YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 241 of 356

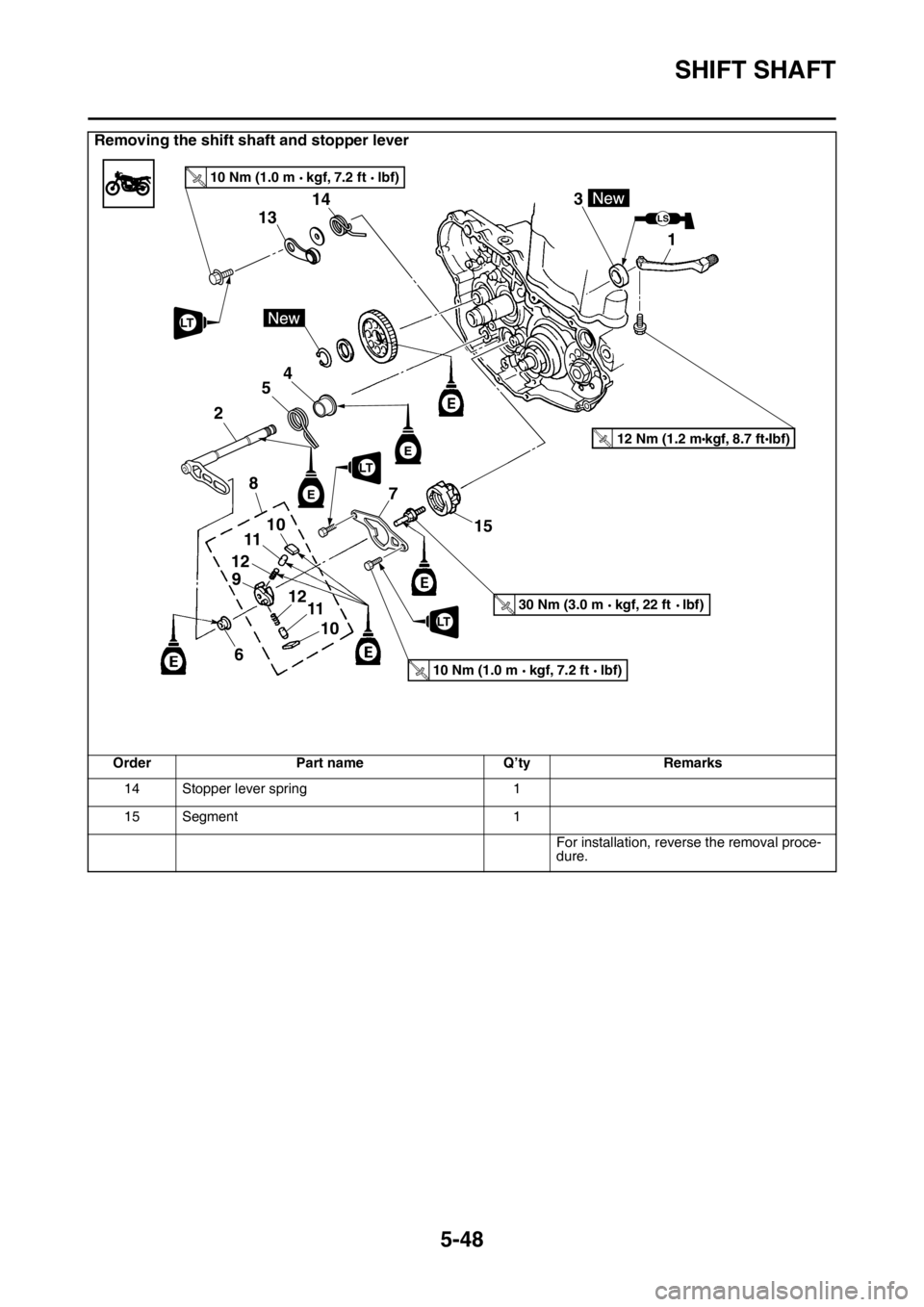

SHIFT SHAFT

5-48

14 Stopper lever spring 1

15 Segment 1

For installation, reverse the removal proce-

dure.

