YAMAHA YZ250F 2010 Owners Manual

Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ250F, Model: YAMAHA YZ250F 2010Pages: 196, PDF Size: 13.74 MB

Page 121 of 196

4-47

KICK SHAFT AND SHIFT SHAFT

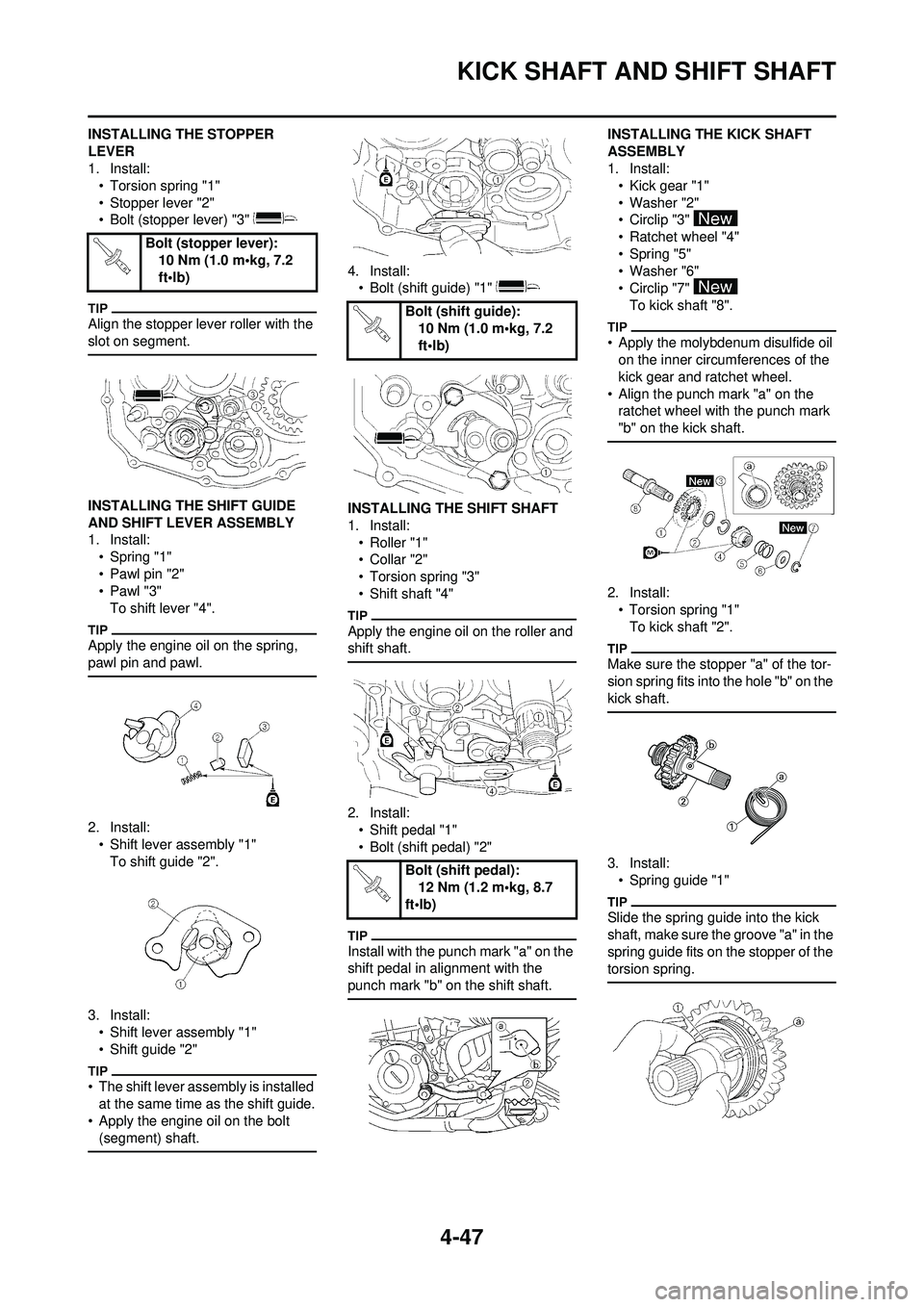

INSTALLING THE STOPPER

LEVER

1. Install:• Torsion spring "1"

• Stopper lever "2"

• Bolt (stopper lever) "3"

Align the stopper lever roller with the

slot on segment.

INSTALLING THE SHIFT GUIDE

AND SHIFT LEVER ASSEMBLY

1. Install:• Spring "1"

• Pawl pin "2"

•Pawl "3"To shift lever "4".

Apply the engine oil on the spring,

pawl pin and pawl.

2. Install:

• Shift lever assembly "1"To shift guide "2".

3. Install: • Shift lever assembly "1"

• Shift guide "2"

• The shift lever assembly is installed at the same time as the shift guide.

• Apply the engine oil on the bolt

(segment) shaft.

4. Install:• Bolt (shift guide) "1"

INSTALLING TH E SHIFT SHAFT

1. Install: • Roller "1"

• Collar "2"

• Torsion spring "3"

• Shift shaft "4"

Apply the engine oil on the roller and

shift shaft.

2. Install:• Shift pedal "1"

• Bolt (shift pedal) "2"

Install with the punch mark "a" on the

shift pedal in alignment with the

punch mark "b" on the shift shaft.

INSTALLING THE KICK SHAFT

ASSEMBLY

1. Install:• Kick gear "1"

• Washer "2"

• Circlip "3"

• Ratchet wheel "4"

• Spring "5"

• Washer "6"

• Circlip "7"

To kick shaft "8".

• Apply the molybdenum disulfide oil on the inner circumferences of the

kick gear and ratchet wheel.

• Align the punch mark "a" on the ratchet wheel with the punch mark

"b" on the kick shaft.

2. Install:• Torsion spring "1"To kick shaft "2".

Make sure the stopper "a" of the tor-

sion spring fits into the hole "b" on the

kick shaft.

3. Install:• Spring guide "1"

Slide the spring guide into the kick

shaft, make sure the groove "a" in the

spring guide fits on the stopper of the

torsion spring.

