YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 171 of 356

FRONT FORK

4-47

30.Fill:

• Front fork leg

ECA14210

NOTICE

• Be sure to use the recommended oil. Other

oils may have an adverse effect on front

fork performance.

• When disassembling and assembling the

front fork leg, do not allow any foreign ma-

terial to enter the front fork.

31.Install:

• Damper assembly “1”

(to the outer tube)

TIP

Temporarily tighten the damper assembly.

32.Install:

• Protector guide “1”

EAS1SM5171INSTALLING THE FRONT FORK LEGS

1. Install:

• Front fork “1”

TIP

• Temporarily tighten the pinch bolts (lower

bracket).

• Do not tighten the pinch bolts (upper bracket)

yet.

2. Tighten:

• Damper assembly “1”

TIP

Use the cap bolt ring wrench “2” to tighten the

damper assembly. Recommended oil

Suspension oil S1

Standard oil amount

335 cm

3 (11.33 US oz, 11.82

lmp.oz) (USA) (CAN)

355 cm

3 (12.00 US oz, 12.52

lmp.oz) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Extent of adjustment

300–365 cm

3 (10.14–12.34 US

oz, 10.58–12.87 lmp.oz)

Damper assembly

30 Nm (3.0 m·kgf, 22 ft·lbf)

Cap bolt ring wrench

90890-01501

YM-01501

1

T R..

