transmission oil YAMAHA YZ250LC 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250LC, Model: YAMAHA YZ250LC 2001Pages: 578, PDF Size: 14.12 MB

Page 16 of 578

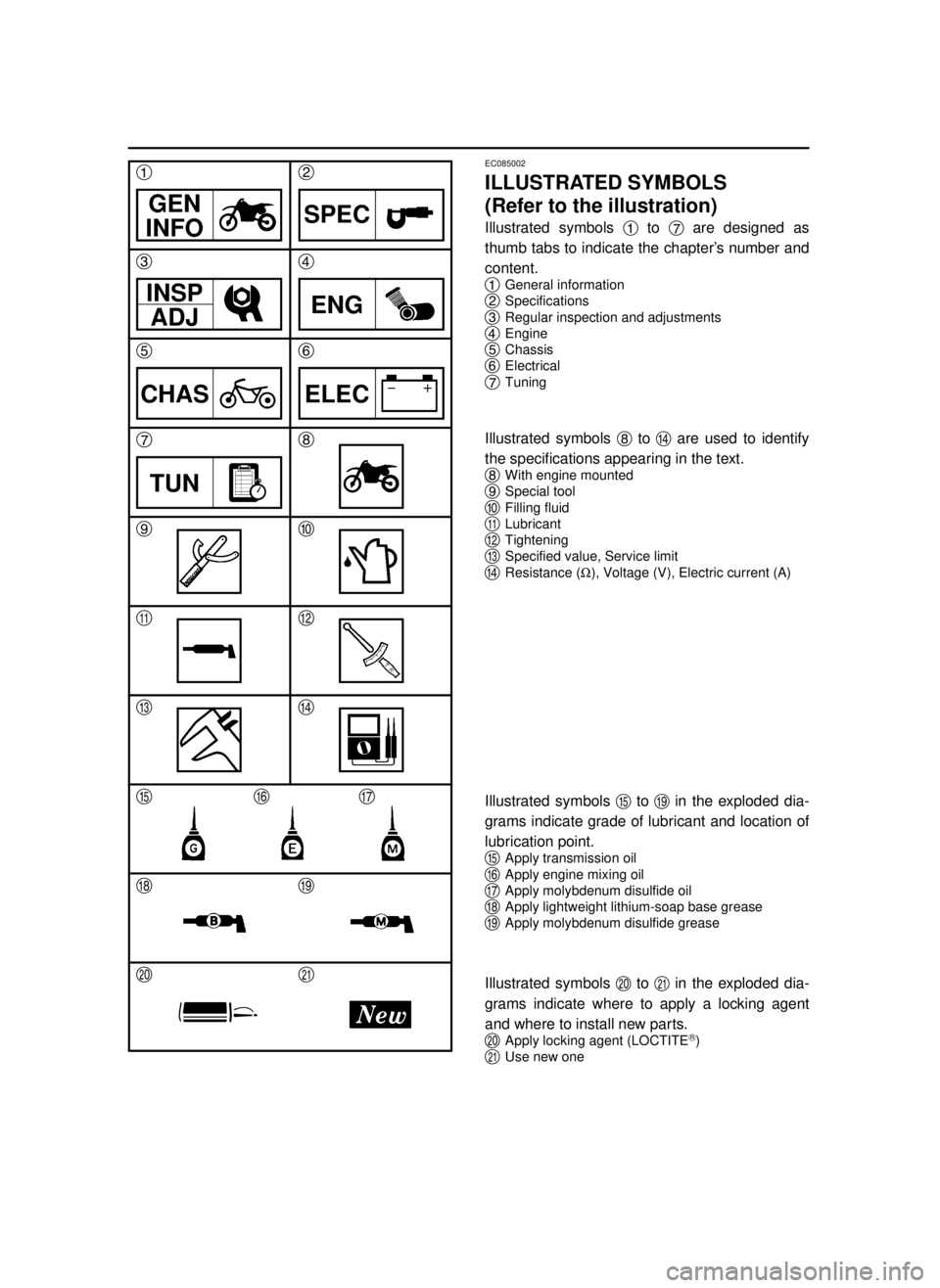

EC085002

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1to 7are designed as

thumb tabs to indicate the chapter’s number and

content.

1

General information

2Specifications

3Regular inspection and adjustments

4Engine

5Chassis

6Electrical

7Tuning

Illustrated symbols 8to rare used to identify

the specifications appearing in the text.

8

With engine mounted

9Special tool

0Filling fluid

qLubricant

wTightening

eSpecified value, Service limit

rResistance (½), Voltage (V), Electric current (A)

Illustrated symbols tto oin the exploded dia-

grams indicate grade of lubricant and location of

lubrication point.

t

Apply transmission oil

yApply engine mixing oil

uApply molybdenum disulfide oil

iApply lightweight lithium-soap base grease

oApply molybdenum disulfide grease

Illustrated symbols pto ain the exploded dia-

grams indicate where to apply a locking agent

and where to install new parts.

p

Apply locking agent (LOCTITER)

aUse new one

GEN

INFO

12

3

5

74

6

8

90

qw

er

tyu

io

pa

SPEC

INSP

ADJENG

CHASELEC

TUN

5MW-9-30-0 7/5/00 2:15 PM Page 14

Page 17 of 578

ABGEBILDETEN SYMBOLE

(Siehe Abbildung)

Die abgebildeten Symbole 1bis 7

sind zur einfachen Auffindung der Sei-

ten mit Daumeneinkerbungen verse-

hen. Die Abschnittsnummer sowie der

lnhalt können sofort ersehen werden.

1Allgemein Angaben

2Technische Daten

3Regelmäßige Prüfung und

Einstellungen

4Motor

5Fahrgestell

6Elektrische Einrichtungen

7Tuning

Die abgebildeten Symbole von 8bis

rwerden zur Unterscheidung der

Spezifikationen in diesem Text

benutzt.