Removing the shift shaft and stopper lever

Order Part name Q’ty Remarks

LS

1 3

10 Nm (1.0 m kgf, 7.2 ft lbf)

13

15 14

10 Nm (1.0 m kgf, 7.2 ft lbf)

30 Nm (3.0 m kgf, 22 ft lbf)

LT

610 11 12

118

1210

4

25

LT

7

LT

E

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R.E

Page 242 of 356

SHIFT SHAFT

5-49

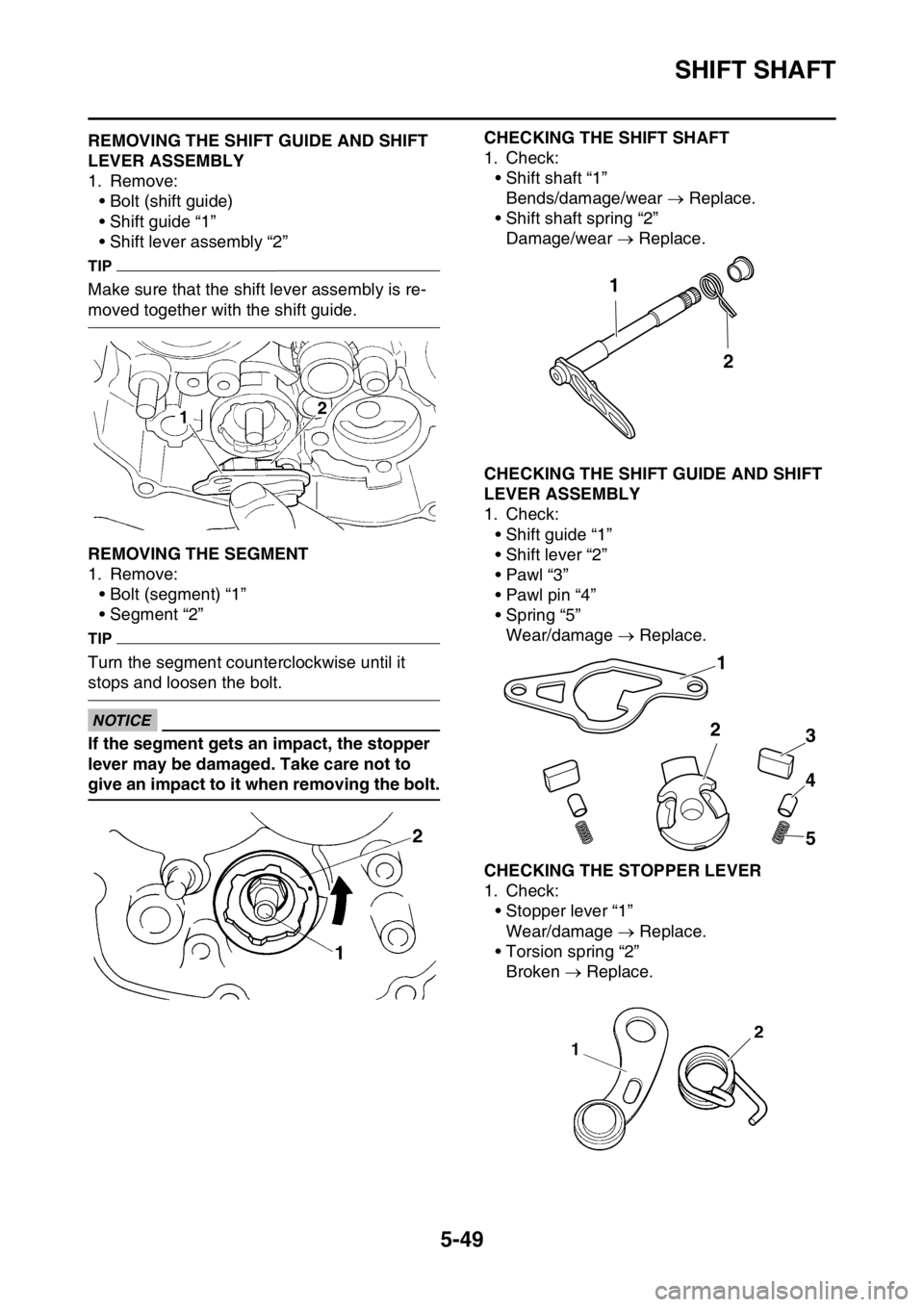

EAS1SM5256REMOVING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Remove:

• Bolt (shift guide)

• Shift guide “1”

• Shift lever assembly “2”

TIP

Make sure that the shift lever assembly is re-

moved together with the shift guide.

EAS1SM5257REMOVING THE SEGMENT

1. Remove:

• Bolt (segment) “1”

• Segment “2”

TIP

Turn the segment counterclockwise until it

stops and loosen the bolt.

ECA1DX1021

NOTICE

If the segment gets an impact, the stopper

lever may be damaged. Take care not to

give an impact to it when removing the bolt.

EAS1SM5258

CHECKING THE SHIFT SHAFT

1. Check:

• Shift shaft “1”

Bends/damage/wear Replace.

• Shift shaft spring “2”

Damage/wear Replace.

EAS1SM5259CHECKING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Check:

• Shift guide “1”

• Shift lever “2”

•Pawl “3”

• Pawl pin “4”

• Spring “5”

Wear/damage Replace.

EAS1SM5260CHECKING THE STOPPER LEVER

1. Check:

• Stopper lever “1”

Wear/damage Replace.

• Torsion spring “2”

Broken Replace.

