YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 261 of 356

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT

5-68

EAS1SM5288INSTALLING THE CRANKSHAFT ASSEM-

BLY

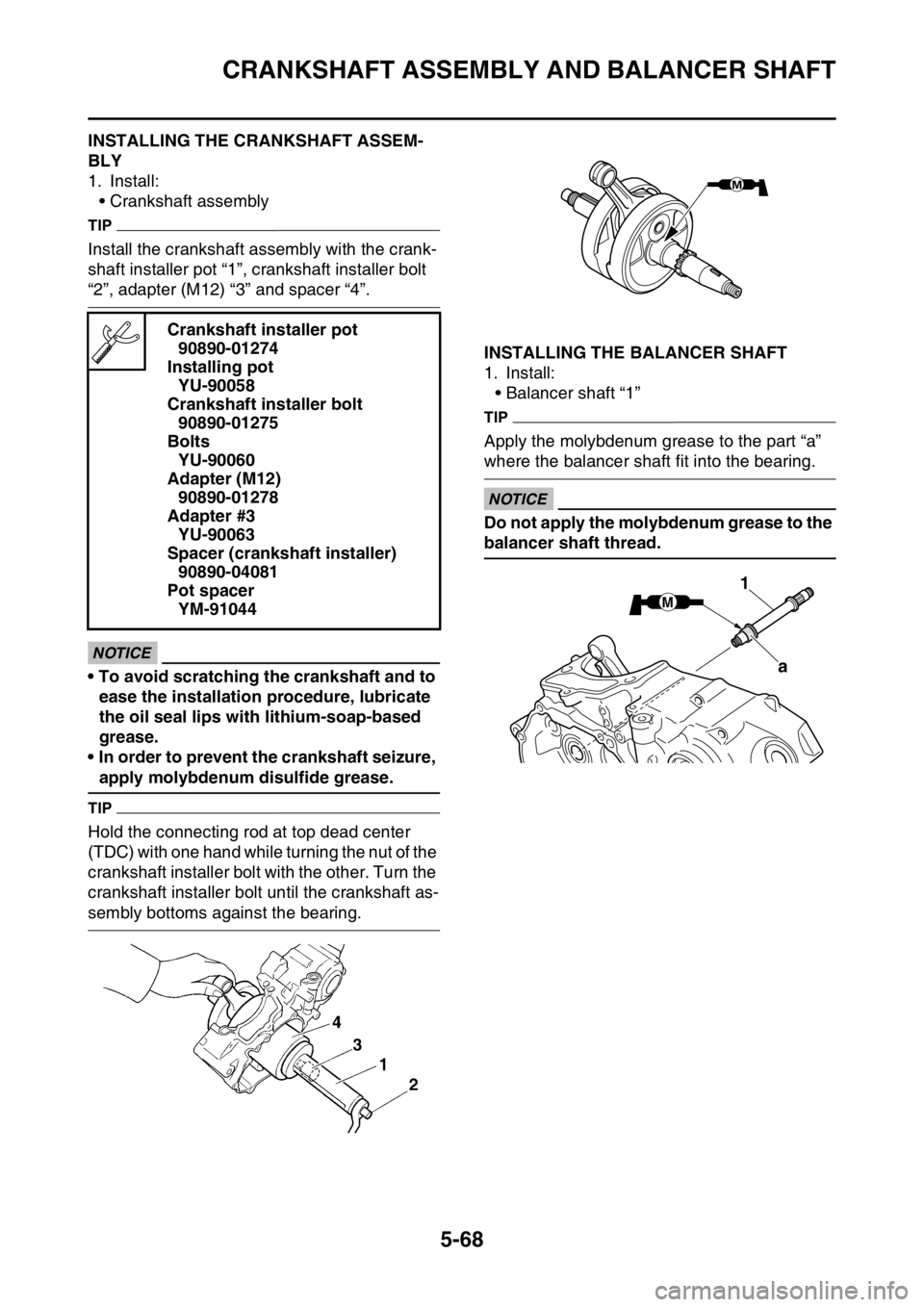

1. Install:

⢠Crankshaft assembly

TIP

Install the crankshaft assembly with the crank-

shaft installer pot â1â, crankshaft installer bolt

â2â, adapter (M12) â3â and spacer â4â.

ECA13970

NOTICE

⢠To avoid scratching the crankshaft and to

ease the installation procedure, lubricate

the oil seal lips with lithium-soap-based

grease.

⢠In order to prevent the crankshaft seizure,

apply molybdenum disulfide grease.

TIP

Hold the connecting rod at top dead center

(TDC) with one hand while turning the nut of the

crankshaft installer bolt with the other. Turn the

crankshaft installer bolt until the crankshaft as-

sembly bottoms against the bearing.

EAS1SM5289INSTALLING THE BALANCER SHAFT

1. Install:

⢠Balancer shaft â1â

TIP

Apply the molybdenum grease to the part âaâ

where the balancer shaft fit into the bearing.

