YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 251 of 356

AC MAGNETO

5-58

EAS1SM5273

AC MAGNETO

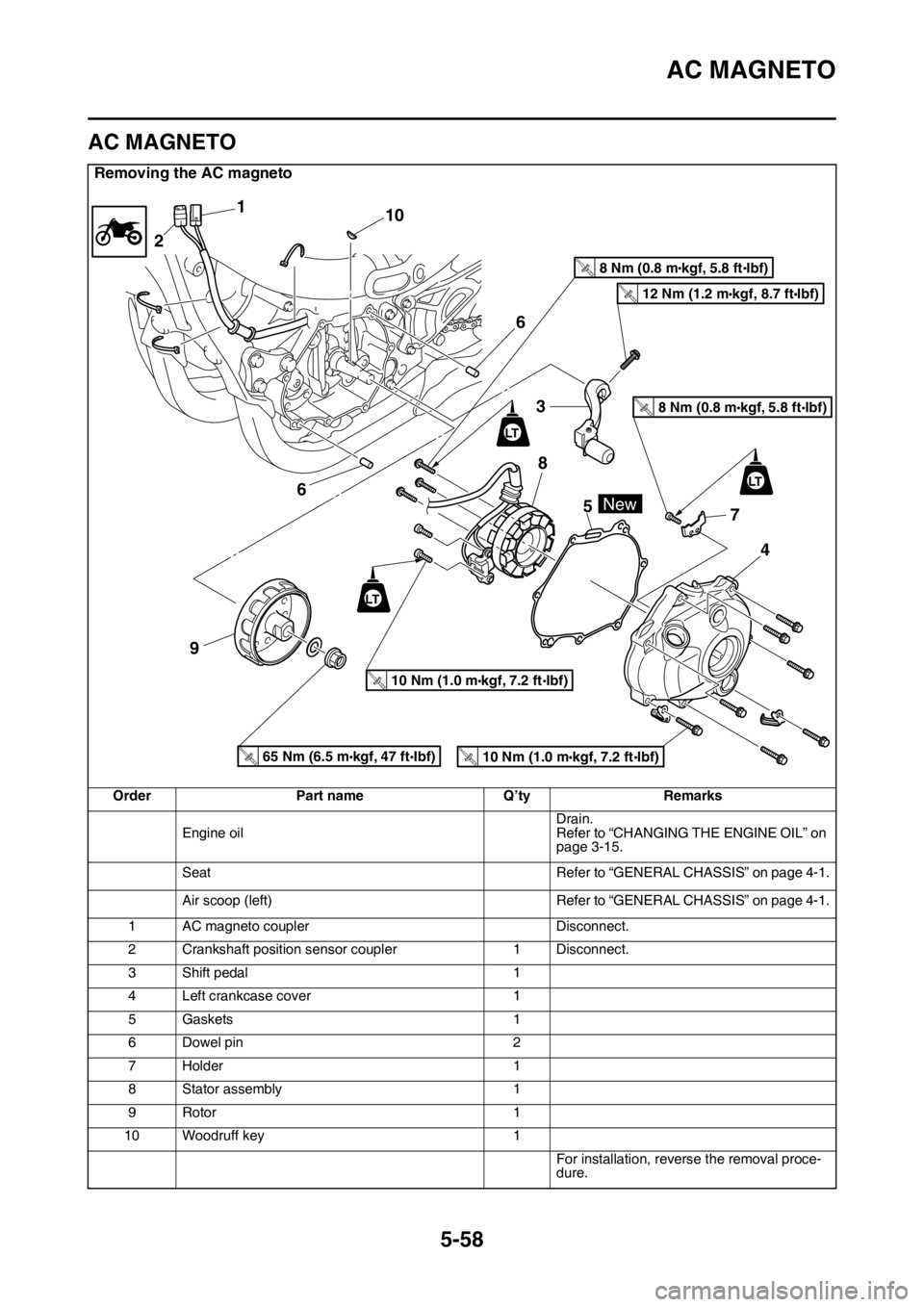

Removing the AC magneto

Order Part name Q’ty Remarks

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-15.

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left) Refer to “GENERAL CHASSIS” on page 4-1.

1 AC magneto coupler Disconnect.

2 Crankshaft position sensor coupler 1 Disconnect.

3 Shift pedal 1

4 Left crankcase cover 1

5 Gaskets 1

6 Dowel pin 2

7Holder 1

8 Stator assembly 1

9 Rotor 1

10 Woodruff key 1

For installation, reverse the removal proce-

dure.

110

2

4 7 5 8 3

96

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

65 Nm (6.5 mkgf, 47 ftIbf)T.R.

New

LT

6

LT

LT

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R.

