YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 181 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-57

2. Remove:

• Upper bearing “1”

TIP

Remove the bearing by pressing its outer race.

3. Remove:

• Lower bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS1SM5181CHECKING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Check:

• Rear shock absorber rod

Bends/damage Replace the rear shock

absorber assembly.

• Rear shock absorber

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

•Spring

Damage/wear Replace.

• Spring guide

Damage/wear Replace.

• Bearing

Damage/wear Replace.

•Bolts

Bends/damage/wear Replace.

EAS1SM5182

CHECKING THE CONNECTING ARM AND

RELAY ARM

1. Check:

• Connecting arm

• Relay arm

Damage/wear Replace.

2. Check:

• Bearing

• Spacers

Damage/pitting/scratches Replace the

bearings and spacers as a set.

3. Check:

• Oil seals

Damage/pitting Replace.

EAS1SM5183INSTALLING THE RELAY ARM

1. Lubricate:

• Oil seals

• Bearing

• Spacers

• Washers

•Collars

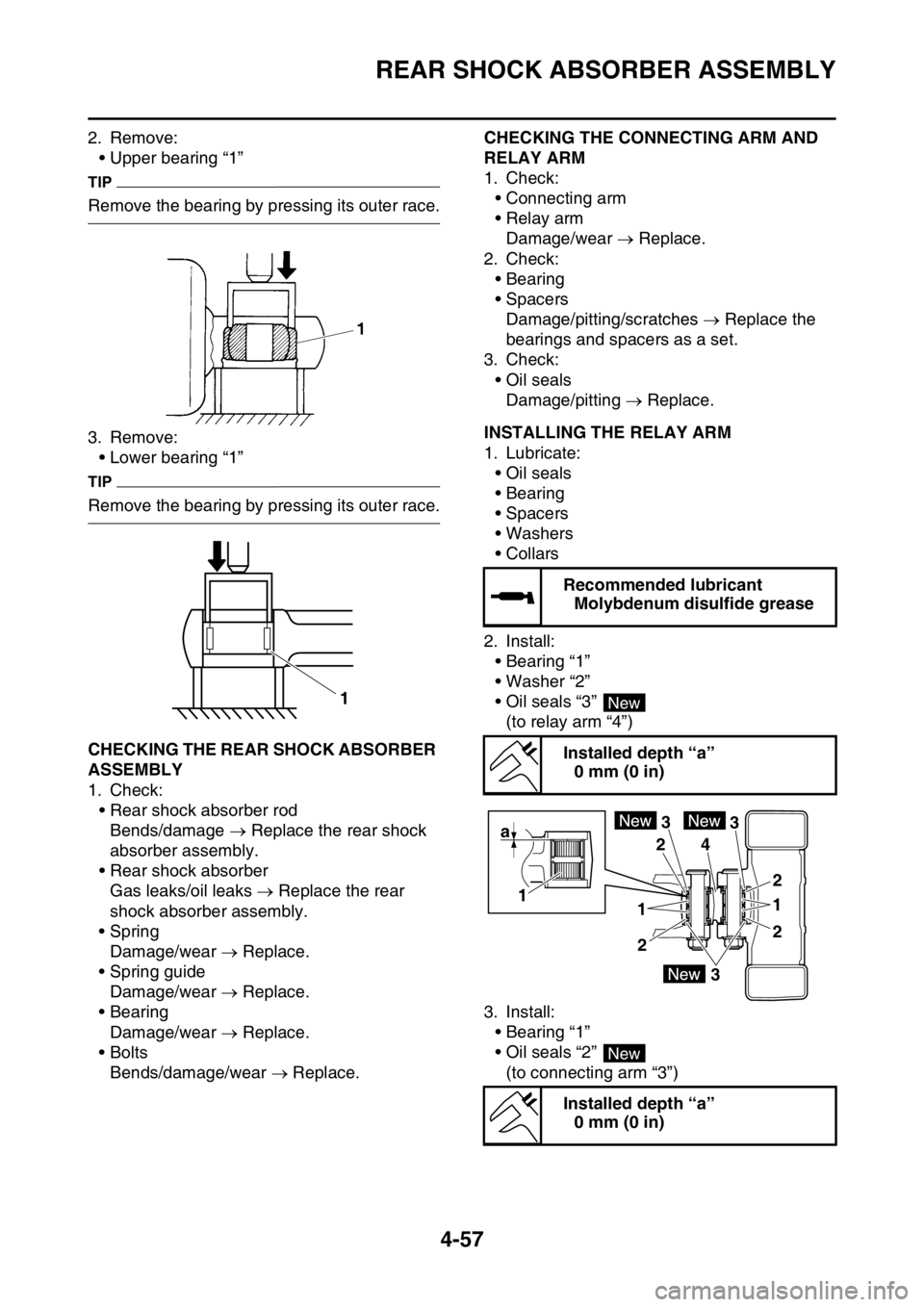

2. Install:

• Bearing “1”

• Washer “2”

• Oil seals “3”

(to relay arm “4”)

3. Install:

• Bearing “1”

• Oil seals “2”

(to connecting arm “3”)

1

Recommended lubricant

Molybdenum disulfide grease

Installed depth “a”

0 mm (0 in)

Installed depth “a”

0 mm (0 in)

New

3 3

43

2 2

22

a

1

11

New

Page 182 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-58

EAS1SM5184INSTALLING THE REAR SHOCK ABSORB-

ER ASSEMBLY

1. Lubricate:

• Bearing (lower side)

•Dust seal

•Collars

• Bushing

ECA1DX1012

NOTICE

Do not apply the grease to the bearing outer

race because it will wear the rear shock ab-

sorber surface on which the bearing is

press fitted.