2

1

Page 172 of 356

FRONT FORK

4-48

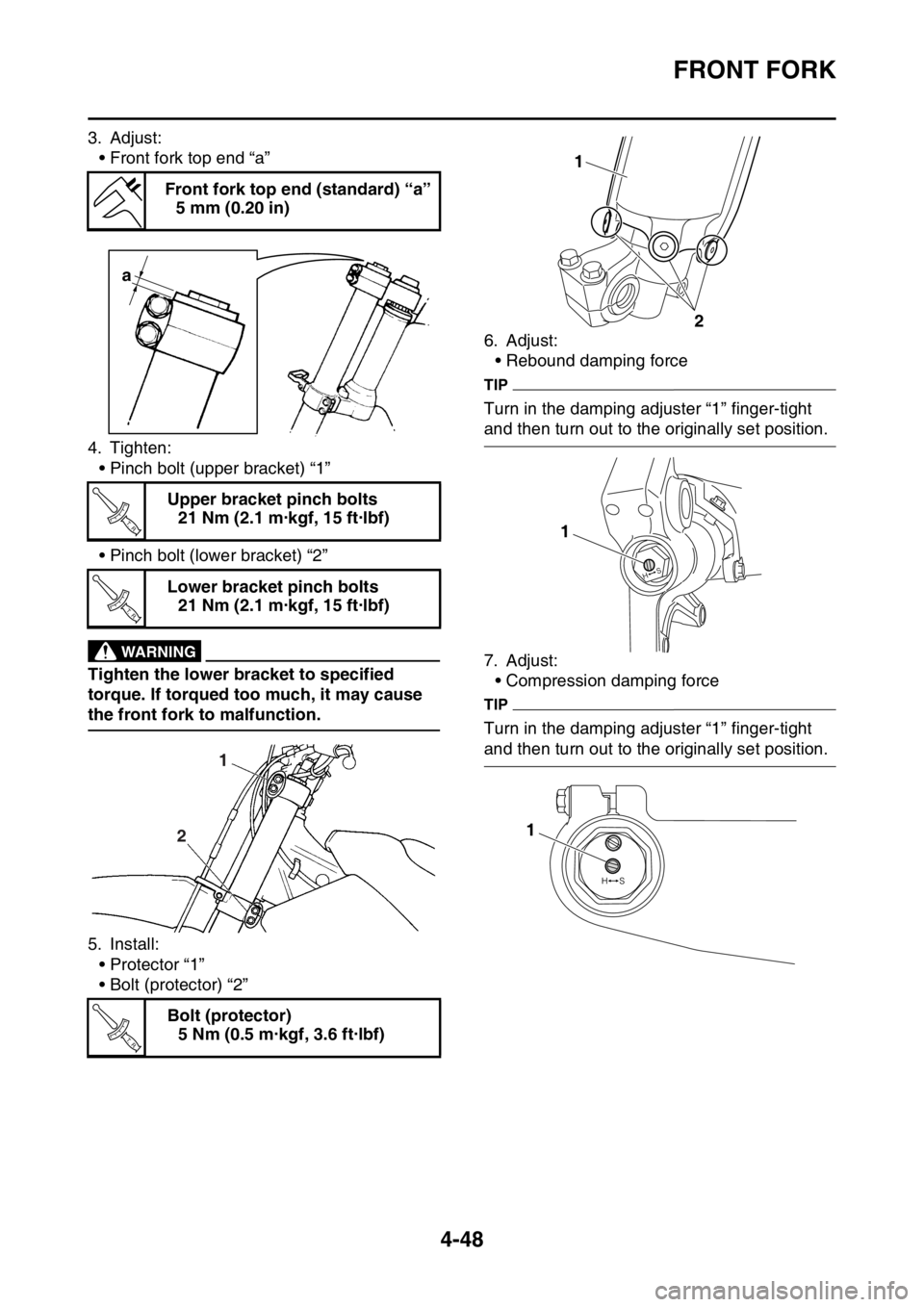

3. Adjust:

• Front fork top end “a”

4. Tighten:

• Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA33DD044

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:

• Protector “1”

• Bolt (protector) “2”6. Adjust:

• Rebound damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position.

7. Adjust:

• Compression damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position. Front fork top end (standard) “a”

5 mm (0.20 in)

Upper bracket pinch bolts

21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts

21 Nm (2.1 m·kgf, 15 ft·lbf)

Bolt (protector)

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

a

T R..

T R..

21

T R..

1

2

1

1

Page 173 of 356

STEERING HEAD

4-49

EAS1SM5172

STEERING HEAD

Removing the lower bracket

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Number plate Refer to “GENERAL CHASSIS” on page 4-1.

Handlebar Refer to “HANDLEBAR” on page 4-31.

1 Front fender 1

2 Steering stem nut 1

3 Front fork leg (s) 2 Refer to “FRONT FORK” on page 4-37.

4 Upper bracket 1

5 Steering ring nut 1

6 Lower bracket 1

7 Bearing race cover 1

8 Upper bearing 1

9 Bearing (lower side) 1

10 Bearing races 2

For installation, reverse the removal proce-

dure.

2

4

5

7

3

1

6

8

9

10

LS

1st

2ndT.R.