Bolt (stopper lever): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (shift guide):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (shift pedal): 12 Nm (1.2 m•kg, 8.7

ft•lb)

Page 122 of 196

4-48

KICK SHAFT AND SHIFT SHAFT

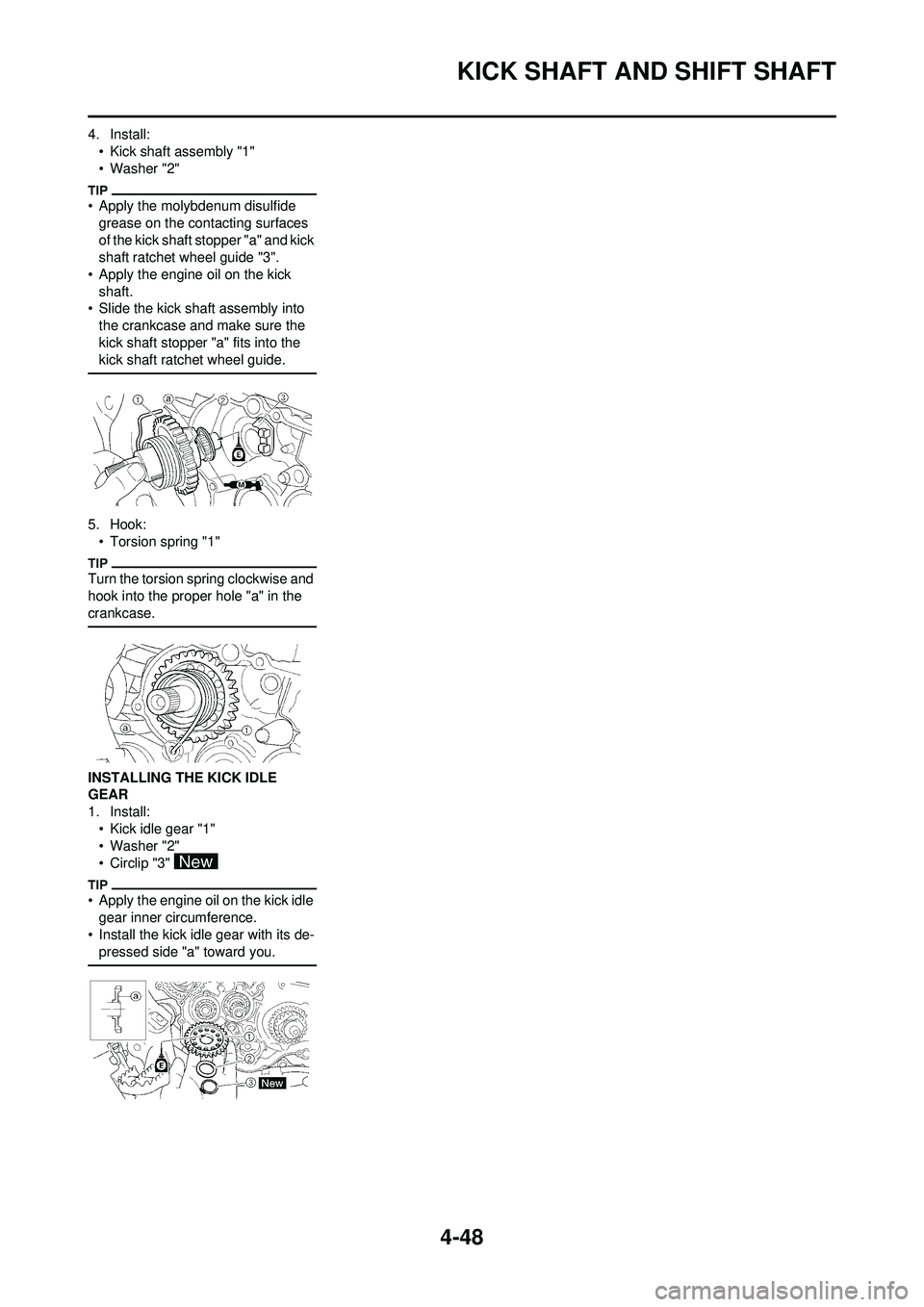

4. Install:• Kick shaft assembly "1"

• Washer "2"

• Apply the molybdenum disulfide grease on the contacting surfaces

of the kick shaft stopper "a" and kick

shaft ratchet wheel guide "3".

• Apply the engine oil on the kick

shaft.

• Slide the kick shaft assembly into the crankcase and make sure the

kick shaft stopper "a" fits into the

kick shaft ratchet wheel guide.

5. Hook:

• Torsion spring "1"

Turn the torsion spring clockwise and

hook into the proper hole "a" in the

crankcase.

INSTALLING THE KICK IDLE

GEAR

1. Install:• Kick idle gear "1"

• Washer "2"

• Circlip "3"

• Apply the engine oil on the kick idle gear inner circumference.

• Install the kick idle gear with its de-

pressed side "a " toward you.

