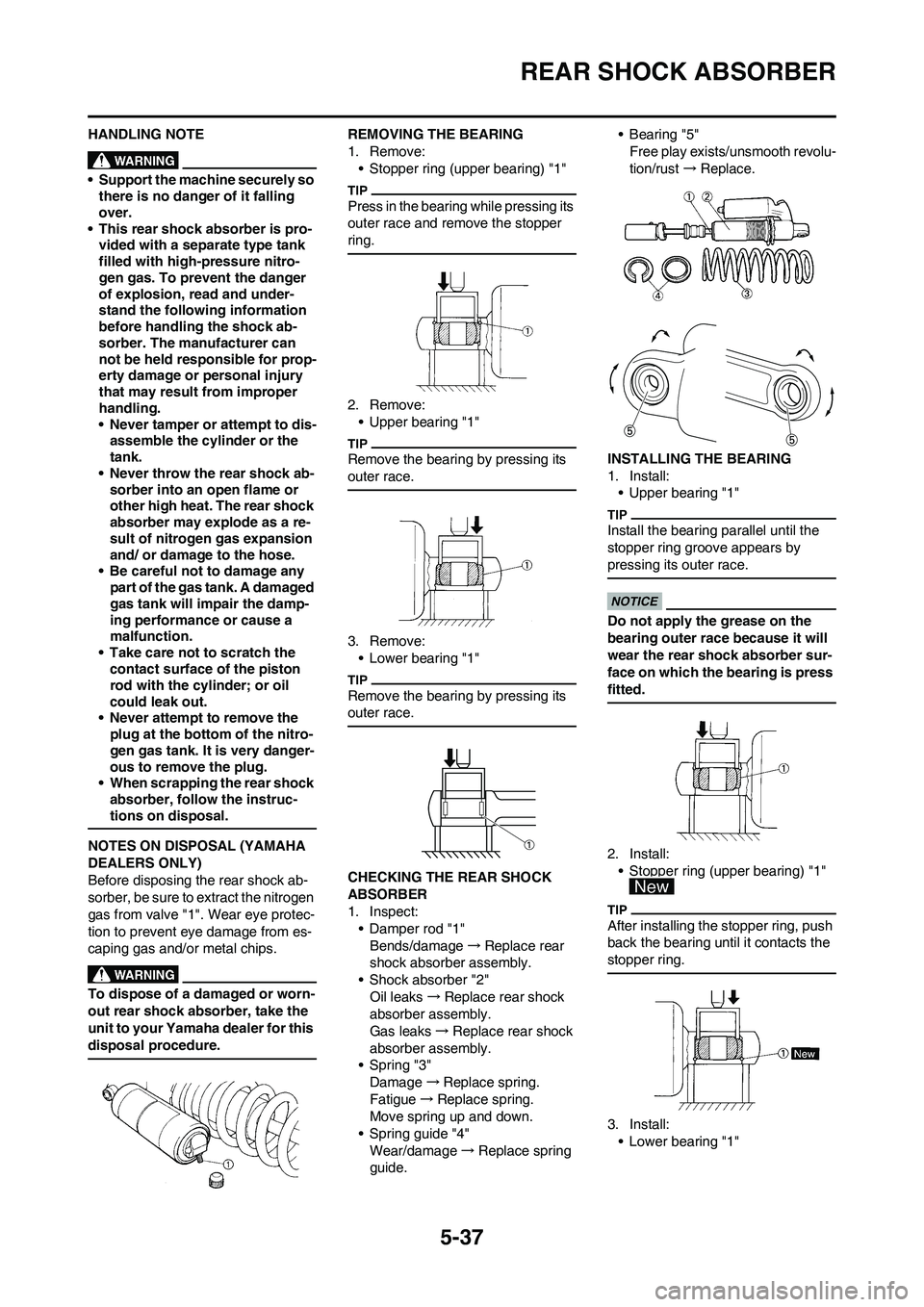

HANDLING NOTE

• Support the machine securely so

there is no danger of it falling

over.

• This rear shock absorber is pro-

vided with a separate type tank

filled with high-pressure nitro-

gen gas. To prevent the danger

of explosion, read and under-

stand the following information

before handling the shock ab-

sorber. The manufacturer can

not be held responsible for prop-

erty damage or personal injury

that may result from improper

handling.

• Never tamper or attempt to dis-

assemble the cylinder or the

tank.