1

2

1

2

3

4

5

Page 243 of 356

SHIFT SHAFT

5-50

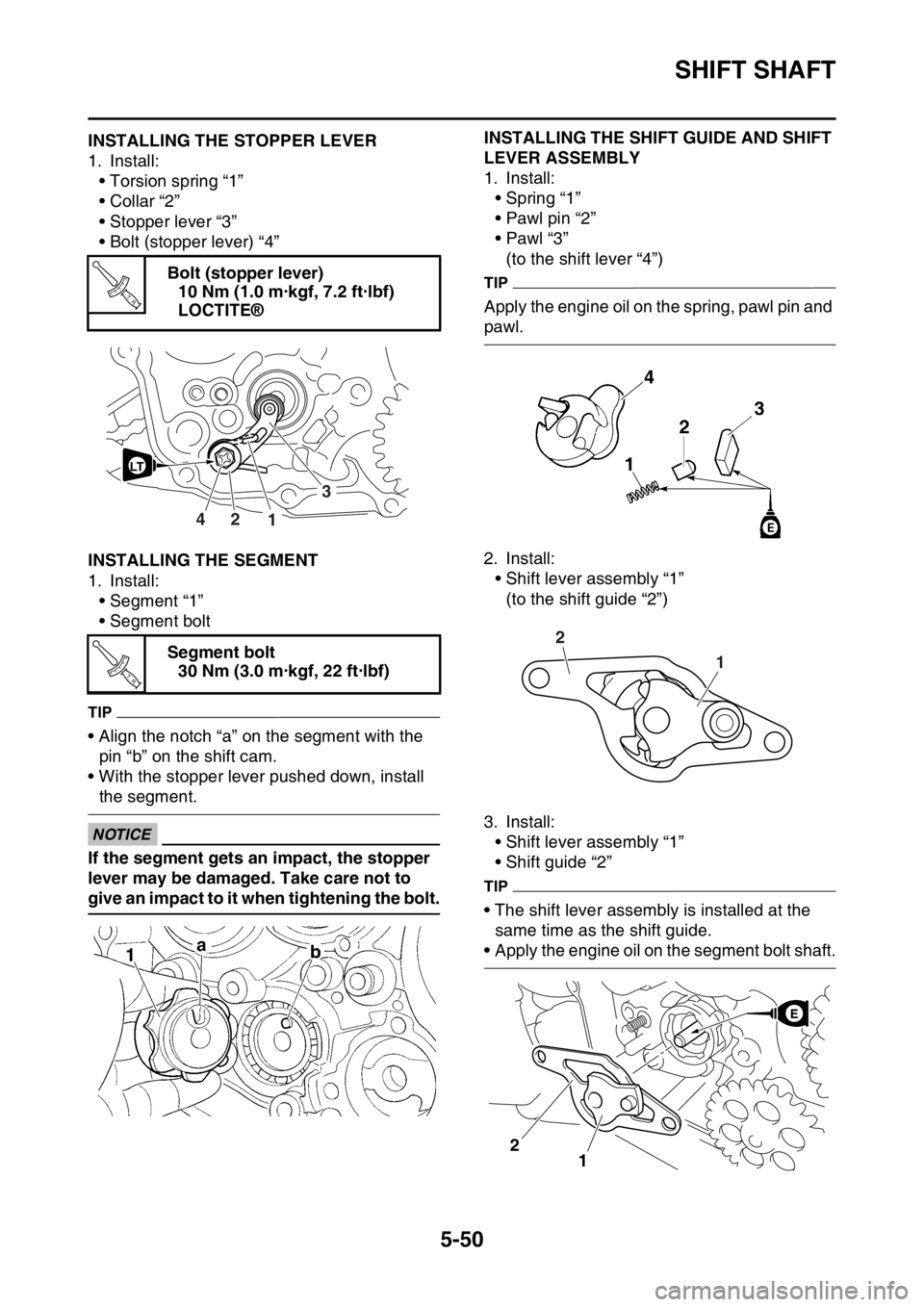

EAS1SM5261INSTALLING THE STOPPER LEVER

1. Install:

• Torsion spring “1”

• Collar “2”

• Stopper lever “3”

• Bolt (stopper lever) “4”

EAS1SM5262INSTALLING THE SEGMENT

1. Install:

• Segment “1”

• Segment bolt

TIP

• Align the notch “a” on the segment with the

pin “b” on the shift cam.

• With the stopper lever pushed down, install

the segment.

ECA1DX1022

NOTICE

If the segment gets an impact, the stopper

lever may be damaged. Take care not to

give an impact to it when tightening the bolt.

EAS1SM5263

INSTALLING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Install:

• Spring “1”

• Pawl pin “2”

•Pawl “3”

(to the shift lever “4”)

TIP

Apply the engine oil on the spring, pawl pin and

pawl.

2. Install:

• Shift lever assembly “1”

(to the shift guide “2”)

3. Install:

• Shift lever assembly “1”

• Shift guide “2”

TIP

• The shift lever assembly is installed at the

same time as the shift guide.

• Apply the engine oil on the segment bolt shaft. Bolt (stopper lever)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Segment bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

T R..

42

13

LT

T R..

1

2

1 2

Page 244 of 356

SHIFT SHAFT

5-51

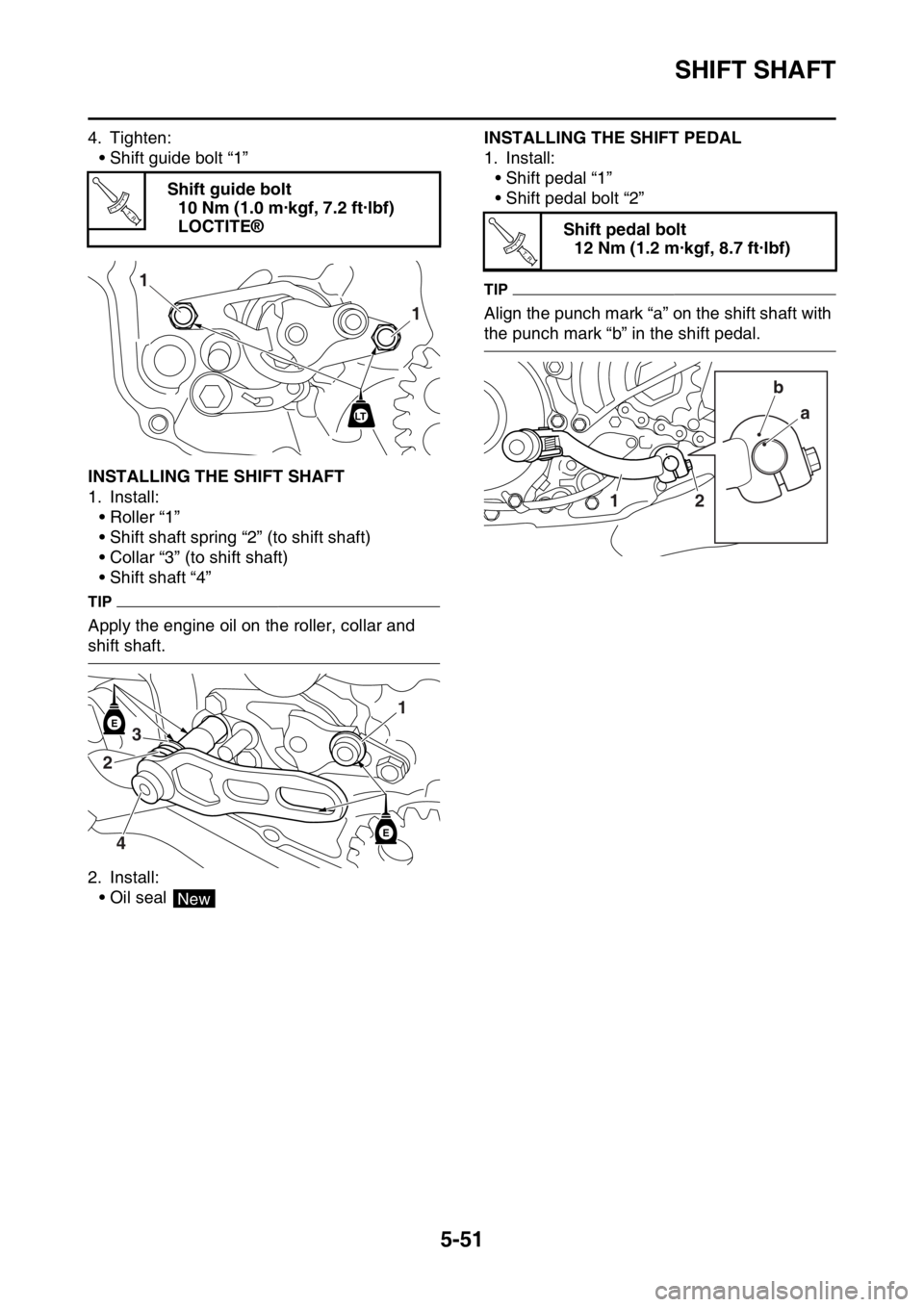

4. Tighten:

• Shift guide bolt “1”

