lock YAMAHA YZ250F 2010 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ250F, Model: YAMAHA YZ250F 2010Pages: 196, PDF Size: 13.74 MB

Page 61 of 196

3-11

ENGINE

b. Turn the throttle stop screw "1" until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

• This section is intended for those who have basic knowledge and skill

concerning the servicing of Yama-

ha motorcycles (e.g., Yamaha deal-

ers, service engineers, etc.) Those

who have little knowledge and skill

concerning servicing are requested

not to undertake inspection, adjust-

ment, disassembly, or reassembly

only by reference to this manual. It

may lead to servicing trouble and

mechanical damage.

• The valve clearance should be ad-

justed when the engine is cool to

the touch.

• The piston must be at Top Dead

Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:•Seat

•Fuel tankRefer to "SEAT, FUEL TANK

AND SIDE COVERS" section in

the CHAPTER 4.

2. Remove:

• Spark plug

• Cylinder head coverRefer to "CAMSHAFTS" section

in the CHAPTER 4.

3. Remove: • Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

• O-ring

4. Check: • Valve clearanceOut of specification →Adjust.

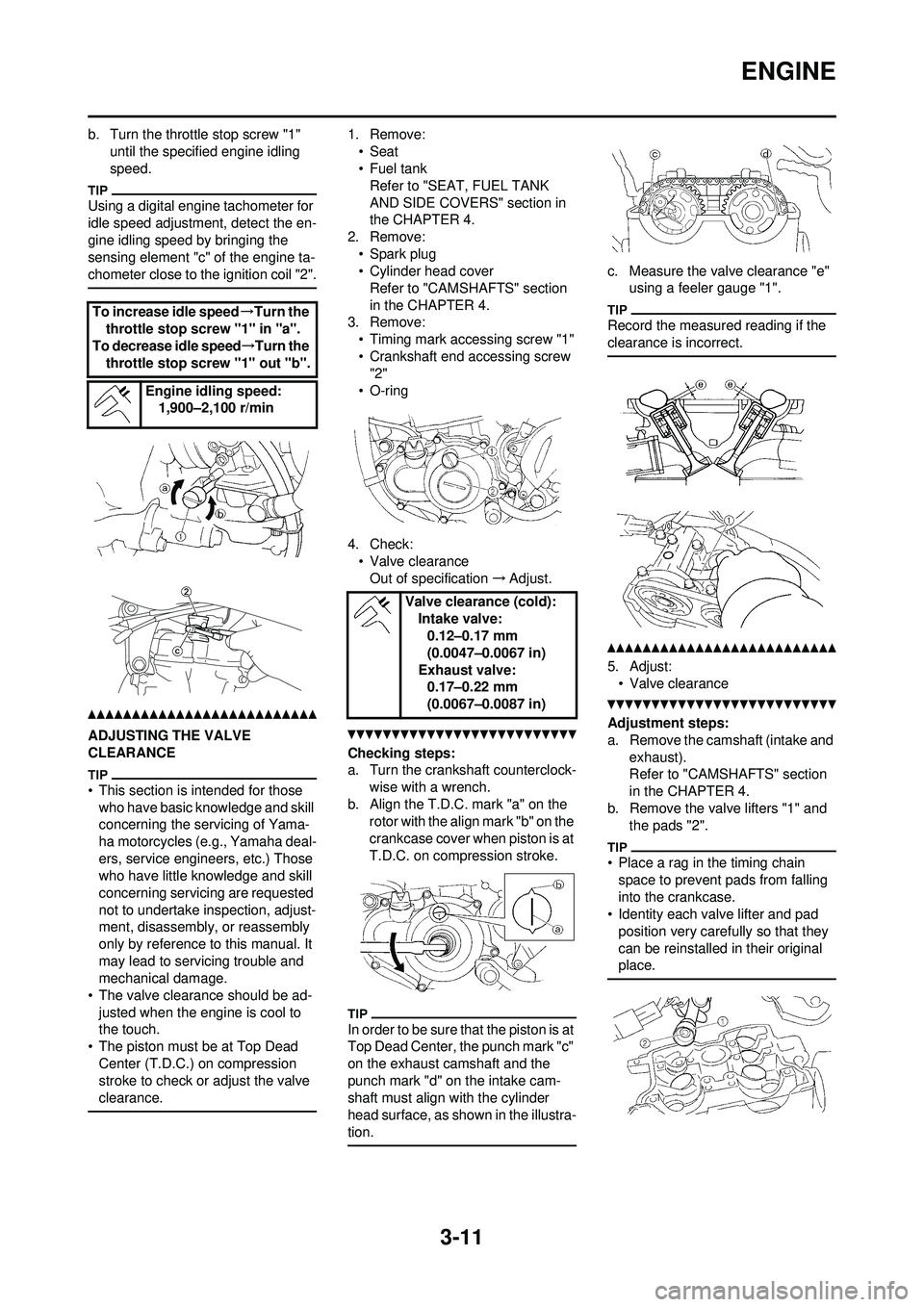

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

c. Measure the valve clearance "e" using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

5. Adjust:

• Valve clearance

Adjustment steps:

a. Remove the camshaft (intake and exhaust).

Refer to "CAMSHAFTS" section

in the CHAPTER 4.

b. Remove the valve lifters "1" and the pads "2".

• Place a rag in the timing chain

space to prevent pads from falling

into the crankcase.

• Identity each valve lifter and pad

position very carefully so that they

can be reinstalled in their original

place.

To increase idle speed →Turn the

throttle stop screw "1" in "a".

To decrease idle speed →Turn the

throttle stop screw "1" out "b".

Engine idling speed:1,900–2,100 r/min

Valve clearance (cold):Intake valve:

0.12–0.17 mm

(0.0047–0.0067 in)

Exhaust valve: 0.17–0.22 mm

(0.0067–0.0087 in)

Page 64 of 196

3-14

CHASSIS

CHASSIS

BLEEDING THE HYDRAULIC

BRAKE SYSTEM

Bleed the brake system if:

• The system has been disassem-bled.

• A brake hose has been loosened or removed.

• The brake fluid is very low.

