lock YAMAHA YZ450F 2005 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 346 of 646

4 - 53

ENGCLUTCH

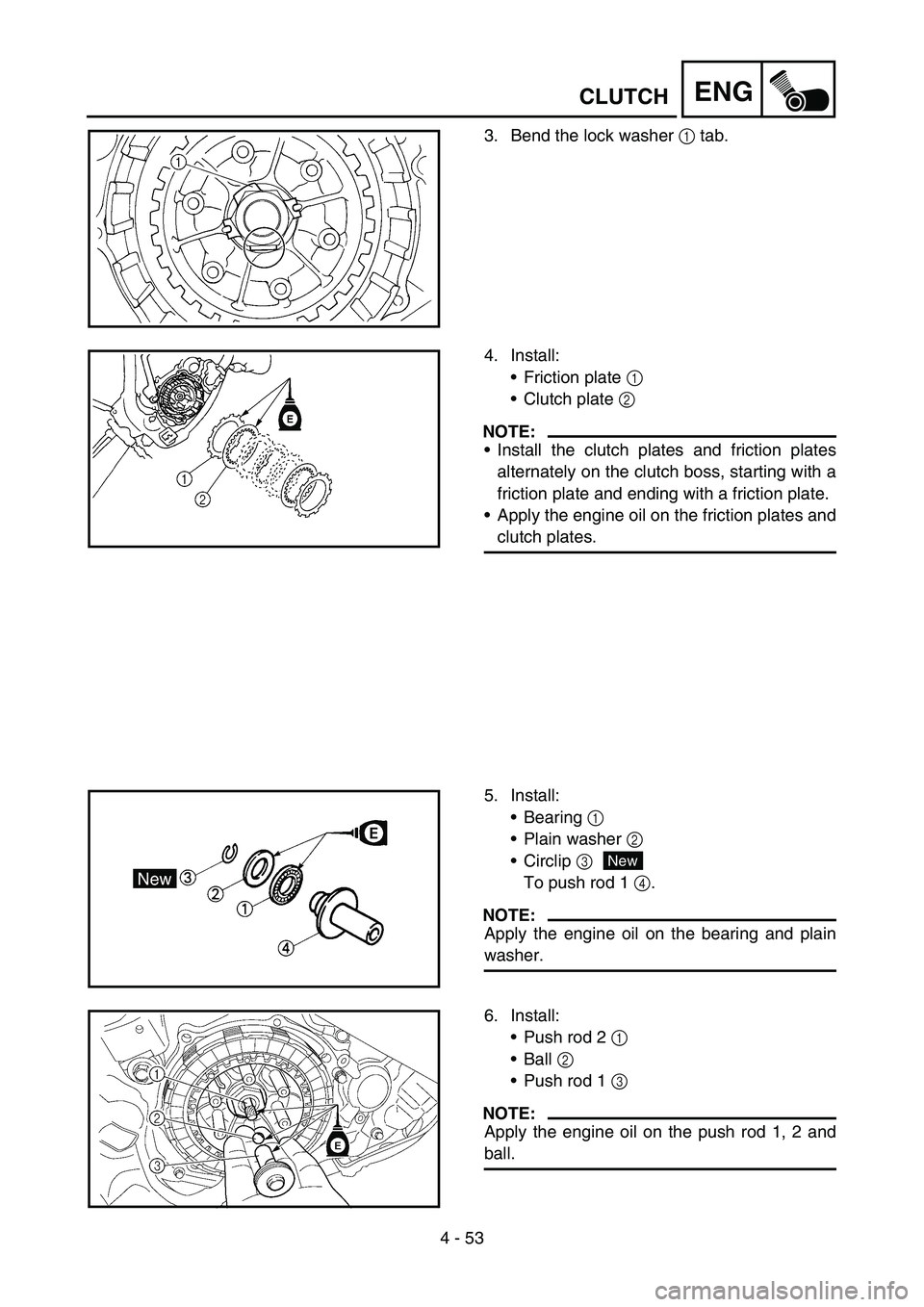

3. Bend the lock washer 1 tab.

4. Install:

Friction plate 1

Clutch plate 2

NOTE:

Install the clutch plates and friction plates

alternately on the clutch boss, starting with a

friction plate and ending with a friction plate.

Apply the engine oil on the friction plates and

clutch plates.

5. Install:

Bearing 1

Plain washer 2

Circlip 3

To push rod 1 4.

NOTE:

Apply the engine oil on the bearing and plain

washer.

New

6. Install:

Push rod 2 1

Ball 2

Push rod 1 3

NOTE:

Apply the engine oil on the push rod 1, 2 and

ball.