Page 252 of 356

AC MAGNETO

5-59

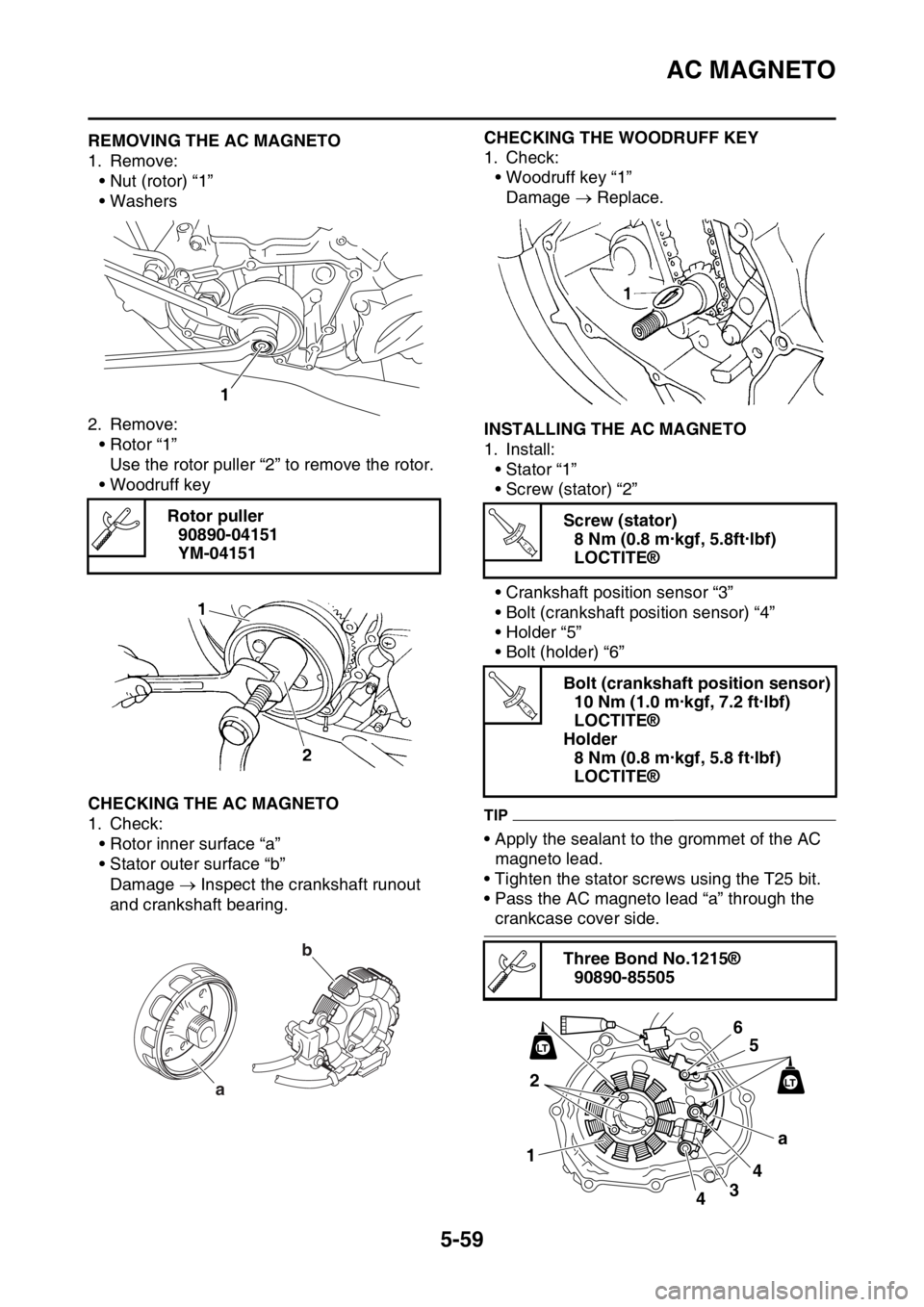

EAS1SM5274REMOVING THE AC MAGNETO

1. Remove:

• Nut (rotor) “1”

• Washers

2. Remove:

• Rotor “1”

Use the rotor puller “2” to remove the rotor.

• Woodruff key

EAS1SM5275CHECKING THE AC MAGNETO

1. Check:

• Rotor inner surface “a”

• Stator outer surface “b”

Damage Inspect the crankshaft runout

and crankshaft bearing.

EAS1SM5276

CHECKING THE WOODRUFF KEY

1. Check:

• Woodruff key “1”

Damage Replace.

EAS1SM5277INSTALLING THE AC MAGNETO

1. Install:

• Stator “1”

• Screw (stator) “2”

• Crankshaft position sensor “3”

• Bolt (crankshaft position sensor) “4”

• Holder “5”

• Bolt (holder) “6”

TIP

• Apply the sealant to the grommet of the AC

magneto lead.

• Tighten the stator screws using the T25 bit.

• Pass the AC magneto lead “a” through the

crankcase cover side. Rotor puller

90890-04151

YM-04151

1

ab

Screw (stator)

8 Nm (0.8 m·kgf, 5.8ft·lbf)

LOCTITE®

Bolt (crankshaft position sensor)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Holder

8 Nm (0.8 m·kgf, 5.8 ft·lbf)

LOCTITE®

Three Bond No.1215®

90890-85505

T R..

T R..