ECA13970

NOTICE

Do not apply the molybdenum grease to the

balancer shaft thread. Crankshaft installer pot

90890-01274

Installing pot

YU-90058

Crankshaft installer bolt

90890-01275

Bolts

YU-90060

Adapter (M12)

90890-01278

Adapter #3

YU-90063

Spacer (crankshaft installer)

90890-04081

Pot spacer

YM-91044

M

1

a

Page 262 of 356

TRANSMISSION

5-69

EAS1SM5290

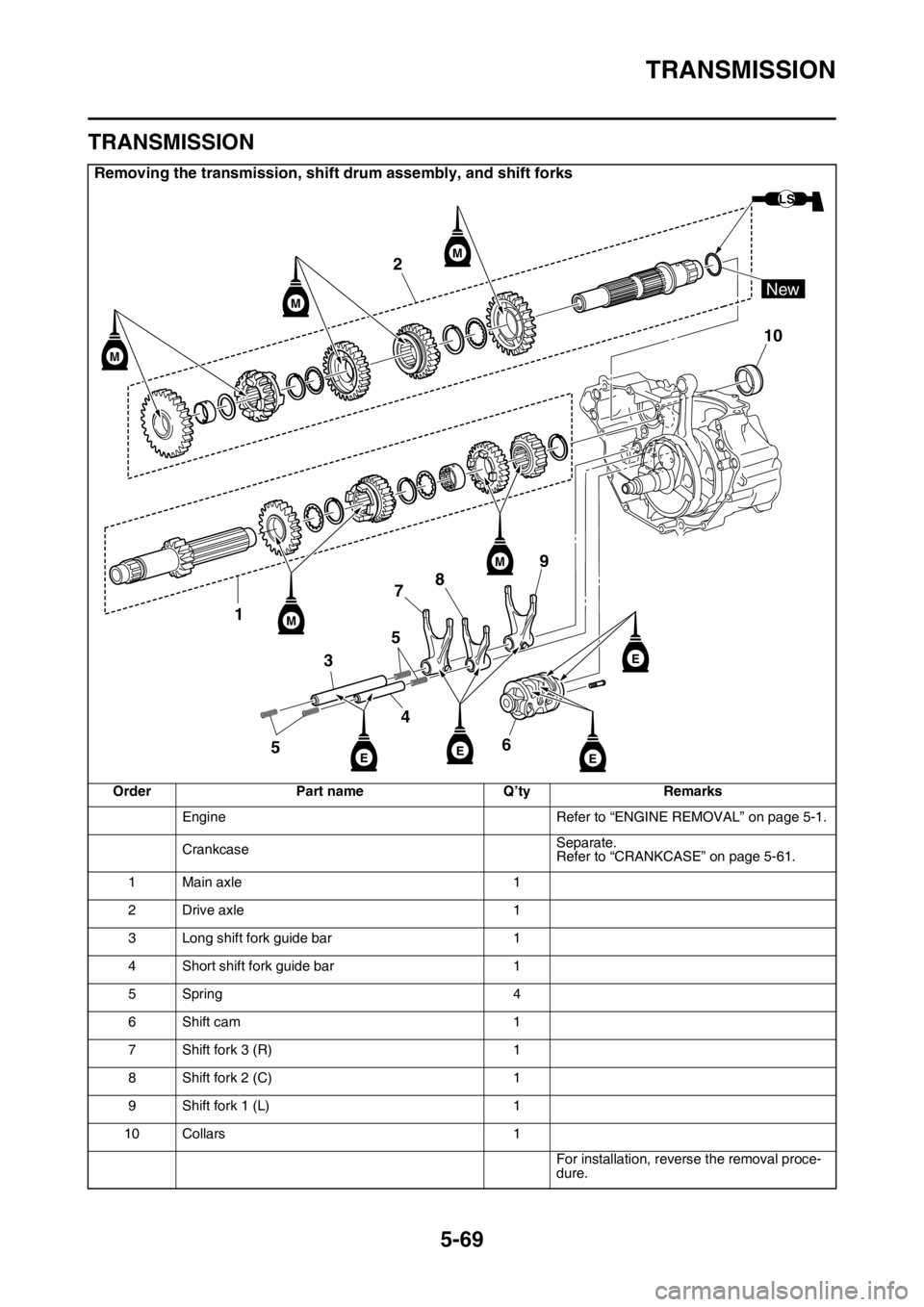

TRANSMISSION

Removing the transmission, shift drum assembly, and shift forks

Order Part name Qâty Remarks

Engine Refer to âENGINE REMOVALâ on page 5-1.

CrankcaseSeparate.

Refer to âCRANKCASEâ on page 5-61.

1 Main axle 1

2 Drive axle 1

3 Long shift fork guide bar 1

4 Short shift fork guide bar 1

5Spring 4

6 Shift cam 1

7 Shift fork 3 (R) 1

8 Shift fork 2 (C) 1

9 Shift fork 1 (L) 1

10 Collars 1

For installation, reverse the removal proce-

dure.