EAS1SM5264INSTALLING THE SHIFT SHAFT

1. Install:

• Roller “1”

• Shift shaft spring “2” (to shift shaft)

• Collar “3” (to shift shaft)

• Shift shaft “4”

TIP

Apply the engine oil on the roller, collar and

shift shaft.

2. Install:

• Oil seal

EAS1SM5265

INSTALLING THE SHIFT PEDAL

1. Install:

• Shift pedal “1”

• Shift pedal bolt “2”

TIP

Align the punch mark “a” on the shift shaft with

the punch mark “b” in the shift pedal. Shift guide bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

T R..

1 1

LT

E

E

1

23

4

New

Shift pedal bolt

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

T R..

a

12b

Page 245 of 356

OIL PUMP AND BALANCER GEAR

5-52

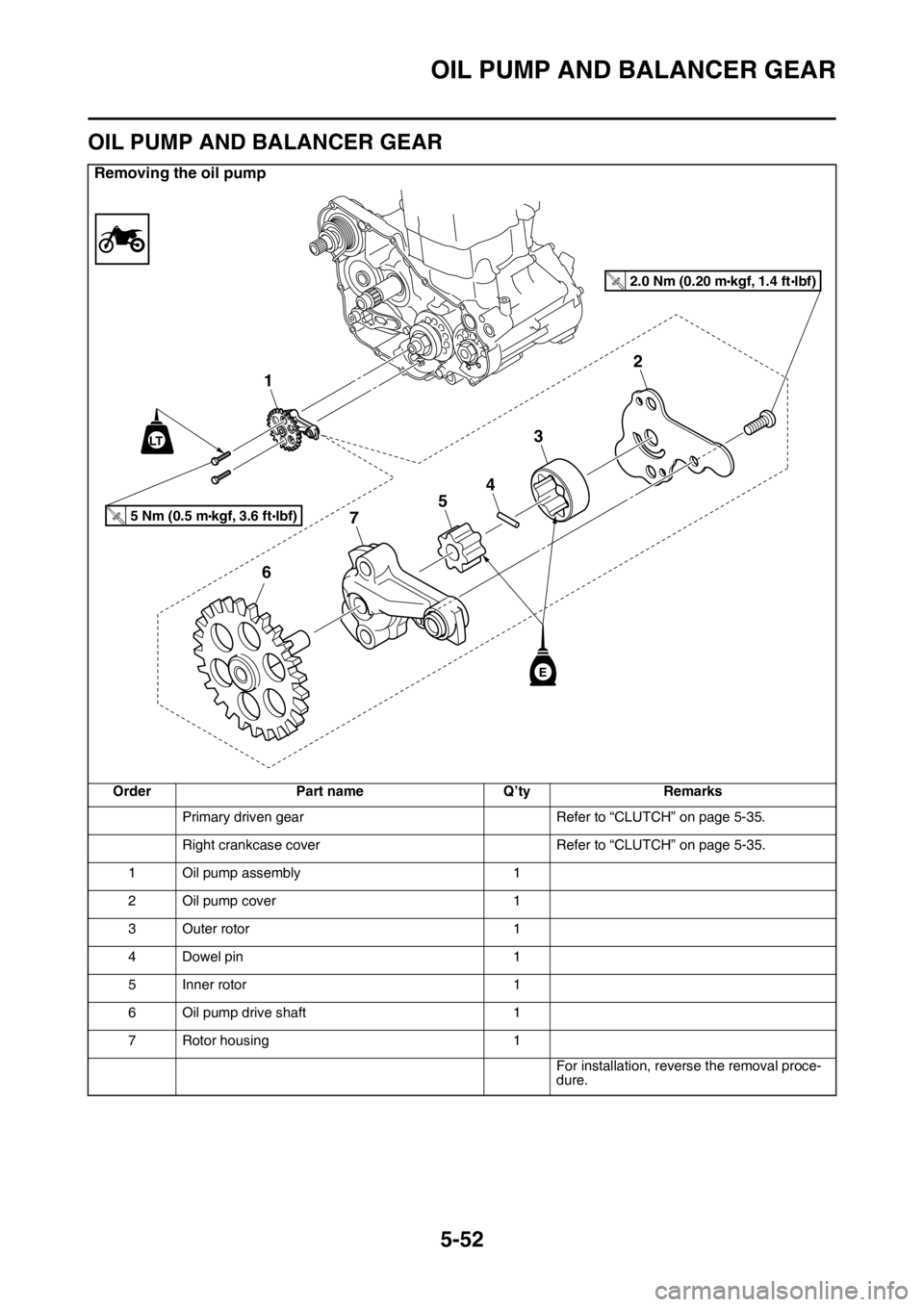

EAS1SM5266

OIL PUMP AND BALANCER GEAR

Removing the oil pump

Order Part name Q’ty Remarks

Primary driven gear Refer to “CLUTCH” on page 5-35.

Right crankcase cover Refer to “CLUTCH” on page 5-35.

1 Oil pump assembly 1

2 Oil pump cover 1

3 Outer rotor 1

4 Dowel pin 1

5 Inner rotor 1

6 Oil pump drive shaft 1

7 Rotor housing 1

For installation, reverse the removal proce-

dure.

2.0 Nm (0.20 mkgf, 1.4 ftIbf)T.R

.