26

5

4

3

4a

1

LT

LT

Page 253 of 356

AC MAGNETO

5-60

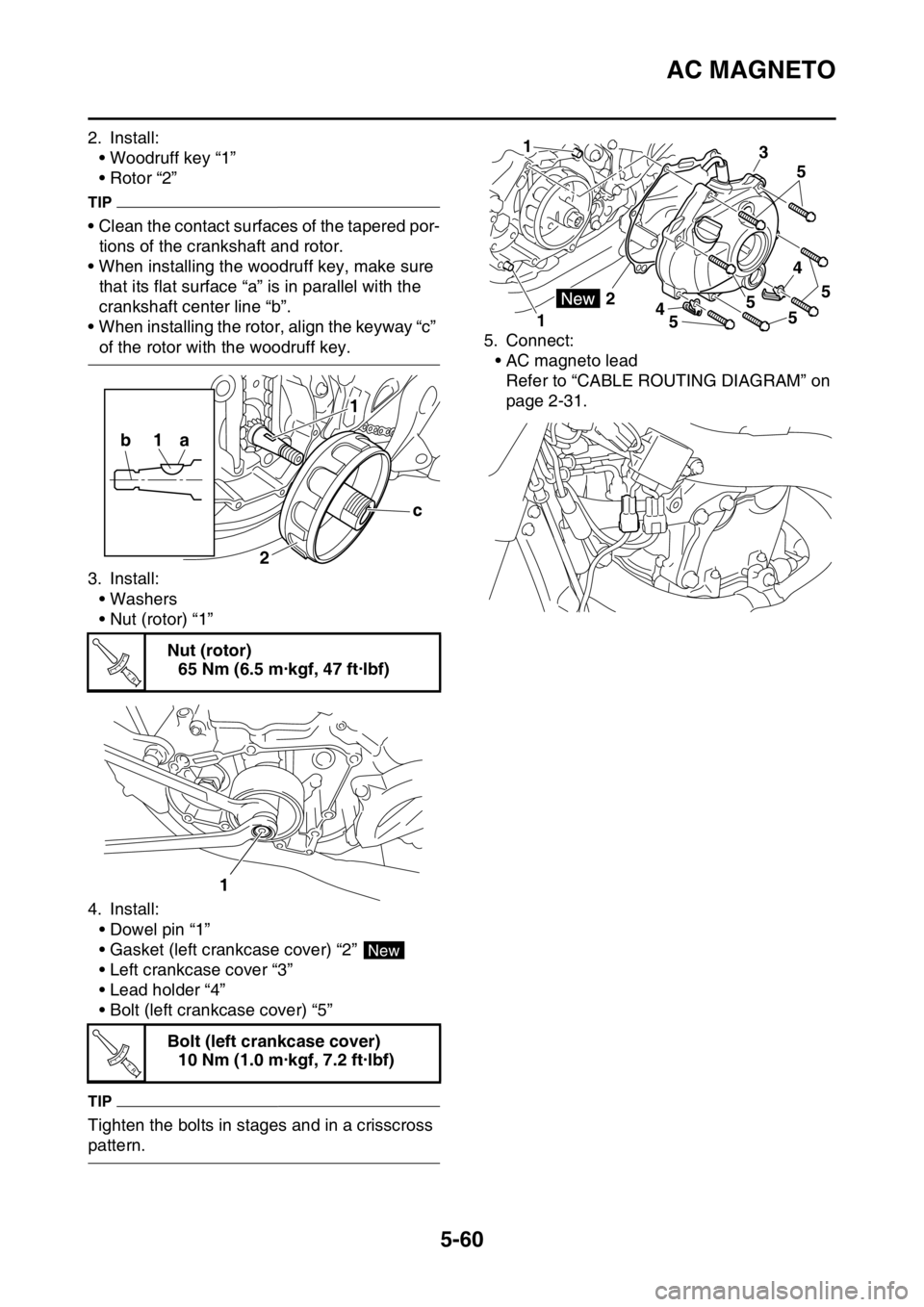

2. Install:

• Woodruff key “1”

• Rotor “2”

TIP

• Clean the contact surfaces of the tapered por-

tions of the crankshaft and rotor.

• When installing the woodruff key, make sure

that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the rotor, align the keyway “c”

of the rotor with the woodruff key.

3. Install:

• Washers

• Nut (rotor) “1”

4. Install:

• Dowel pin “1”

• Gasket (left crankcase cover) “2”

• Left crankcase cover “3”

• Lead holder “4”

• Bolt (left crankcase cover) “5”

TIP

Tighten the bolts in stages and in a crisscross

pattern.5. Connect:

• AC magneto lead

Refer to “CABLE ROUTING DIAGRAM” on

page 2-31.

Nut (rotor)

65 Nm (6.5 m·kgf, 47 ft·lbf)

Bolt (left crankcase cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

b11

c

2 a

T R..

1

New

T R..