• The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

• Brake master cylinder cap

• Diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

2. Bleed: • Brake fluid

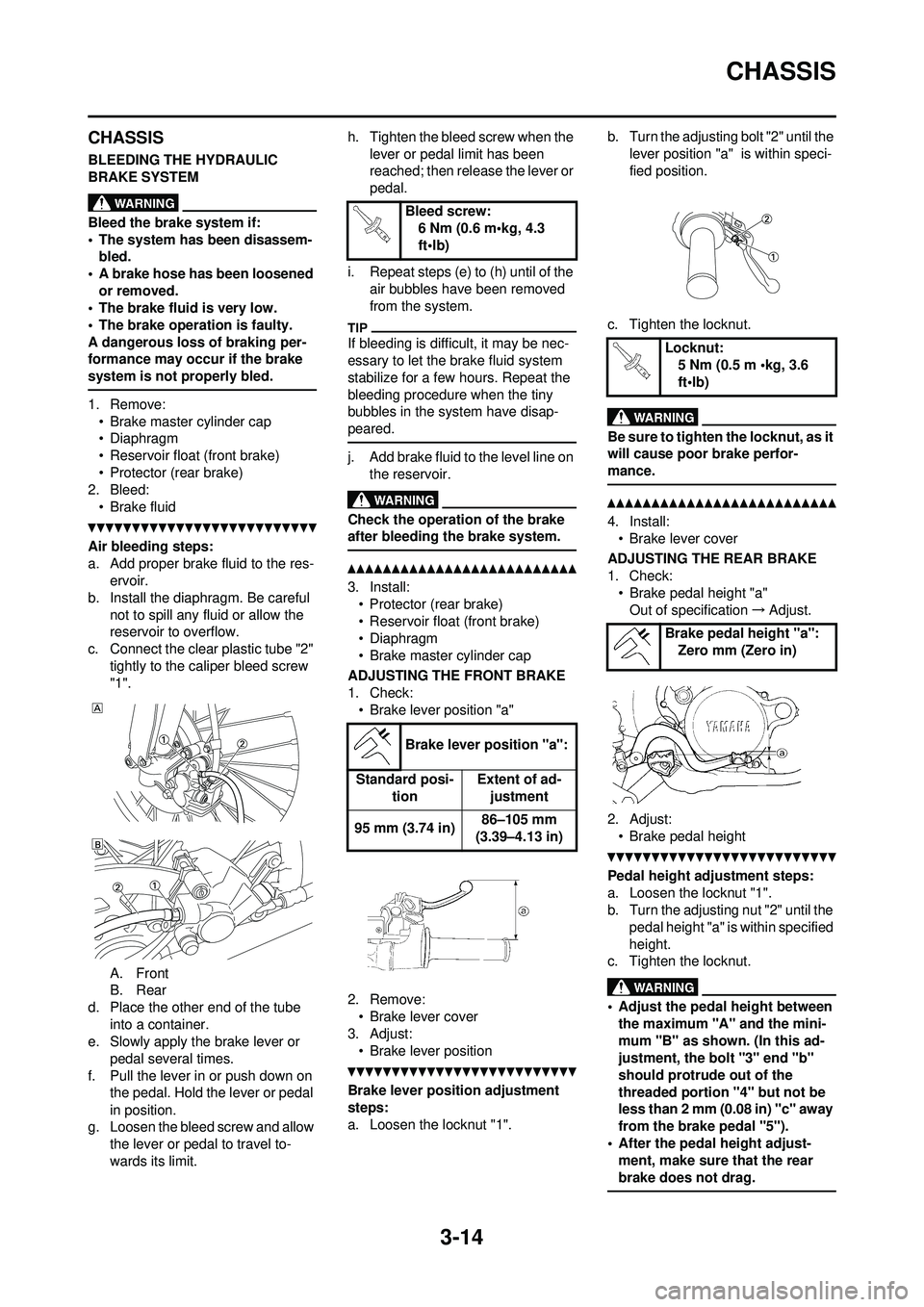

Air bleeding steps:

a. Add proper brake fluid to the res- ervoir.

b. Install the diaphragm. Be careful

not to spill any fluid or allow the

reservoir to overflow.

c. Connect the clear plastic tube "2"

tightly to the caliper bleed screw

"1".

A. Front

B. Rear

d. Place the other end of the tube

into a container.

e. Slowly apply the brake lever or

pedal several times.

f. Pull the lever in or push down on the pedal. Hold the lever or pedal

in position.

g. Loosen the bleed screw and allow the lever or pedal to travel to-

wards its limit. h. Tighten the bleed screw when the

lever or pedal limit has been

reached; then release the lever or

pedal.

i. Repeat steps (e) to (h) until of the air bubbles have been removed

from the system.

If bleeding is difficult, it may be nec-

essary to let the brake fluid system

stabilize for a few hours. Repeat the

bleeding procedure when the tiny

bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on the reservoir.

Check the operation of the brake

after bleeding the brake system.

3. Install:• Protector (rear brake)

• Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap

ADJUSTING THE FRONT BRAKE

1. Check: • Brake lever position "a"

2. Remove: • Brake lever cover

3. Adjust: • Brake lever position

Brake lever position adjustment

steps:

a. Loosen the locknut "1". b. Turn the adjusting bolt "2" until the

lever position "a" is within speci-

fied position.

c. Tighten the locknut.

Be sure to tighten the locknut, as it

will cause poor brake perfor-

mance.

4. Install: • Brake lever cover

ADJUSTING THE REAR BRAKE

1. Check: • Brake pedal height "a"

Out of specification →Adjust.

2. Adjust: • Brake pedal height

Pedal height adjustment steps:

a. Loosen the locknut "1".

b. Turn the adjusting nut "2" until the pedal height "a" is within specified

height.

c. Tighten the locknut.

• Adjust the pedal height between

the maximum "A" and the mini-

mum "B" as shown. (In this ad-

justment, the bo lt "3" end "b"

should protrude out of the

threaded portion "4" but not be

less than 2 mm (0.08 in) "c" away

from the brake pedal "5").

• After the pedal height adjust- ment, make sure that the rear

brake does not drag.

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Brake lever position "a":

Standard posi- tion Extent of ad-

justment

95 mm (3.74 in) 86–105 mm

(3.39–4.13 in)

Locknut: 5 Nm (0.5 m •kg, 3.6

ft•lb)

Brake pedal height "a": Zero mm (Zero in)

Page 67 of 196

3-17

CHASSIS

CHECKING THE SPROCKET

1. Inspect:• Sprocket teeth "a"Excessive wear →Replace.

Replace the drive sprocket, rear

wheel sprocket and drive chain as a

set.