5 Nm (0.5 mkgf, 3.6 ftIbf)T.R

.

LT

E

3

2

1

4

5

7

6

Page 246 of 356

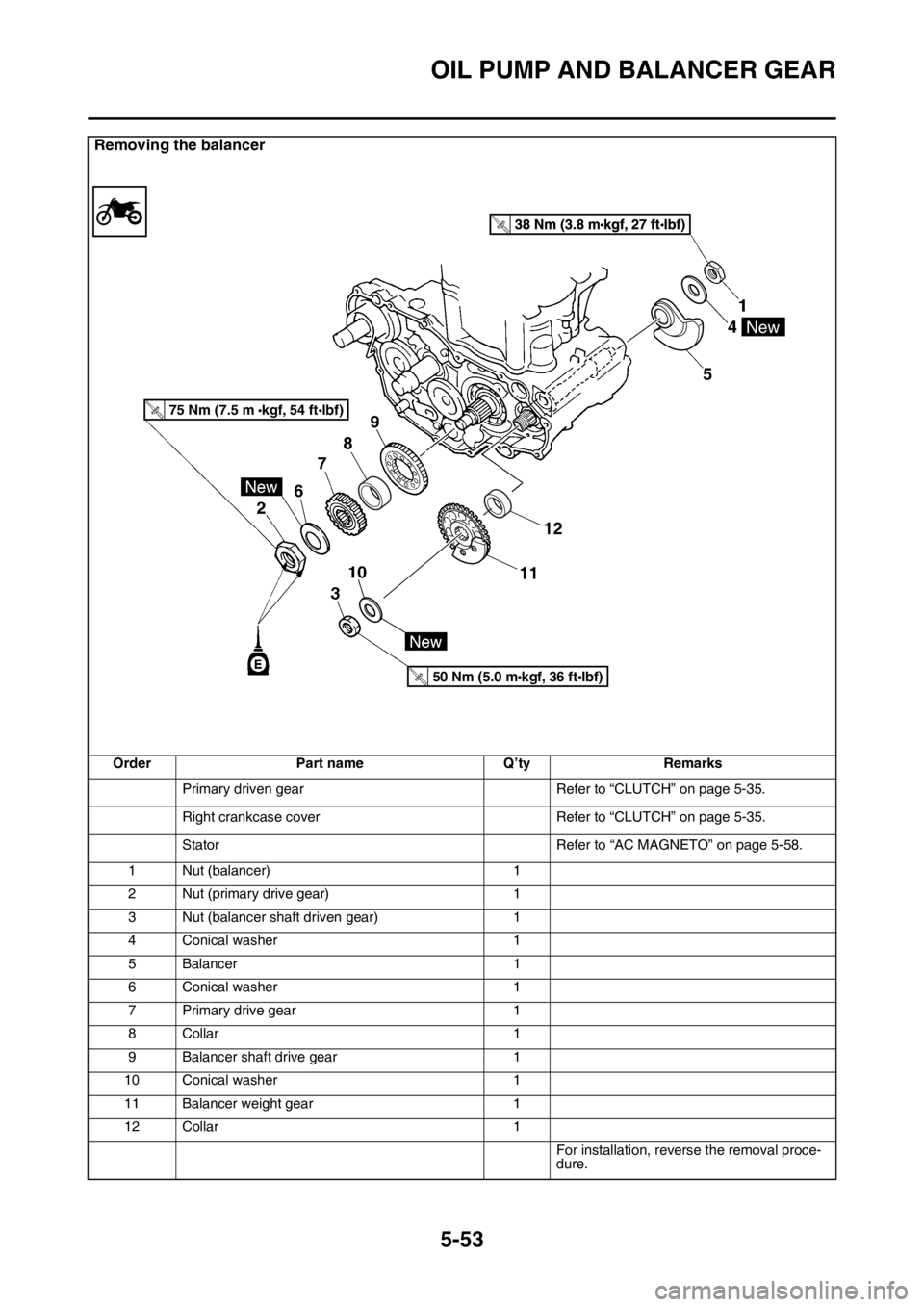

OIL PUMP AND BALANCER GEAR

5-53

Removing the balancer

Order Part name Q’ty Remarks

Primary driven gear Refer to “CLUTCH” on page 5-35.

Right crankcase cover Refer to “CLUTCH” on page 5-35.

Stator Refer to “AC MAGNETO” on page 5-58.

1 Nut (balancer) 1

2 Nut (primary drive gear) 1

3 Nut (balancer shaft driven gear) 1

4 Conical washer 1

5Balancer 1

6 Conical washer 1

7 Primary drive gear 1

8Collar 1

9 Balancer shaft drive gear 1

10 Conical washer 1

11 Balancer weight gear 1

12 Collar 1

For installation, reverse the removal proce-

dure.

T

.R.

75 Nm (7.5 mkgf, 54 ftlbf)T.R.

50 Nm (5.0 mkgf, 36 ftIbf)T

.R.