Page 364 of 646

4 - 62

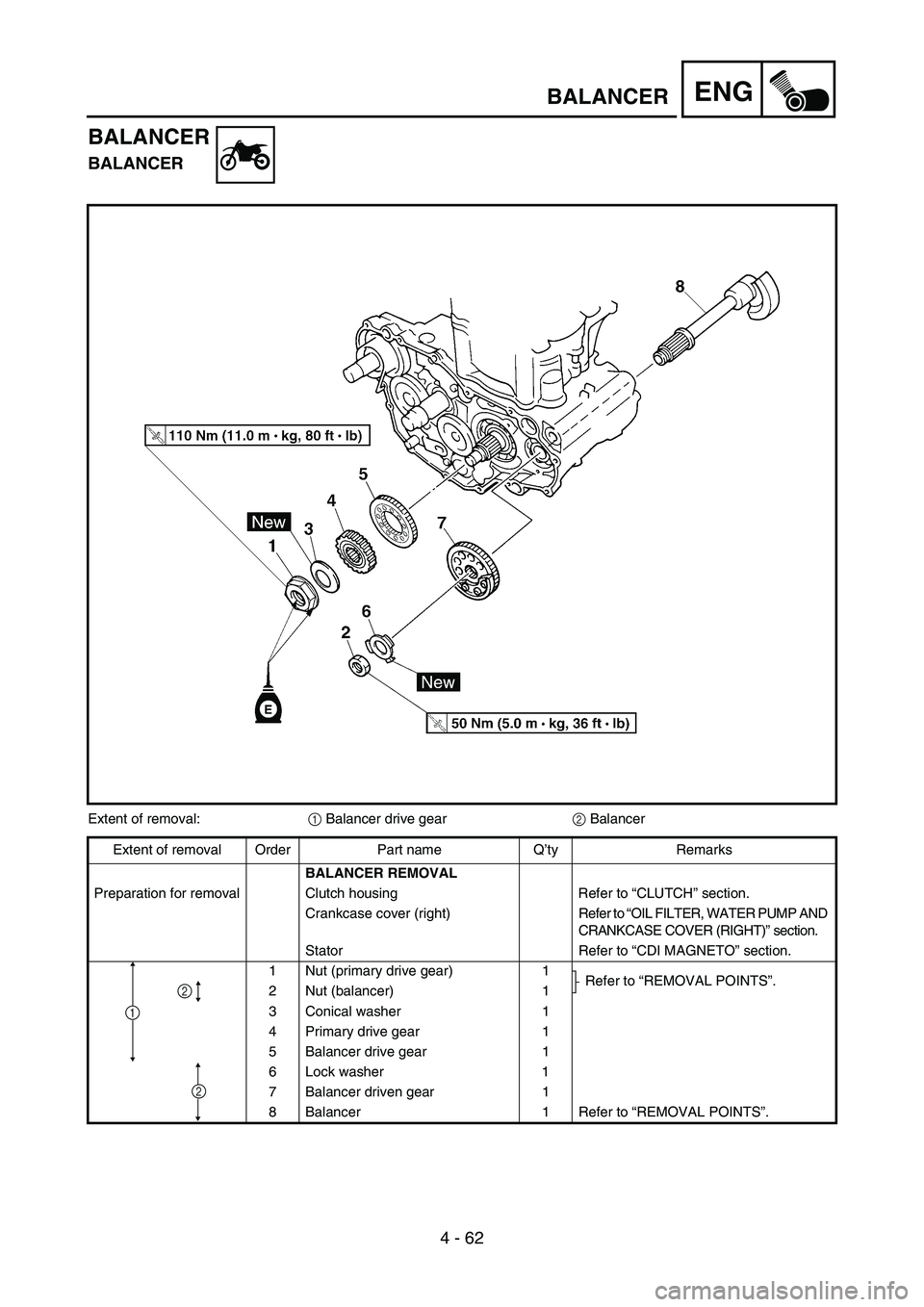

ENGBALANCER

BALANCER

BALANCER

Extent of removal:

1 Balancer drive gear

2 Balancer

Extent of removal Order Part name Q’ty Remarks

BALANCER REMOVAL

Preparation for removal Clutch housing Refer to “CLUTCH” section.

Crankcase cover (right) Refer to “OIL FILTER, WATER PUMP AND

CRANKCASE COVER (RIGHT)” section.

Stator Refer to “CDI MAGNETO” section.

1 Nut (primary drive gear) 1

Refer to “REMOVAL POINTS”.