8Mit dem Motor eingebaut

9Spezialwerkzeug

0Einfüllen von Flüssigkeit

qSchmiermittel

wFestziehen (Anzugsmoment)

eVerschleißgrenze, Wartungs-

Toleranzgrenze

rWiderstand (½), Spannung (V),

elektrischer Strom (A)

Die abgebildeten Symbole tbis oin

der Explosionszeichnung zeigen die

Schmierstoffklasse sowie die

Schmierstellen an.

tGetriebeöl auftragen

yMotor-Mischöl auftragen

uMolybdändisulfid-Öl auftragen

iLeichtes Lithium-Fett auftragen

oMolybdändisulfid-Fett auftragen

Die abgebildeten Symbole pbis ain

der Explosionszeichnung zeigen die

Stellen, wo Sicherungslack aufzutra-

gen ist und neue Teile einzubauen

sind.

pSicherungslack (LOCTITE®)

auftragen

aNeues Teil verwenden

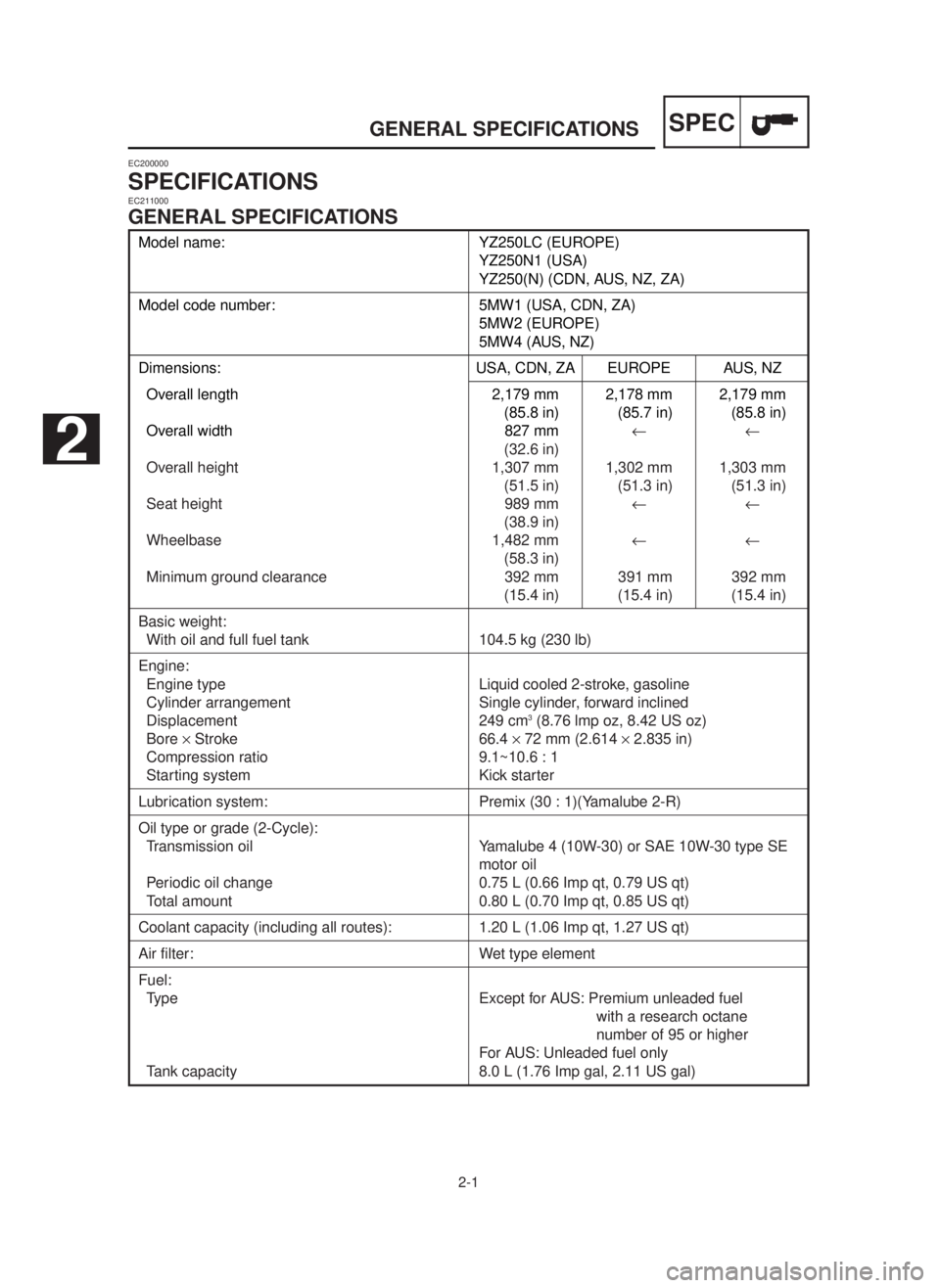

SYMBOLES GRAPHIQUES

(Voir l’illustration)

Les symboles graphiques 1à 7ser-

vent à repérer les différents chapitres et

à indiquer leur contenu.

1Renseignements généraux

2Caracteristiques

3Verification et réglages courants

4Moteur

5Partie cycle

6Partie électrique

7Mise au point

Les symboles graphiques 8á rper-

mettent d’identifier les spécifications

encadrées dans le texte.

8Avec de montage du moteur

9Outil spécial

0Liquide de remplissage

qLubrifiant

wSerrage

eValeur spécifiée, limite de service

rRésistance (½), tension (V), intensité (A)

Les symboles graphiques tà odans

les vues éclatées indiquent le grade de

lubrifiant et l’emplacement des points

de lubrification.

tAppliquer de l’huile de transmissionyAppliquer de l’huile de mélange du moteuruAppliquer de l’huile au bisulfure de molybdèneiAppliquer de la graisse fluide à base de savon

au lithium

oAppliquer de la graisse au bisulfure de

molybdène

Les symboles graphiques pet adans

les vues éclatées indiquent où appliquer

de l’agent bloquant et où installer de

nouveaux composants.

pAppliquer un agent de blocage

(LOCTITE®)

aUtiliser une pièce neuve

IC085002

SIMBOLI ILLUSTRATI

(Fare riferimento all’illustra-

zione)

I simboli illustrati da 1a 7sono pro-

gettati come linguette da sfogliare che

indichino il numero e il contenuto del

capitolo.

1Informazioni generali

2Specifiche

3Ispezione e regolazioni regolari

4Motore

5Telaio

6Parte elettrica

7Messa a punto

I simboli illustrati da 8a rvengono

usati per identificare le specifiche che

compaiono nel testo.

8Con motore montato

9Utensile speciale

0Liquido di riempimento

qLubrificante

wSerraggio

eValore specificato, limite di servizio

rResistenza (½), Tensione (V), Corrente

elettrica (A)

I simboli da ta oillustrati nei dia-

grammi esplosi indicano la qualità di

lubrificante e la posizione del punto di

lubrificazione.

tApplicare olio per trasmissioneyApplicare olio per miscela per motoriuApplicare olio a base di bisolfuro di molibdenoiApplicare grasso leggero a base di sapone di

litio

oApplicare grasso a base di bisolfuro di

molibdeno

I simboli pe aillustrati nei diagram-

mi esplosi indicano dove applicare

l’agente bloccante e dove montare il

pezzo di ricambio.