2. Lubricate:

• O-ring

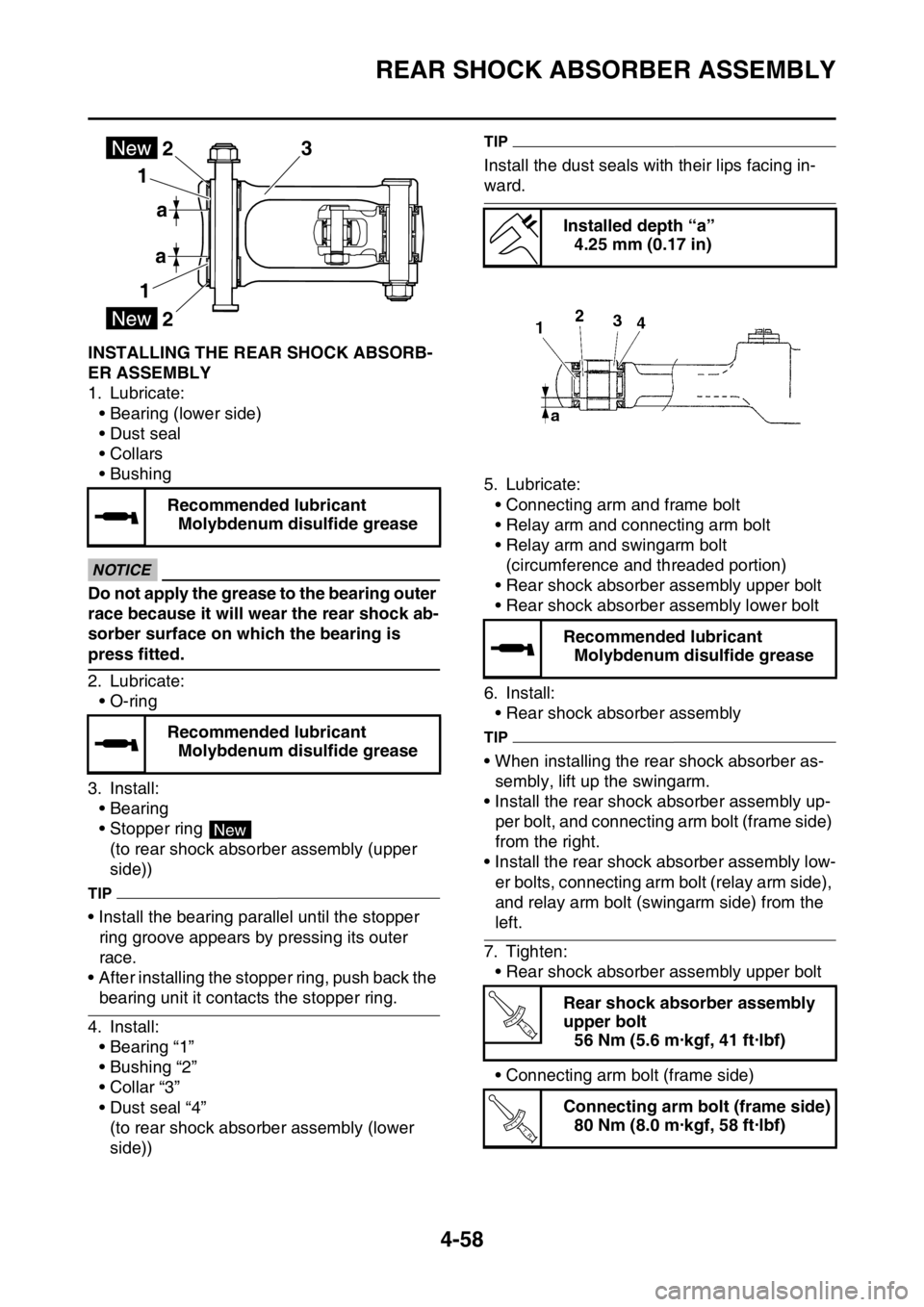

3. Install:

• Bearing

• Stopper ring

(to rear shock absorber assembly (upper

side))

TIP

• Install the bearing parallel until the stopper

ring groove appears by pressing its outer

race.

• After installing the stopper ring, push back the

bearing unit it contacts the stopper ring.

4. Install:

• Bearing “1”

• Bushing “2”

• Collar “3”

• Dust seal “4”

(to rear shock absorber assembly (lower

side))

TIP

Install the dust seals with their lips facing in-

ward.

5. Lubricate:

• Connecting arm and frame bolt

• Relay arm and connecting arm bolt

• Relay arm and swingarm bolt

(circumference and threaded portion)

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly lower bolt

6. Install:

• Rear shock absorber assembly

TIP

• When installing the rear shock absorber as-

sembly, lift up the swingarm.

• Install the rear shock absorber assembly up-

per bolt, and connecting arm bolt (frame side)

from the right.

• Install the rear shock absorber assembly low-

er bolts, connecting arm bolt (relay arm side),

and relay arm bolt (swingarm side) from the

left.

7. Tighten:

• Rear shock absorber assembly upper bolt

• Connecting arm bolt (frame side) Recommended lubricant

Molybdenum disulfide grease

Recommended lubricant

Molybdenum disulfide grease

3

a 1

12

a

2

New

Installed depth “a”

4.25 mm (0.17 in)

Recommended lubricant

Molybdenum disulfide grease

Rear shock absorber assembly

upper bolt

56 Nm (5.6 m·kgf, 41 ft·lbf)