LS

LS

T.R.21 Nm (2.1 mlbf) kgf, 15 ft

T.R.9 Nm (0.9 mlbf) kgf, 6.5 ft

T.R.21 Nm (2.1 mlbf) kgf, 15 ft

T.R.10 Nm (1.0 mlbf) kgf, 7.2 ft

T.R.145 Nm (14.5 mlbf) kgf, 105 ft

38 Nm (3.8 m

lbf) kgf, 27 ft

7 Nm (0.7 m

lbf) kgf, 5.1 ft

Page 174 of 356

STEERING HEAD

4-50

EAS1SM5173REMOVING THE LOWER BRACKET

1. Use a suitable stand to raise the front wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Ring nut “1”

TIP

Remove the ring nut with the steering nut

wrench “2”.

EWA13730

WARNING

Securely support the lower bracket so that

there is no danger of it falling.

EAS1SM5174CHECKING THE STEERING HEAD

1. Wash with kerosene:

• Bearing

• Bearing races

2. Check:

• Bearing

• Bearing races

Damage/pitting Replace.

3. Replace:

• Bearing

• Bearing races

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the bearing race from the steering

head pipe with a long rod “1” and a hammer.

b. Remove the bearing race from the lower

bracket with a chisel “2” and a hammer.

c. Install a new bearing race.

ECA14270

NOTICE

If the bearing race is not installed properly,

the steering head pipe could be damaged.

TIP

Always replace the bearing and the bearing

race as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Check:

• Upper bracket

• Lower bracket

(along with the steering stem)

Bends/cracks/damage Replace.