pApplicare agente bloccante

(LOCTITE®)

aUsare un pezzo nuovo

5MW-9-30-0 7/5/00 2:15 PM Page 15

Page 26 of 578

1-1

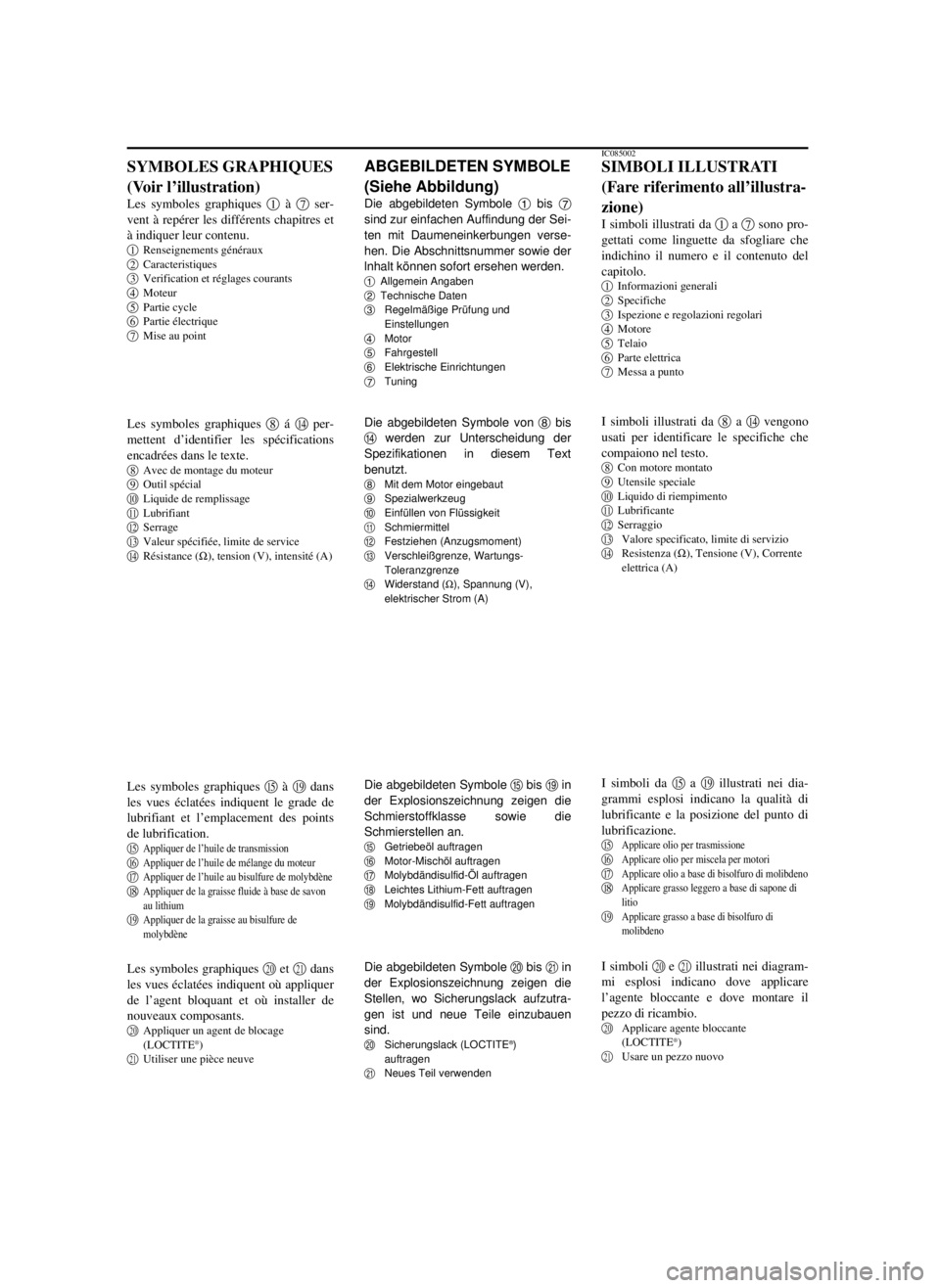

DESCRIPTION

GEN

INFO

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1Clutch lever

2“ENGINE STOP” button

3Front brake lever

4Throttle grip

5Radiator cap

6Fuel tank cap

7Kick starter

8Fuel tank

9Radiator

0Coolant drain bolt

qCheck bolt (Transmission oil level)

wRear brake pedal

eValve joint

rFuel cock

tStarter knob

yDrive chain

uAir cleaner

iShift pedal

oFront fork

NOTE:

9The machine you have purchased may differ

slightly from those shown in the following.

9Designs and specifications are subject to

change without notice.