2

10

1

53

4 578

69

M

M

M

M

M

EE

E

E

LS

New

Page 263 of 356

TRANSMISSION

5-70

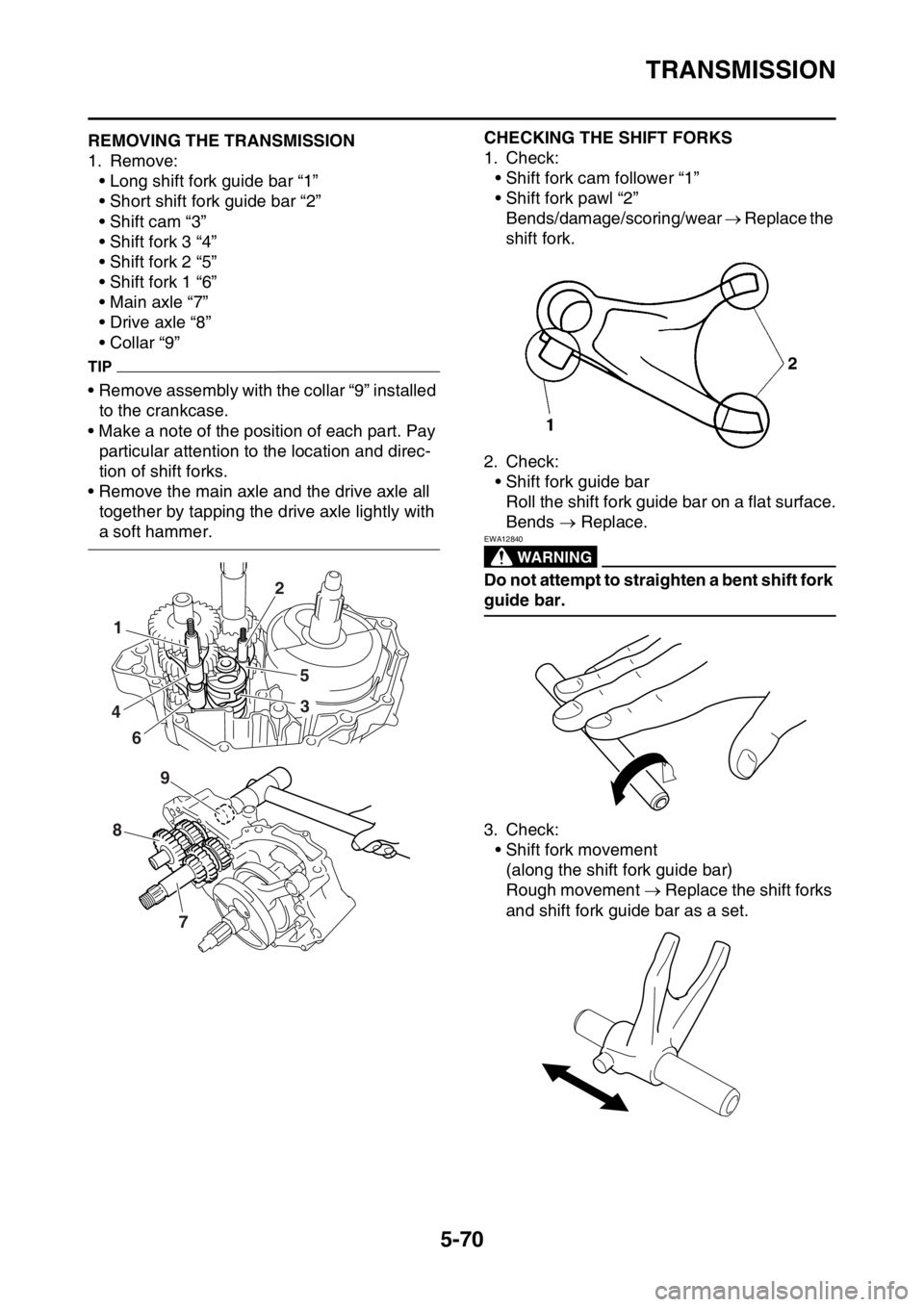

EAS1SM5291REMOVING THE TRANSMISSION

1. Remove:

⢠Long shift fork guide bar â1â

⢠Short shift fork guide bar â2â

⢠Shift cam â3â

⢠Shift fork 3 â4â

⢠Shift fork 2 â5â

⢠Shift fork 1 â6â

⢠Main axle â7â

⢠Drive axle â8â

⢠Collar â9â

TIP

⢠Remove assembly with the collar â9â installed

to the crankcase.

⢠Make a note of the position of each part. Pay

particular attention to the location and direc-

tion of shift forks.

⢠Remove the main axle and the drive axle all

together by tapping the drive axle lightly with

a soft hammer.

EAS1SM5292

CHECKING THE SHIFT FORKS

1. Check:

⢠Shift fork cam follower â1â

⢠Shift fork pawl â2â

Bends/damage/scoring/wear ï® Replace the

shift fork.

2. Check:

⢠Shift fork guide bar

Roll the shift fork guide bar on a flat surface.

Bends ï® Replace.

EWA12840

WARNING

Do not attempt to straighten a bent shift fork

guide bar.

3. Check:

⢠Shift fork movement

(along the shift fork guide bar)

Rough movement ï® Replace the shift forks

and shift fork guide bar as a set.

