bolt pattern YAMAHA YZ426F 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ426F, Model: YAMAHA YZ426F 2001Pages: 626, PDF Size: 47.57 MB

Page 182 of 626

3 - 20

INSP

ADJ

VALVE CLEARANCE ADJUSTMENT

5. Adjust:

lValve clearance

Adjustment steps:

lLoosen the timing chain tensioner cap

bolt.

lRemove the timing chain tensioner and

camshaft caps.

NOTE:

Remove the camshaft cap bolts in a criss-

cross pattern from the outside working

inwards.

lRemove the camshaft (intake 1 and

exhaust 2).

NOTE:

Attach a wire 3 to the timing chain to pre-

vent it from falling into the crankcase.

lRemove the decompression guide 4,

cable 5, bolt 6 and decompression shaft

7.

lRemove the valve lifters 8 and the pads

9.

NOTE:

lPlace a rag in the timing chain space to

prevent pads from falling into the crank-

case.

lIdentity each valve lifter and pad position

very carefully so that they can be rein-

stalled in their original place.

lSelect the proper pad using the pad

selecting table.

Pad rangePad Availability:

25 increments

No. 120

~

No. 2401.20 mm

~

2.40 mmPads are available in

0.05 mm increments

NOTE:

The thickness a of each pad is indicated in

hundreths of millimeters on the pad upper

surface.

Page 278 of 626

4 - 21

ENG

CAMSHAFTS

REMOVAL POINTS

Camshaft

1. Remove:

l

Timing plug

1

l

Straight plug

2

2. Align:

l

“I” mark

With stationary pointer.

Checking steps:

l

Turn the crankshaft counterclockwise with

a wrench.

l

Align the “I” mark

a

on the rotor with the

stationary pointer

b

on the crankcase

cover. When the “I” mark is aligned with

the stationary pointer, the piston is at the

Top Dead Center (T.D.C.).

NOTE:

l

In order to be sure that the piston is at Top

Dead Center, the punch mark

c

on the

exhaust camshaft and the punch mark

d

on the intake camshaft must align with the

cylinder head surface, as shown in the

illustration.

l

If there is no clearance, rotate the crank-

shaft counterclockwise one turn.

3. Loosen:

l

Tensioner cap bolt

1

4. Remove:

l

Timing chain tensioner

2

5. Remove:

l

Bolt (camshaft cap)

1

l

Camshaft caps

2

NOTE:

Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

CAUTION:

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

Page 282 of 626

4 - 23

ENG

CAMSHAFTS

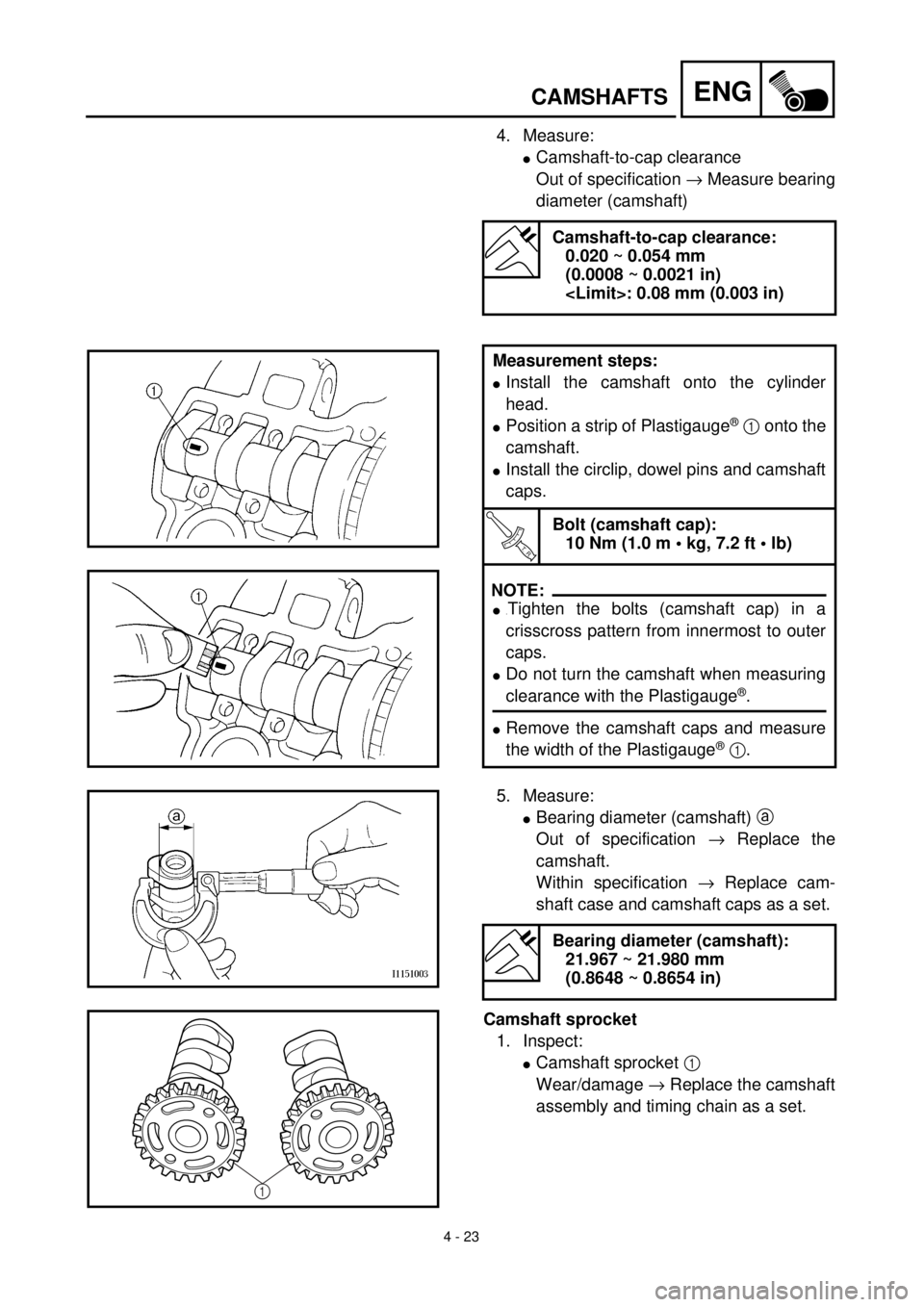

4. Measure:

l

Camshaft-to-cap clearance

Out of specification

®

Measure bearing

diameter (camshaft)

Camshaft-to-cap clearance:

0.020 ~ 0.054 mm

(0.0008 ~ 0.0021 in)

Measurement steps:

l

Install the camshaft onto the cylinder

head.

l

Position a strip of Plastigauge

®

1

onto the

camshaft.

l

Install the circlip, dowel pins and camshaft

caps.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

NOTE:

l

.

Tighten the bolts (camshaft cap) in a

crisscross pattern from innermost to outer

caps.

l

Do not turn the camshaft when measuring

clearance with the Plastigauge

®

.

l

Remove the camshaft caps and measure

the width of the Plastigauge

®

1

.

5. Measure:

l

Bearing diameter (camshaft)

a

Out of specification

®

Replace the

camshaft.

Within specification

®

Replace cam-

shaft case and camshaft caps as a set.

Camshaft sprocket

1. Inspect:

l

Camshaft sprocket

1

Wear/damage

®

Replace the camshaft

assembly and timing chain as a set.

Bearing diameter (camshaft):

21.967 ~ 21.980 mm

(0.8648 ~ 0.8654 in)

1

Page 286 of 626

4 - 25

ENGCAMSHAFTS

2. Install:

lTiming chain tensioner

3. Turn:

lCrankshaft

Counterclockwise several turns

4. Check:

lRotor “I” mark

Align with the crankcase stationary

pointer.

lCamshaft match marks

Align with the cylinder head surface.

Out of alignment ® Adjust.

lInstall the dowel pins, clips and camshaft

caps 4.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

NOTE:

.Tighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly or damage to the cylinder

head, camshaft caps and camshaft will

result.

Installation steps:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

lWith the rod fully wound and the chain

tensioner UP mark a facing upward,

install the gasket 1 and the chain ten-

sioner 2, and tighten the bolt 3 to the

specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

lRelease the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket 4 and the cap bolt 5 to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

Page 338 of 626

4 - 51

ENGCLUTCH

7. Install:

lPush rod 2 1

lBall 2

lPush rod 1 3

NOTE:

Apply the engine oil on the push rod 1, 2 and

ball.