1

5MW-9-30-1 7/3/00 1:36 PM Page 2

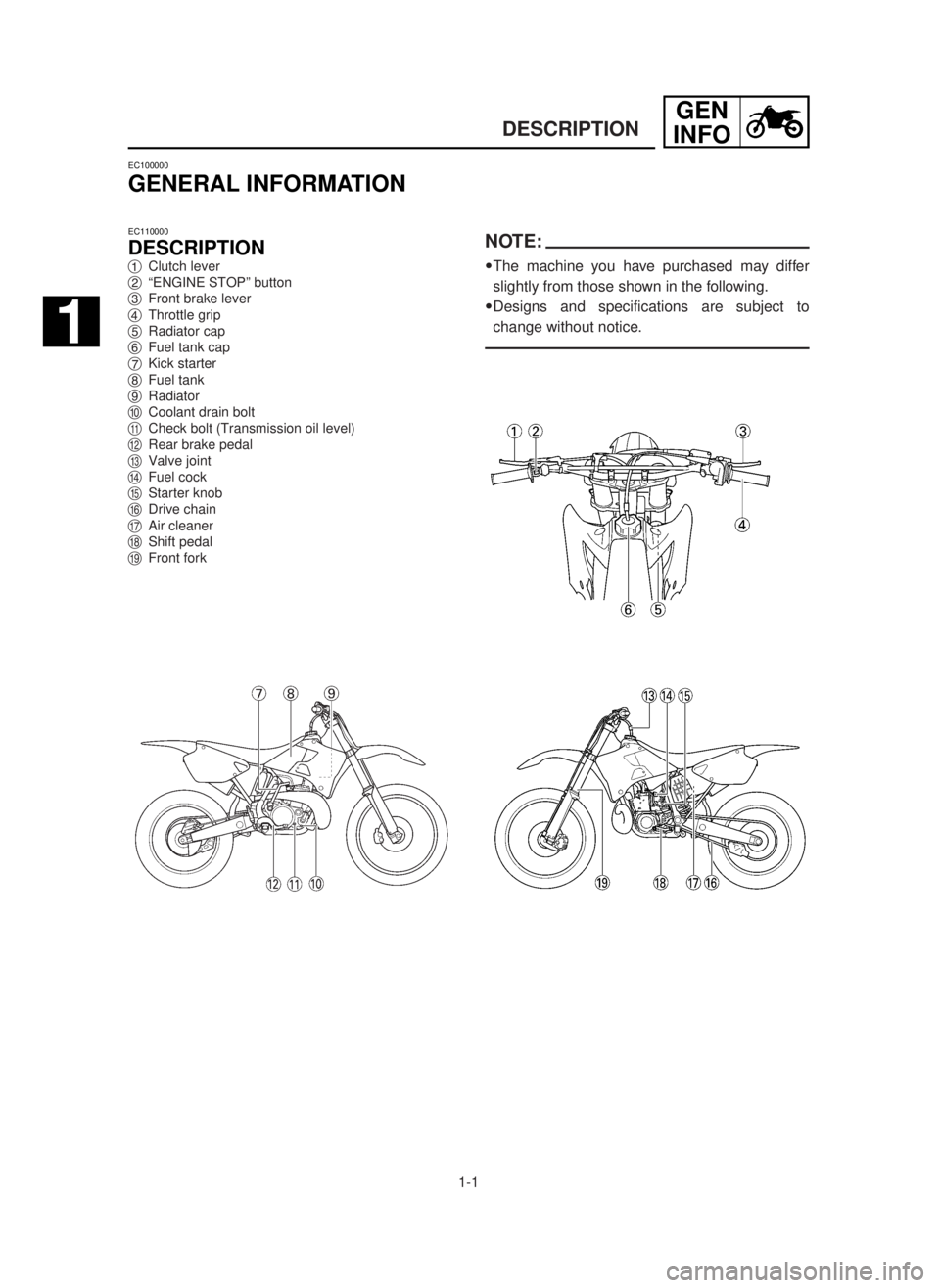

Page 68 of 578

2-1

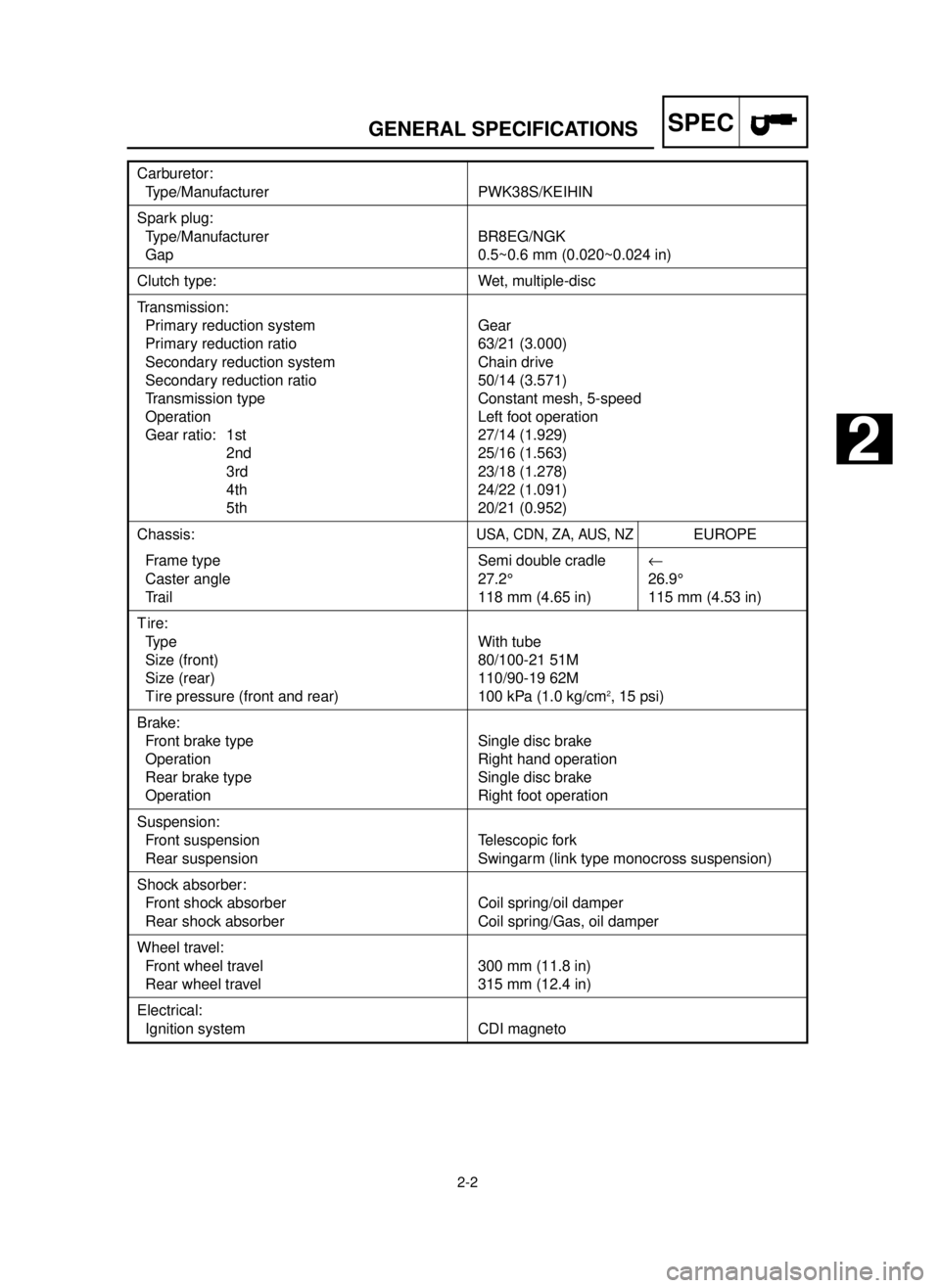

GENERAL SPECIFICATIONSSPEC

Model name: YZ250LC (EUROPE)

YZ250N1 (USA)

YZ250(N) (CDN, AUS, NZ, ZA)

Model code number: 5MW1 (USA, CDN, ZA)

5MW2 (EUROPE)

5MW4 (AUS, NZ)

Dimensions: USA, CDN, ZA EUROPE AUS, NZ

Overall length 2,179 mm 2,178 mm 2,179 mm

(85.8 in) (85.7 in) (85.8 in)

Overall width 827 mm¬¬

(32.6 in)

Overall height 1,307 mm 1,302 mm 1,303 mm

(51.5 in) (51.3 in) (51.3 in)

Seat height 989 mm¬¬

(38.9 in)

Wheelbase 1,482 mm¬¬

(58.3 in)

Minimum ground clearance 392 mm 391 mm 392 mm

(15.4 in) (15.4 in) (15.4 in)

Basic weight:

With oil and full fuel tank 104.5 kg (230 lb)

Engine:

Engine type Liquid cooled 2-stroke, gasoline

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3(8.76 lmp oz, 8.42 US oz)

Bore ´Stroke 66.4 ´72 mm (2.614 ´2.835 in)