1

4

62

5

3

8

7

9

Page 264 of 356

TRANSMISSION

5-71

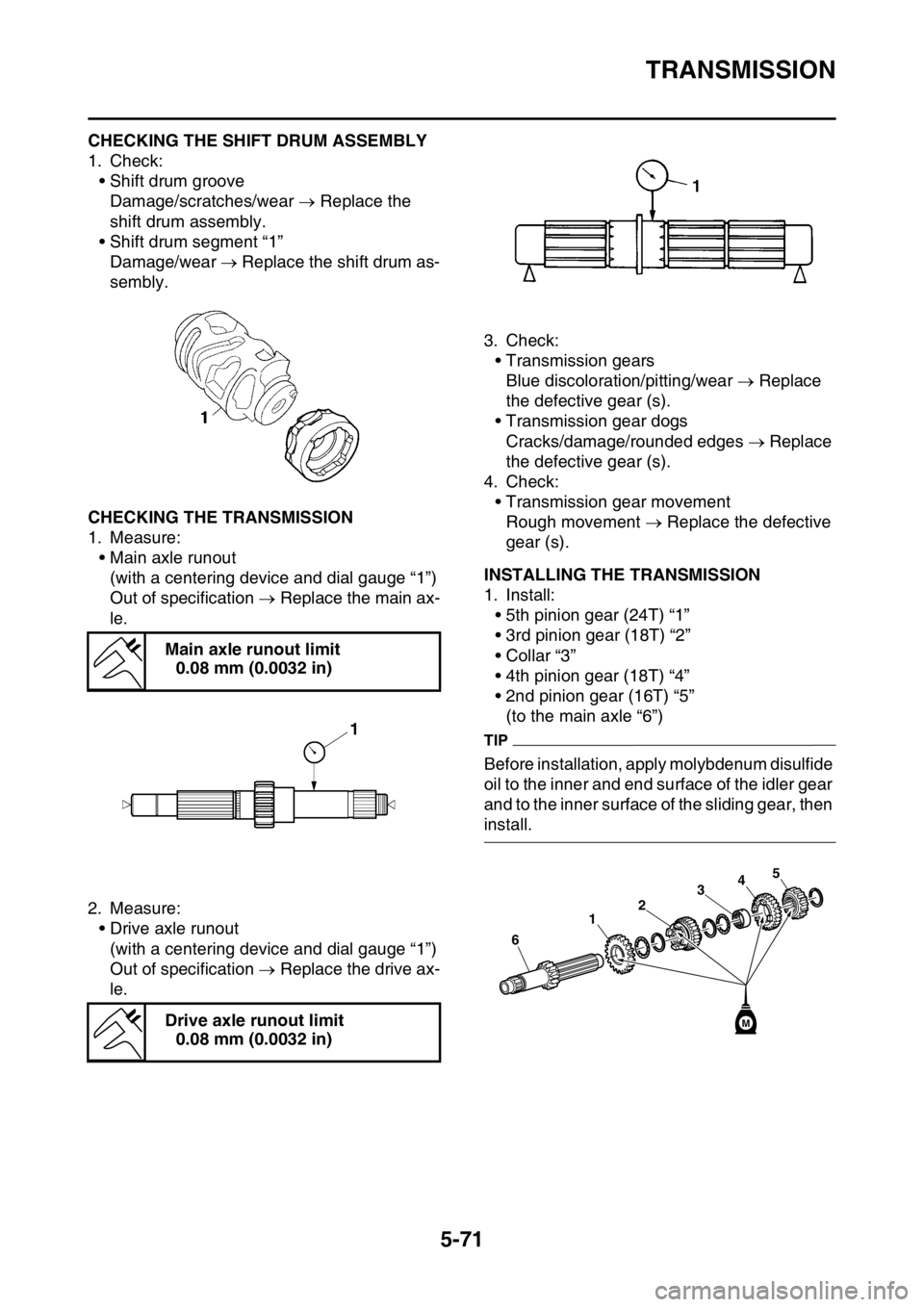

EAS1SM5293CHECKING THE SHIFT DRUM ASSEMBLY

1. Check:

⢠Shift drum groove

Damage/scratches/wear ï® Replace the

shift drum assembly.

⢠Shift drum segment â1â

Damage/wear ï® Replace the shift drum as-

sembly.

EAS1SM5294CHECKING THE TRANSMISSION

1. Measure:

⢠Main axle runout

(with a centering device and dial gauge â1â)

Out of specification ï® Replace the main ax-

le.

2. Measure:

⢠Drive axle runout

(with a centering device and dial gauge â1â)

Out of specification ï® Replace the drive ax-

le.3. Check:

⢠Transmission gears

Blue discoloration/pitting/wear ï® Replace

the defective gear (s).

⢠Transmission gear dogs

Cracks/damage/rounded edges ï® Replace

the defective gear (s).

4. Check:

⢠Transmission gear movement

Rough movement ï® Replace the defective

gear (s).

EAS1SM5295INSTALLING THE TRANSMISSION

1. Install:

⢠5th pinion gear (24T) â1â

⢠3rd pinion gear (18T) â2â

⢠Collar â3â

⢠4th pinion gear (18T) â4â

⢠2nd pinion gear (16T) â5â

(to the main axle â6â)

TIP

Before installation, apply molybdenum disulfide

oil to the inner and end surface of the idler gear

and to the inner surface of the sliding gear, then

install. Main axle runout limit

0.08 mm (0.0032 in)

Drive axle runout limit

0.08 mm (0.0032 in)