Page 123 of 196

4-49

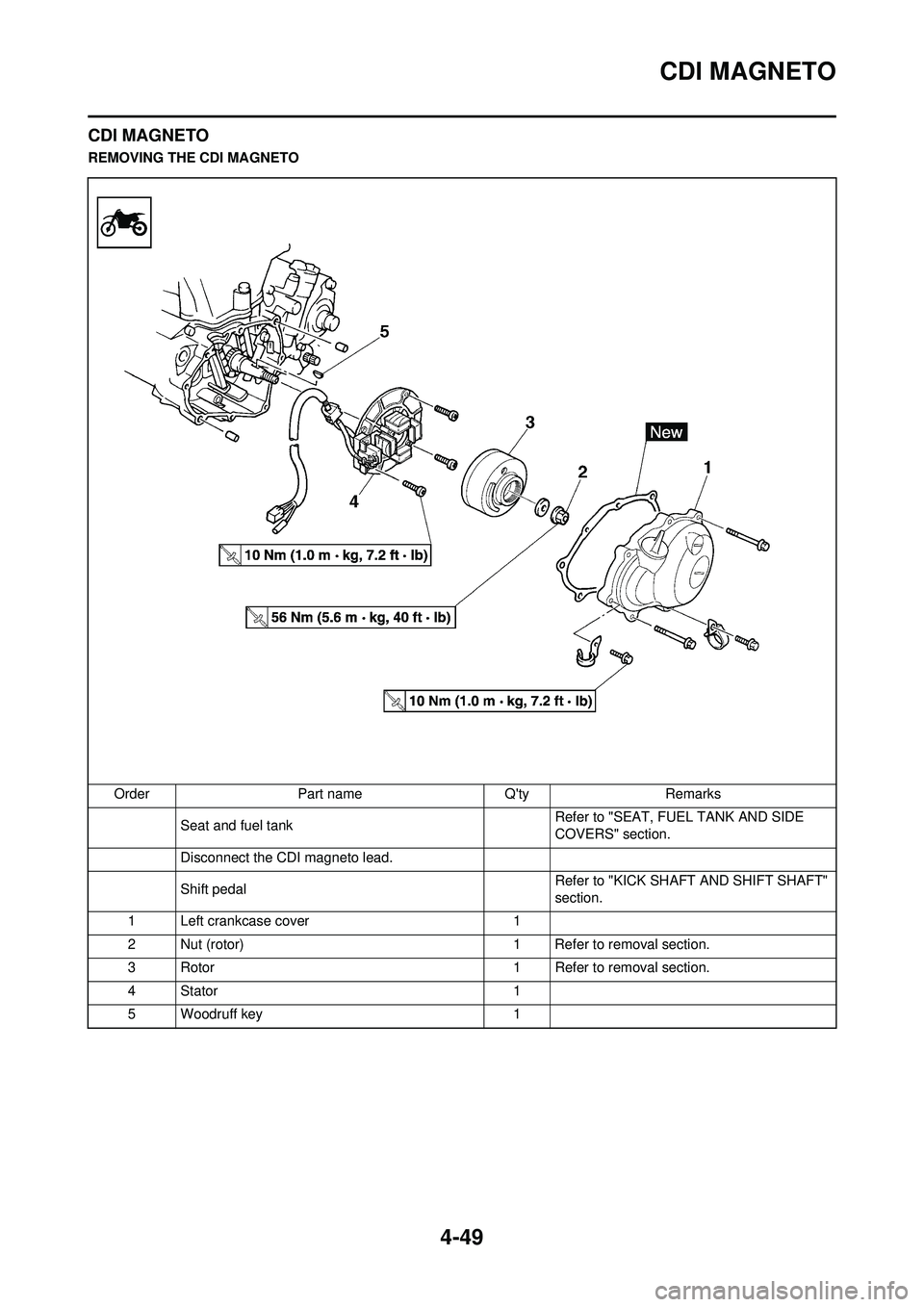

CDI MAGNETO

CDI MAGNETO

REMOVING THE CDI MAGNETOOrder Part name Q'ty Remarks Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Disconnect the CDI magneto lead.

Shift pedal Refer to "KICK SHAFT AND SHIFT SHAFT"

section.

1 Left crankcase cover 1

2 Nut (rotor) 1 Refer to removal section.

3 Rotor 1 Refer to removal section.

4 Stator 1

5 Woodruff key 1

Page 124 of 196

4-50

CDI MAGNETO

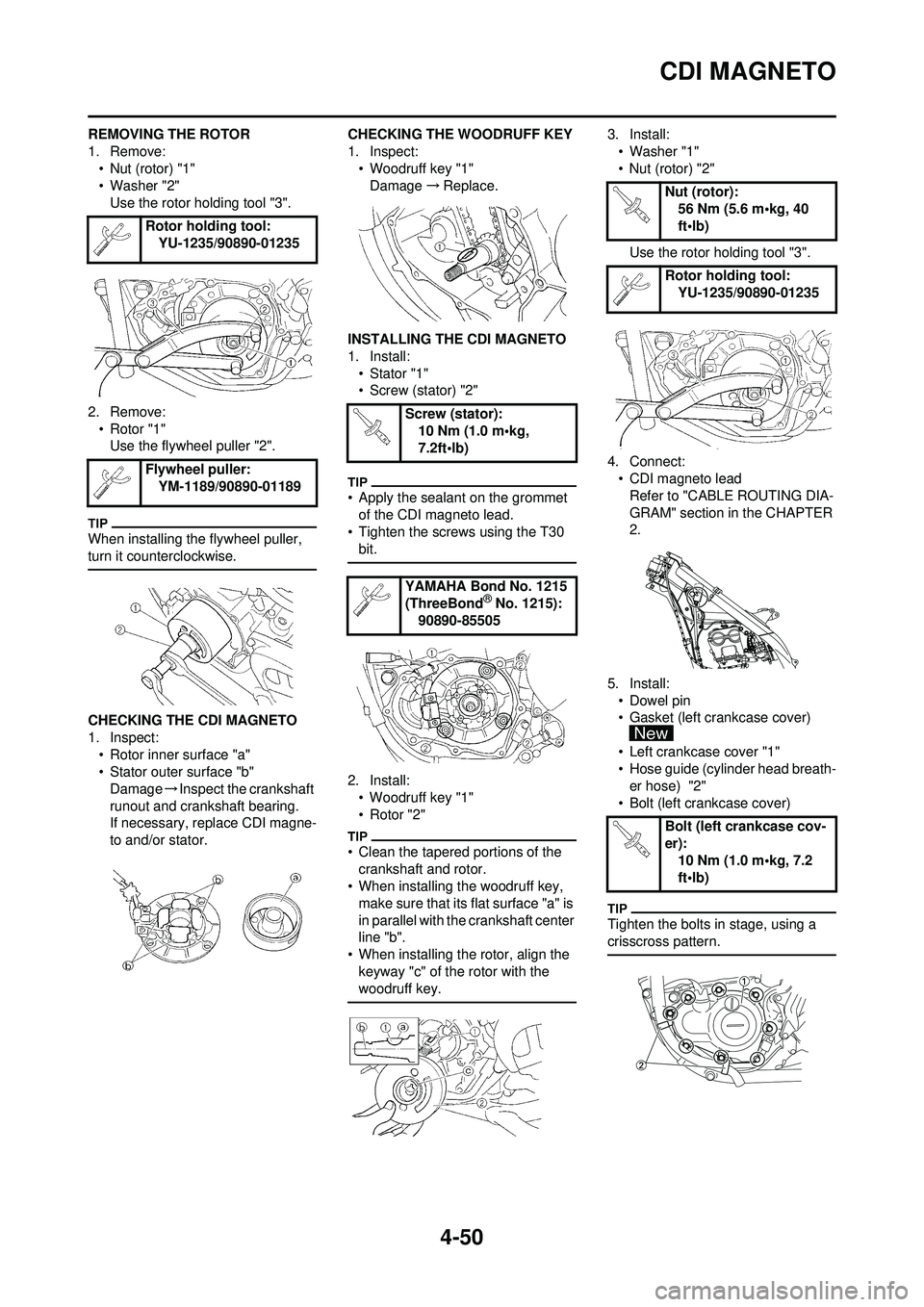

REMOVING THE ROTOR

1. Remove:• Nut (rotor) "1"

• Washer "2"

Use the rotor holding tool "3".