Connecting arm bolt (frame side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

T R..

T R..

Page 183 of 356

REAR SHOCK ABSORBER ASSEMBLY

4-59

• Connecting arm bolt (relay arm side)

• Relay arm bolt (swingarm side)

• Rear shock absorber assembly lower boltConnecting arm bolt (relay arm

side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

Relay arm bolt (swingarm side)

70 Nm (7.0 m·kgf, 51 ft·lbf)

Rear shock absorber assembly

lower bolt

53 Nm (5.3 m·kgf, 38 ft·lbf)

T R..

T R..

T R..

Page 184 of 356

SWINGARM

4-60

EAS1SM5185

SWINGARM

Removing the swingarm

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Brake hose holder Refer to “REAR BRAKE” on page 4-21.

Rear brake caliper Refer to “REAR BRAKE” on page 4-21.

Bolt (brake pedal)

Drive chain

1Collars 2

2Oil seals 2

3Thrust bearing 2

4Bushing 2

5Oil seals 2

6Bearing 4

For installation, reverse the removal proce-

dure.

1

2

3

6

4

6

4

1

3

6

2

5

T.R.70 Nm (7.0 mlbf) kgf, 51 ft

T.R.4.0 Nm (0.40 mlbf) kgf, 2.9 ft

Page 185 of 356

SWINGARM

4-61

EAS1SM5186REMOVING THE SWINGARM

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Measure:

• Swingarm side play

• Swingarm vertical movement

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure the tightening torque of the pivot

shaft nut.

b. Measure the swingarm side play “a” by mov-

ing the swingarm from side to side.

c. If the swingarm side play is out of specifica-

tion, check the spacers, the bearings, and

the collars.

d. Check the swingarm vertical movement “b”

by moving the swingarm up and down.