34

2

1

6

5

M

Page 265 of 356

TRANSMISSION

5-72

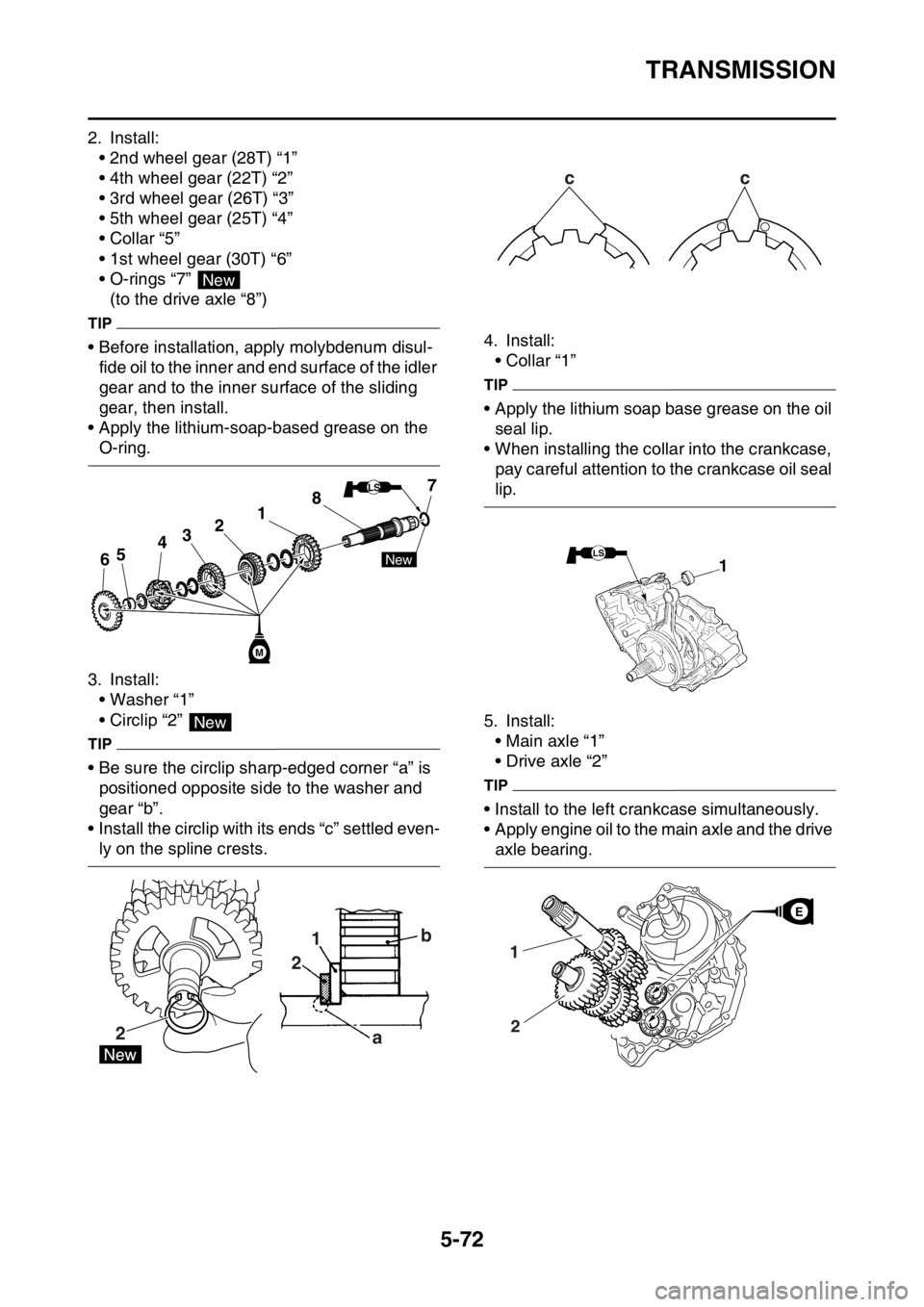

2. Install:

⢠2nd wheel gear (28T) â1â

⢠4th wheel gear (22T) â2â

⢠3rd wheel gear (26T) â3â

⢠5th wheel gear (25T) â4â

⢠Collar â5â

⢠1st wheel gear (30T) â6â

⢠O-rings â7â

(to the drive axle â8â)

TIP

⢠Before installation, apply molybdenum disul-

fide oil to the inner and end surface of the idler

gear and to the inner surface of the sliding

gear, then install.

⢠Apply the lithium-soap-based grease on the

O-ring.

3. Install:

⢠Washer â1â

⢠Circlip â2â

TIP

⢠Be sure the circlip sharp-edged corner âaâ is

positioned opposite side to the washer and

gear âbâ.

⢠Install the circlip with its ends âcâ settled even-

ly on the spline crests.4. Install:

⢠Collar â1â

TIP

⢠Apply the lithium soap base grease on the oil

seal lip.

⢠When installing the collar into the crankcase,

pay careful attention to the crankcase oil seal

lip.

5. Install:

⢠Main axle â1â

⢠Drive axle â2â

TIP

⢠Install to the left crankcase simultaneously.

⢠Apply engine oil to the main axle and the drive

axle bearing.