New

6

12

11

7

8

Page 247 of 356

OIL PUMP AND BALANCER GEAR

5-54

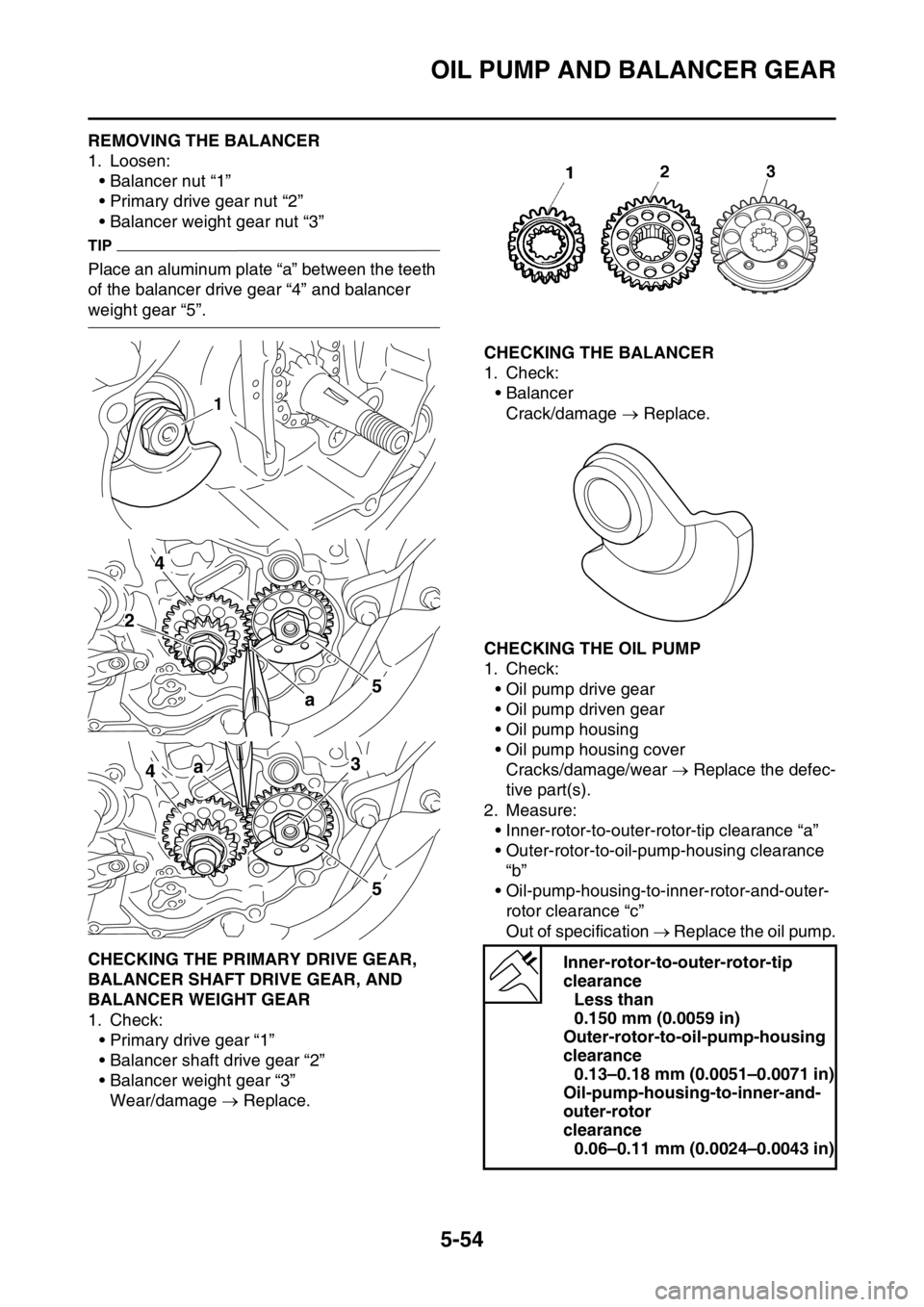

EAS1SM5267REMOVING THE BALANCER

1. Loosen:

• Balancer nut “1”

• Primary drive gear nut “2”

• Balancer weight gear nut “3”

TIP

Place an aluminum plate “a” between the teeth

of the balancer drive gear “4” and balancer

weight gear “5”.

EAS1SM5268CHECKING THE PRIMARY DRIVE GEAR,

BALANCER SHAFT DRIVE GEAR, AND

BALANCER WEIGHT GEAR

1. Check:

• Primary drive gear “1”

• Balancer shaft drive gear “2”

• Balancer weight gear “3”

Wear/damage Replace.

EAS1SM5269CHECKING THE BALANCER

1. Check:

•Balancer

Crack/damage Replace.

EAS1SM5270CHECKING THE OIL PUMP

1. Check:

• Oil pump drive gear

• Oil pump driven gear

• Oil pump housing

• Oil pump housing cover

Cracks/damage/wear Replace the defec-

tive part(s).

2. Measure:

• Inner-rotor-to-outer-rotor-tip clearance “a”

• Outer-rotor-to-oil-pump-housing clearance

“b”

• Oil-pump-housing-to-inner-rotor-and-outer-

rotor clearance “c”

Out of specification Replace the oil pump.

1

4

a5

2

4a

5

3

Inner-rotor-to-outer-rotor-tip

clearance

Less than

0.150 mm (0.0059 in)

Outer-rotor-to-oil-pump-housing

clearance

0.13–0.18 mm (0.0051–0.0071 in)

Oil-pump-housing-to-inner-and-

outer-rotor

clearance

0.06–0.11 mm (0.0024–0.0043 in)