2 Nut (balancer) 1

3 Conical washer 1

4 Primary drive gear 1

5 Balancer drive gear 1

6 Lock washer 1

7 Balancer driven gear 1

8 Balancer 1 Refer to “REMOVAL POINTS”.

2

1

2

Page 366 of 646

4 - 63

ENGBALANCER

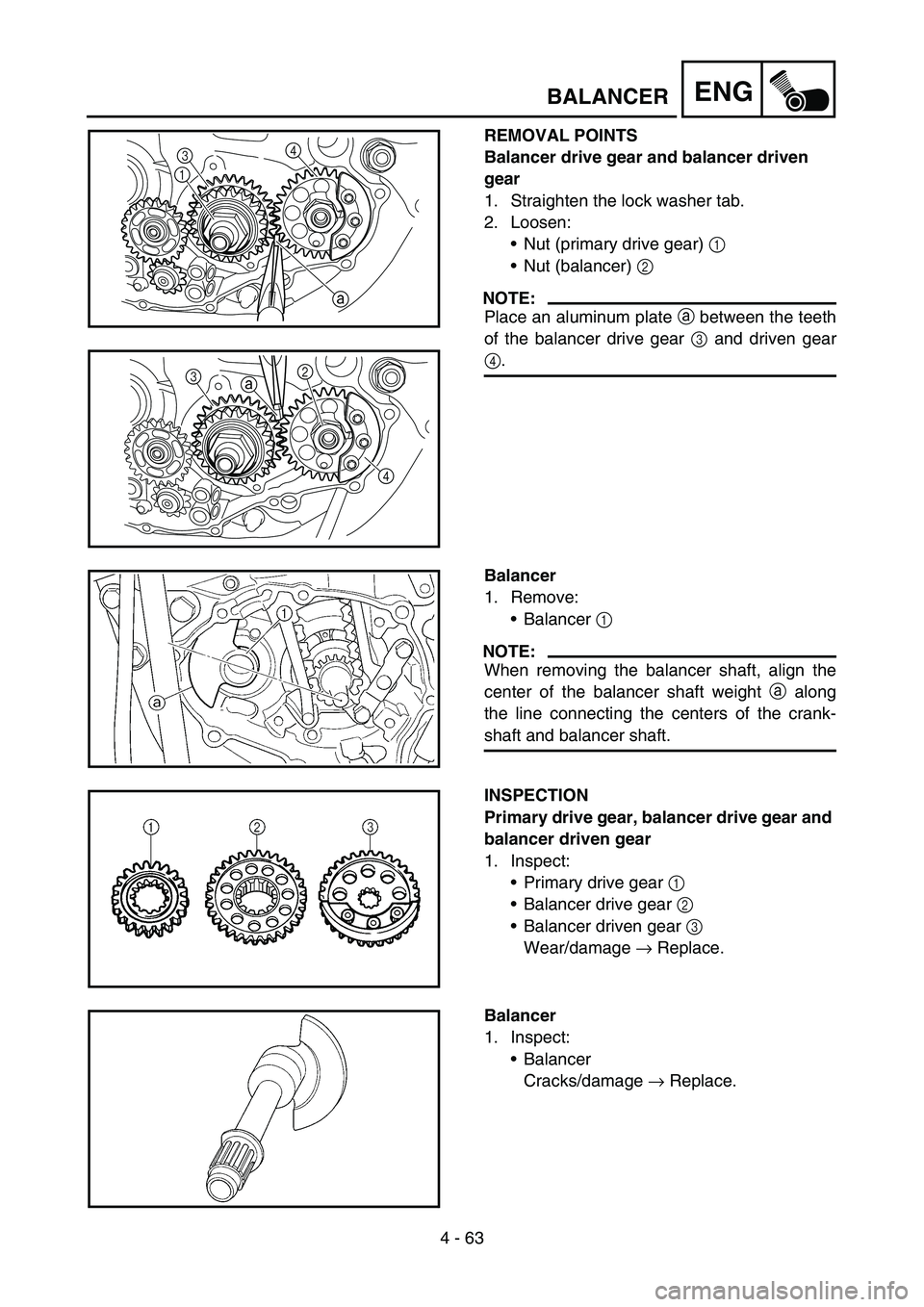

REMOVAL POINTS

Balancer drive gear and balancer driven

gear

1. Straighten the lock washer tab.

2. Loosen:

Nut (primary drive gear) 1

Nut (balancer) 2

NOTE:

Place an aluminum plate a between the teeth

of the balancer drive gear 3 and driven gear

4.

a 3

14

2

4 3

a

Balancer

1. Remove:

Balancer 1

NOTE:

When removing the balancer shaft, align the

center of the balancer shaft weight a along

the line connecting the centers of the crank-

shaft and balancer shaft.

INSPECTION

Primary drive gear, balancer drive gear and

balancer driven gear

1. Inspect:

Primary drive gear 1

Balancer drive gear 2

Balancer driven gear 3

Wear/damage → Replace.

Balancer

1. Inspect:

Balancer

Cracks/damage → Replace.

Page 367 of 646

4 - 63

ENG

DEMONTAGE-EINZELHEITEN

Ausgleichswellen-Antriebsritzel und -rad

1. Die Lasche der Sicherungsscheibe umbie-

gen.

2. Lockern:

Mutter (Primärantriebsritzel) 1

Ausgleichswellen-Mutter 2

HINWEIS:

Ein Alu-Blechstück a zwischen das Antriebs-

ritzel 3 und das Antriebsrad 4 klemmen.

Ausgleichswelle

1. Demontieren:

Ausgleichswelle 1

HINWEIS:

Zur Demontage der Ausgleichswelle die Mitte

a des Ausgleichsgewichts auf die Mitte der

Ausgleichs- und Kurbelwellen ausrichten.