New

187

2

3

4

5

6

New

M

LS

New

21

2

ab

cc

1

2

EE

Page 266 of 356

TRANSMISSION

5-73

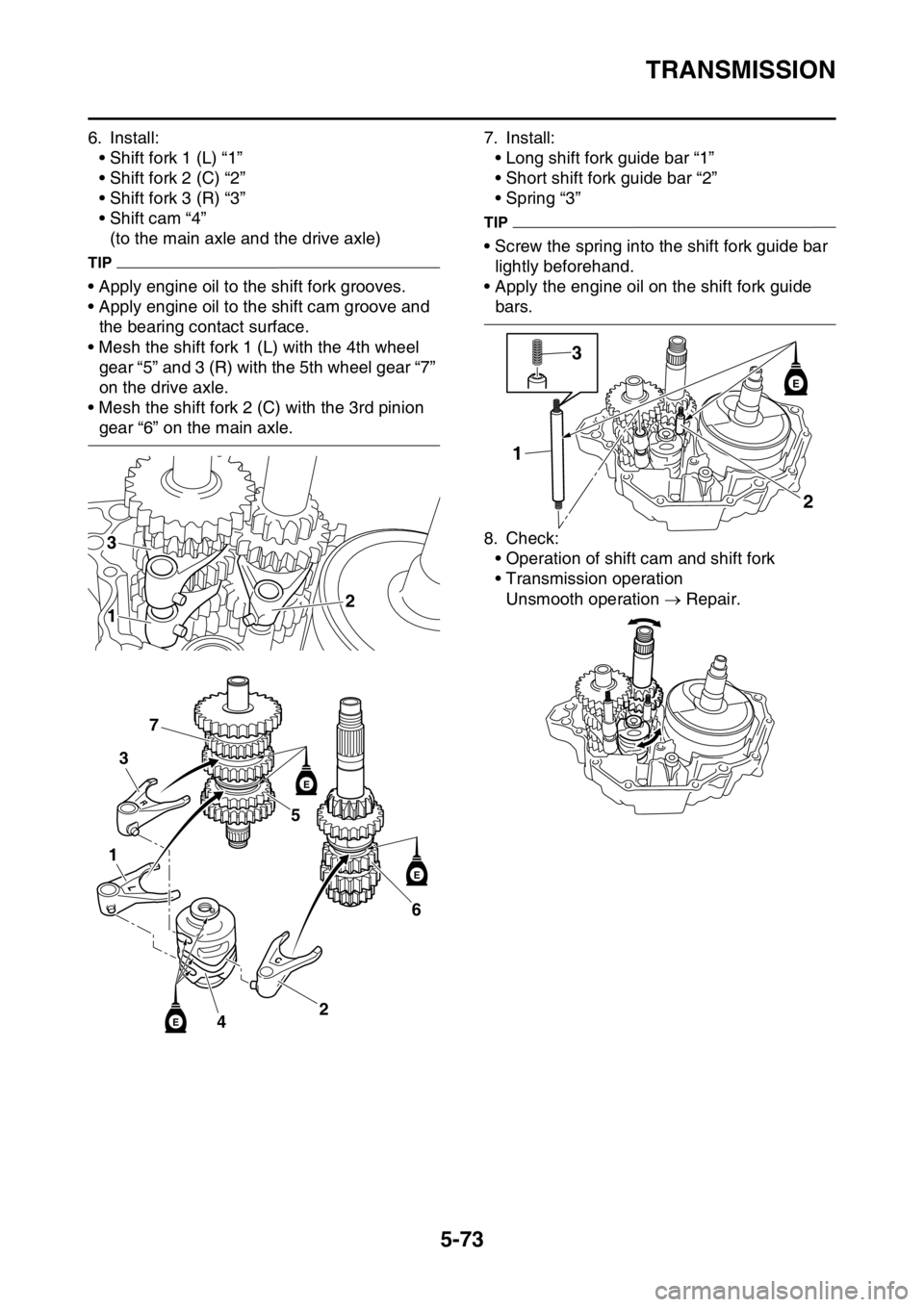

6. Install:

⢠Shift fork 1 (L) â1â

⢠Shift fork 2 (C) â2â

⢠Shift fork 3 (R) â3â

⢠Shift cam â4â

(to the main axle and the drive axle)

TIP

⢠Apply engine oil to the shift fork grooves.

⢠Apply engine oil to the shift cam groove and

the bearing contact surface.

⢠Mesh the shift fork 1 (L) with the 4th wheel

gear â5â and 3 (R) with the 5th wheel gear â7â

on the drive axle.

⢠Mesh the shift fork 2 (C) with the 3rd pinion

gear â6â on the main axle.7. Install:

⢠Long shift fork guide bar â1â

⢠Short shift fork guide bar â2â

⢠Spring â3â

TIP

⢠Screw the spring into the shift fork guide bar

lightly beforehand.

⢠Apply the engine oil on the shift fork guide

bars.

8. Check:

⢠Operation of shift cam and shift fork

⢠Transmission operation

Unsmooth operation ï® Repair.