If swingarm vertical movement is not smooth

or if there is binding, check the spacers, the

bearings, and the collars.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM5187REMOVING THE BEARING

1. Remove:

• Bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS1SM5188CHECKING THE SWINGARM

1. Check:

• Swingarm

Bends/cracks/damage Replace.

2. Check:

• Pivot shaft

Roll the pivot shaft on a flat surface.

Bends Replace.

EWA13770

WARNING

Do not attempt to straighten a bent pivot

shaft.

3. Wash with kerosene:

• Pivot shaft

• Spacers

•Collars

• Bearing

4. Check:

• Oil seals

Damage Replace.

• Bearing

• Spacers

Free play exists/unsmooth revolution/rust

Replace bearing and bushing as a set. Pivot shaft nut

85 Nm (8.5 m·kgf, 61 ft·lbf)

Swingarm end free play limit (ra-

dial)

1.0 mm (0.04 in)

T R..

Page 186 of 356

SWINGARM

4-62

EAS1SM5189INSTALLING THE SWINGARM

1. Lubricate:

• Bearing

•Collars

• Spacers

• Oil seal

• Pivot shaft

2. Install:

• Bearing “1”

• Oil seals “2”

(to the swingarm)

TIP

First install the outer and then the inner bear-

ings to a specified depth from inside.

3. Install:

• Swingarm

TIP

Install the pivot shaft from the right.

4. Install:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7.

5. Adjust:

• Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-27.Recommended lubricant

Molybdenum disulfide grease

Installed depth “a”

0–0.5 mm (0–0.02 in)

Installed depth “b”

6.5 mm (0.26 in)

Pivot shaft nut

85 Nm (8.5 m·kgf, 61 ft·lbf)

Drive chain slack

50–60 mm (1.97–2.36 in)

New

New

2 22

1 1

aaa

b ba

NewNewNew

T R..