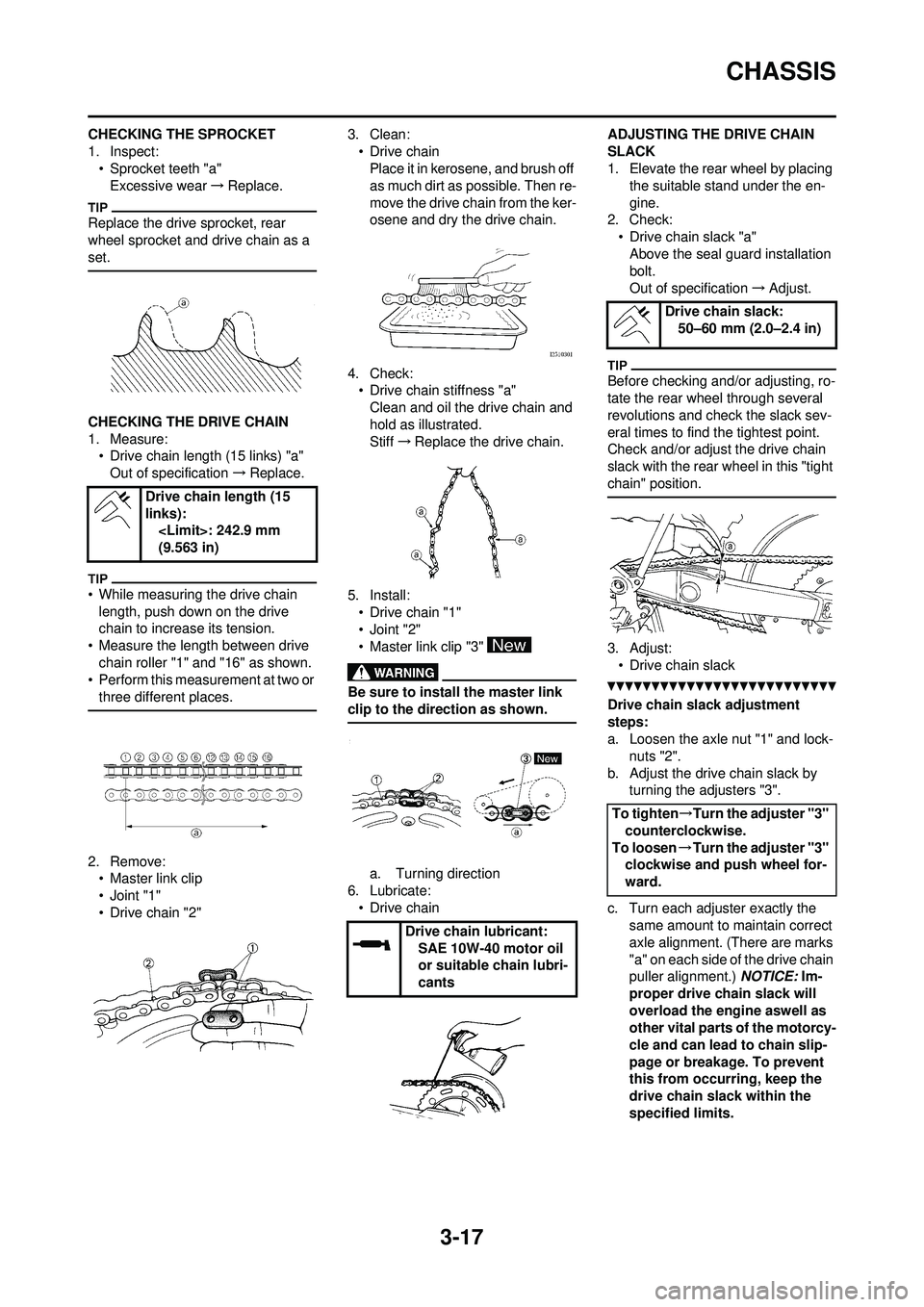

CHECKING THE DRIVE CHAIN

1. Measure:

• Drive chain length (15 links) "a"Out of specification →Replace.

• While measuring the drive chain

length, push down on the drive

chain to increase its tension.

• Measure the length between drive

chain roller "1" and "16" as shown.

• Perform this measurement at two or three different places.

2. Remove:• Master link clip

•Joint "1"

• Drive chain "2" 3. Clean:

• Drive chainPlace it in kerosene, and brush off

as much dirt as possible. Then re-

move the drive chain from the ker-

osene and dry the drive chain.

4. Check: • Drive chain stiffness "a"

Clean and oil the drive chain and

hold as illustrated.

Stiff →Replace the drive chain.

5. Install: • Drive chain "1"

•Joint "2"

• Master link clip "3"

Be sure to install the master link

clip to the direction as shown.

a. Turning direction

6. Lubricate: • Drive chain ADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Check: • Drive chain slack "a"

Above the seal guard installation

bolt.

Out of specification →Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight

chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock- nuts "2".

b. Adjust the drive chain slack by turning the adjusters "3".

c. Turn each adjuster exactly the same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.) NOTICE: Im-

proper drive chain slack will

overload the engine aswell as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. To prevent

this from occurring, keep the

drive chain slack within the

specified limits.

Drive chain length (15

links):

(9.563 in)

Drive chain lubricant:

SAE 10W-40 motor oil

or suitable chain lubri-

cants

Drive chain slack: 50–60 mm (2.0–2.4 in)

To tighten →Turn the adjuster "3"

counterclockwise.

To loosen →Turn the adjuster "3"

clockwise and push wheel for-

ward.