KONTROLLE

Primärantriebsritzel, Ausgleichswellen-

Antriebsritzel und -rad

1. Kontrollieren:

Primärantriebsritzel 1

Ausgleichswellen-Antriebsritzel 2

Ausgleichswellen-Antriebsrad 3

Verschlissen/beschädigt → Erneuern.

Ausgleichswelle

1. Kontrollieren:

Ausgleichswelle

Rissig/beschädigt → Erneuern.

BALANCIER

AUSGLEICHSWELLE

POINTS DE DEPOSE

Pignon menant et pignon mené du balancier

1. Redresser l’onglet de la rondelle-frein.

2. Desserrer:

Ecrou (pignon menant de transmission pri-

maire) 1

Ecrou (balancier) 2

N.B.:

Placer une plaque d’aluminium a entre les dents

du pignon menant 3 et du pignon mené 4 du

balancier.

Balancier

1. Déposer:

Balancier 1

N.B.:

Pour déposer l’arbre de balancier, aligner le centre

a du contrepoids d’arbre de balancier sur la ligne

raccordant les centres du vilebrequin et de l’arbre

de balancier.

CONTROLE

Pignon menant de transmission primaire,

pignon menant et pignon mené du balancier

1. Contrôler:

Pignon menant de transmission primaire 1

Pignon menant du balancier 2

Pignon mené du balancier 3

Usure/endommagement → Remplacer.

Balancier

1. Contrôler:

Balancier

Craquelures/endommagement → Remplacer.

Page 368 of 646

4 - 64

ENGBALANCER

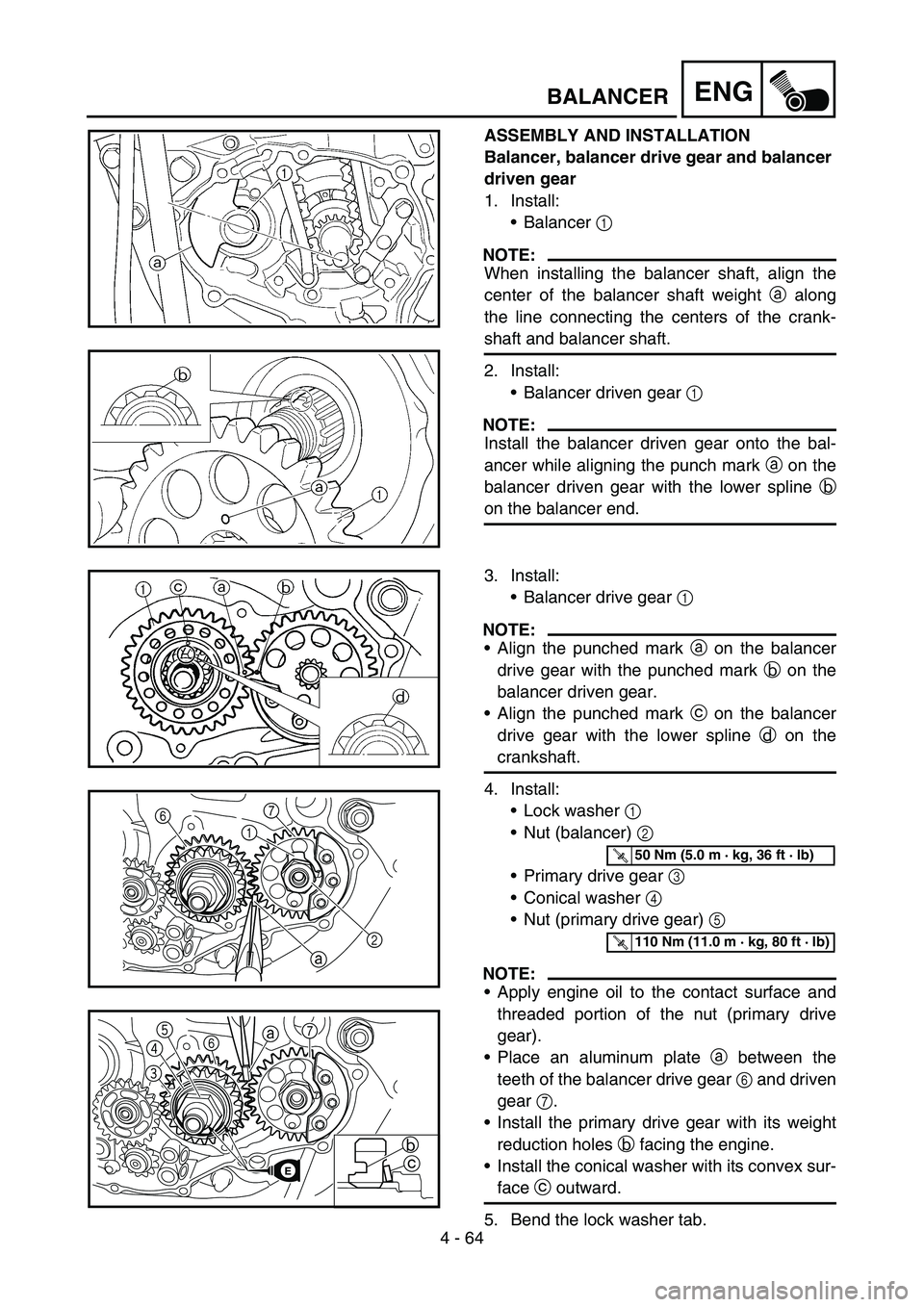

ASSEMBLY AND INSTALLATION

Balancer, balancer drive gear and balancer

driven gear

1. Install:

Balancer 1

NOTE:

When installing the balancer shaft, align the

center of the balancer shaft weight a along

the line connecting the centers of the crank-

shaft and balancer shaft.