• Never throw the rear shock ab-

sorber into an open flame or

other high heat. The rear shock

absorber may explode as a re-

sult of nitrogen gas expansion

and/ or damage to the hose.

• Be careful not to damage any

part of the gas tank. A damaged

gas tank will impair the damp-

ing performance or cause a

malfunction.

• Take care not to scratch the

contact surface of the piston

rod with the cylinder; or oil

could leak out.

• Never attempt to remove the

plug at the bottom of the nitro-

gen gas tank. It is very danger-

ous to remove the plug.

• When scrapping the rear shock

absorber, follow the instruc-

tions on disposal.

NOTES ON DISPOSAL (YAMAHA

DEALERS ONLY)

Before disposing the rear shock ab-

sorber, be sure to extract the nitrogen

gas from valve "1". Wear eye protec-

tion to prevent eye damage from es-

caping gas and/or metal chips.

To dispose of a damaged or worn-

out rear shock absorber, take the

unit to your Yamaha dealer for this

disposal procedure.

REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) "1"

Press in the bearing while pressing its

outer race and remove the stopper

ring.

2. Remove:

• Upper bearing "1"

Remove the bearing by pressing its

outer race.

3. Remove:

• Lower bearing "1"

Remove the bearing by pressing its

outer race.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Damper rod "1"

Bends/damage→Replace rear

shock absorber assembly.

• Shock absorber "2"

Oil leaks→Replace rear shock

absorber assembly.

Gas leaks→Replace rear shock

absorber assembly.

• Spring "3"

Damage→Replace spring.

Fatigue→Replace spring.

Move spring up and down.

• Spring guide "4"

Wear/damage→Replace spring

guide.• Bearing "5"

Free play exists/unsmooth revolu-

tion/rust →Replace.

INSTALLING THE BEARING

1. Install:

• Upper bearing "1"

Install the bearing parallel until the

stopper ring groove appears by

pressing its outer race.

Do not apply the grease on the

bearing outer race because it will

wear the rear shock absorber sur-

face on which the bearing is press

fitted.

2. Install:

• Stopper ring (upper bearing) "1"

After installing the stopper ring, push

back the bearing until it contacts the

stopper ring.

3. Install:

• Lower bearing "1"