8. Install:

lPressure plate 1

9. Install:

lClutch spring

lBolt (clutch spring)

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

10. Install:

lGasket (clutch cover) 1

lDowel pin 2

New

11. Install:

lClutch cover 1

lBolt (clutch cover)

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 348 of 626

4 - 56

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

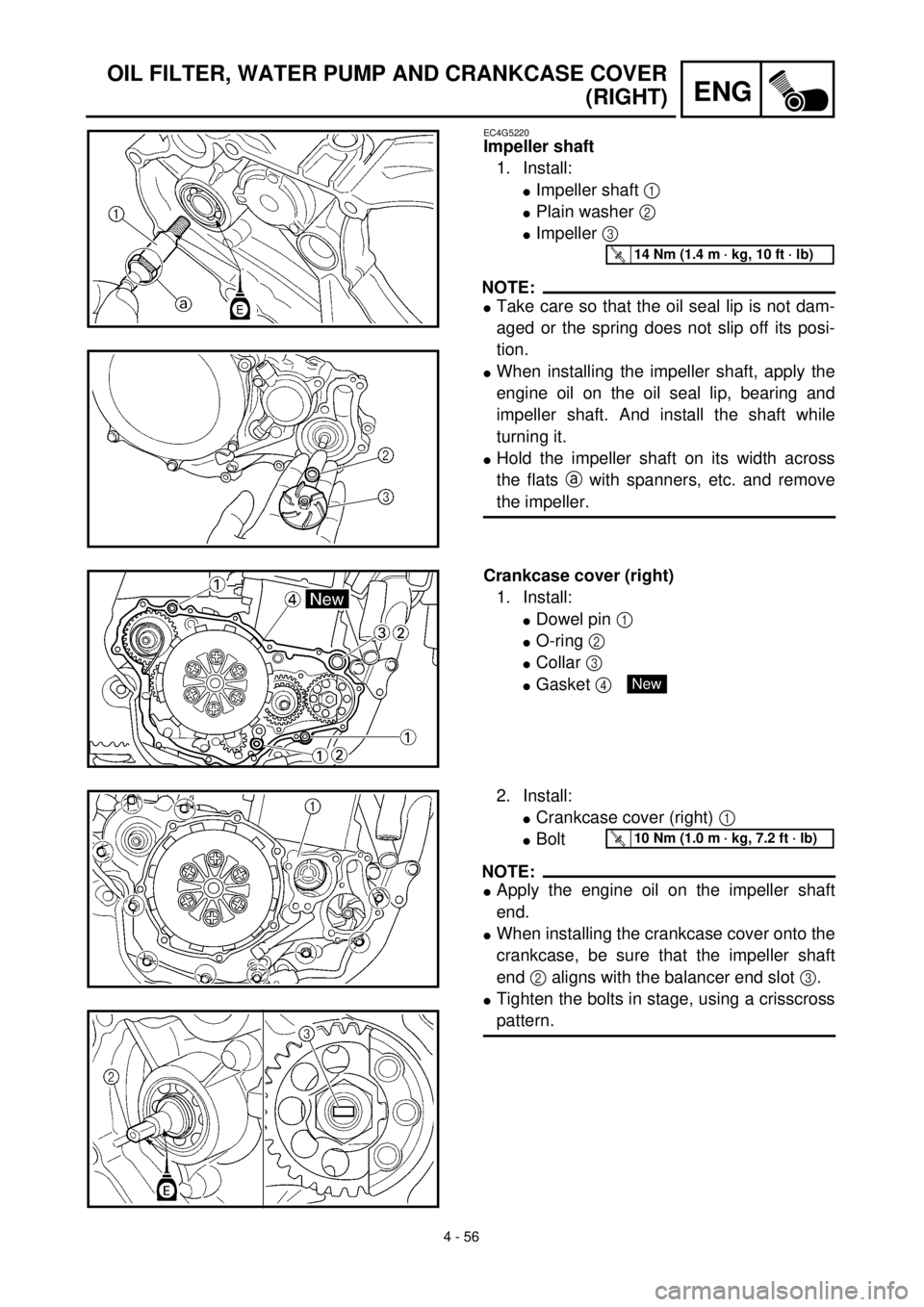

EC4G5220

Impeller shaft

1. Install:

lImpeller shaft 1

lPlain washer 2

lImpeller 3

NOTE:

lTake care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

lWhen installing the impeller shaft, apply the

engine oil on the oil seal lip, bearing and

impeller shaft. And install the shaft while

turning it.

lHold the impeller shaft on its width across

the flats a with spanners, etc. and remove

the impeller.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

Crankcase cover (right)

1. Install:

lDowel pin 1

lO-ring 2

lCollar 3

lGasket 4 New

2. Install:

lCrankcase cover (right) 1

lBolt

NOTE:

lApply the engine oil on the impeller shaft

end.

lWhen installing the crankcase cover onto the

crankcase, be sure that the impeller shaft

end 2 aligns with the balancer end slot 3.

lTighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 388 of 626

![YAMAHA YZ426F 2001 Notices Demploi (in French) 4 - 76

ENGCDI MAGNETO

4. Connect:

lCDI magneto lead

Refer to “CABLE ROUTING DIA-

GRAM” section in the CHAPTER 2.