Page 68 of 196

3-18

CHASSIS

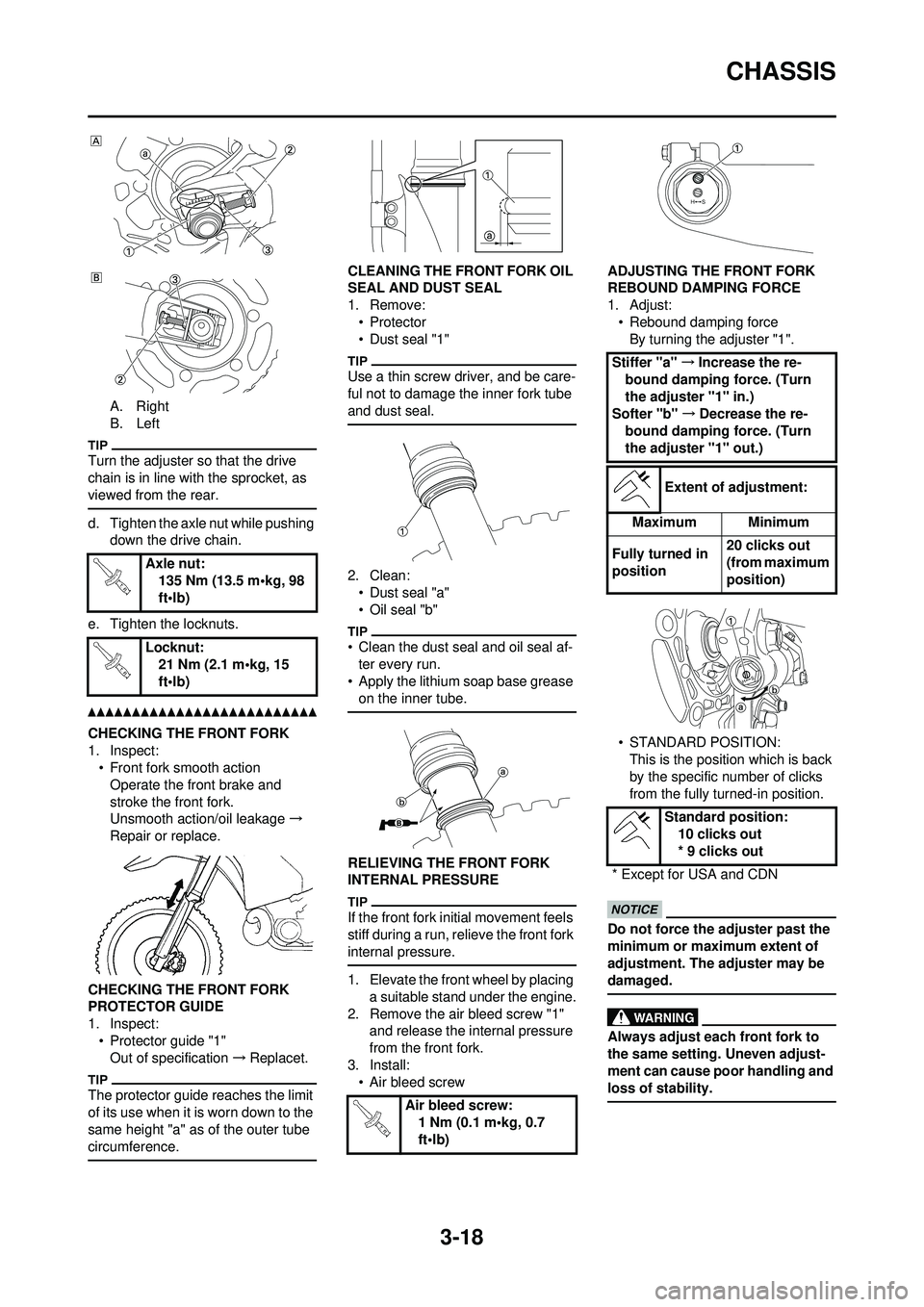

A. Right

B. Left

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

d. Tighten the axle nut while pushing down the drive chain.

e. Tighten the locknuts.

CHECKING THE FRONT FORK

1. Inspect: • Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage →

Repair or replace.

CHECKING THE FRONT FORK

PROTECTOR GUIDE

1. Inspect: • Protector guide "1"Out of specification →Replacet.

The protector guide reaches the limit

of its use when it is worn down to the

same height "a" as of the outer tube

circumference.

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:

•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, re lieve the front fork

internal pressure.

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Remove the air bleed screw "1" and release the internal pressure

from the front fork.

3. Install: • Air bleed screw ADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping forceBy turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

Axle nut: 135 Nm (13.5 m•kg, 98

ft•lb)

Locknut: 21 Nm (2.1 m•kg, 15

ft•lb)

Air bleed screw:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 10 clicks out