3

12

6

24

5

3

7

1

E

E

E

2 13

E

Page 267 of 356

6

COOLING SYSTEM

RADIATOR....................................................................................................... 6-1

HANDLING NOTE ...................................................................................... 6-3

CHECKING THE RADIATOR ..................................................................... 6-3

WATER PUMP.................................................................................................. 6-4

REMOVING THE OIL SEAL ....................................................................... 6-6

CHECKING THE WATER PUMP ............................................................... 6-6

CHECKING THE BEARING....................................................................... 6-6

INSTALLING THE OIL SEAL..................................................................... 6-6

ASSEMBLING THE WATER PUMP........................................................... 6-6

Page 268 of 356

RADIATOR

6-1

EAS1SM5296

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SM5297

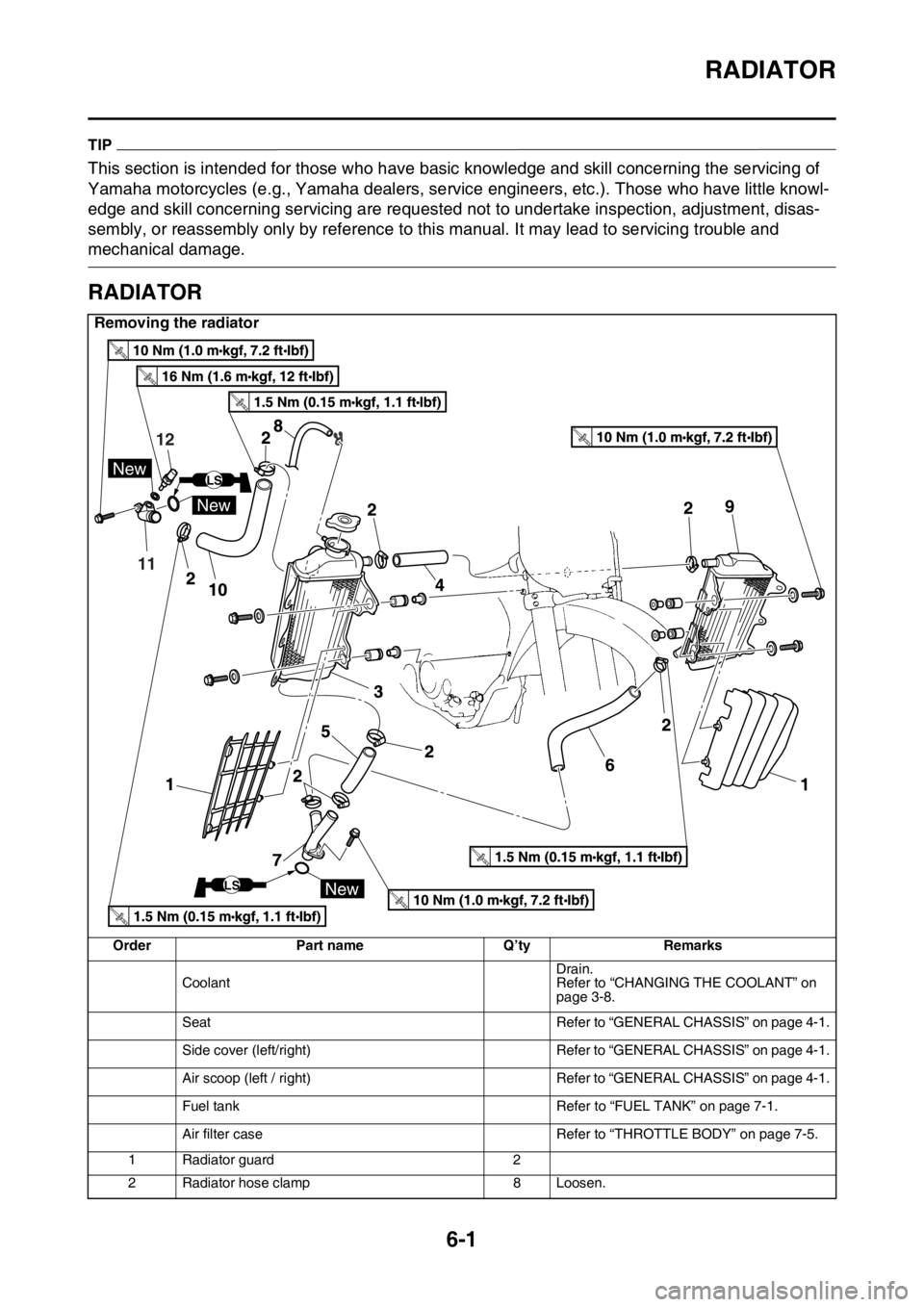

RADIATOR

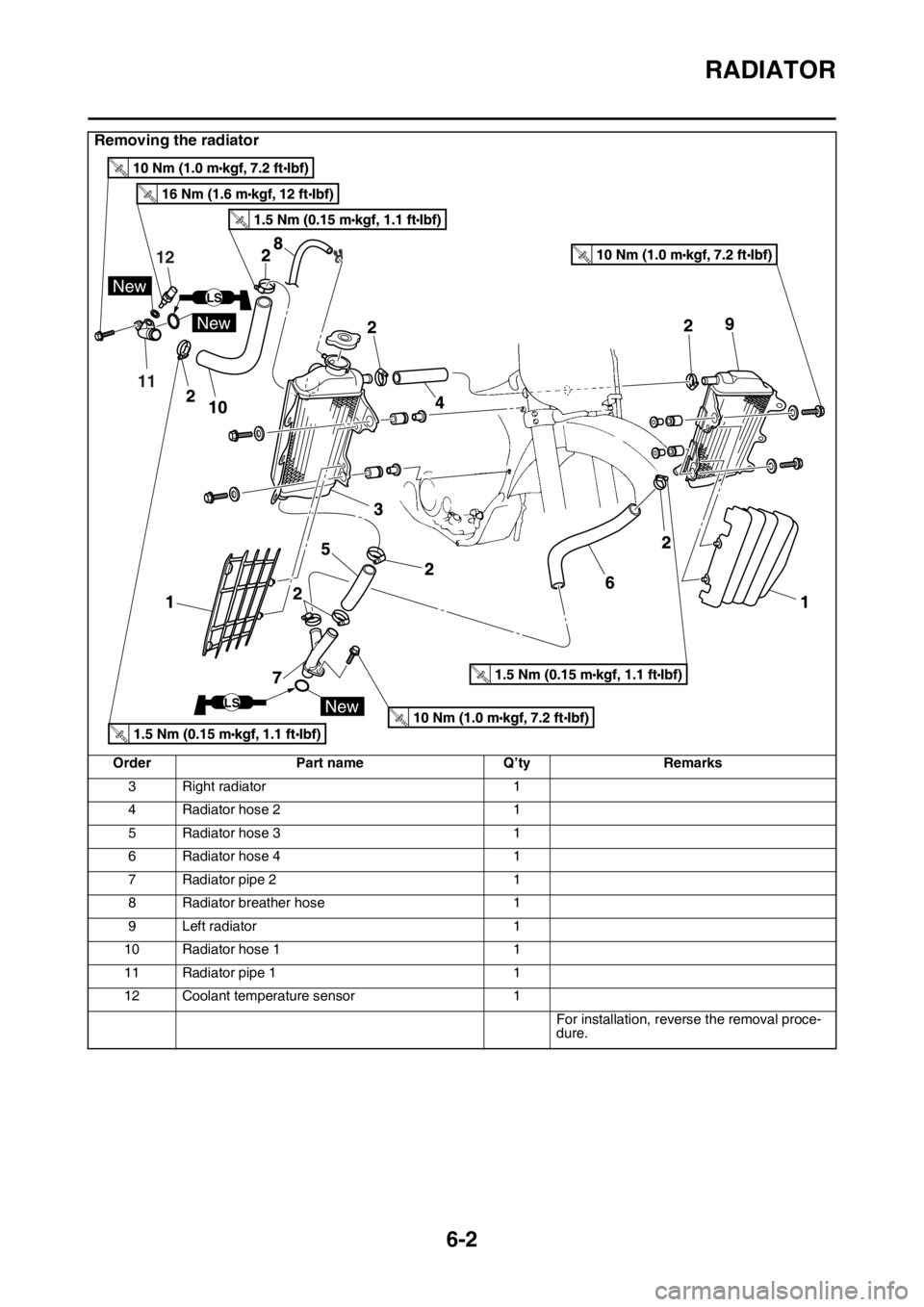

Removing the radiator

Order Part name Qâty Remarks

CoolantDrain.