1

1

2

3

5

5

5

5

4

45

Page 254 of 356

CRANKCASE

5-61

EAS1SM5278

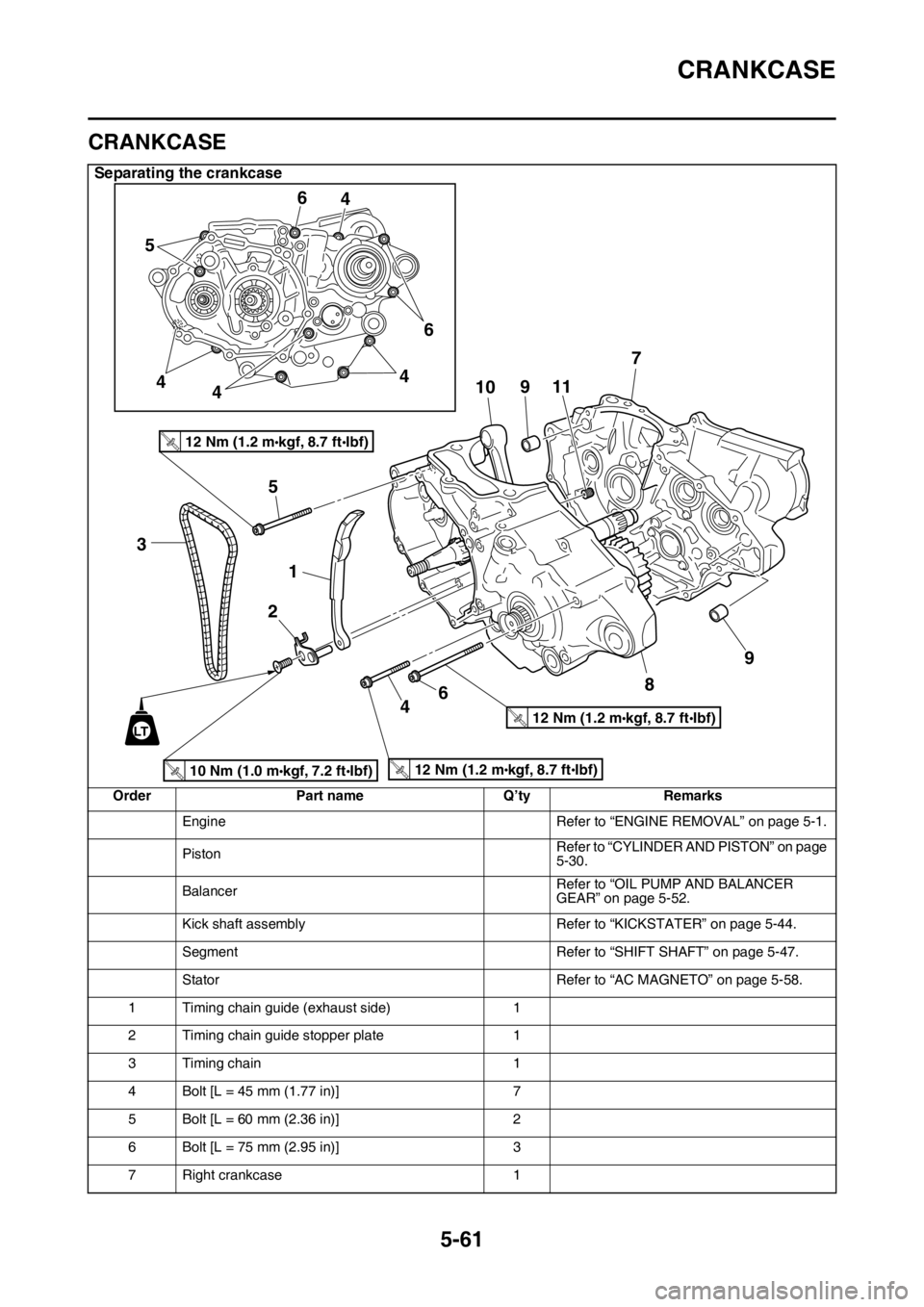

CRANKCASE

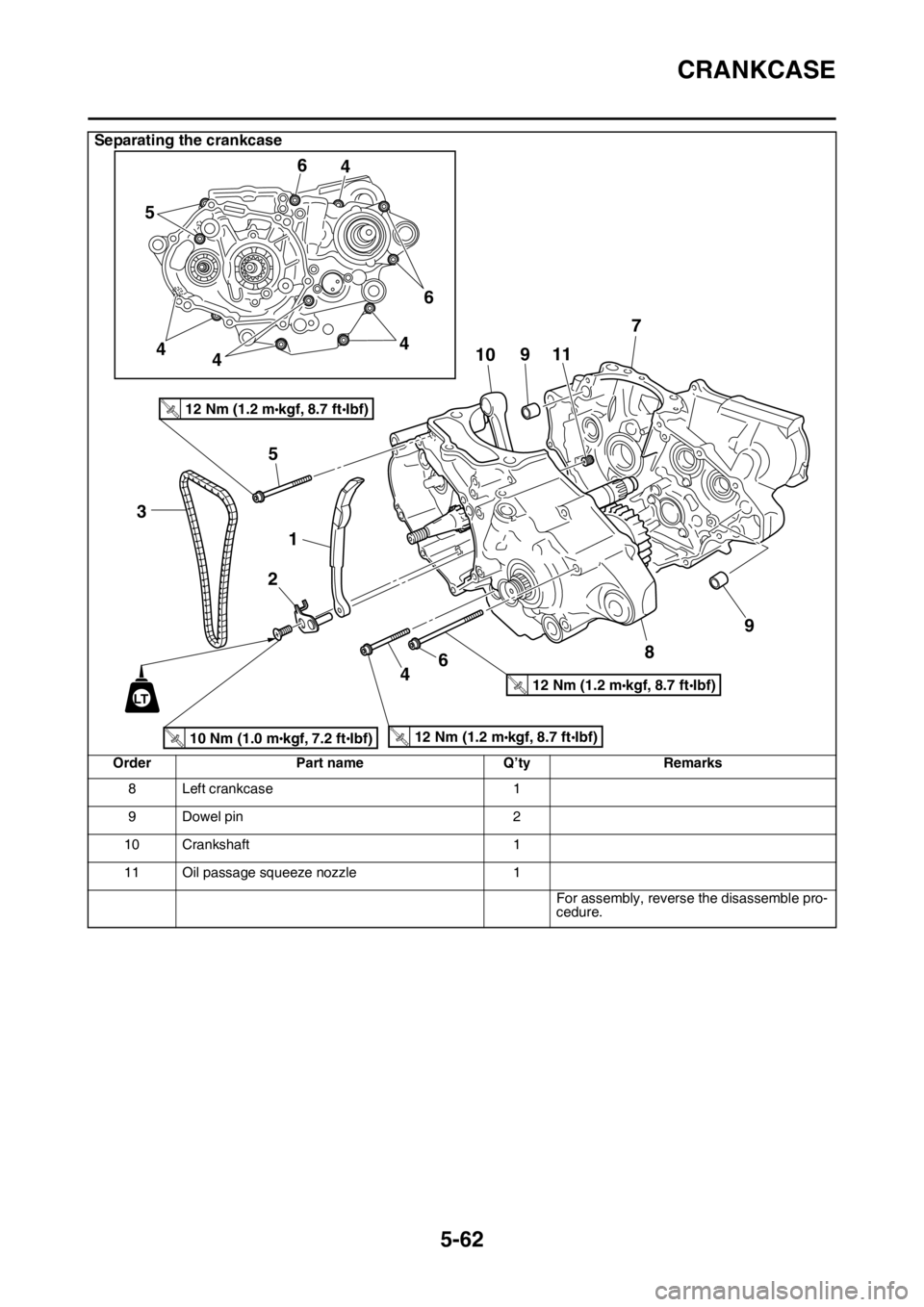

Separating the crankcase

Order Part name Q’ty Remarks

Engine Refer to “ENGINE REMOVAL” on page 5-1.

PistonRefer to “CYLINDER AND PISTON” on page

5-30.

BalancerRefer to “OIL PUMP AND BALANCER

GEAR” on page 5-52.

Kick shaft assembly Refer to “KICKSTATER” on page 5-44.

Segment Refer to “SHIFT SHAFT” on page 5-47.

Stator Refer to “AC MAGNETO” on page 5-58.

1 Timing chain guide (exhaust side) 1

2 Timing chain guide stopper plate 1

3 Timing chain 1

4 Bolt [L = 45 mm (1.77 in)] 7

5 Bolt [L = 60 mm (2.36 in)] 2

6 Bolt [L = 75 mm (2.95 in)] 3

7 Right crankcase 1

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R

.

3

1 5

2

6410 56

4

4

446

9117

8

9

LT

Page 255 of 356

CRANKCASE

5-62

8 Left crankcase 1

9 Dowel pin 2

10 Crankshaft 1

11 Oil passage squeeze nozzle 1

For assembly, reverse the disassemble pro-

cedure.