Page 187 of 356

CHAIN DRIVE

4-63

EAS1SM5190

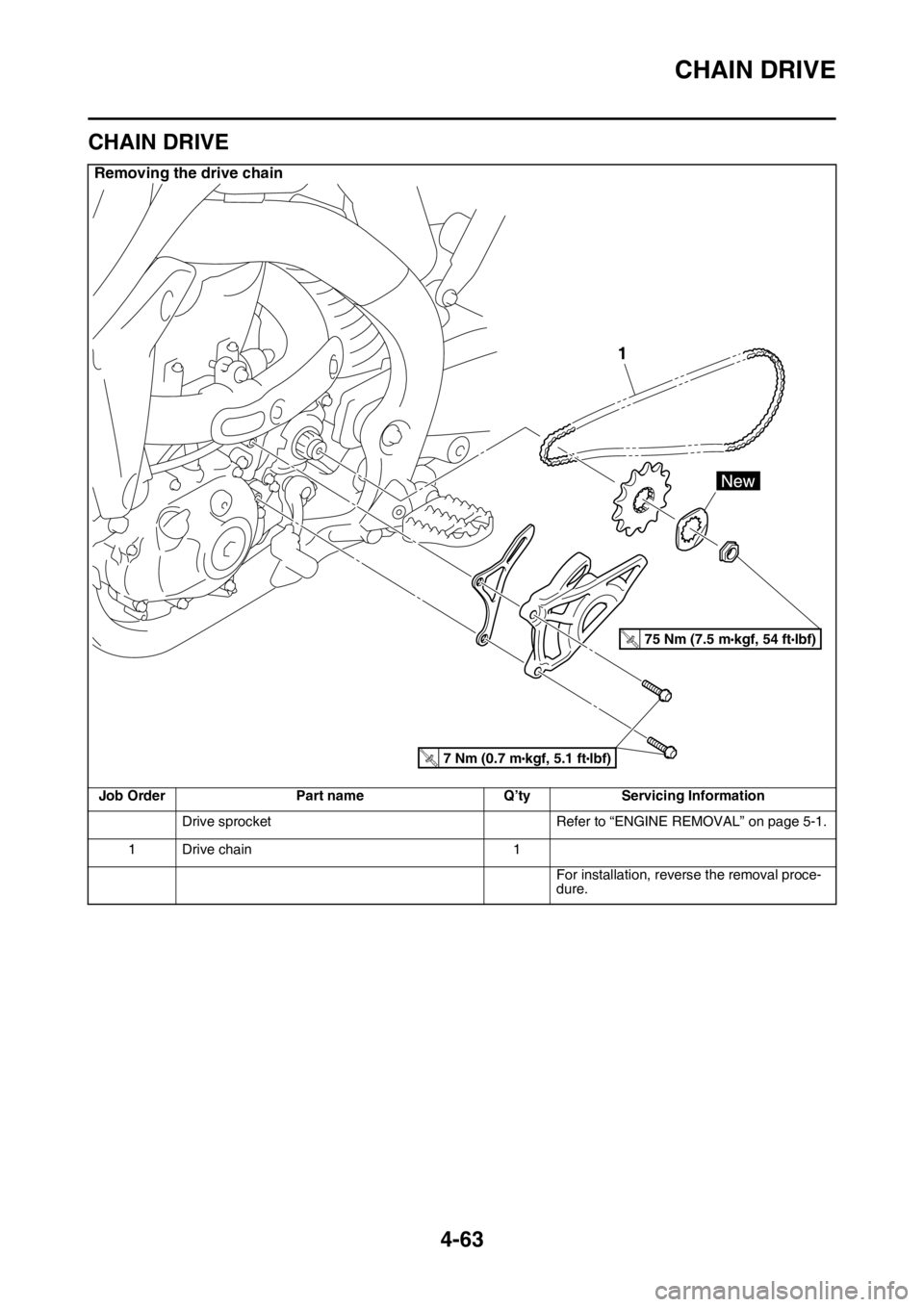

CHAIN DRIVE

Removing the drive chain

Job Order Part name Q’ty Servicing Information

Drive sprocket Refer to “ENGINE REMOVAL” on page 5-1.

1 Drive chain 1

For installation, reverse the removal proce-

dure.

1

T.R.75 Nm (7.5 mlbf) kgf, 54 ft

T.R.7 Nm (0.7 mlbf) kgf, 5.1 ft

Page 188 of 356

CHAIN DRIVE

4-64

EAS1SM5191REMOVING THE DRIVE CHAIN

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Joint clip

• Drive chain joint “1”

• Drive chain “2”