* 9 clicks out

* Except for USA and CDN

Page 69 of 196

3-19

CHASSIS

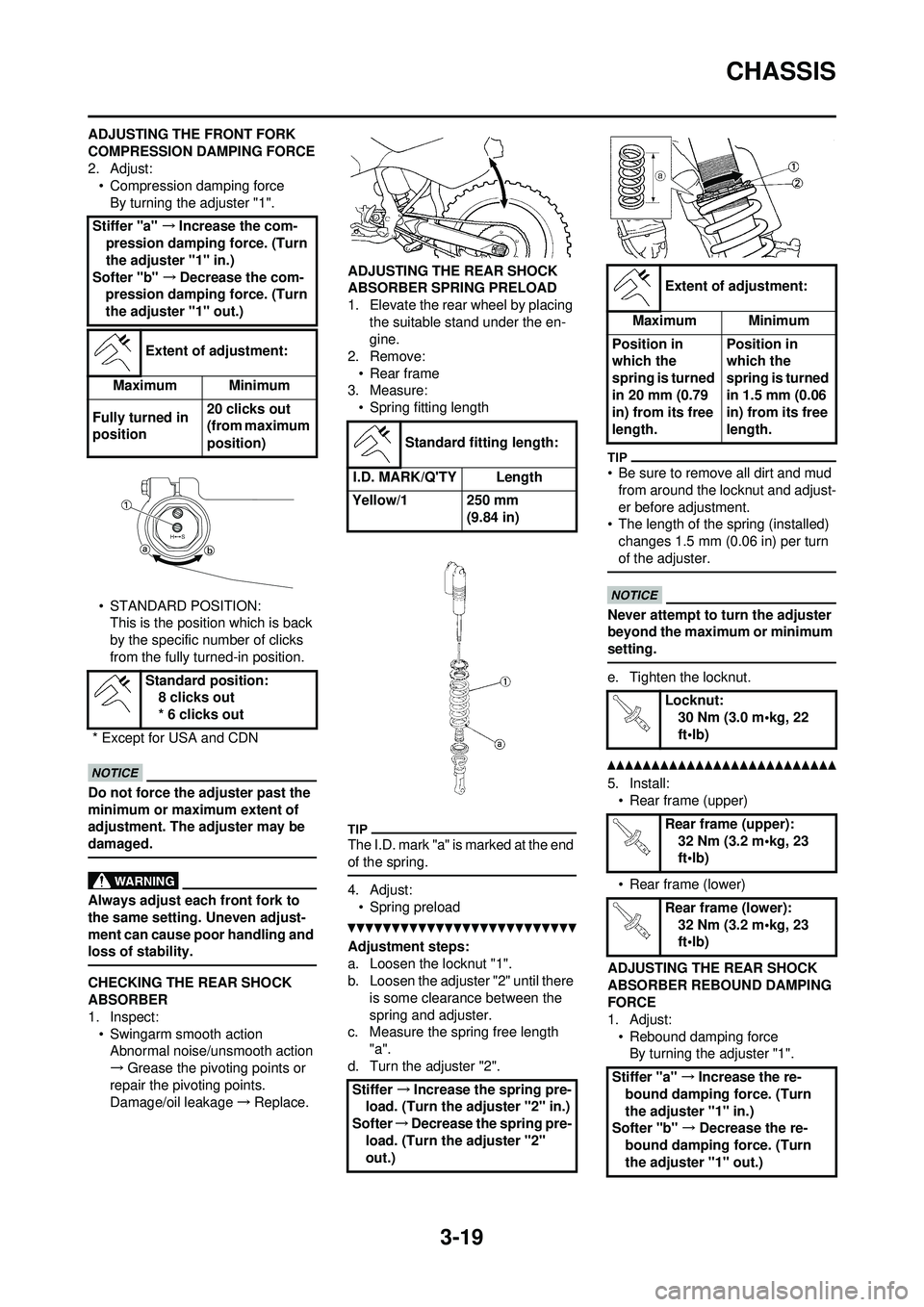

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

2. Adjust:• Compression damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:• Swingarm smooth actionAbnormal noise/unsmooth action

→ Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage →Replace. ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Remove: • Rear frame

3. Measure:

• Spring fitting length

The I.D. mark "a" is marked at the end

of the spring.

4. Adjust: • Spring preload

Adjustment steps:

a. Loosen the locknut "1".

b. Loosen the adjuster "2" until there is some clearance between the

spring and adjuster.

c. Measure the spring free length

"a".

d. Turn the adjuster "2".

• Be sure to remove all dirt and mud from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed) changes 1.5 mm (0.06 in) per turn

of the adjuster.

Never attempt to tu rn the adjuster

beyond the maximum or minimum

setting.

e. Tighten the locknut.

5. Install: • Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust: • Rebound damping forceBy turning the adjuster "1".

Stiffer "a"

→Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 8 clicks out

* 6 clicks out

* Except for USA and CDN

Standard fitti ng length:

I.D. MARK/Q'TY Length

Yellow/1 250 mm (9.84 in)

Stiffer →Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer →Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Extent of adjustment:

Maximum Minimum

Position in

which the

spring is turned

in 20 mm (0.79

in) from its free

length. Position in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length.

Locknut: 30 Nm (3.0 m•kg, 22

ft•lb)

Rear frame (upper): 32 Nm (3.2 m•kg, 23

ft•lb)