Separating the crankcase

Order Part name Q’ty Remarks

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R

.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R.

3

1 5

2

6410 56

4

4

446

9117

8

9

LT

Page 256 of 356

CRANKCASE

5-63

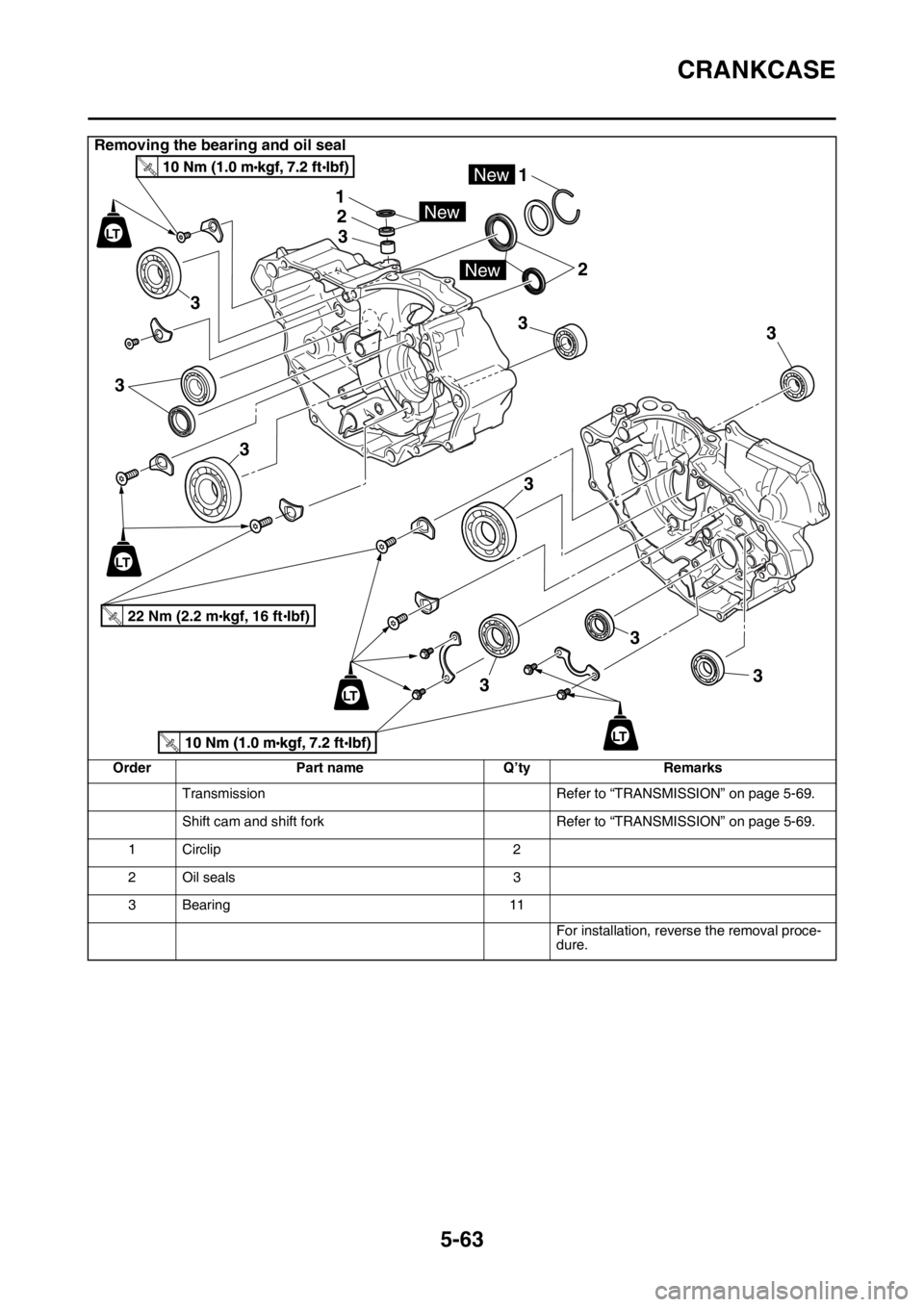

Removing the bearing and oil seal

Order Part name Q’ty Remarks

Transmission Refer to “TRANSMISSION” on page 5-69.

Shift cam and shift fork Refer to “TRANSMISSION” on page 5-69.

1 Circlip 2

2Oil seals 3

3 Bearing 11

For installation, reverse the removal proce-

dure.