EAS1SM5175INSTALLING THE STEERING HEAD

1. Install:

• Lower bearing “1”

TIP

Apply the lithium soap base grease on the dust

seal lip and bearing inner circumference. Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

Page 175 of 356

STEERING HEAD

4-51

2. Install:

• Bearing races

• Upper bearing “1”

• Bearing race cover “2”

TIP

Apply the lithium soap base grease on the

bearing and bearing race cover lip.

3. Install:

• Lower bracket “1”

TIP

Apply the lithium soap base grease on the

bearing, the portion “a” and thread of the steer-

ing stem.

4. Install:

• Steering ring nut “1”

TIP

Install the steering nut with its stepped side “a”

facing downward.

Tighten the steering ring nut with a steering

nut wrench “2”.

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-33.5. Check the steering stem by turning this lock

to lock. If there is any binding, remove the

steering stem and check the steering bear-

ing.

6. Install:

• Washer “1”

7. Install:

• Front fork “1”

• Upper bracket “2”

TIP

• Temporarily tighten the pinch bolts (lower

bracket).

• Do not tighten the pinch bolts (upper bracket)

yet. Steering ring nut

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LS

1 a

LSLS

T R..

Page 176 of 356

STEERING HEAD

4-52

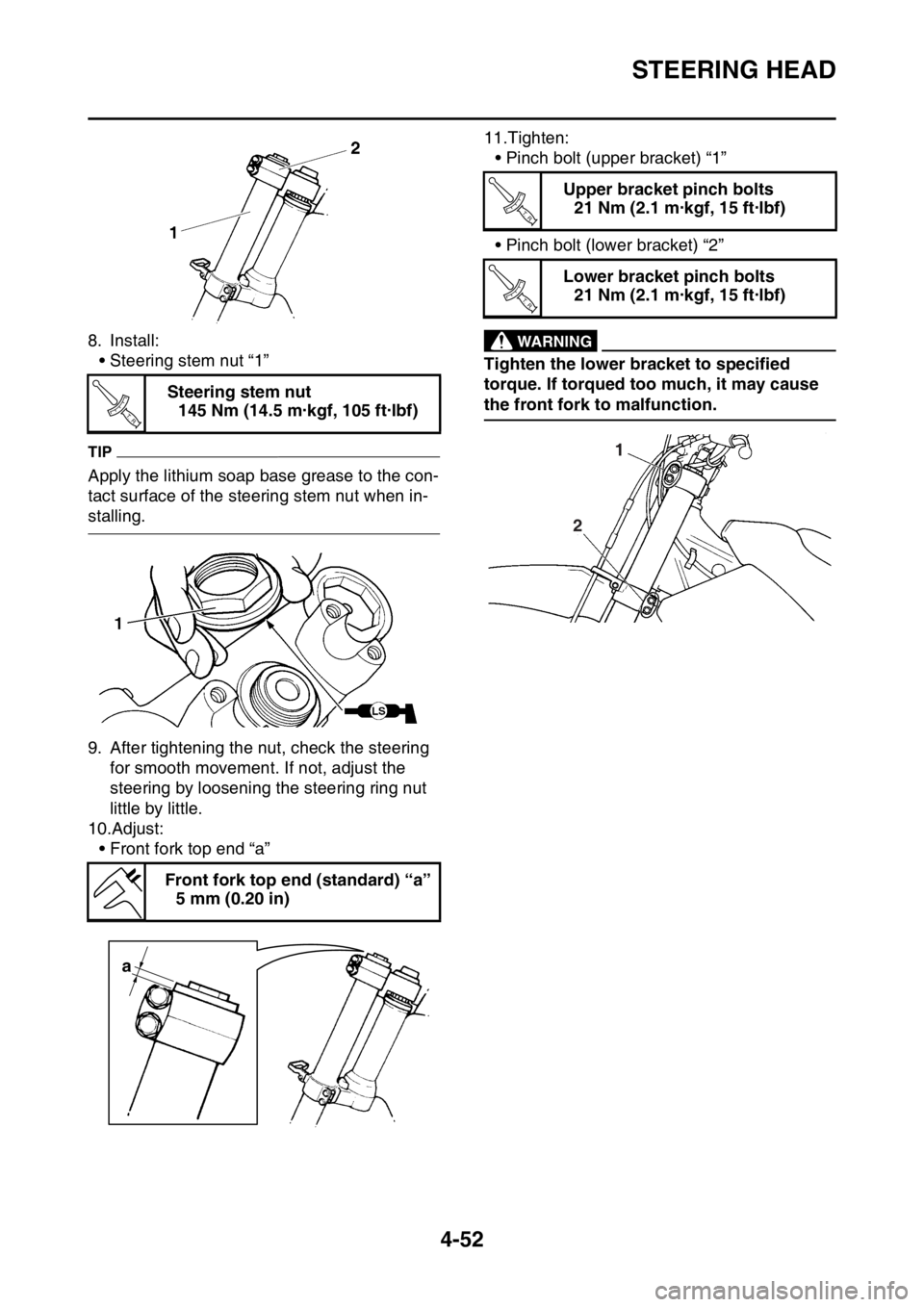

8. Install:

• Steering stem nut “1”

TIP

Apply the lithium soap base grease to the con-

tact surface of the steering stem nut when in-

stalling.

9. After tightening the nut, check the steering

for smooth movement. If not, adjust the

steering by loosening the steering ring nut

little by little.

10.Adjust:

• Front fork top end “a”11.Tighten:

• Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA33DD049

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction. Steering stem nut

145 Nm (14.5 m·kgf, 105 ft·lbf)

Front fork top end (standard) “a”

5 mm (0.20 in)T R..

a

Upper bracket pinch bolts

21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts

21 Nm (2.1 m·kgf, 15 ft·lbf)

T R..

T R..