2. Remove: • Rotor "1"Use the flywheel puller "2".

When installing the flywheel puller,

turn it counterclockwise.

CHECKING THE CDI MAGNETO

1. Inspect:• Rotor inner surface "a"

• Stator outer surface "b"

Damage →Inspect the crankshaft

runout and crankshaft bearing.

If necessary, replace CDI magne-

to and/or stator. CHECKING THE WOODRUFF KEY

1. Inspect:

• Woodruff key "1"Damage →Replace.

INSTALLING THE CDI MAGNETO

1. Install: • Stator "1"

• Screw (stator) "2"

• Apply the sealant on the grommet

of the CDI magneto lead.

• Tighten the screws using the T30 bit.

2. Install:• Woodruff key "1"

• Rotor "2"

• Clean the tapered portions of the

crankshaft and rotor.

• When installing the woodruff key, make sure that its flat surface "a" is

in parallel with the crankshaft center

line "b".

• When installing the rotor, align the

keyway "c" of the rotor with the

woodruff key.

3. Install:• Washer "1"

• Nut (rotor) "2"

Use the rotor holding tool "3".

4. Connect: • CDI magneto leadRefer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

5. Install: • Dowel pin

• Gasket (left cr ankcase cover)

• Left crankcase cover "1"

• Hose guide (cylinder head breath- er hose) "2"

• Bolt (left crankcase cover)

Tighten the bolts in stage, using a

crisscross pattern.

Rotor holding tool: YU-1235/90890-01235

Flywheel puller: YM-1189/90890-01189

Screw (stator):

10 Nm (1.0 m•kg,

7.2ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Nut (rotor): 56 Nm (5.6 m•kg, 40

ft•lb)

Rotor holding tool: YU-1235/90890-01235

Bolt (left crankcase cov-

er): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 125 of 196

4-51

ENGINE REMOVAL

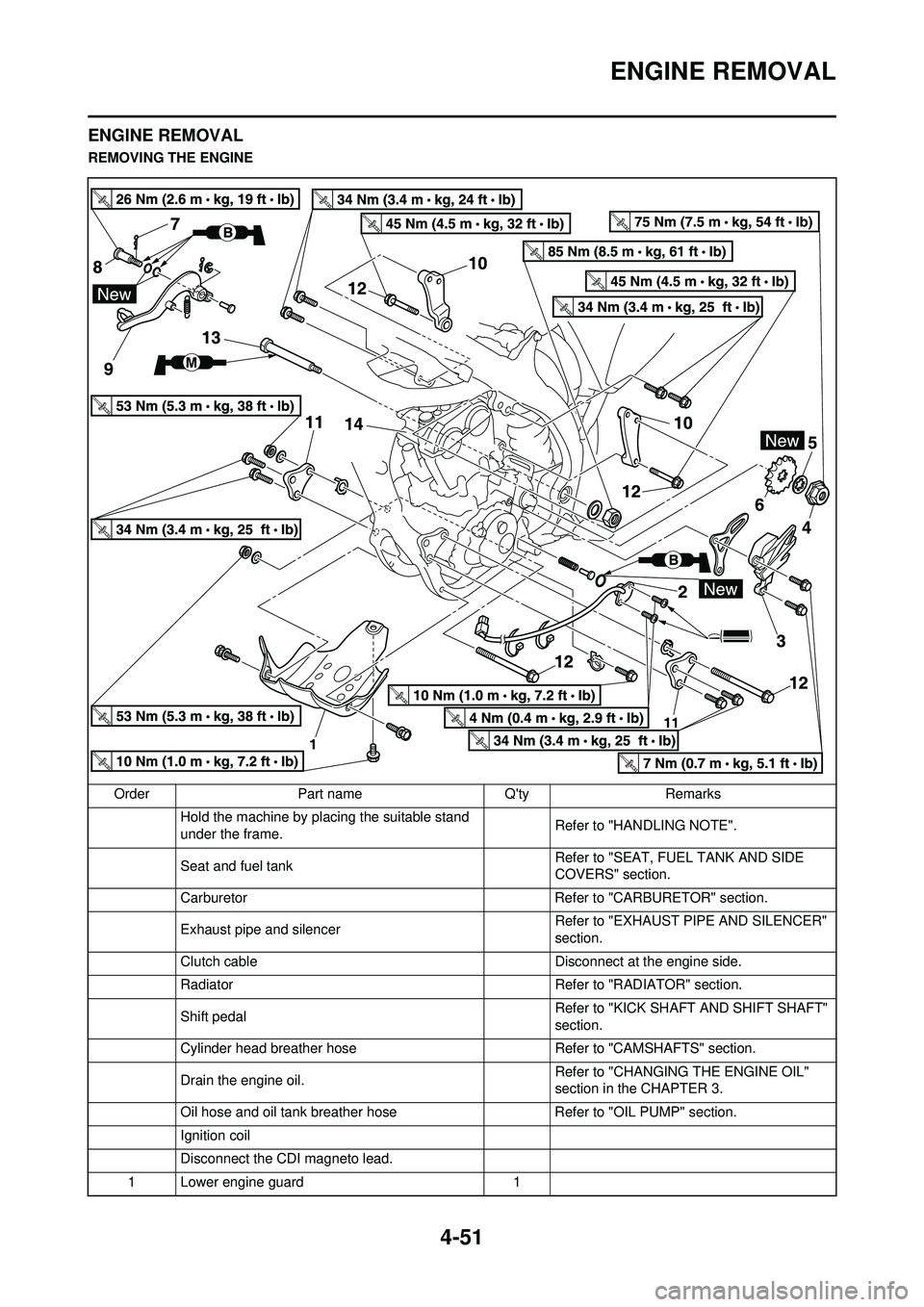

ENGINE REMOVAL

REMOVING THE ENGINEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the frame. Refer to "HANDLING NOTE".

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Carburetor Refer to "CARBURETOR" section.