Refer to âCHANGING THE COOLANTâ on

page 3-8.

Seat Refer to âGENERAL CHASSISâ on page 4-1.

Side cover (left/right) Refer to âGENERAL CHASSISâ on page 4-1.

Air scoop (left / right) Refer to âGENERAL CHASSISâ on page 4-1.

Fuel tank Refer to âFUEL TANKâ on page 7-1.

Air filter case Refer to âTHROTTLE BODYâ on page 7-5.

1 Radiator guard 2

2 Radiator hose clamp 8 Loosen.

11

12

New

New

New

LS

LS

Page 269 of 356

RADIATOR

6-2

3 Right radiator 1

4 Radiator hose 2 1

5 Radiator hose 3 1

6 Radiator hose 4 1

7 Radiator pipe 2 1

8 Radiator breather hose 1

9 Left radiator 1

10 Radiator hose 1 1

11 Radiator pipe 1 1

12 Coolant temperature sensor 1

For installation, reverse the removal proce-

dure.

Removing the radiator

Order Part name Qâty Remarks

11

12

New

New

New

LS

LS

Page 270 of 356

RADIATOR

6-3

EAS1SM5298HANDLING NOTEEWA1DX1007

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

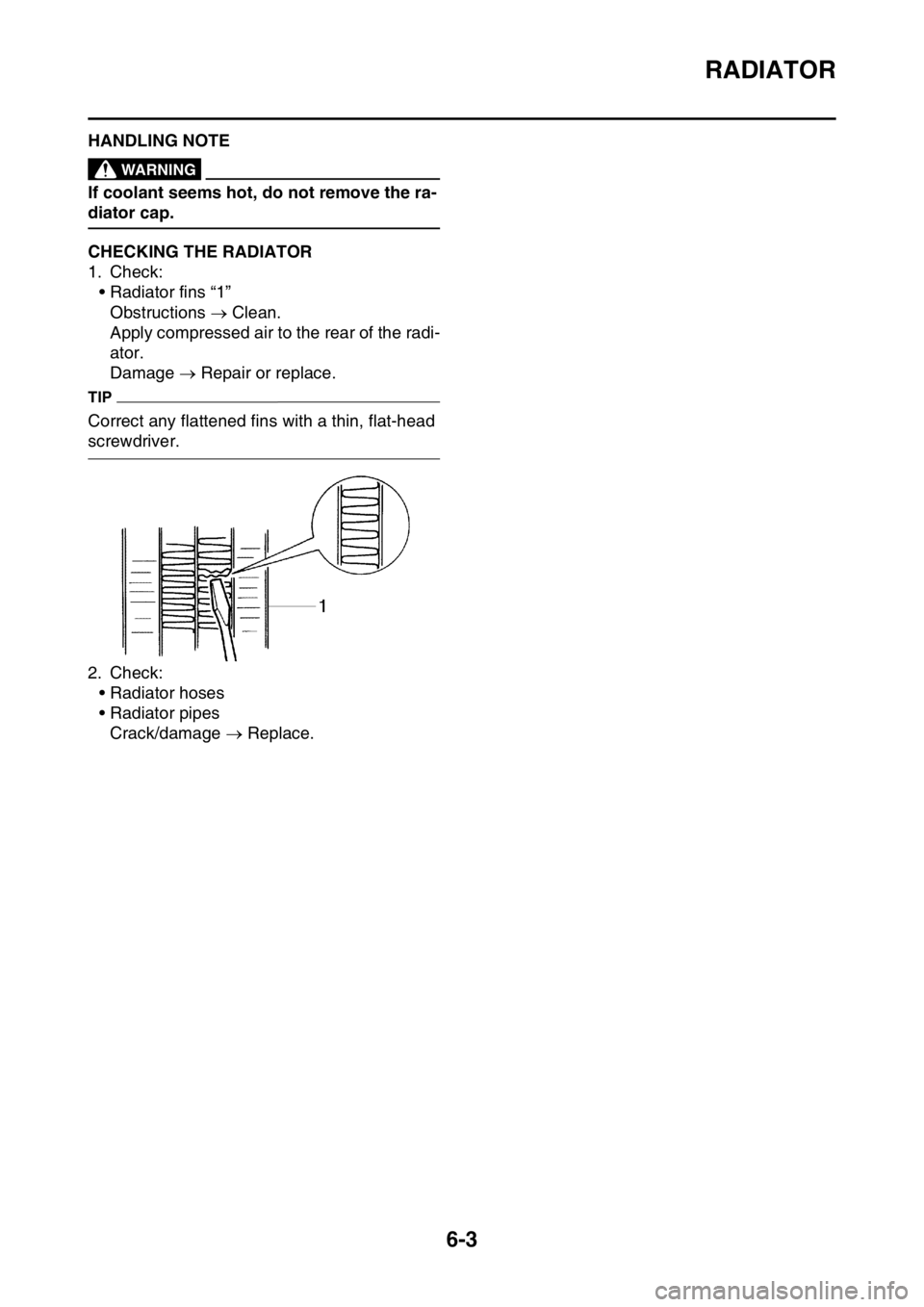

EAS1SM5299CHECKING THE RADIATOR

1. Check:

⢠Radiator fins â1â

Obstructions ï® Clean.

Apply compressed air to the rear of the radi-

ator.

Damage ï® Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

⢠Radiator hoses

⢠Radiator pipes

Crack/damage ï® Replace.