5. Install:

lGasket [crankcase cover (left)]

lCrankcase cover (left) 1

lHose hold YAMAHA YZ426F 2001 Notices Demploi (in French) 4 - 76

ENGCDI MAGNETO

4. Connect:

lCDI magneto lead

Refer to “CABLE ROUTING DIA-

GRAM” section in the CHAPTER 2.

5. Install:

lGasket [crankcase cover (left)]

lCrankcase cover (left) 1

lHose hold](/img/51/53971/w960_53971-387.png)

4 - 76

ENGCDI MAGNETO

4. Connect:

lCDI magneto lead

Refer to “CABLE ROUTING DIA-

GRAM” section in the CHAPTER 2.

5. Install:

lGasket [crankcase cover (left)]

lCrankcase cover (left) 1

lHose holder (cylinder head breather

hose) 2

lBolt [crankcase cover (left)]

NOTE:

Tighten the screws in stage, using a crisscross

pattern.

6. Install:

lShift pedal 1

lBolt (shift pedal)

NOTE:

When installing the shift pedal onto the shift

shaft, be sure that the center of the shift pedal

is about 2 mm a above the top of the footrest.

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 416 of 626

4 - 90

ENGCRANKCASE AND CRANKSHAFT

6. Tighten:

lHose guide 1

lClutch cable holder 2

lBolt (crankcase)

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

7. Install:

lOil delivery pipe

lO-ring

lBolt (oil delivery pipe)

8. Install:

lTiming chain

lTiming chain guide (rear)

lBolt (timing chain guide)

9. Remove:

lSealant

Forced out on the cylinder mating sur-

face.

10. Apply:

lEngine oil

To the crank pin, bearing and oil deliv-

ery hole.

11. Check:

lCrankshaft and transmission operation.

Unsmooth operation ® Repair.

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 436 of 626

5 - 5

CHASFRONT WHEEL AND REAR WHEEL

EC595000

ASSEMBLY AND INSTALLATION

EC595100

Front wheel

1. Install:

lBearing (left) 1

lSpacer 2

lBearing (right) 3

lOil seal 4

NOTE:

lApply the lithium soap base grease on the

bearing and oil seal lip when installing.

lUse a socket that matches the outside diam-

eter of the race of the bearing.

lLeft side of bearing shall be installed first.

lInstall the oil seal with its manufacture’s

marks or numbers facing outward.

ACHTUNG:CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

2. Install:

lBrake disc 1

lBolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

New

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

3. Install:

lCollar 1

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lInstall the collars with their projections a

facing the wheel.

4. Install:

lWheel

NOTE:

Install the brake disc 1 between the brake

pads 2 correctly.

Page 440 of 626

![YAMAHA YZ426F 2001 Notices Demploi (in French) 5 - 7

CHASFRONT WHEEL AND REAR WHEEL

9. Install:

lHose cover 1

lPlain washer 2

lBolt [hose cover (M8)] 3

lBolt [hose cover (M6)] 4

T R..16 Nm (1.6 m · kg, 11 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 YAMAHA YZ426F 2001 Notices Demploi (in French) 5 - 7

CHASFRONT WHEEL AND REAR WHEEL

9. Install:

lHose cover 1

lPlain washer 2

lBolt [hose cover (M8)] 3

lBolt [hose cover (M6)] 4

T R..16 Nm (1.6 m · kg, 11 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1](/img/51/53971/w960_53971-439.png)

5 - 7

CHASFRONT WHEEL AND REAR WHEEL

9. Install:

lHose cover 1

lPlain washer 2

lBolt [hose cover (M8)] 3

lBolt [hose cover (M6)] 4

T R..16 Nm (1.6 m · kg, 11 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

EC5251A0

Rear wheel

1. Install:

lBearing (right) 1

lCirclip 2

lSpacer 3

lBearing (left) 4

lOil seal 5

NOTE:

lApply the lithium soap base grease on the

bearing and oil seal lip when installing.

lInstall the bearing with seal facing outward.

lUse a socket that matches the outside diam-

eter of the race of the bearing.

lRight side of bearing shall be installed first.

lInstall the oil seal with its manufacture’s

marks or numbers facing outward.

ACHTUNG:CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

New

New

2. Install:

lBrake disc 1

lBolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..14 Nm (1.4 m · kg, 10 ft · lb)