Page 178 of 190

7-1

ENGINE

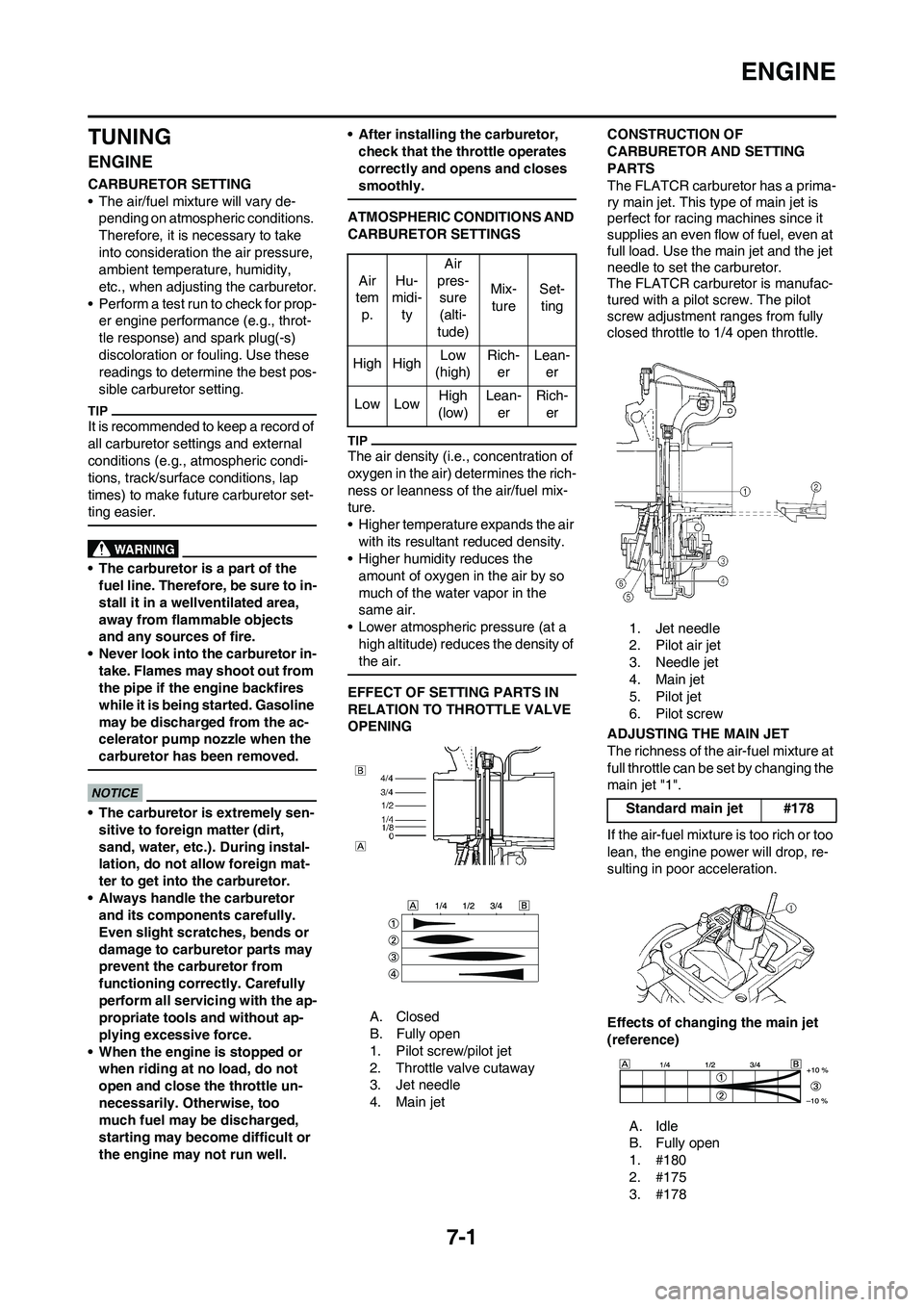

TUNING

ENGINE

CARBURETOR SETTING

• The air/fuel mixture will vary de-

pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop-

er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the

fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in-

take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-

sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor

and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or

when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well.• After installing the carburetor,

check that the throttle operates

correctly and opens and closes

smoothly.

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air

with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a

high altitude) reduces the density of

the air.

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot screw/pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jetCONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

The FLATCR carburetor is manufac-

tured with a pilot screw. The pilot

screw adjustment ranges from fully

closed throttle to 1/4 open throttle.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