LT

LT

LT

2

3

33

3

3

3 3

33

New

1

1

2

3

New

New

LT

22 Nm (2.2 mkgf, 16 ftIbf)T.R.

Page 257 of 356

CRANKCASE

5-64

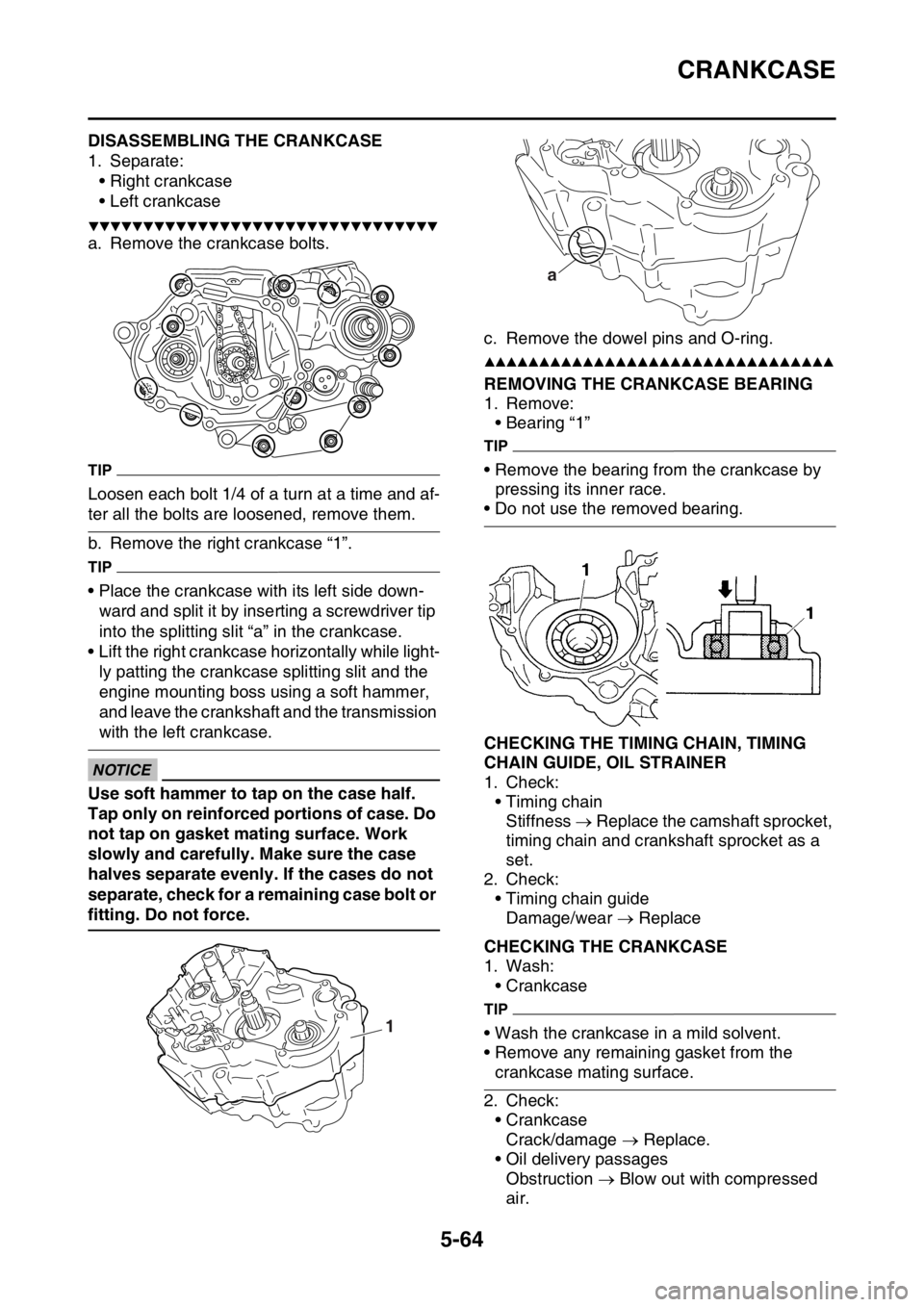

EAS1SM5279DISASSEMBLING THE CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1”.

TIP

• Place the crankcase with its left side down-

ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA33DD041

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force.c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM5280REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by

pressing its inner race.

• Do not use the removed bearing.

EAS1SM5281CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:

• Timing chain

Stiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check:

• Timing chain guide

Damage/wear Replace

EAS1SM5282CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

2. Check:

• Crankcase

Crack/damage Replace.

• Oil delivery passages

Obstruction Blow out with compressed

air.