Compression ratio 9.1~10.6 : 1

Starting system Kick starter

Lubrication system: Premix (30 : 1)(Yamalube 2-R)

Oil type or grade (2-Cycle):

Transmission oil Yamalube 4 (10W-30) or SAE 10W-30 type SE

motor oil

Periodic oil change 0.75 L (0.66 Imp qt, 0.79 US qt)

Total amount 0.80 L (0.70 Imp qt, 0.85 US qt)

Coolant capacity (including all routes): 1.20 L (1.06 Imp qt, 1.27 US qt)

Air filter: Wet type element

Fuel:

Type Except for AUS: Premium unleaded fuel

with a research octane

number of 95 or higher

For AUS: Unleaded fuel only

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

EC200000

SPECIFICATIONSEC211000

GENERAL SPECIFICATIONS

2

5MW-9-30-2 7/3/00 2:19 PM Page 2

Page 69 of 578

2-2

GENERAL SPECIFICATIONSSPEC

Carburetor:

Type/Manufacturer PWK38S/KEIHIN

Spark plug:

Type/Manufacturer BR8EG/NGK

Gap 0.5~0.6 mm (0.020~0.024 in)

Clutch type: Wet, multiple-disc

Transmission:

Primary reduction system Gear

Primary reduction ratio 63/21 (3.000)

Secondary reduction system Chain drive

Secondary reduction ratio 50/14 (3.571)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 27/14 (1.929)

2nd 25/16 (1.563)

3rd 23/18 (1.278)

4th 24/22 (1.091)

5th 20/21 (0.952)

Chassis:USA, CDN, ZA, AUS, NZEUROPE

Frame type Semi double cradle¬

Caster angle 27.2° 26.9°

Trail 118 mm (4.65 in) 115 mm (4.53 in)

T ire:

Type With tube

Size (front) 80/100-21 51M

Size (rear) 110/90-19 62M

T ire pressure (front and rear) 100 kPa (1.0 kg/cm2, 15 psi)

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/Gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Electrical:

Ignition system CDI magneto

2

5MW-9-30-2 7/3/00 2:19 PM Page 3

Page 71 of 578

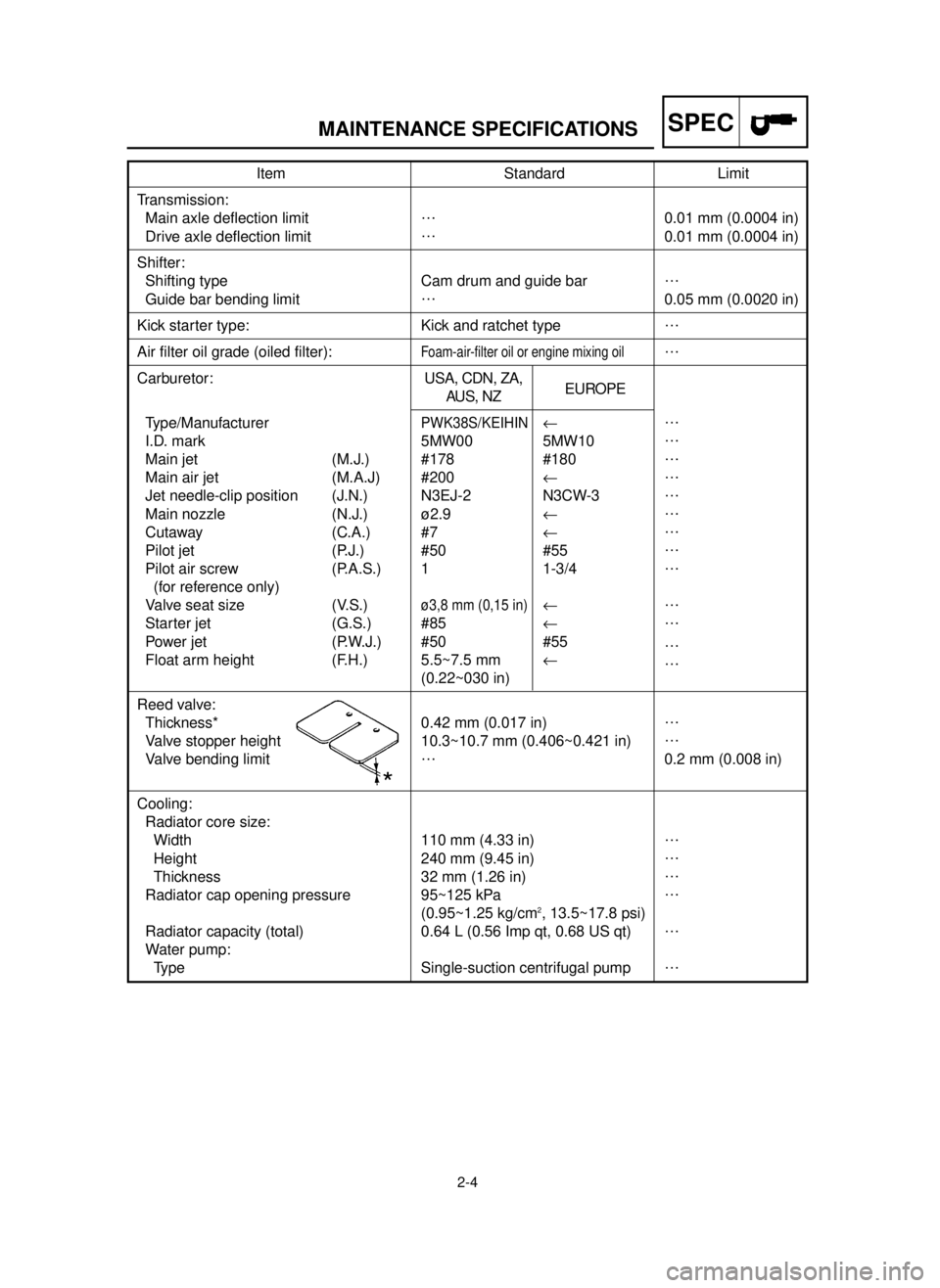

2-4

MAINTENANCE SPECIFICATIONSSPEC

Item Standard Limit

Transmission:

Main axle deflection limit…

0.01 mm (0.0004 in)

Drive axle deflection limit…

0.01 mm (0.0004 in)

Shifter:

Shifting type Cam drum and guide bar…

Guide bar bending limit…

0.05 mm (0.0020 in)

Kick starter type: Kick and ratchet type…

Air filter oil grade (oiled filter):Foam-air-filter oil or engine mixing oil…

Carburetor:USA, CDN, ZA,

EUROPE

AUS, NZ

Type/Manufacturer

PWK38S/KEIHIN¬…

I.D. mark 5MW00 5MW10…

Main jet (M.J.) #178 #180…

Main air jet (M.A.J) #200¬…

Jet needle-clip position (J.N.) N3EJ-2 N3CW-3…

Main nozzle (N.J.) ø2.9¬…

Cutaway (C.A.) #7¬…

Pilot jet (P.J.) #50 #55…

Pilot air screw (P.A.S.) 1 1-3/4…

(for reference only)

Valve seat size (V.S.)