EAS1SM5192CHECKING THE DRIVE CHAIN

1. Measure:

• 15-link section of the drive chain

Out of specification Replace the drive

chain.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

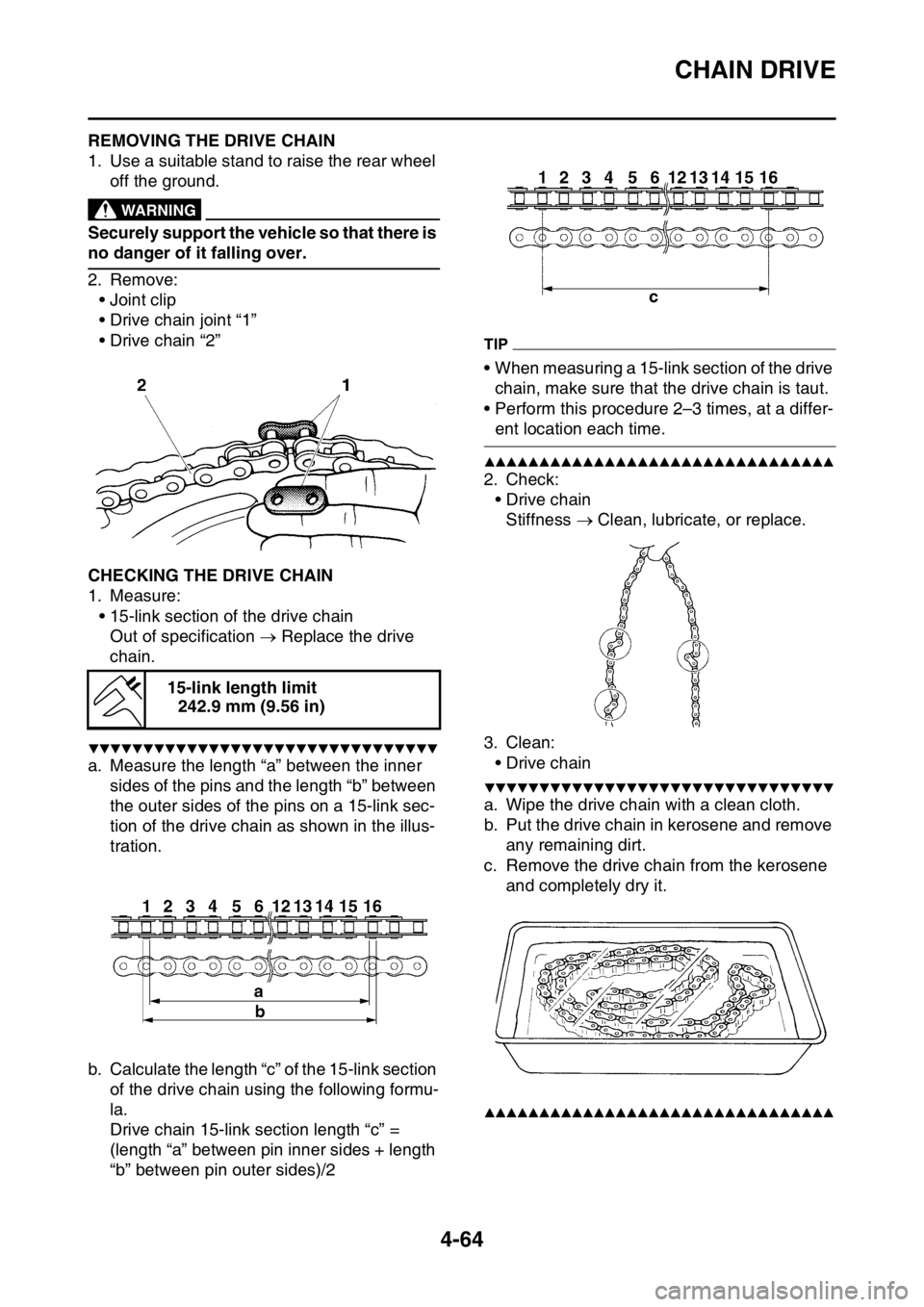

a. Measure the length “a” between the inner

sides of the pins and the length “b” between

the outer sides of the pins on a 15-link sec-

tion of the drive chain as shown in the illus-

tration.

b. Calculate the length “c” of the 15-link section

of the drive chain using the following formu-

la.

Drive chain 15-link section length “c” =

(length “a” between pin inner sides + length

“b” between pin outer sides)/2

TIP

• When measuring a 15-link section of the drive

chain, make sure that the drive chain is taut.

• Perform this procedure 2–3 times, at a differ-

ent location each time.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check:

•Drive chain

Stiffness Clean, lubricate, or replace.