Exhaust pipe and silencer Refer to "EXHAUST PIPE AND SILENCER"

section.

Clutch cable Disconnect at the engine side.

Radiator Refer to "RADIATOR" section.

Shift pedal Refer to "KICK SHAFT AND SHIFT SHAFT"

section.

Cylinder head breather hose Refer to "CAMSHAFTS" section.

Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Oil hose and oil tank breather ho seRefer to "OIL PUMP" section.

Ignition coil

Disconnect the CDI magneto lead.

1 Lower engine guard 1

Page 126 of 196

4-52

ENGINE REMOVAL

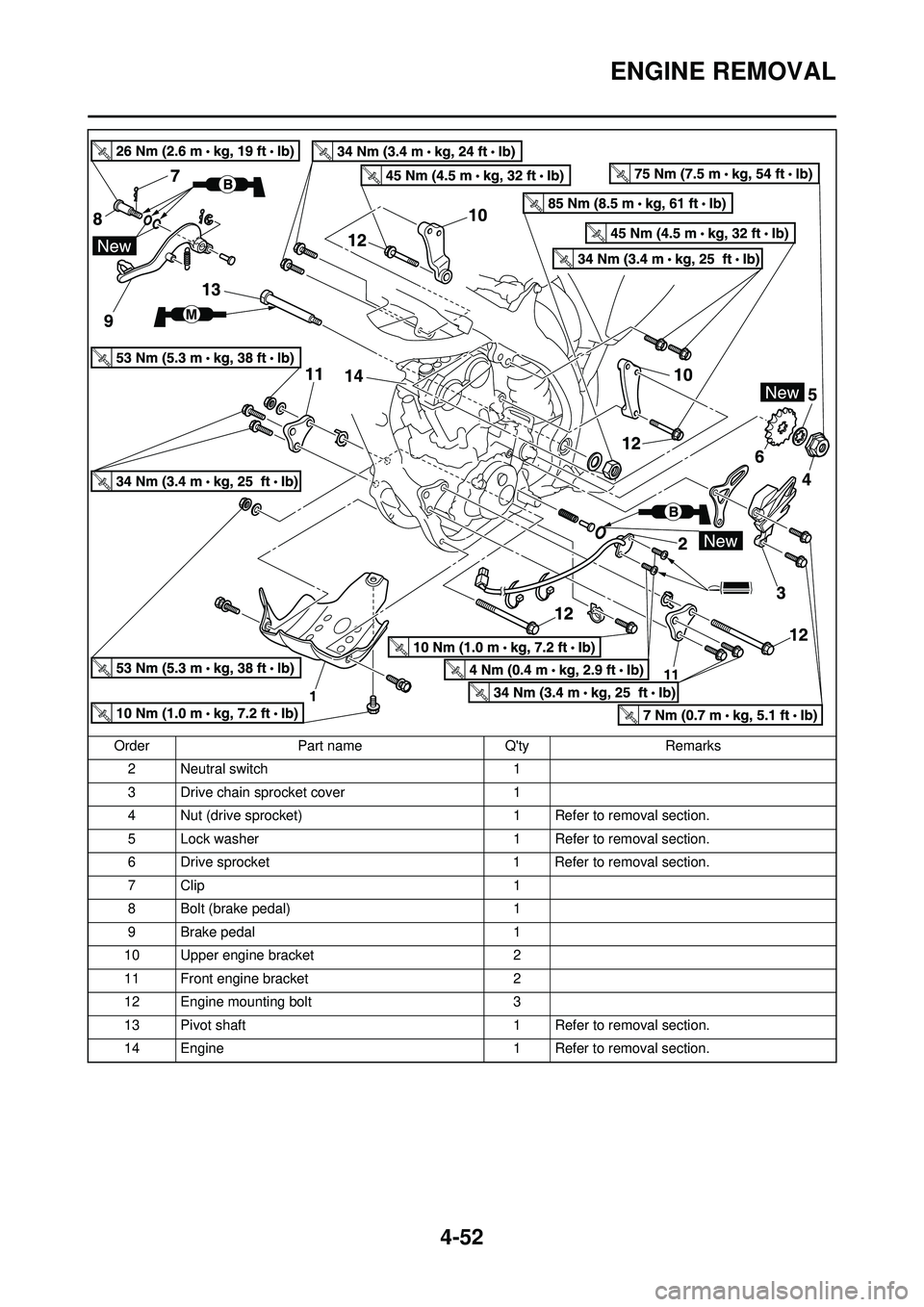

2 Neutral switch1

3 Drive chain sprocket cover 1

4 Nut (drive sprocket) 1 Refer to removal section.

5 Lock washer 1 Refer to removal section.

6 Drive sprocket 1 Refer to removal section.

7Clip 1

8 Bolt (brake pedal) 1

9 Brake pedal 1

10 Upper engine bracket 2

11 Front engine bracket 2

12 Engine mounting bolt 3

13 Pivot shaft 1 Refer to removal section.

14 Engine 1 Refer to removal section.

Order

Part name Q'tyRemarks

Page 127 of 196

4-53

ENGINE REMOVAL

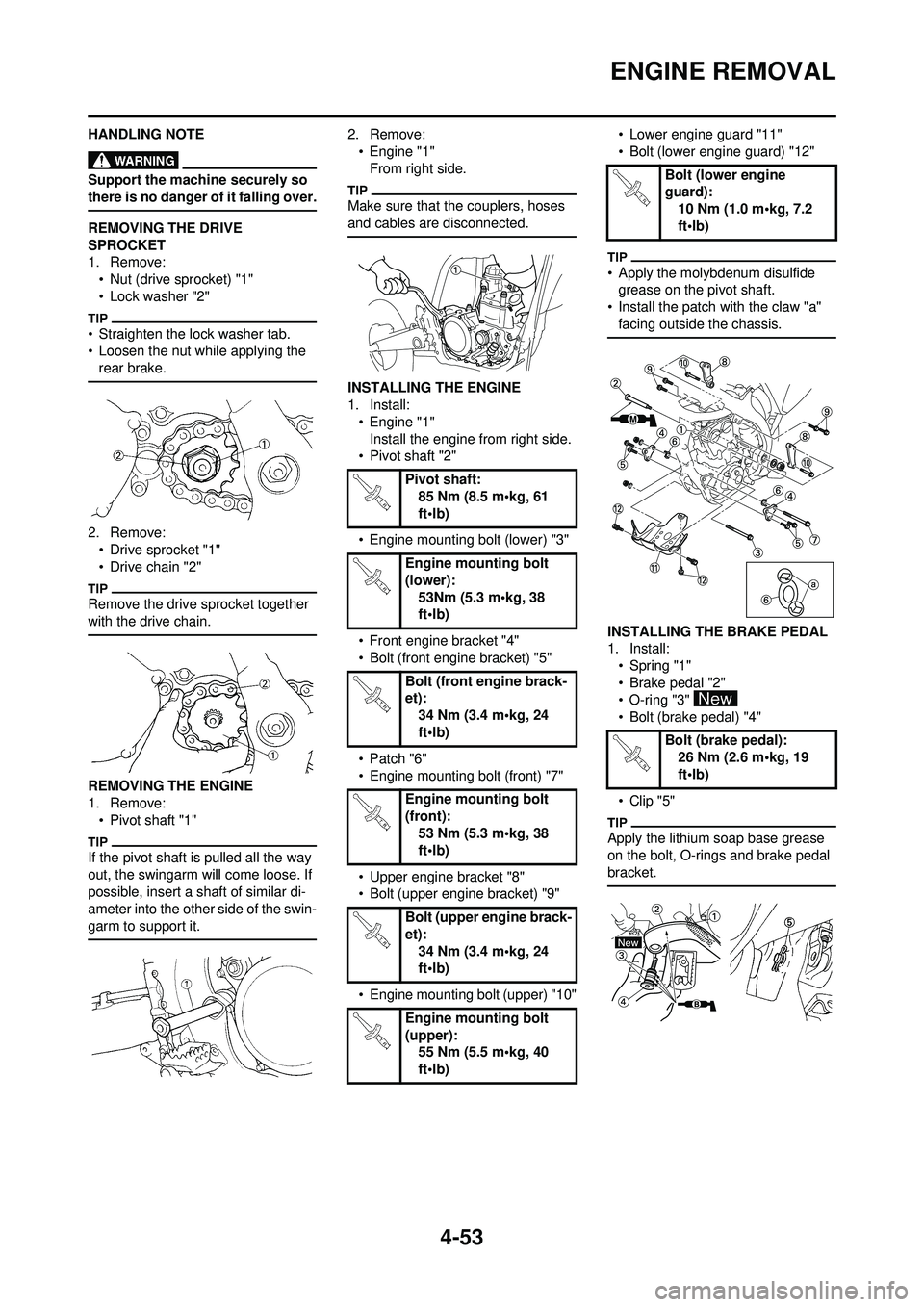

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE DRIVE

SPROCKET

1. Remove:• Nut (drive sprocket) "1"

• Lock washer "2"

• Straighten the lock washer tab.

• Loosen the nut while applying the rear brake.

2. Remove:• Drive sprocket "1"

• Drive chain "2"

Remove the drive sprocket together

with the drive chain.

REMOVING THE ENGINE

1. Remove:• Pivot shaft "1"

If the pivot shaft is pulled all the way