21

Page 177 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-53

EAS1SM5176

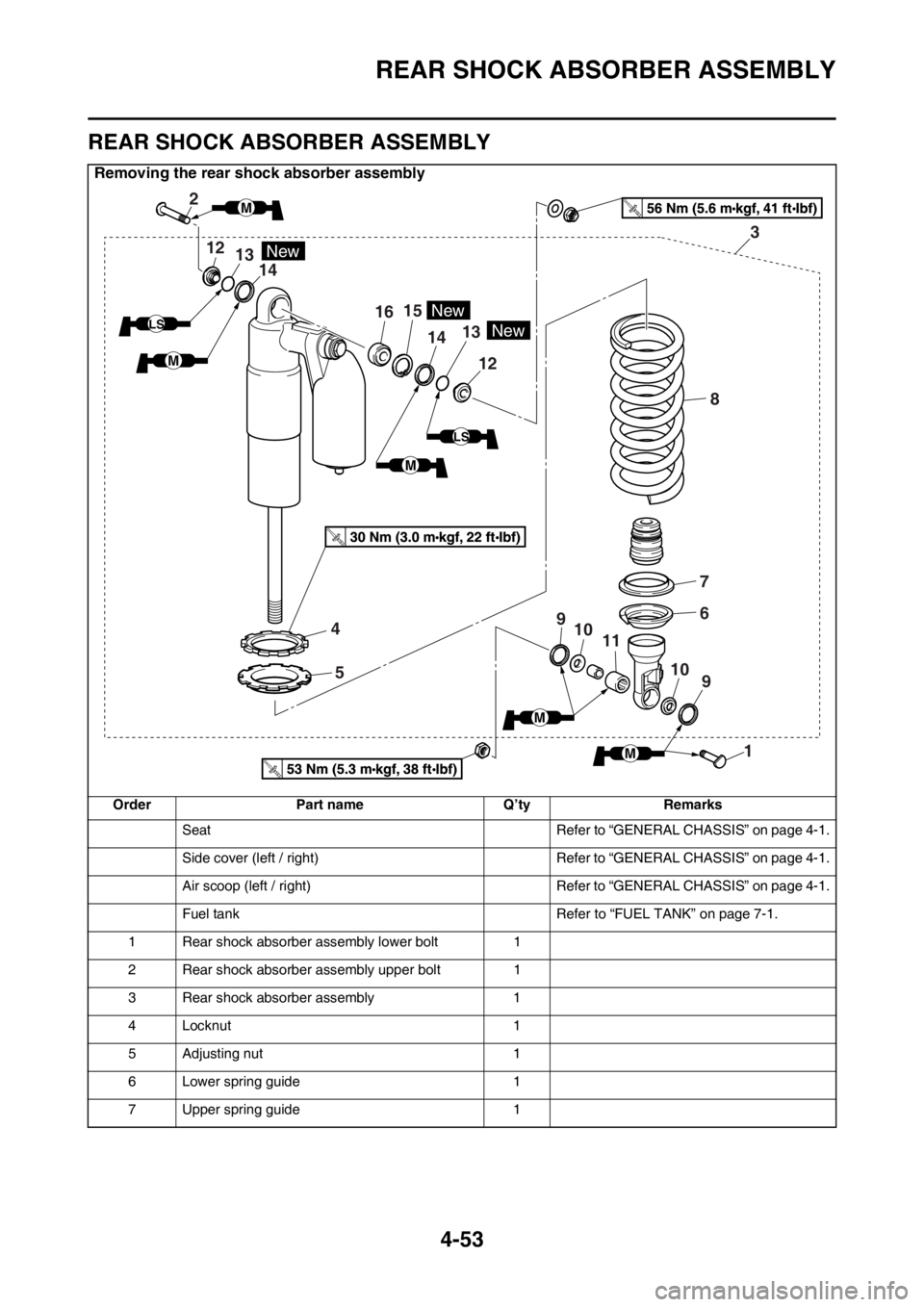

REAR SHOCK ABSORBER ASSEMBLY

Removing the rear shock absorber assembly

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Side cover (left / right) Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tank Refer to “FUEL TANK” on page 7-1.

1 Rear shock absorber assembly lower bolt 1

2 Rear shock absorber assembly upper bolt 1

3 Rear shock absorber assembly 1

4 Locknut 1

5 Adjusting nut 1

6 Lower spring guide 1

7 Upper spring guide 1

2

12

1615

1413

12

14

4

5

7

6

83

9

9 10

10 11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 178 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-54

Removing the rear shock absorber assembly

Order Part name Q’ty Remarks

8Spring 1

9 Dust seal 2

10 Collars 2

11 Bushing 1

12 Collars 2

13 O-ring 2

14 Dust seal 2

15 Stopper ring 1

16 Bearing 1

For installation, reverse the removal proce-

dure.

2

12

1615

1413

12

14

4

5

7

6

83

9

9 10

10 11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 179 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-55