Page 248 of 356

OIL PUMP AND BALANCER GEAR

5-55

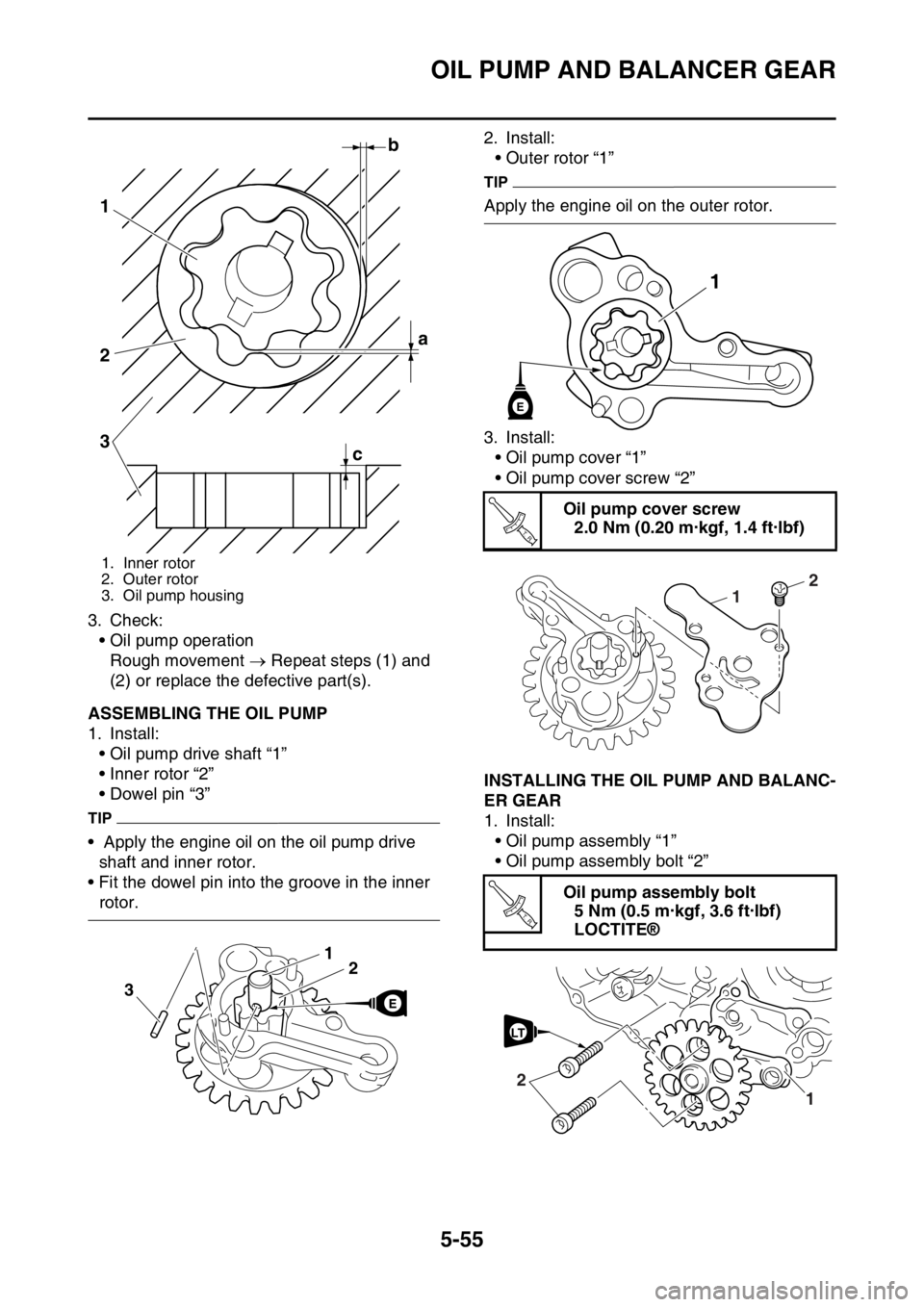

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS1SM5271ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2”

EAS1SM5272INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA1DX1023

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

21

3

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

1

E

T R..

2

1

T R..

1

2

LT

Page 249 of 356

OIL PUMP AND BALANCER GEAR

5-56

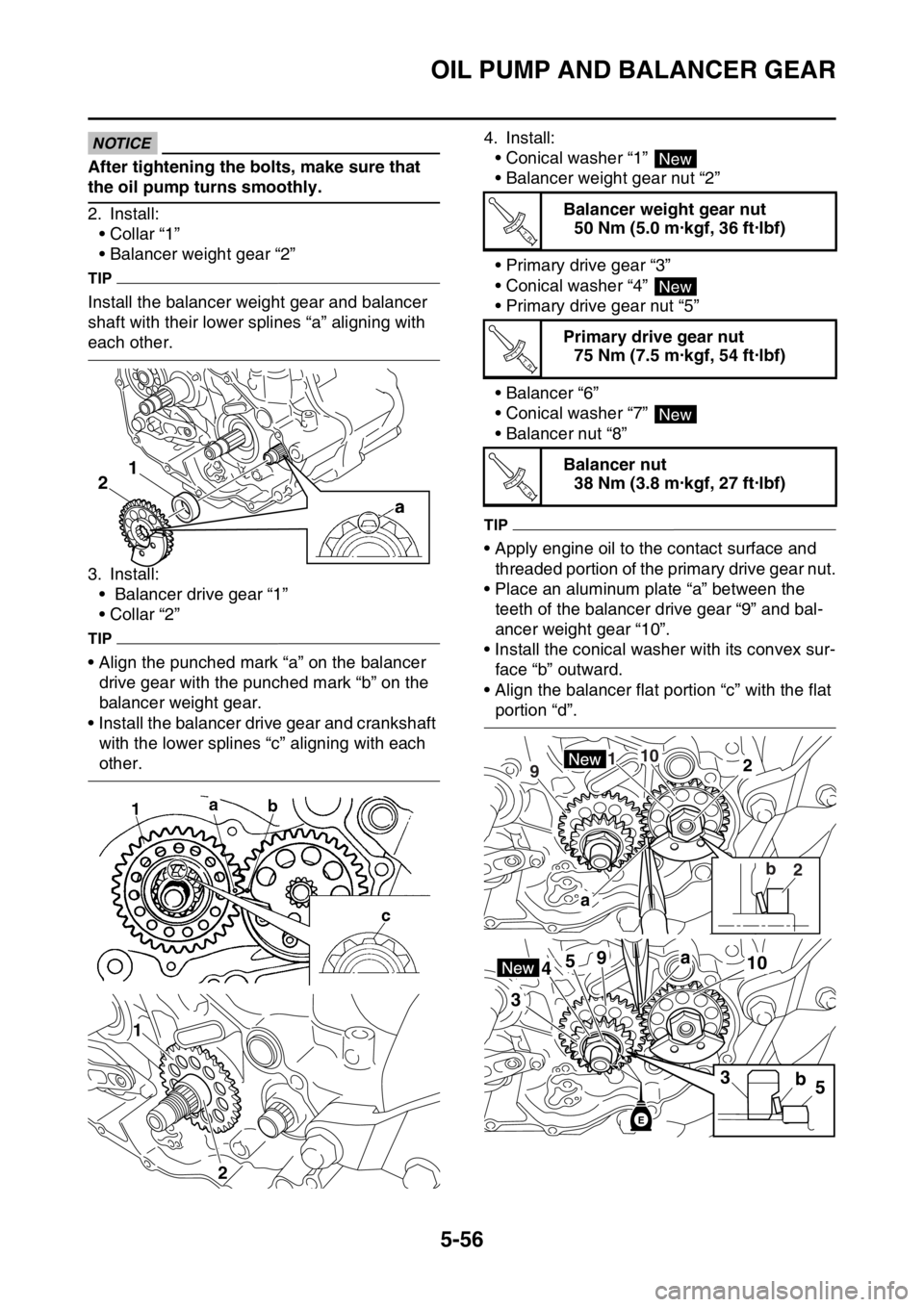

NOTICE

After tightening the bolts, make sure that

the oil pump turns smoothly.