2. Install:

Balancer driven gear 1

NOTE:

Install the balancer driven gear onto the bal-

ancer while aligning the punch mark a on the

balancer driven gear with the lower spline b

on the balancer end.

3. Install:

Balancer drive gear 1

NOTE:

Align the punched mark a on the balancer

drive gear with the punched mark b on the

balancer driven gear.

Align the punched mark c on the balancer

drive gear with the lower spline d on the

crankshaft.

4. Install:

Lock washer 1

Nut (balancer) 2

Primary drive gear 3

Conical washer 4

Nut (primary drive gear) 5

NOTE:

Apply engine oil to the contact surface and

threaded portion of the nut (primary drive

gear).

Place an aluminum plate a between the

teeth of the balancer drive gear 6 and driven

gear 7.

Install the primary drive gear with its weight

reduction holes b facing the engine.

Install the conical washer with its convex sur-

face c outward.

5. Bend the lock washer tab.

a 6

17

2

T R..50 Nm (5.0 m · kg, 36 ft · lb)

E

7

6a

c b

5

4

3

T R..110 Nm (11.0 m · kg, 80 ft · lb)

Page 382 of 646

4 - 71

ENGKICK AXLE AND SHIFT SHAFT

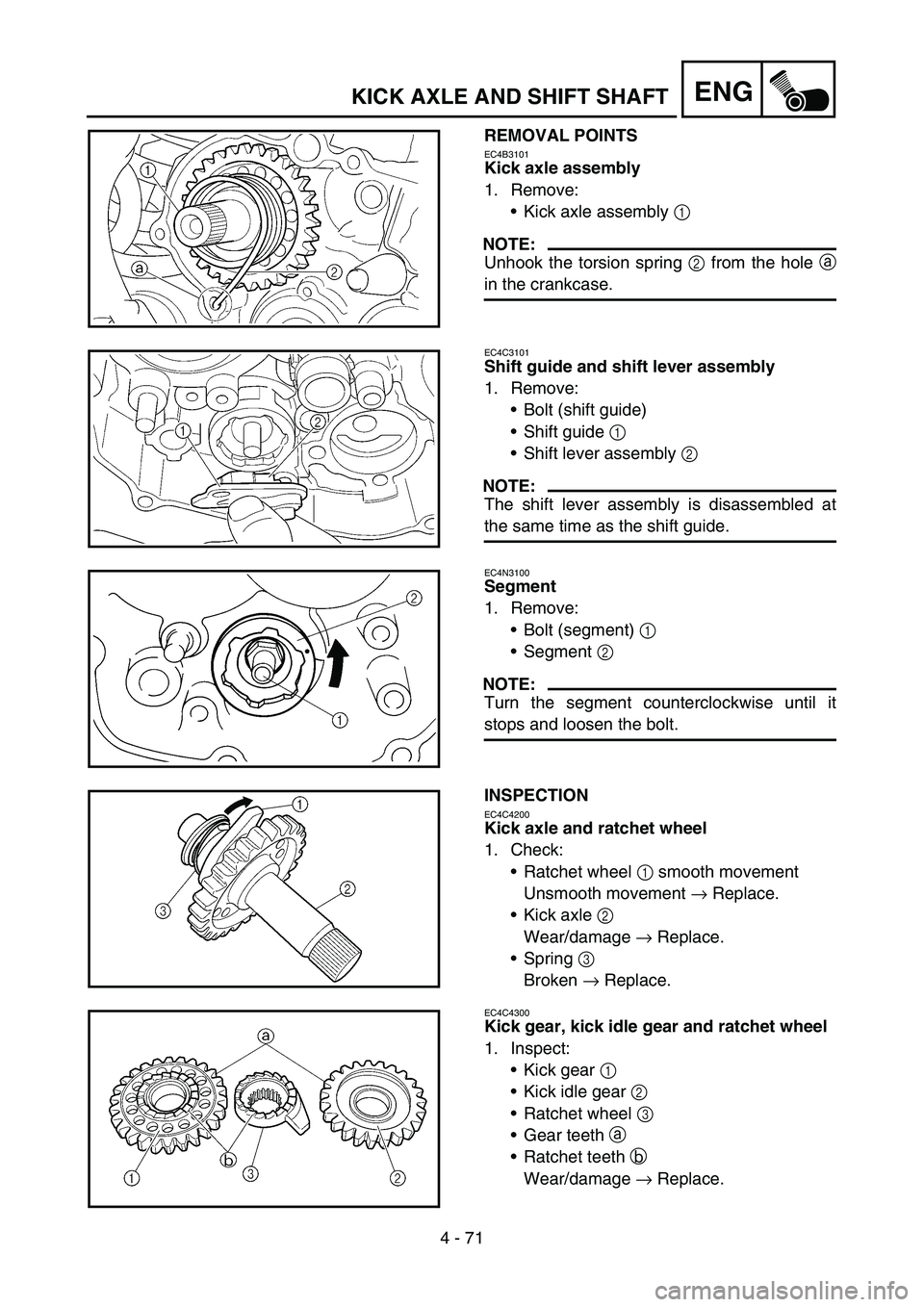

REMOVAL POINTS

EC4B3101

Kick axle assembly

1. Remove:

Kick axle assembly 1

NOTE:

Unhook the torsion spring 2 from the hole a

in the crankcase.

EC4C3101

Shift guide and shift lever assembly

1. Remove:

Bolt (shift guide)

Shift guide 1

Shift lever assembly 2

NOTE:

The shift lever assembly is disassembled at

the same time as the shift guide.

EC4N3100

Segment

1. Remove:

Bolt (segment) 1

Segment 2

NOTE:

Turn the segment counterclockwise until it

stops and loosen the bolt.

INSPECTION

EC4C4200

Kick axle and ratchet wheel

1. Check:

Ratchet wheel 1 smooth movement

Unsmooth movement → Replace.

Kick axle 2

Wear/damage → Replace.

Spring 3

Broken → Replace.

EC4C4300

Kick gear, kick idle gear and ratchet wheel

1. Inspect:

Kick gear 1

Kick idle gear 2

Ratchet wheel 3

Gear teeth a

Ratchet teeth b

Wear/damage → Replace.

Page 383 of 646

4 - 71

ENG

DEMONTAGE-EINZELHEITEN

Kickhebelwelle komplett

1. Demontieren:

Kickhebelwelle komplett 1

HINWEIS:

Die Torsionsfeder 2 aus der Bohrung a im

Kurbelgehäuse lösen.

Schaltführung und Schaltklinke

1. Demontieren:

Schaltführungs-Schraube

Schaltführung 1

Schaltklinke komplett 2

HINWEIS:

Schaltklinke und Schaltführung werden

gemeinsam zerlegt.

Stiftplatte

1. Demontieren:

Stiftplatten-Schraube 1

Stiftplatte 2

HINWEIS:

Die Stiftplatte bis zum Anschlag im Gegenuhr-

zeigersinn drehen und die Schraube lockern.

KONTROLLE

Kickhebelwelle und Klinkenrad

1. Kontrollieren:

Leichtgängigkeit des Klinkenrads 1

Stockend → Erneuern.

Kickhebelwelle 2

Verschlissen/beschädigt → Erneuern.

Feder 3

Gebrochen → Erneuern.

Kickstarter-Ritzel, -Zwischenrad und -Klin-

kenrad

1. Kontrollieren:

Kickstarter-Ritzel 1

Kickstarter-Zwischenrad 2

Klinkenrad 3

Verzahnung a

Klinkenverzahnung b

Verschlissen/beschädigt → Erneuern.

ARBRE DE KICK ET AXE DE SELECTEUR

KICKHEBELWELLE UND SCHALTWELLE

POINTS DE DEPOSE

Arbre de kick complet

1. Déposer:

Arbre de kick complet 1

N.B.:

Décrocher le ressort de torsion 2 de l’orifice a du

carter.

Guide de sélecteur et levier de sélecteur complet

1. Déposer:

Boulon (guide de sélecteur)

Guide de sélecteur 1

Levier de sélecteur complet 2

N.B.:

Le levier de sélecteur complet se démonte en même

temps que le guide de sélecteur.

Segment

1. Déposer:

Boulon (segment) 1

Segment 2

N.B.:

Tourner le segment dans le sens inverse des

aiguilles d’une montre jusqu’à la butée et desserrer

le boulon.

CONTROLE

Arbre de kick et roue à rochet

1. Contrôler:

Mouvement libre de la roue à rochet 1

Mouvement irrégulier → Remplacer.

Arbre de kick 2

Usure/endommagement → Remplacer.

Ressort 3

Cassé → Remplacer.

Pignon de kick, pignon fou de kick et roue à

rochet

1. Contrôler:

Pignon de kick 1

Pignon fou de kick 2

Roue à rochet 3

Dents du pignon a

Dents du rochet b

Usure/endommagement → Remplacer.

Page 390 of 646

4 - 75

ENGKICK AXLE AND SHIFT SHAFT

3. Install:

Spring guide 1

NOTE:

Slide the spring guide into the kick axle, make

sure the groove a in the spring guide fits on

the stopper of the torsion spring.