out, the swingarm will come loose. If

possible, insert a sh aft of similar di-

ameter into the other side of the swin-

garm to support it.

2. Remove:

• Engine "1"From right side.

Make sure that the couplers, hoses

and cables are disconnected.

INSTALLING THE ENGINE

1. Install:• Engine "1"

Install the engine from right side.

• Pivot shaft "2"

• Engine mounting bolt (lower) "3"

• Front engine bracket "4"

• Bolt (front engine bracket) "5"

• Patch "6"

• Engine mounting bolt (front) "7"

• Upper engine bracket "8"

• Bolt (upper engine bracket) "9"

• Engine mounting bolt (upper) "10" • Lower engine guard "11"

• Bolt (lower engine guard) "12"

• Apply the molybdenum disulfide

grease on the pivot shaft.

• Install the patch with the claw "a"

facing outside the chassis.

INSTALLING THE BRAKE PEDAL

1. Install:• Spring "1"

• Brake pedal "2"

• O-ring "3"

• Bolt (brake pedal) "4"

• Clip "5"

Apply the lithium soap base grease

on the bolt, O-rings and brake pedal

bracket.

Pivot shaft: 85 Nm (8.5 m•kg, 61

ft•lb)

Engine mounting bolt

(lower): 53Nm (5.3 m•kg, 38

ft•lb)

Bolt (front engine brack-

et): 34 Nm (3.4 m•kg, 24

ft•lb)

Engine mounting bolt

(front): 53 Nm (5.3 m•kg, 38

ft•lb)

Bolt (upper engine brack-

et): 34 Nm (3.4 m•kg, 24

ft•lb)

Engine mounting bolt

(upper): 55 Nm (5.5 m•kg, 40

ft•lb)

Bolt (lower engine

guard): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (brake pedal): 26 Nm (2.6 m•kg, 19

ft•lb)