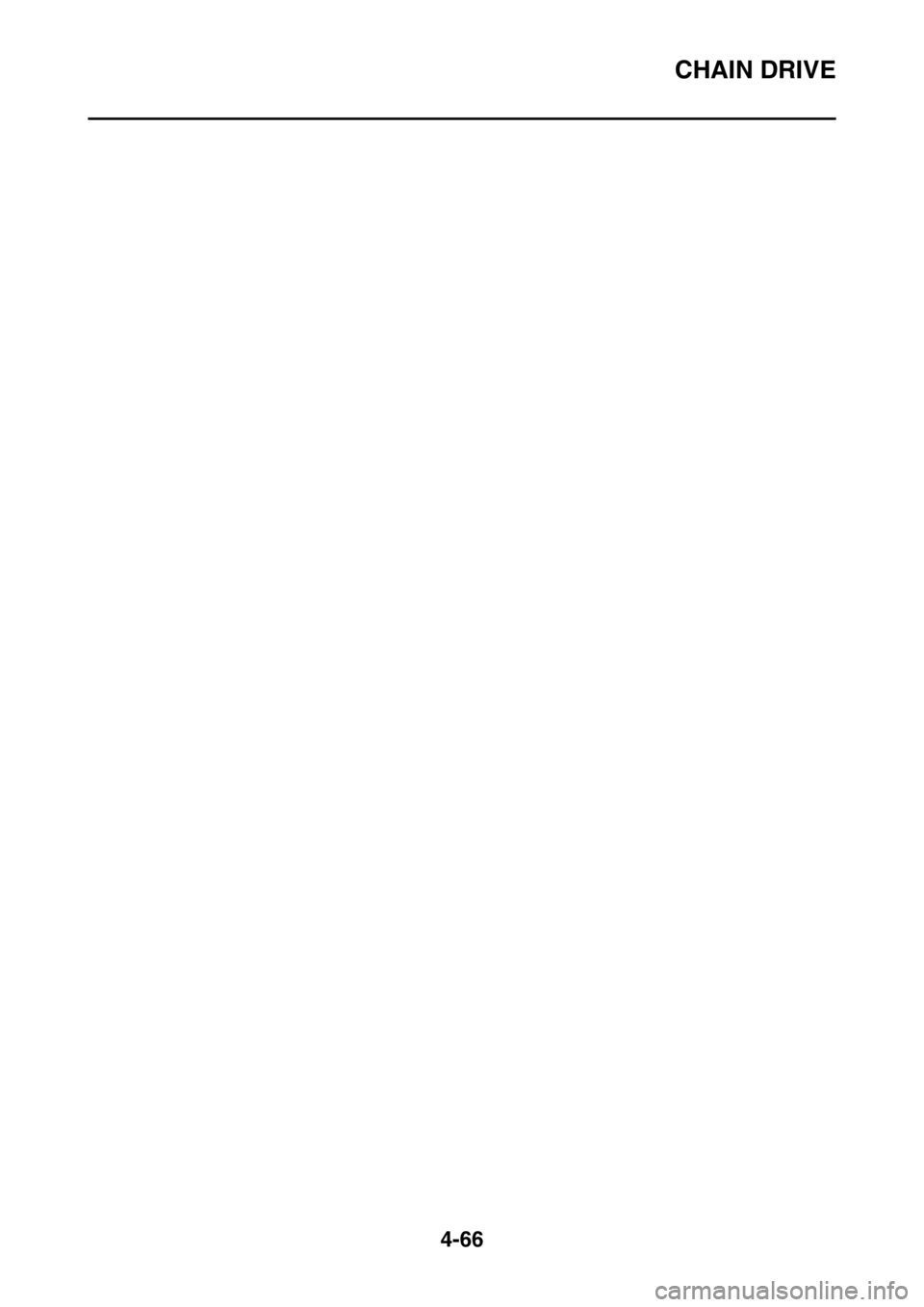

3. Clean:

•Drive chain

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Wipe the drive chain with a clean cloth.

b. Put the drive chain in kerosene and remove

any remaining dirt.

c. Remove the drive chain from the kerosene

and completely dry it.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

15-link length limit

242.9 mm (9.56 in)