Rear frame (lower): 32 Nm (3.2 m•kg, 23

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Page 71 of 196

3-21

CHASSIS

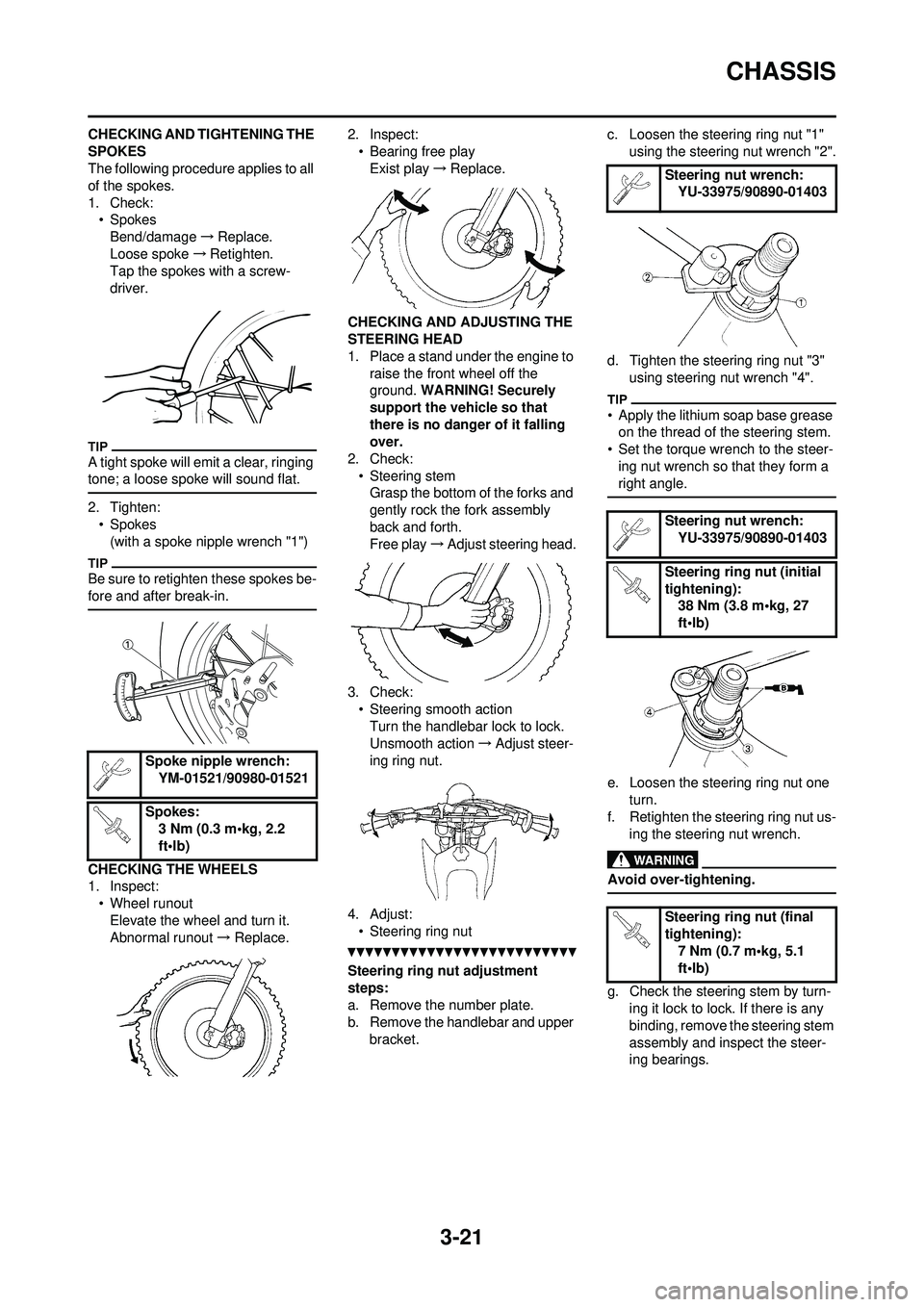

CHECKING AND TIGHTENING THE

SPOKES

The following procedure applies to all

of the spokes.

1. Check:• SpokesBend/damage →Replace.

Loose spoke →Retighten.

Tap the spokes with a screw-

driver.

A tight spoke will emit a clear, ringing

tone; a loose spoke will sound flat.

2. Tighten: • Spokes

(with a spoke nipple wrench "1")

Be sure to retighten these spokes be-

fore and after break-in.

CHECKING THE WHEELS

1. Inspect:• Wheel runout

Elevate the wheel and turn it.

Abnormal runout → Replace. 2. Inspect:

• Bearing free playExist play →Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Place a stand under the engine to raise the front wheel off the

ground. WARNING! Securely

support the vehicle so that

there is no danger of it falling

over.

2. Check: • Steering stemGrasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play →Adjust steering head.

3. Check: • Steering smooth actionTurn the handlebar lock to lock.

Unsmooth action →Adjust steer-

ing ring nut.

4. Adjust: • Steering ring nut

Steering ring nut adjustment

steps:

a. Remove the number plate.

b. Remove the handlebar and upper

bracket. c. Loosen the steering ring nut "1"

using the steering nut wrench "2".

d. Tighten the steering ring nut "3" using steering nut wrench "4".

• Apply the lithium soap base grease on the thread of the steering stem.

• Set the torque wrench to the steer-

ing nut wrench so that they form a

right angle.

e. Loosen the steering ring nut one turn.

f. Retighten the steering ring nut us- ing the steering nut wrench.

Avoid over-tightening.

g. Check the steering stem by turn-ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

Spoke nipple wrench:

YM-01521/90980-01521

Spokes: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Steering nut wrench:YU-33975/90890-01403

Steering nut wrench: YU-33975/90890-01403

Steering ring nut (initial

tightening): 38 Nm (3.8 m•kg, 27

ft•lb)

Steering ring nut (final

tightening): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 80 of 196

4-6

RADIATOR

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

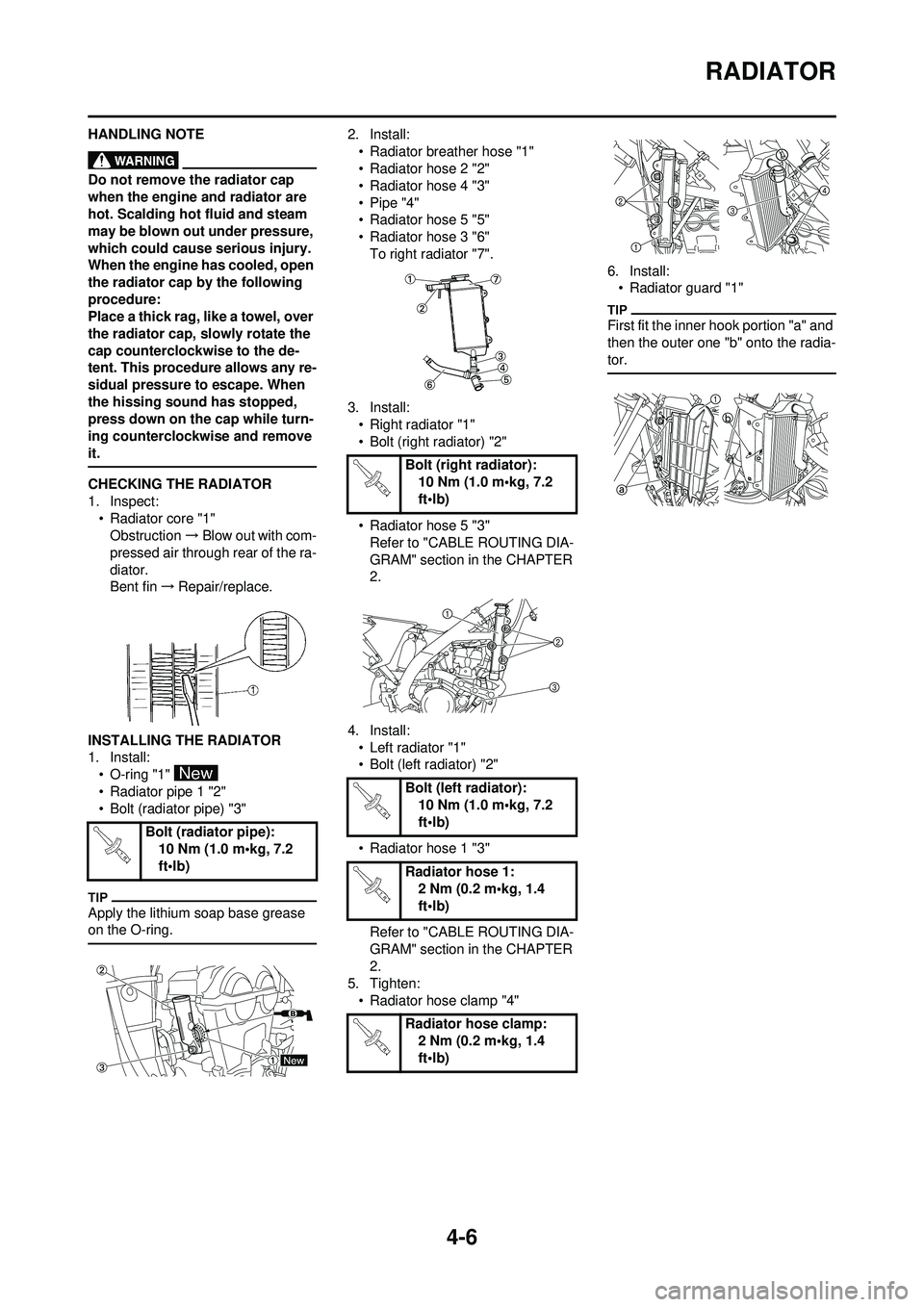

CHECKING THE RADIATOR

1. Inspect:• Radiator core "1"

Obstruction →Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin →Repair/replace.