ø3,8 mm (0,15 in)¬…

Starter jet (G.S.) #85¬…

Power jet (P.W.J.) #50 #55 …

Float arm height (F.H.) 5.5~7.5 mm¬…

(0.22~030 in)

Reed valve:

Thickness* 0.42 mm (0.017 in)…

Valve stopper height 10.3~10.7 mm (0.406~0.421 in)…

Valve bending limit…

0.2 mm (0.008 in)

Cooling:

Radiator core size:

Width 110 mm (4.33 in)…

Height 240 mm (9.45 in)…

Thickness 32 mm (1.26 in)…

Radiator cap opening pressure 95~125 kPa…

(0.95~1.25 kg/cm

2, 13.5~17.8 psi)

Radiator capacity (total) 0.64 L (0.56 Imp qt, 0.68 US qt)…

Water pump:

Type Single-suction centrifugal pump…

5MW-9-30-2 7/3/00 2:20 PM Page 5

Page 87 of 578

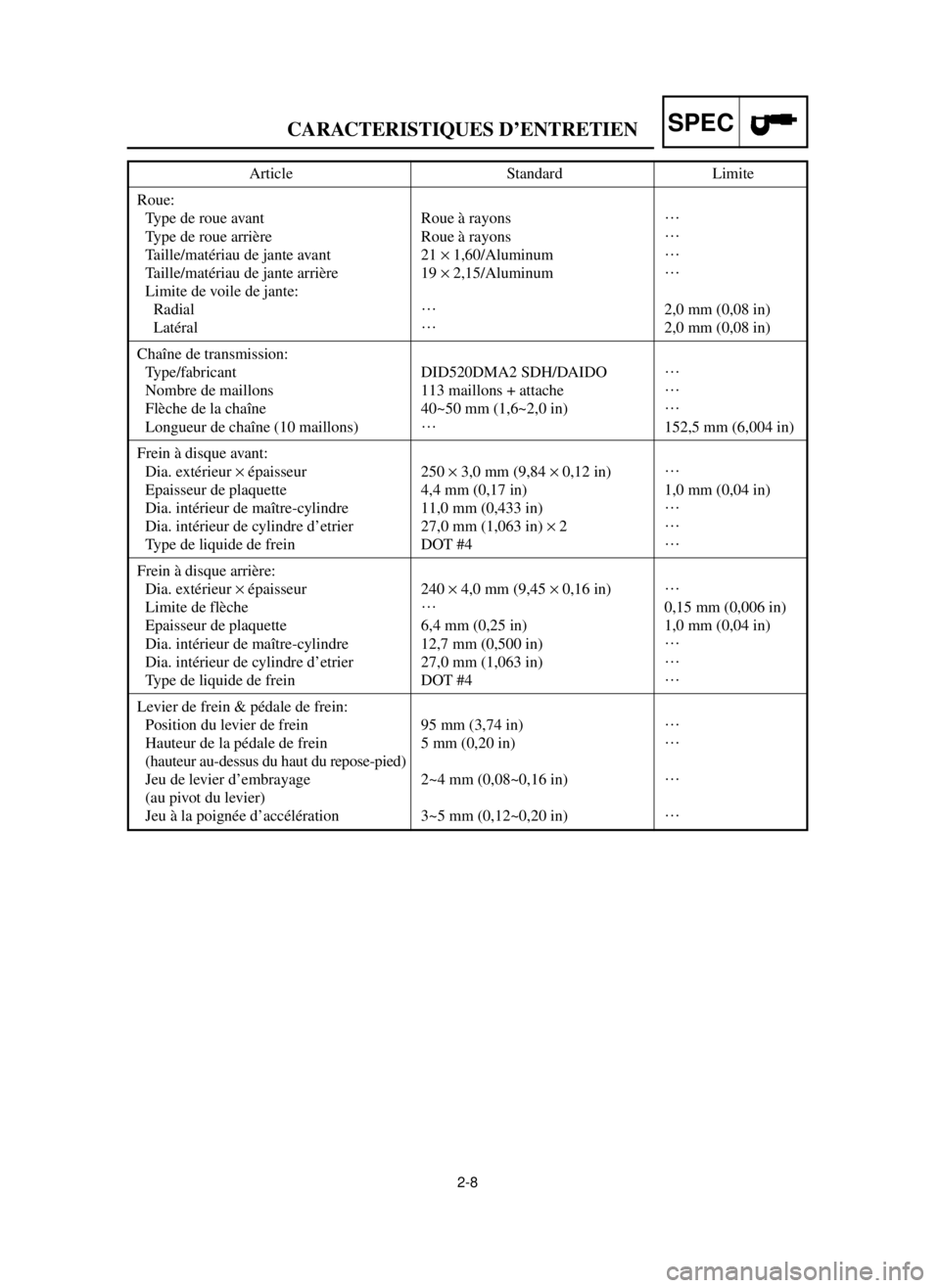

2-8

CARACTERISTIQUES D’ENTRETIENSPEC

Article Standard Limite

Roue:

Type de roue avant Roue à rayons…

Type de roue arrière Roue à rayons…

Taille/matériau de jante avant 21 ´1,60/Aluminum…

Taille/matériau de jante arrière 19 ´2,15/Aluminum…

Limite de voile de jante:

Radial…

2,0 mm (0,08 in)

Latéral…

2,0 mm (0,08 in)

Chaîne de transmission:

Type/fabricant DID520DMA2 SDH/DAIDO…

Nombre de maillons 113 maillons + attache…

Flèche de la chaîne 40~50 mm (1,6~2,0 in)…

Longueur de chaîne (10 maillons)…

152,5 mm (6,004 in)

Frein à disque avant:

Dia. extérieur ´épaisseur 250 ´3,0 mm (9,84 ´0,12 in)…

Epaisseur de plaquette 4,4 mm (0,17 in) 1,0 mm (0,04 in)

Dia. intérieur de maître-cylindre 11,0 mm (0,433 in)…

Dia. intérieur de cylindre d’etrier 27,0 mm (1,063 in) ´2…

Type de liquide de frein DOT #4…

Frein à disque arrière:

Dia. extérieur ´épaisseur 240 ´4,0 mm (9,45 ´0,16 in)…

Limite de flèche…

0,15 mm (0,006 in)

Epaisseur de plaquette 6,4 mm (0,25 in) 1,0 mm (0,04 in)