1

a

Page 258 of 356

CRANKCASE

5-65

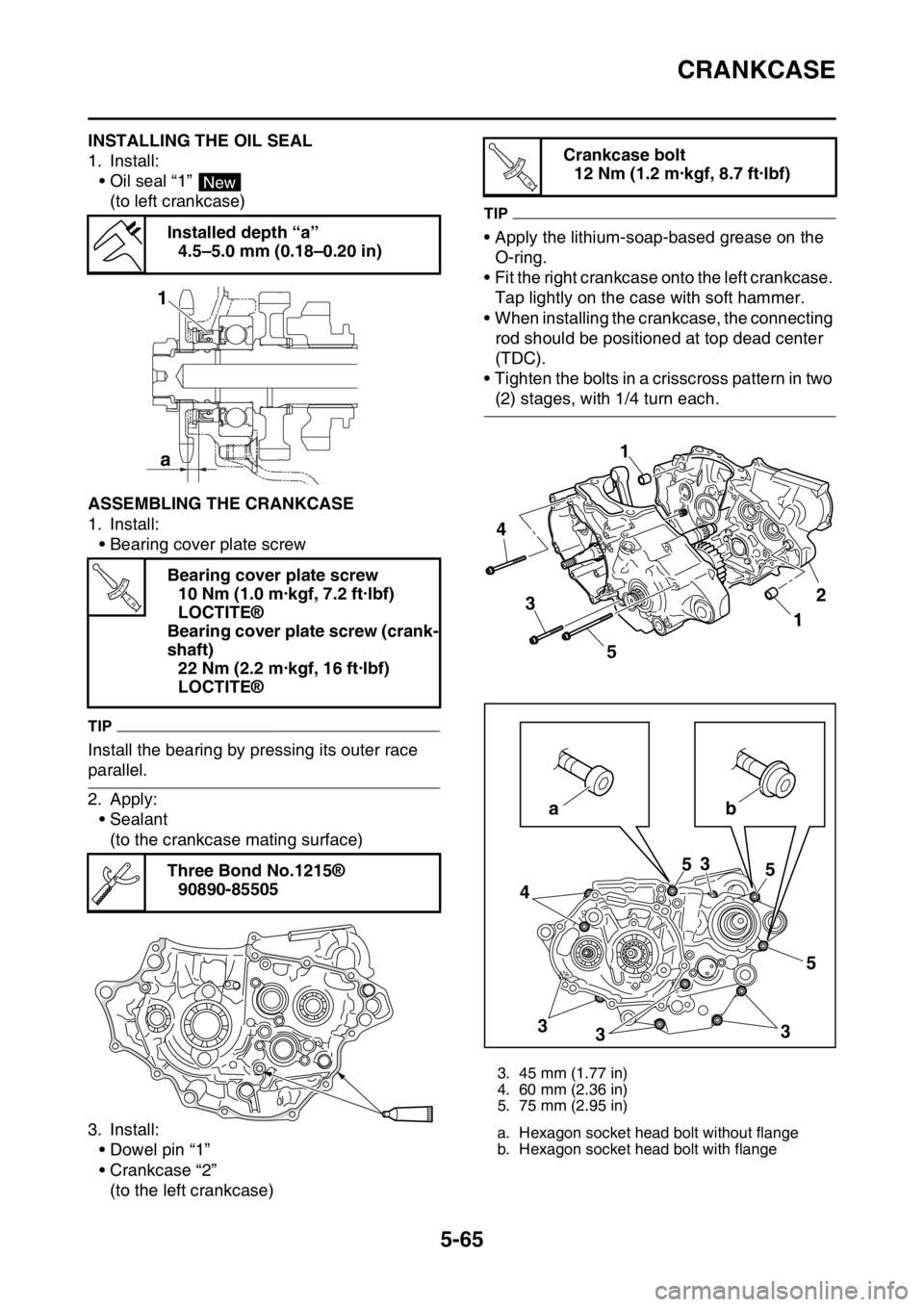

EAS1SM5283INSTALLING THE OIL SEAL

1. Install:

• Oil seal “1”

(to left crankcase)

EAS1SM5284ASSEMBLING THE CRANKCASE

1. Install:

• Bearing cover plate screw

TIP

Install the bearing by pressing its outer race

parallel.

2. Apply:

• Sealant

(to the crankcase mating surface)

3. Install:

• Dowel pin “1”

• Crankcase “2”

(to the left crankcase)

TIP

• Apply the lithium-soap-based grease on the

O-ring.

• Fit the right crankcase onto the left crankcase.

Tap lightly on the case with soft hammer.

• When installing the crankcase, the connecting

rod should be positioned at top dead center

(TDC).

• Tighten the bolts in a crisscross pattern in two

(2) stages, with 1/4 turn each. Installed depth “a”

4.5–5.0 mm (0.18–0.20 in)

Bearing cover plate screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Bearing cover plate screw (crank-

shaft)

22 Nm (2.2 m·kgf, 16 ft·lbf)

LOCTITE®

Three Bond No.1215®

90890-85505

New

a 1

T R..

Crankcase bolt

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

3. 45 mm (1.77 in)

4. 60 mm (2.36 in)

5. 75 mm (2.95 in)

a. Hexagon socket head bolt without flange

b. Hexagon socket head bolt with flange

T R..

4

5

3

43

335 5 5

3

ab1

1

2

Page 259 of 356

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT

5-66

EAS1SM5285

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT

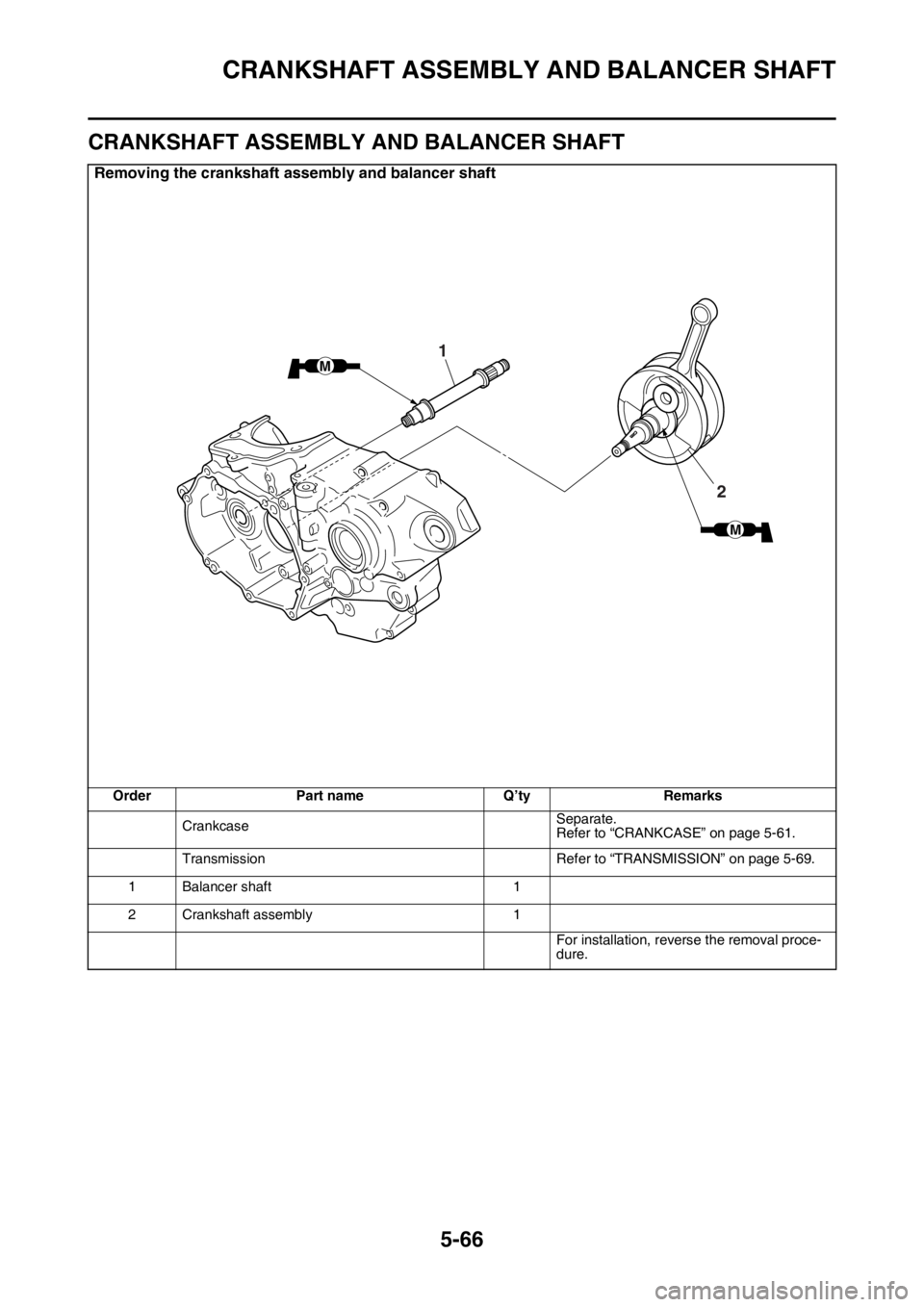

Removing the crankshaft assembly and balancer shaft

Order Part name Q’ty Remarks

CrankcaseSeparate.