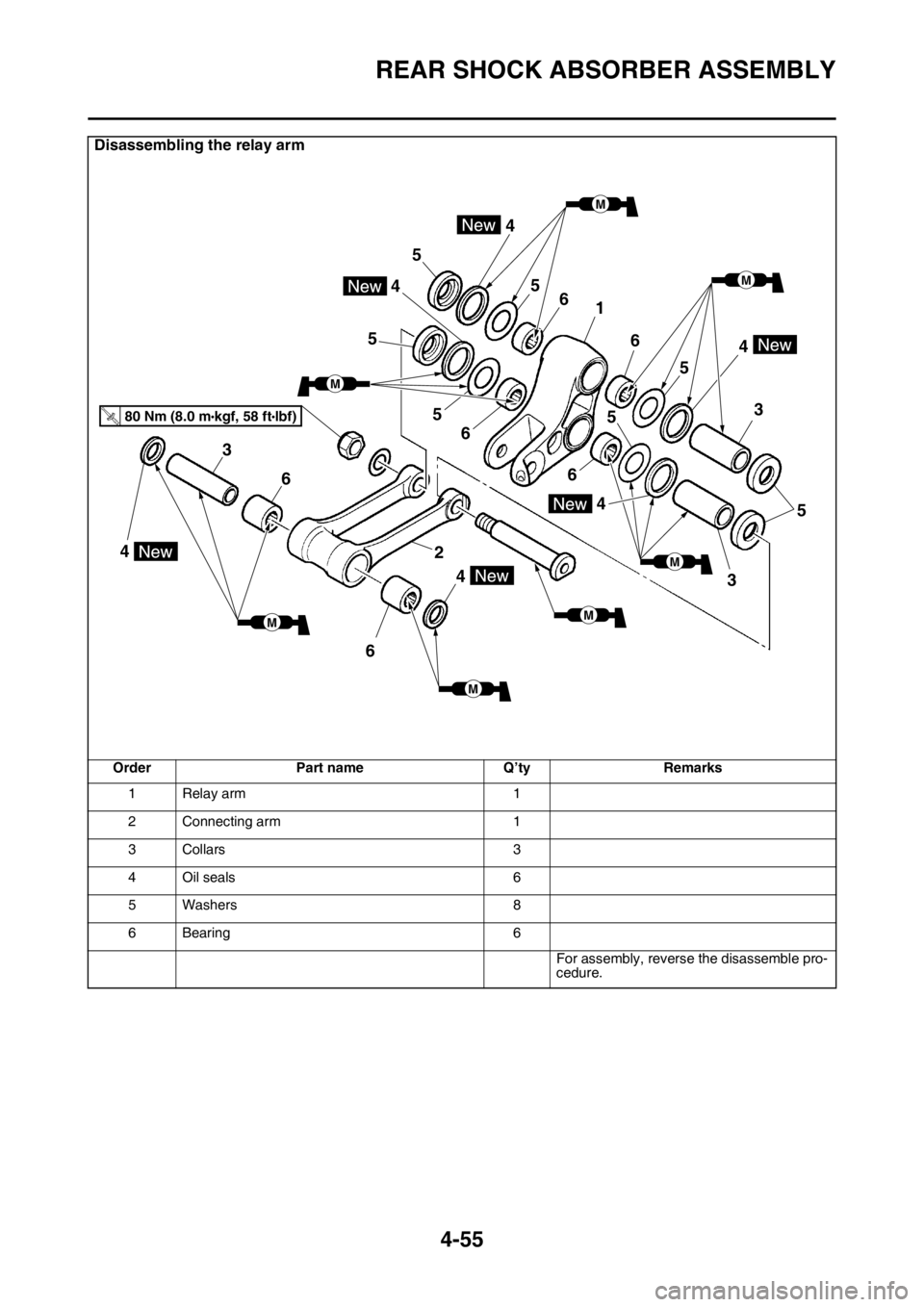

Disassembling the relay arm

Order Part name Q’ty Remarks

1 Relay arm 1

2 Connecting arm 1

3Collars 3

4Oil seals 6

5Washers 8

6 Bearing 6

For assembly, reverse the disassemble pro-

cedure.

5

3

5

6

165

4

5

5

4

5

6

6

5

4

3

2

4

6

6

3

4

4

T.R.80 Nm (8.0 mlbf) kgf, 58 ft

M

M

M

M

M MM

Page 180 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-56

EAS1SM5177HANDLING THE REAR SHOCK ABSORBEREWA13740

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure that you understand the following in-

formation. The manufacturer cannot be held

responsible for property damage or person-

al injury that may result from improper han-

dling of the rear shock absorber.

• Do not tamper or attempt to open the rear

shock absorber.

• Do not subject the rear shock absorber to

an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

• Do not deform or damage the rear shock

absorber in any way. Rear shock absorber

damage will result in poor damping perfor-

mance.

TIP

A break-in is required up to about 50 km of run-

ning.

EAS1SM5178DISPOSING OF A REAR SHOCK ABSORB-

ER

Before disposing the rear shock absorber, be

sure to extract the nitrogen gas from valve “1”.

EWA33DD052

WARNING

• Wear protective glasses to prevent your

eyes from damage due to possible gas or

metal chips scattered.

• To dispose of a damaged or a worn-out

rear shock absorber, take the unit to your

Yamaha dealer for this disposal proce-

dure.