Dia. intérieur de maître-cylindre 12,7 mm (0,500 in)…

Dia. intérieur de cylindre d’etrier 27,0 mm (1,063 in)…

Type de liquide de frein DOT #4…

Levier de frein & pédale de frein:

Position du levier de frein 95 mm (3,74 in)…

Hauteur de la pédale de frein 5 mm (0,20 in)…

(hauteur au-dessus du haut du repose-pied)

Jeu de levier d’embrayage 2~4 mm (0,08~0,16 in)…

(au pivot du levier)

Jeu à la poignée d’accélération 3~5 mm (0,12~0,20 in)…

5MW-9-30-2 7/3/00 2:21 PM Page 21

Page 116 of 578

2-13

CABLE ROUTING DIAGRAMSPEC

EC240000

CABLE ROUTING DIAGRAM

1Cable guide

2Clamp

3“ENGINE STOP” button lead

4Throttle cable

5TPS (throttle position sensor)

lead

6Solenoid valve lead

7CDI unit

8CDI unit stay

9CDI unit band

0Air vent hose (left)

qTransmission oil breather hose

wOverflow hose

eAir vent hose (right)APass the throttle cable and

“ENGINE STOP” button lead into

the cable guide. Align with the

cable guide the front end of the

tape on the throttle cable.

BClamp the throttle cable,

“ENGINE STOP” button lead and

CDI unit lead with the clamp

ends downward.

CPass the throttle cable, “ENGINE

STOP” button lead and CDI unit

lead over the radiator hose.

DClamp the clutch cable, throttle

cable, “ENGINE STOP” button

lead, TPS (throttle position sen-

sor) lead and solenoid valve lead

with the clamp ends downward.

In so doing, clamp the “ENGINE

STOP” button lead at its protect-

ing tube.

EClamp the clutch cable so that

the clamp passes with its ends

downward, as shown.

FPass the TPS (throttle position

sensor) lead and solenoid valve

lead through the cable guide.GClamp the TPS (throttle position

sensor) lead and solenoid valve

lead to the frame with the clamp

ends backward.

HPass the solenoid valve lead

through the carburetor clamp.

IPass the air vent hoses, overflow

hose and transmission oil

breather hose between the frame

and connecting rod.

JFit the CDI unit into the CDI unit

stay till it stops.

KInsert the CDI unit into the CDI

unit band till it stops.

LPass the TPS (throttle position

sensor) lead and solenoid valve

lead under the damper.

MClamp the air vent hoses.

NPass the air vent hoses, overflow

hose and transmission oil

breather hose so that all these

hoses do not contact the rear

shock absorber.

5MW-9-30-2 7/3/00 2:24 PM Page 50

Page 124 of 578

INSP

ADJ

3-1

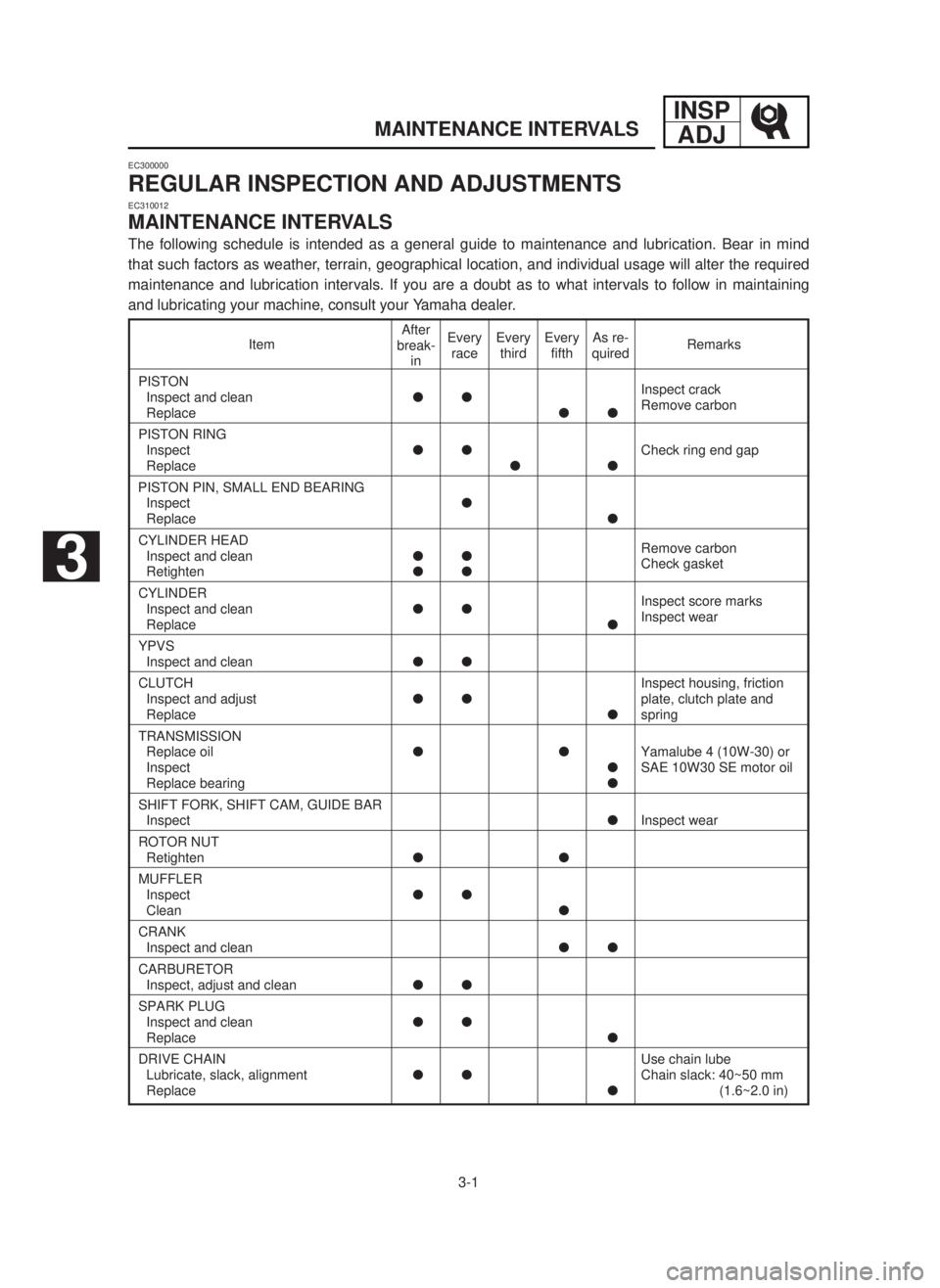

MAINTENANCE INTERVALS

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

EC310012

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the required

maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in maintaining

and lubricating your machine, consult your Yamaha dealer.