Refer to “CRANKCASE” on page 5-61.

Transmission Refer to “TRANSMISSION” on page 5-69.

1 Balancer shaft 1

2 Crankshaft assembly 1

For installation, reverse the removal proce-

dure.

M

M

1

2

Page 260 of 356

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT

5-67

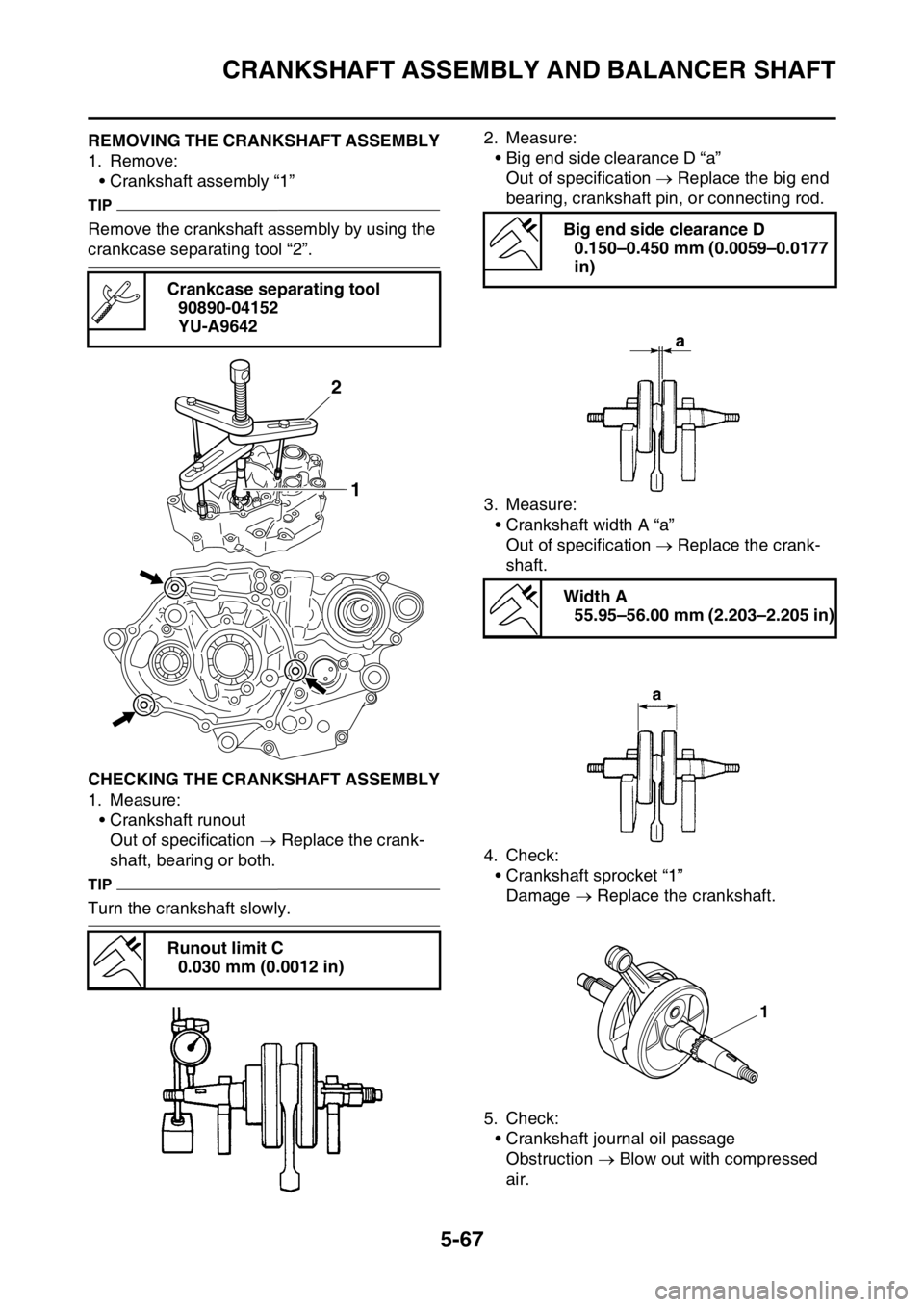

EAS1SM5286REMOVING THE CRANKSHAFT ASSEMBLY

1. Remove:

• Crankshaft assembly “1”

TIP

Remove the crankshaft assembly by using the

crankcase separating tool “2”.

EAS1SM5287CHECKING THE CRANKSHAFT ASSEMBLY

1. Measure:

• Crankshaft runout

Out of specification Replace the crank-

shaft, bearing or both.

TIP

Turn the crankshaft slowly.2. Measure:

• Big end side clearance D “a”

Out of specification Replace the big end

bearing, crankshaft pin, or connecting rod.

3. Measure:

• Crankshaft width A “a”

Out of specification Replace the crank-

shaft.

4. Check:

• Crankshaft sprocket “1”

Damage Replace the crankshaft.

5. Check:

• Crankshaft journal oil passage

Obstruction Blow out with compressed

air. Crankcase separating tool

90890-04152

YU-A9642

Runout limit C

0.030 mm (0.0012 in)

2

1

Big end side clearance D

0.150–0.450 mm (0.0059–0.0177

in)

Width A

55.95–56.00 mm (2.203–2.205 in)

1