4. Install:

Kick axle assembly 1

Plain washer 2

NOTE:

Apply the molybdenum disulfide grease on

the contacting surfaces of the kick axle stop-

per a and ratchet wheel guide 3.

Apply the engine oil on the kick axle.

Slide the kick axle assembly into the crank-

case and make sure the kick axle stopper fits

into the ratchet wheel guide.

5. Hook:

Torsion spring 1

NOTE:

Turn the torsion spring clockwise and hook

into the proper hole a in the crankcase.

Kick idle gear

1. Install:

Kick idle gear 1

Plain washer 2

Circlip 3

NOTE:

Install the kick idle gear with its depressed

side a toward you.

Apply the engine oil on the kick idle gear

inner circumference.

New

Page 394 of 646

4 - 77

ENGCDI MAGNETO

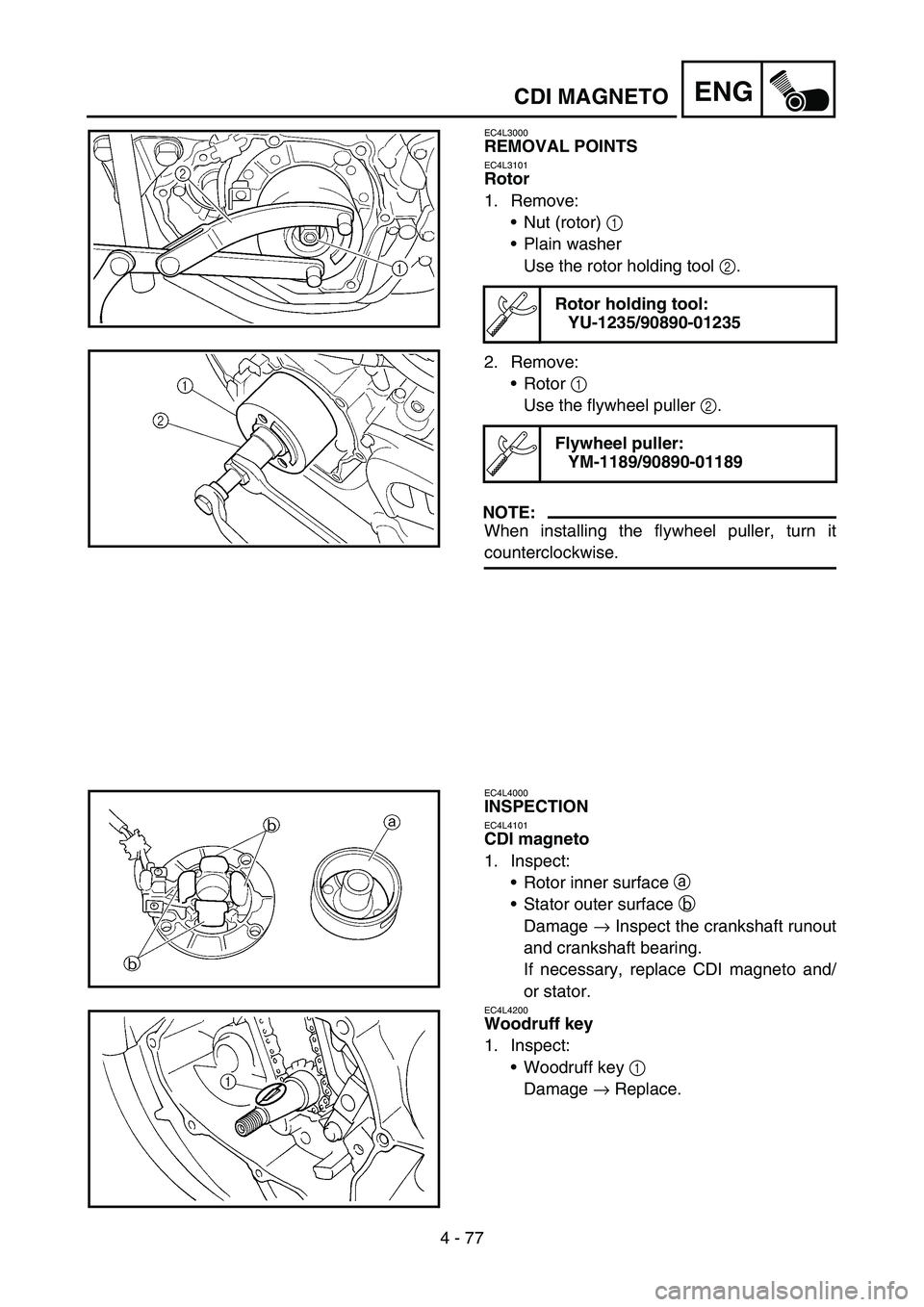

EC4L3000

REMOVAL POINTS

EC4L3101

Rotor

1. Remove:

Nut (rotor) 1

Plain washer

Use the rotor holding tool 2.

2. Remove:

Rotor 1

Use the flywheel puller 2.

NOTE:

When installing the flywheel puller, turn it

counterclockwise.