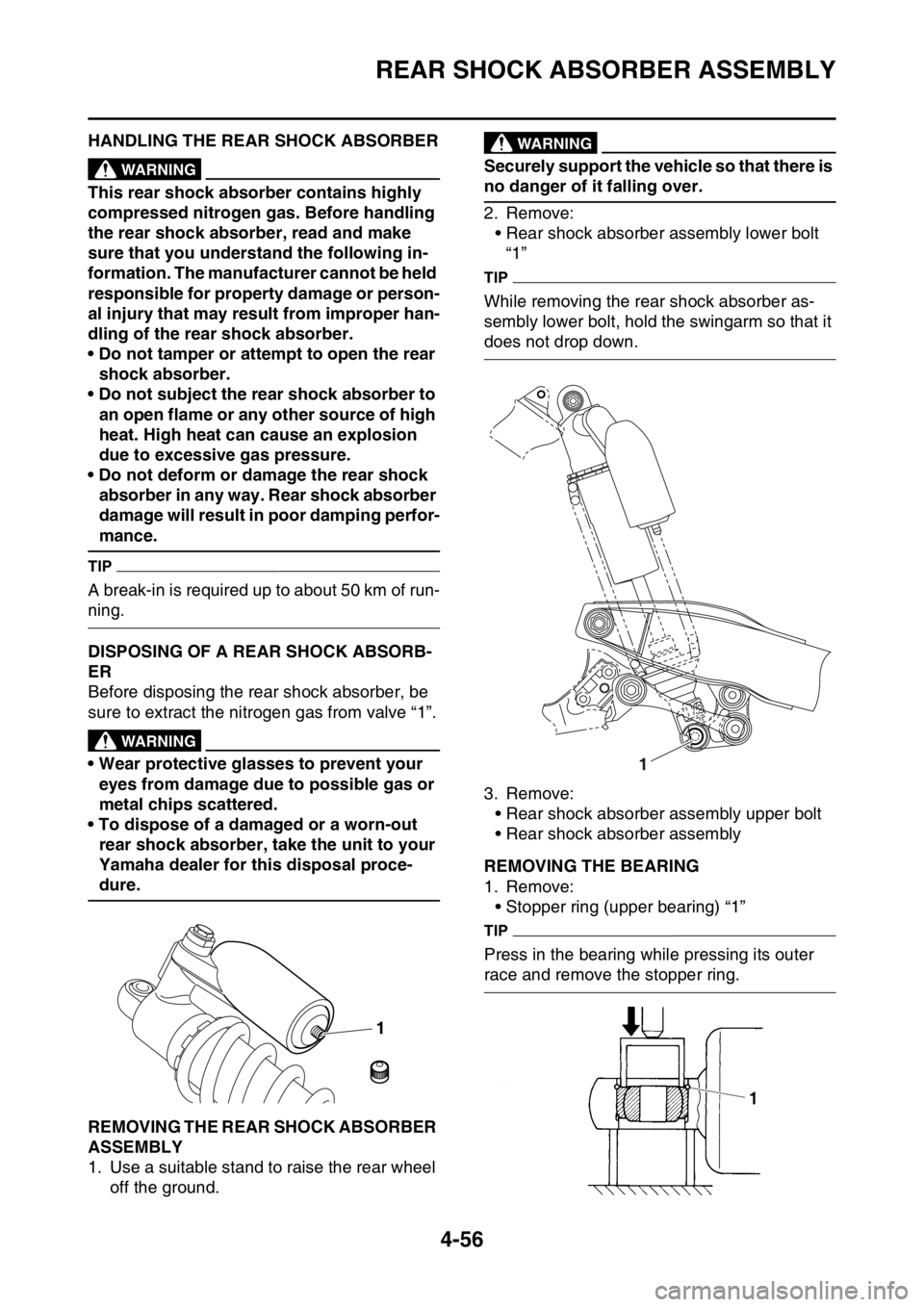

EAS1SM5179REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear shock absorber assembly lower bolt

“1”

TIP

While removing the rear shock absorber as-

sembly lower bolt, hold the swingarm so that it

does not drop down.

3. Remove:

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly

EAS1SM5180REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) “1”

TIP

Press in the bearing while pressing its outer

race and remove the stopper ring.

1

1