6. Pilot screw

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #180

2. #175

3. #178 Air

tem

p.Hu-

midi-

tyAir

pres-

sure

(alti-

tude)Mix-

tureSet-

ting

High HighLow

(high)Rich-

erLean-

er

Low LowHigh

(low)Lean-

erRich-

er

Standard main jet #178

Page 182 of 190

7-5

ENGINE

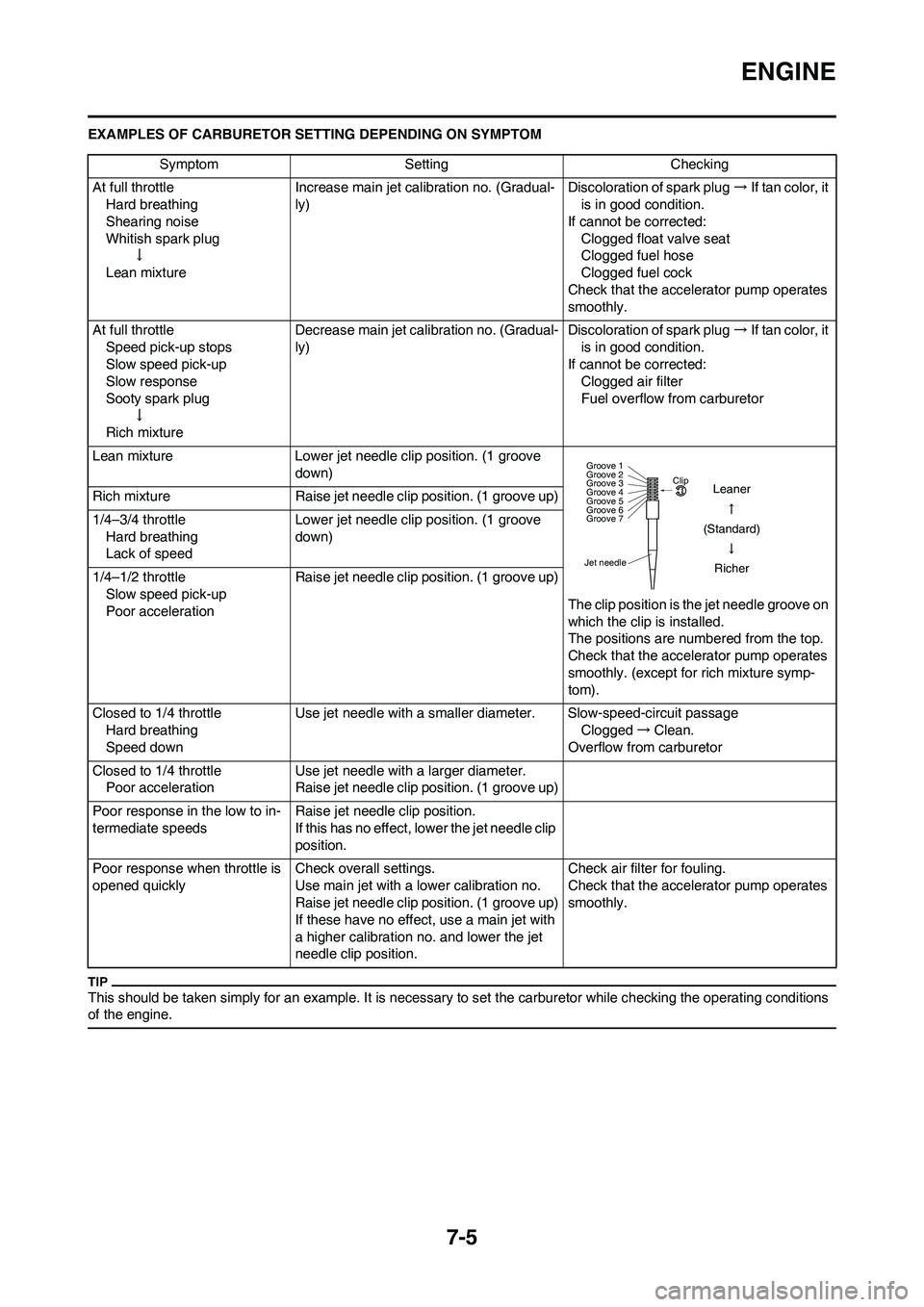

EXAMPLES OF CARBURETOR SETTING DEPENDING ON SYMPTOM

This should be taken simply for an example. It is necessary to set the carburetor while checking the operating conditions

of the engine.

Symptom Setting Checking

At full throttle

Hard breathing

Shearing noise

Whitish spark plug

↓

Lean mixtureIncrease main jet calibration no. (Gradual-

ly)Discoloration of spark plug→If tan color, it

is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

Check that the accelerator pump operates

smoothly.

At full throttle

Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug

↓

Rich mixtureDecrease main jet calibration no. (Gradual-

ly)Discoloration of spark plug→If tan color, it

is in good condition.

If cannot be corrected:

Clogged air filter

Fuel overflow from carburetor

Lean mixture Lower jet needle clip position. (1 groove

down)

The clip position is the jet needle groove on

which the clip is installed.

The positions are numbered from the top.

Check that the accelerator pump operates

smoothly. (except for rich mixture symp-

tom). Rich mixture Raise jet needle clip position. (1 groove up)

1/4–3/4 throttle

Hard breathing

Lack of speedLower jet needle clip position. (1 groove

down)

1/4–1/2 throttle

Slow speed pick-up

Poor accelerationRaise jet needle clip position. (1 groove up)

Closed to 1/4 throttle

Hard breathing

Speed downUse jet needle with a smaller diameter. Slow-speed-circuit passage

Clogged→Clean.

Overflow from carburetor

Closed to 1/4 throttle

Poor accelerationUse jet needle with a larger diameter.

Raise jet needle clip position. (1 groove up)

Poor response in the low to in-

termediate speedsRaise jet needle clip position.

If this has no effect, lower the jet needle clip

position.

Poor response when throttle is

opened quicklyCheck overall settings.

Use main jet with a lower calibration no.

Raise jet needle clip position. (1 groove up)

If these have no effect, use a main jet with

a higher calibration no. and lower the jet

needle clip position.Check air filter for fouling.

Check that the accelerator pump operates

smoothly.

Jet needleClip

Groove 7 Groove 6

Groove 5

Groove 4

Groove 3

Groove 2

Groove 1

Leaner

(Standard)

Richer