Page 189 of 356

CHAIN DRIVE

4-65

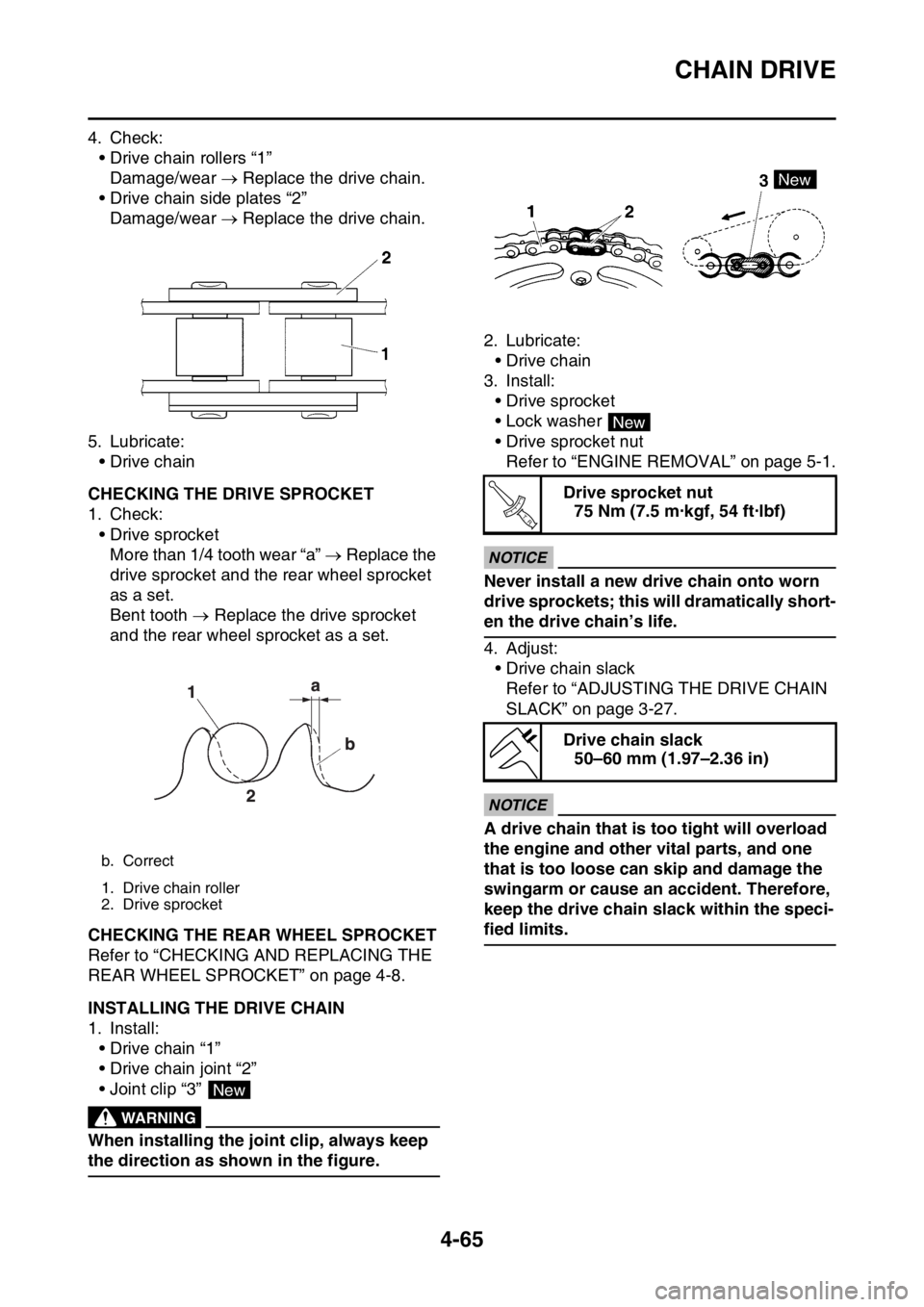

4. Check:

• Drive chain rollers “1”

Damage/wear Replace the drive chain.

• Drive chain side plates “2”

Damage/wear Replace the drive chain.

5. Lubricate:

•Drive chain

EAS1SM5193CHECKING THE DRIVE SPROCKET

1. Check:

• Drive sprocket

More than 1/4 tooth wear “a” Replace the

drive sprocket and the rear wheel sprocket

as a set.

Bent tooth Replace the drive sprocket

and the rear wheel sprocket as a set.

EAS1SM5194CHECKING THE REAR WHEEL SPROCKET

Refer to “CHECKING AND REPLACING THE

REAR WHEEL SPROCKET” on page 4-8.

EAS1SM5195INSTALLING THE DRIVE CHAIN

1. Install:

• Drive chain “1”

• Drive chain joint “2”

• Joint clip “3”

EWA

WARNING

When installing the joint clip, always keep

the direction as shown in the figure.2. Lubricate:

•Drive chain

3. Install:

• Drive sprocket

• Lock washer

• Drive sprocket nut

Refer to “ENGINE REMOVAL” on page 5-1.

ECA1DX1014

NOTICE

Never install a new drive chain onto worn

drive sprockets; this will dramatically short-

en the drive chain’s life.

4. Adjust:

• Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-27.

ECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

b. Correct

1. Drive chain roller

2. Drive sprocket

New

Drive sprocket nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive chain slack

50–60 mm (1.97–2.36 in)

New

T R..

Page 190 of 356

CHAIN DRIVE

4-66