Item Remarks

PISTON

Inspect and cleanllInspect crack

ReplacellRemove carbon

PISTON RING

InspectllCheck ring end gap

Replacell

PISTON PIN, SMALL END BEARING

Inspectl

Replacel

CYLINDER HEAD

Inspect and cleanllRemove carbon

RetightenllCheck gasket

CYLINDER

Inspect and cleanllInspect score marks

ReplacelInspect wear

YPVS

Inspect and cleanll

CLUTCHInspect housing, friction

Inspect and adjustllplate, clutch plate and

Replacelspring

TRANSMISSION

Replace oilllYamalube 4 (10W-30) or

InspectlSAE 10W30 SE motor oil

Replace bearingl

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectlInspect wear

ROTOR NUT

Retightenll

MUFFLER

Inspectll

Cleanl

CRANK

Inspect and cleanll

CARBURETOR

Inspect, adjust and cleanll

SPARK PLUG

Inspect and cleanll

Replacel

DRIVE CHAIN Use chain lube

Lubricate, slack, alignmentllChain slack: 40~50 mm

Replacel(1.6~2.0 in)

After

break-

inEvery

raceEvery

thirdEvery

fifthAs re-

quired

3

5MW-9-30-3A 7/3/00 2:46 PM Page 2

Page 136 of 578

3-4

PRE-OPERATION INSPECTION AND MAINTENANCE

INSP

ADJ

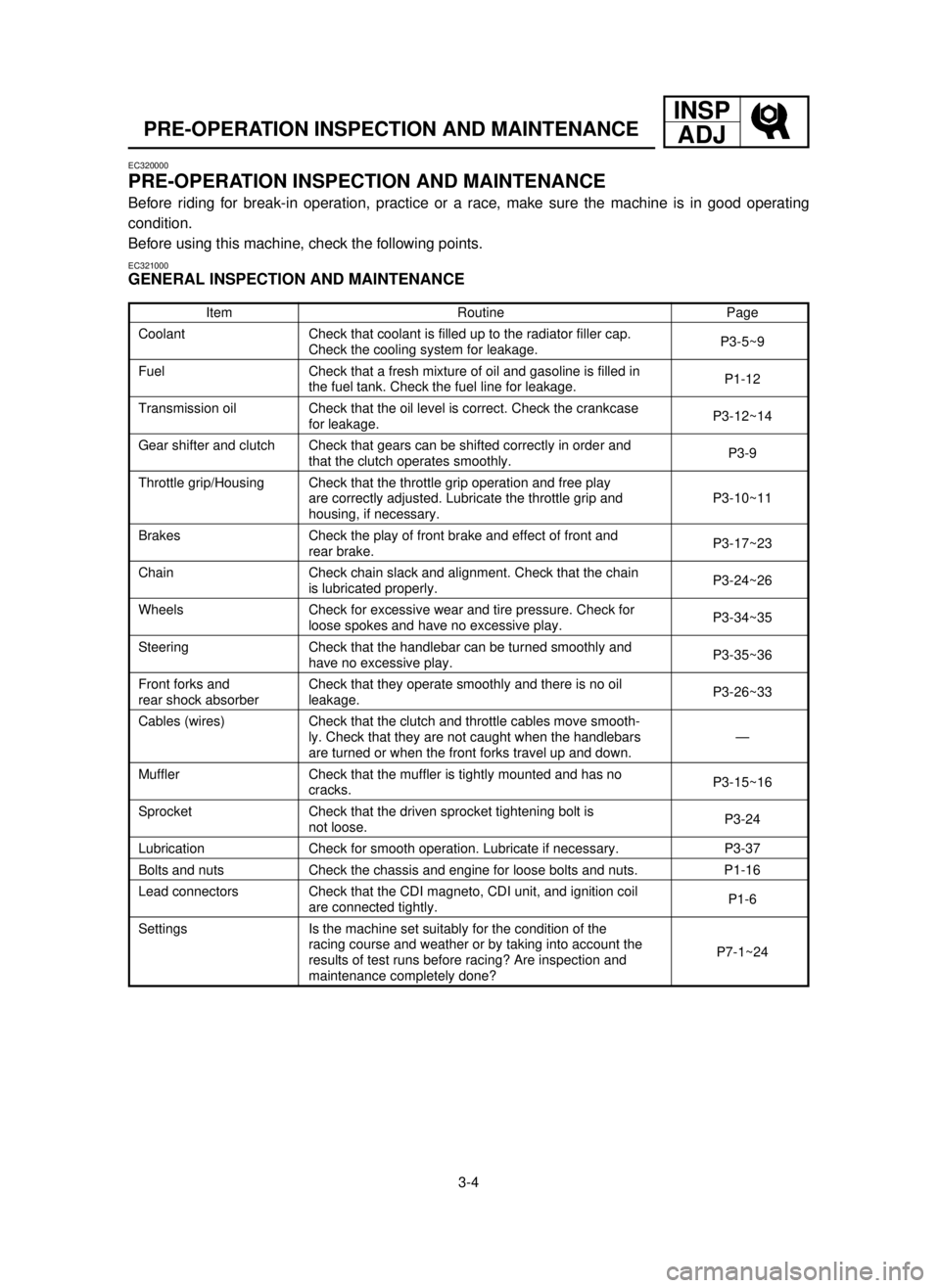

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EC321000

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

Coolant Check that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P3-5~9

Fuel Check that a fresh mixture of oil and gasoline is filled in

the fuel tank. Check the fuel line for leakage.P1-12

Transmission oil Check that the oil level is correct. Check the crankcase

for leakage.P3-12~14

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly.P3-9

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and P3-10~11

housing, if necessary.

Brakes Check the play of front brake and effect of front and

rear brake.P3-17~23

Chain Check chain slack and alignment. Check that the chain

is lubricated properly.P3-24~26

Wheels Check for excessive wear and tire pressure. Check for

loose spokes and have no excessive play.P3-34~35

Steering Check that the handlebar can be turned smoothly and

have no excessive play.P3-35~36

Front forks and Check that they operate smoothly and there is no oil

rear shock absorber leakage.P3-26~33

Cables (wires) Check that the clutch and throttle cables move smooth-

ly. Check that they are not caught when the handlebars —

are turned or when the front forks travel up and down.

Muffler Check that the muffler is tightly mounted and has no

cracks.P3-15~16

Sprocket Check that the driven sprocket tightening bolt is

not loose.P3-24

Lubrication Check for smooth operation. Lubricate if necessary. P3-37

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P1-16

Lead connectors Check that the CDI magneto, CDI unit, and ignition coil

are connected tightly.P1-6

Settings Is the machine set suitably for the condition of the

racing course and weather or by taking into account the

P7-1~24

results of test runs before racing? Are inspection and

maintenance completely done?

5MW-9-30-3A 7/3/00 2:47 PM Page 14