INSTALLING THE RADIATOR

1. Install: • O-ring "1"

• Radiator pipe 1 "2"

• Bolt (radiator pipe) "3"

Apply the lithium soap base grease

on the O-ring.

2. Install:• Radiator breather hose "1"

• Radiator hose 2 "2"

• Radiator hose 4 "3"

• Pipe "4"

• Radiator hose 5 "5"

• Radiator hose 3 "6"To right radiator "7".

3. Install: • Right radiator "1"

• Bolt (right radiator) "2"

• Radiator hose 5 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Install: • Left radiator "1"

• Bolt (left radiator) "2"

• Radiator hose 1 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

5. Tighten:

• Radiator hose clamp "4" 6. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (right radiator):10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (left radiator): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1: 2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose clamp: 2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 90 of 196

4-16

CAMSHAFTS

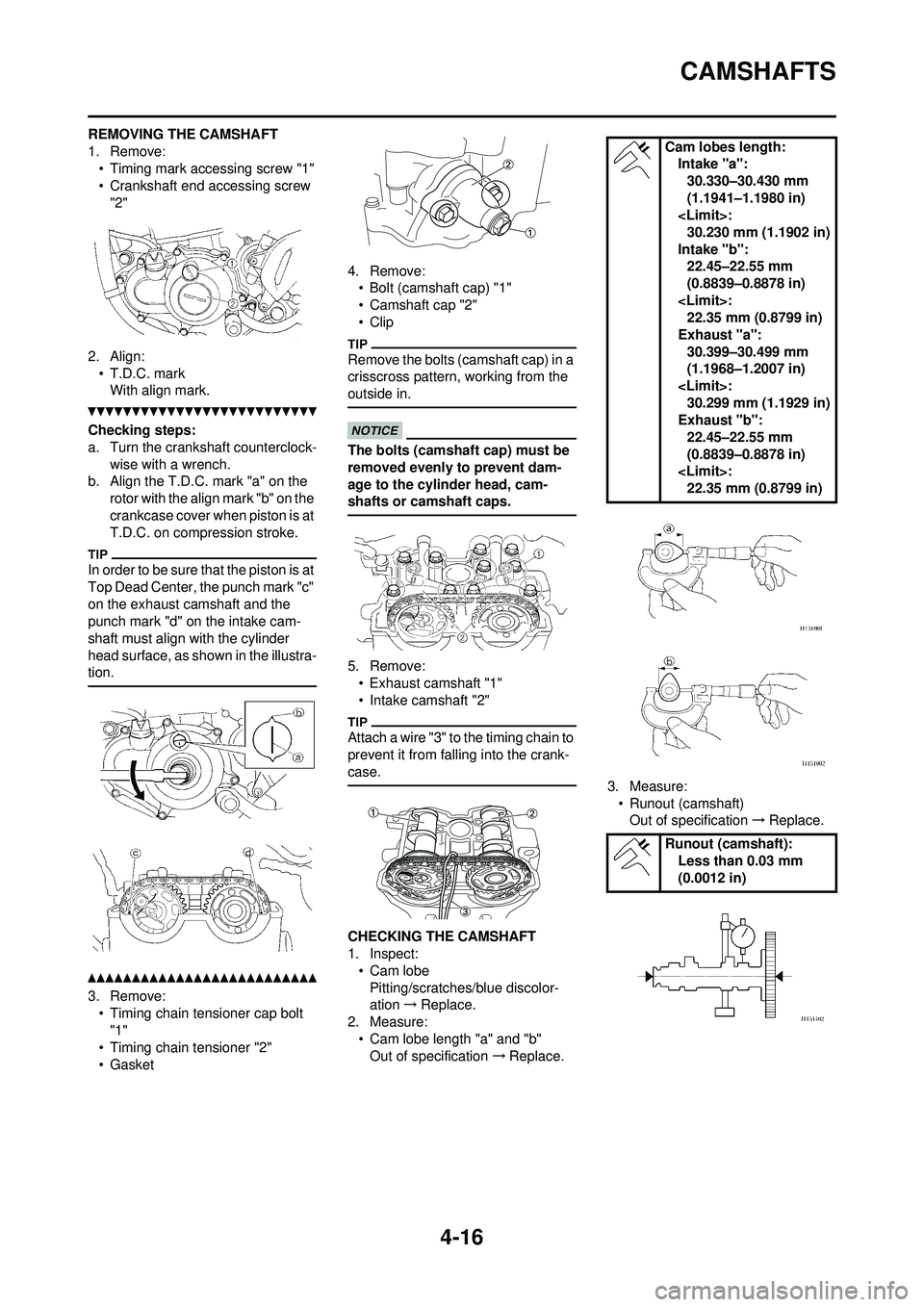

REMOVING THE CAMSHAFT

1. Remove:• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

2. Align: • T.D.C. markWith align mark.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure t hat the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

3. Remove: • Timing chain tensioner cap bolt

"1"

• Timing chain tensioner "2"

• Gasket 4. Remove:

• Bolt (camshaft cap) "1"

• Camshaft cap "2"

• Clip

Remove the bolts (camshaft cap) in a

crisscross pattern, working from the

outside in.

The bolts (camshaft cap) must be

removed evenly to prevent dam-

age to the cylinder head, cam-

shafts or camshaft caps.

5. Remove:• Exhaust camshaft "1"

• Intake camshaft "2"

Attach a wire "3" to the timing chain to

prevent it from falling into the crank-

case.