M

Page 128 of 196

4-54

ENGINE REMOVAL

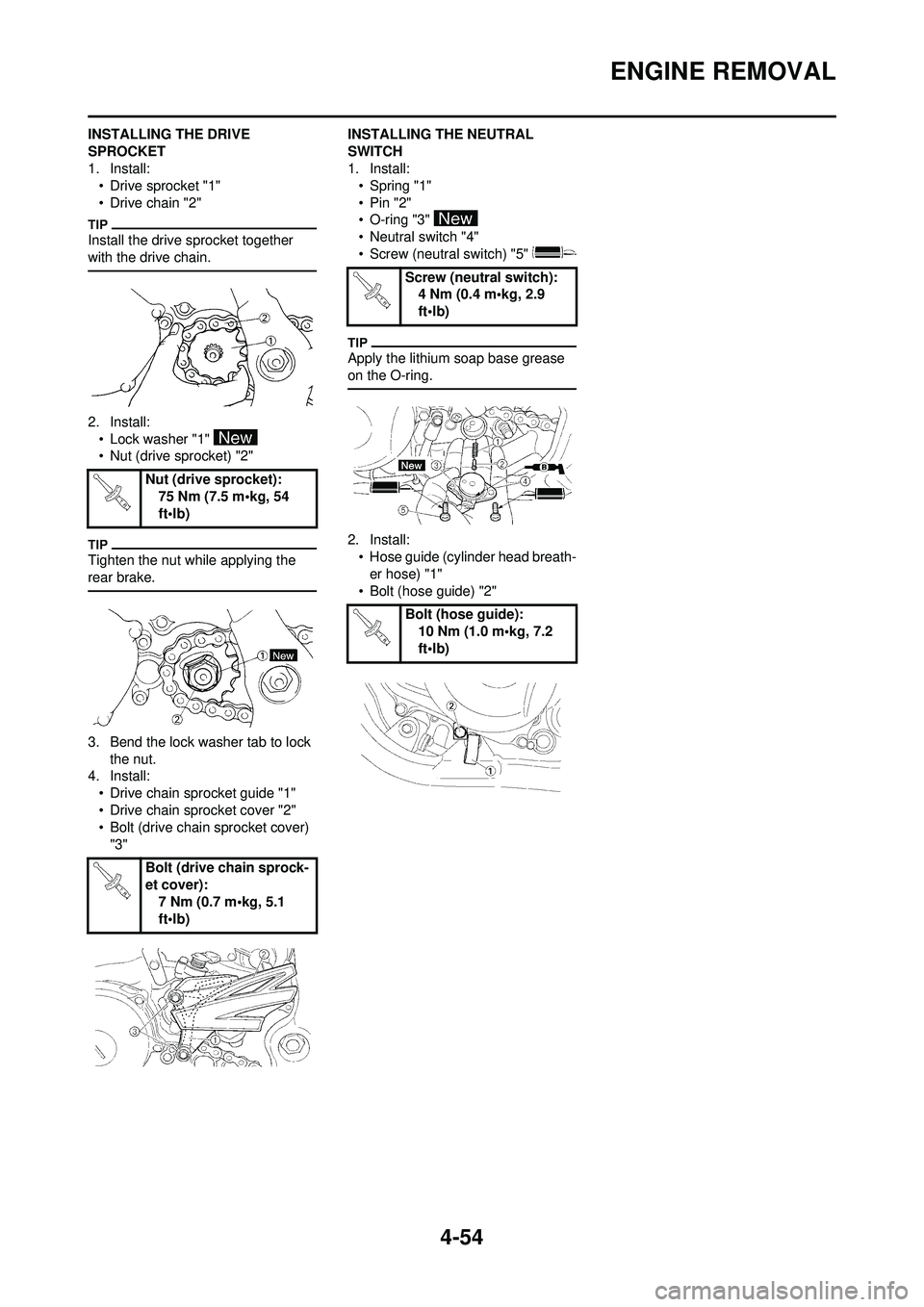

INSTALLING THE DRIVE

SPROCKET

1. Install:• Drive sprocket "1"

• Drive chain "2"

Install the drive sprocket together

with the drive chain.

2. Install:

• Lock washer "1"

• Nut (drive sprocket) "2"

Tighten the nut while applying the

rear brake.

3. Bend the lock washer tab to lock the nut.

4. Install:

• Drive chain sprocket guide "1"

• Drive chain sp rocket cover "2"

• Bolt (drive chain sprocket cover)

"3" INSTALLING THE NEUTRAL

SWITCH

1. Install:

• Spring "1"

•Pin "2"

• O-ring "3"

• Neutral switch "4"

• Screw (neutral switch) "5"

Apply the lithium soap base grease

on the O-ring.

2. Install:• Hose guide (cylinder head breath-

er hose) "1"

• Bolt (hose guide) "2"

Nut (drive sprocket):

75 Nm (7.5 m•kg, 54

ft•lb)

Bolt (drive chain sprock-

et cover): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Screw (neutral switch):4 Nm (0.4 m•kg, 2.9

ft•lb)

Bolt (hose guide): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 129 of 196