Rotor holding tool:

YU-1235/90890-01235

Flywheel puller:

YM-1189/90890-01189

EC4L4000

INSPECTION

EC4L4101

CDI magneto

1. Inspect:

Rotor inner surface a

Stator outer surface b

Damage → Inspect the crankshaft runout

and crankshaft bearing.

If necessary, replace CDI magneto and/

or stator.

EC4L4200

Woodruff key

1. Inspect:

Woodruff key 1

Damage → Replace.

Page 402 of 646

4 - 81

ENGENGINE REMOVAL

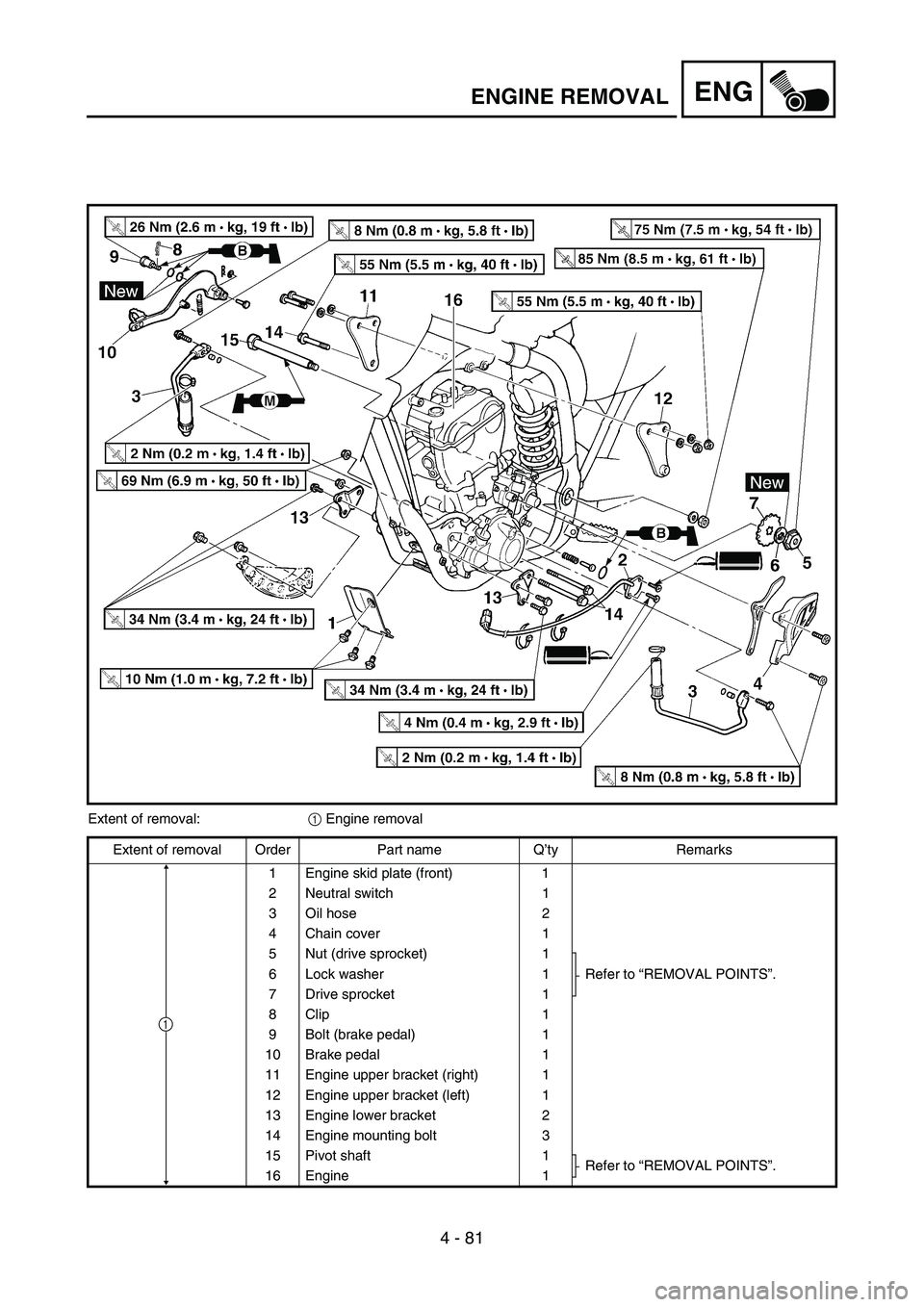

Extent of removal:

1 Engine removal

Extent of removal Order Part name Q’ty Remarks

1 Engine skid plate (front) 1

2 Neutral switch 1

3 Oil hose 2

4 Chain cover 1

5 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 6 Lock washer 1

7 Drive sprocket 1

8Clip 1

9 Bolt (brake pedal) 1

10 Brake pedal 1

11 Engine upper bracket (right) 1

12 Engine upper bracket (left) 1

13 Engine lower bracket 2

14 Engine mounting bolt 3

15 Pivot shaft 1

Refer to “REMOVAL POINTS”.

16 Engine 1

1