CHECKING THE CAMSHAFT

1. Inspect:• Cam lobe

Pitting/scratches/blue discolor-

ation →Replace.

2. Measure:

• Cam lobe length "a" and "b"Out of specification →Replace. 3. Measure:

• Runout (camshaft)Out of specification →Replace.

Cam lobes length:

Intake "a":30.330–30.430 mm

(1.1941–1.1980 in)

Intake "b": 22.45–22.55 mm

(0.8839–0.8878 in)

Exhaust "a":

30.399–30.499 mm

(1.1968–1.2007 in)

30.299 mm (1.1929 in)

Exhaust "b": 22.45–22.55 mm

(0.8839–0.8878 in)

Runout (camshaft): Less than 0.03 mm

(0.0012 in)

Page 91 of 196

4-17

CAMSHAFTS

4. Measure:• Camshaft-to-cap clearanceOut of specification →Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin- der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and camshaft caps.

• Tighten the bolts (camshaft cap) in a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the

Plastigauge

®.

d. Remove the camshaft caps and measure the width of the Plasti-

gauge

® "1".

5. Measure:• Camshaft outside diameter "a"

Out of specification →Replace the

camshaft.

Within specification →Replace

camshaft case and camshaft

caps as a set. CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"Wear/damage →Replace the

camshaft assemb ly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check: • Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:• While pressing the tensioner rod lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as- sembly. INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock- wise with a wrench.

• Apply the molybdenum disulfide oil on the camshafts.

• Apply the engine oil on the decom- pression system.

• Squeezing the decompression le-

ver allows the crankshaft to be

turned easily.

b. Align the T.D.C. mark "a" on the rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter: 21.959–21.972 mm

(0.8645–0.8650 in)

Page 92 of 196

4-18

CAMSHAFTS

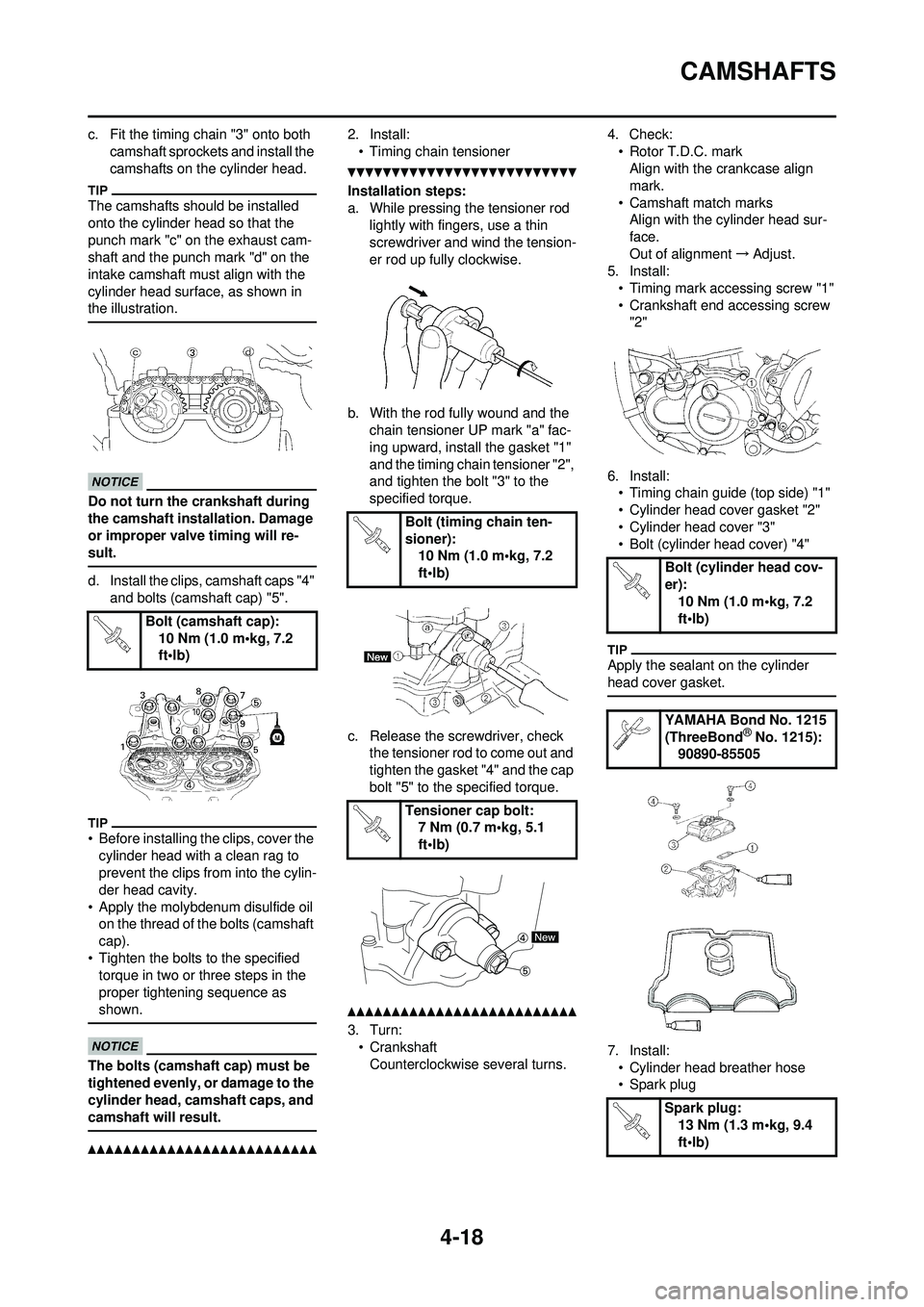

c. Fit the timing chain "3" onto both camshaft sprockets and install the

camshafts on the cylinder head.

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:

• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:• Crankshaft

Counterclockwise several turns. 4. Check:

• Rotor T.D.C. markAlign with the crankcase align

mark.

• Camshaft match marks Align with the cylinder head sur-

face.

Out of alignment →Adjust.

5. Install: • Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

6. Install: • Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:• Cylinder head breather hose

• Spark plug

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er): 10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug: 13 Nm (1.3 m•kg, 9.4

ft•lb)