4-55

CRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

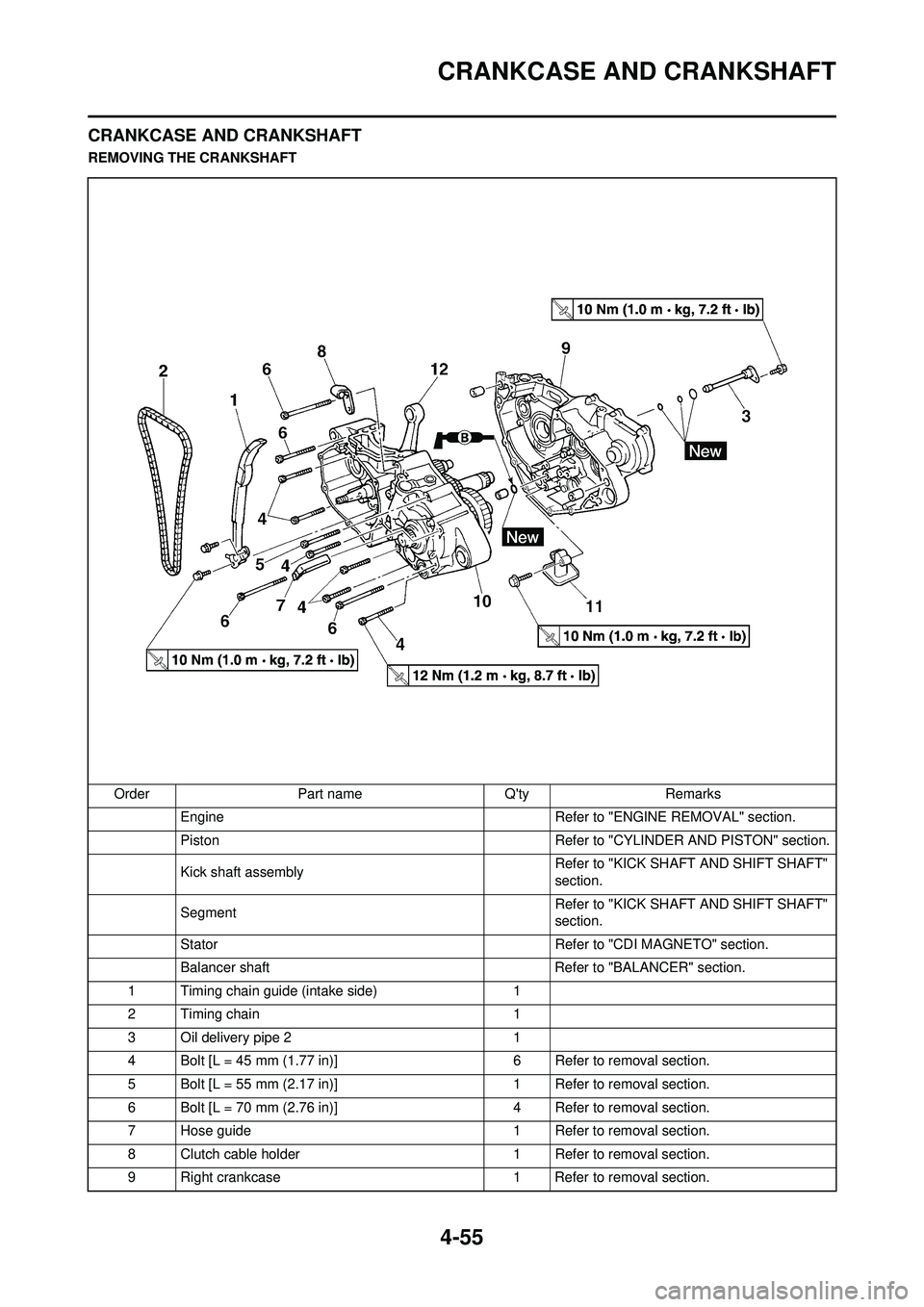

REMOVING THE CRANKSHAFTOrder Part name Q'ty Remarks Engine Refer to "ENGINE REMOVAL" section.

Piston Refer to "CYLINDE R AND PISTON" section.

Kick shaft assembly Refer to "KICK SHAFT AND SHIFT SHAFT"

section.

Segment Refer to "KICK SHAFT AND SHIFT SHAFT"

section.

Stator Refer to "CDI MAGNETO" section.

Balancer shaft Refer to "BALANCER" section.

1 Timing chain guide (intake side) 1

2 Timing chain 1

3 Oil delivery pipe 2 1

4 Bolt [L = 45 mm (1.77 in)] 6 Refer to removal section.

5 Bolt [L = 55 mm (2.17 in)] 1 Refer to removal section.

6 Bolt [L = 70 mm (2.76 in)] 4 Refer to removal section.

7 Hose guide 1 Refer to removal section.

8 Clutch cable holder 1 Refer to removal section.

9 Right crankcase 1 Refer to removal section.

Page 130 of 196

4-56

CRANKCASE AND CRANKSHAFT

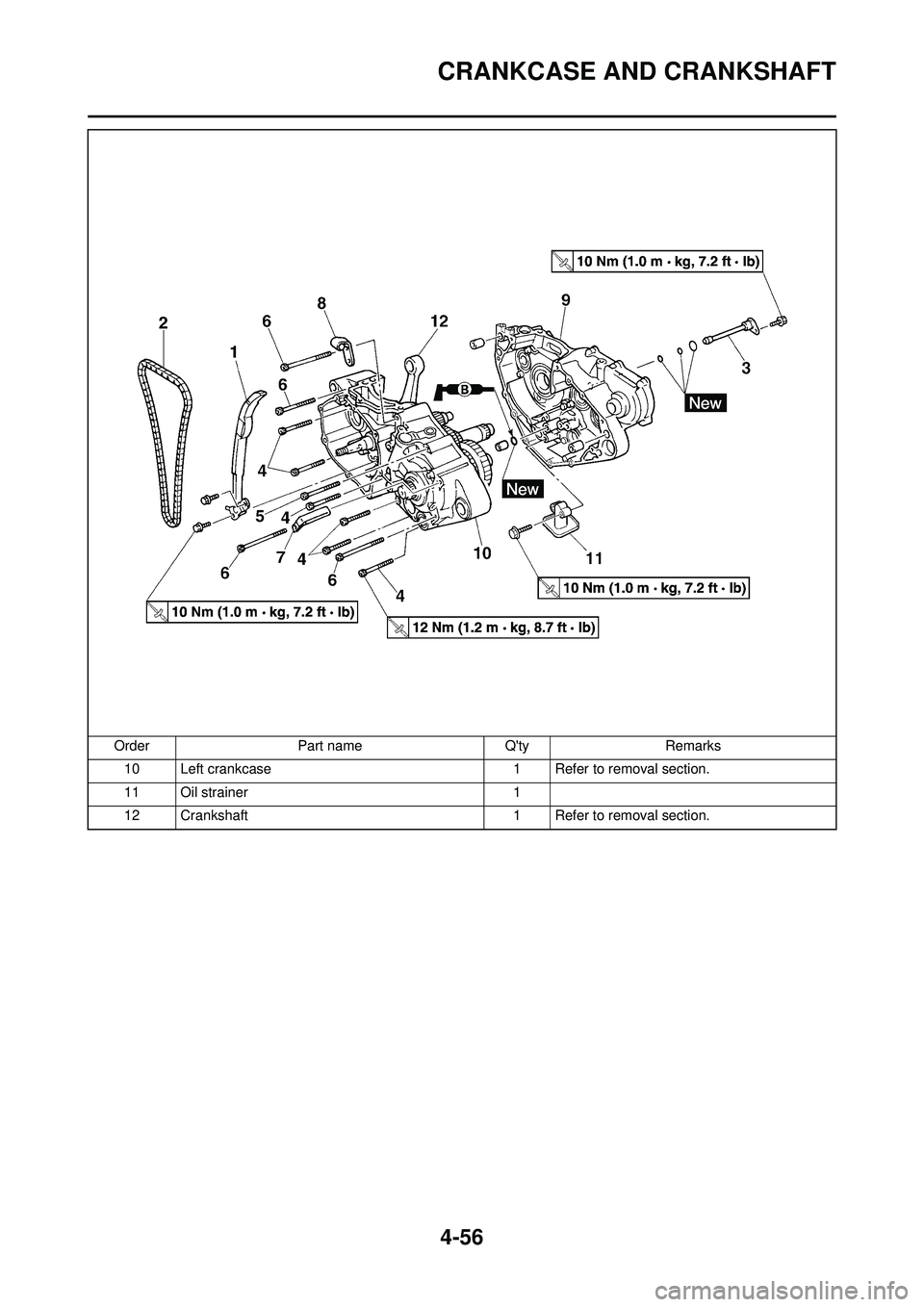

10 Left crankcase1 Refer to removal section.

11 Oil strainer 1

12 Crankshaft 1 Refer to removal section.

Order

Part name Q'tyRemarks