2. Install:

• Collar “1”

• Balancer weight gear “2”

TIP

Install the balancer weight gear and balancer

shaft with their lower splines “a” aligning with

each other.

3. Install:

• Balancer drive gear “1”

• Collar “2”

TIP

• Align the punched mark “a” on the balancer

drive gear with the punched mark “b” on the

balancer weight gear.

• Install the balancer drive gear and crankshaft

with the lower splines “c” aligning with each

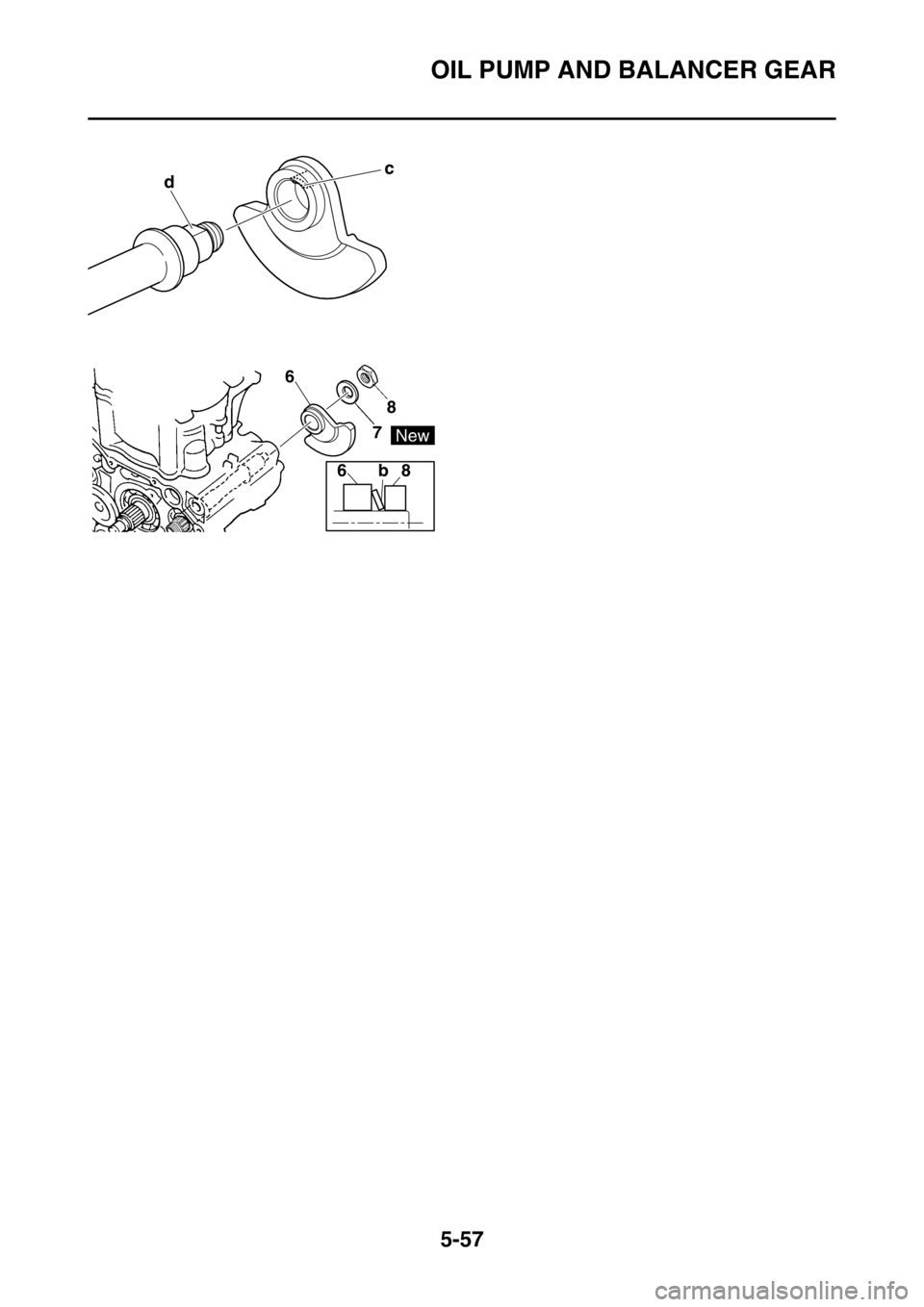

other.4. Install:

• Conical washer “1”

• Balancer weight gear nut “2”

• Primary drive gear “3”

• Conical washer “4”

• Primary drive gear nut “5”

•Balancer “6”

• Conical washer “7”

• Balancer nut “8”

TIP

• Apply engine oil to the contact surface and

threaded portion of the primary drive gear nut.

• Place an aluminum plate “a” between the

teeth of the balancer drive gear “9” and bal-

ancer weight gear “10”.

• Install the conical washer with its convex sur-

face “b” outward.

• Align the balancer flat portion “c” with the flat

portion “d”.

21

1

2

Balancer weight gear nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

Primary drive gear nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Balancer nut

38 Nm (3.8 m·kgf, 27 ft·lbf)

New

T R..

New

T R..

New

T R..

a

210

b

2 91

b53

a41059

3

E

Page 250 of 356

OIL PUMP AND BALANCER GEAR

5-57

c

d

6 6

78

8 b