lock YAMAHA YZ450F 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ450F, Model: YAMAHA YZ450F 2006Pages: 650, PDF Size: 20.71 MB

Page 595 of 650

–+ELEC

HANDHABUNGSHINWEISE

ACHTUNG:

Die Drosselklappensensor-Schrauben 1

dürfen nicht gelockert werden, außer wenn

der Drosselklappensensor zu erneuern ist.

STECKVERBINDER- UND

KABELANSCHLÜSSE KONTROLLIEREN

1. Kontrollieren:

Steckverbinder- und Kabelanschlüsse

Rostig/staubig/locker/kurzgeschlossen →

Instand setzen, ggf. erneuern.

DROSSELKLAPPENSENSOR-SPULE

KONTROLLIEREN

1. Kontrollieren:

Drosselklappensensor-Spule

Nicht nach Vorgabe → Erneuern.

2. Lockern:

Leerlaufeinstellschraube 1

HINWEIS:

Die Leerlaufeinstellschraube herausdrehen,

bis die Drosselklappenwelle sich in der völlig

geschlossenen Stellung befindet.Messkabel (+)→ Blau 1

Messkabel (–) → Schwarz 2

Drosselklappen-

sensor-Spulenwi-

derstandMessgerät-

Wahlschalter

4–6 kΩ bei

20 °C (68 °F)kΩ × 1

SYSTEME TPS (CAPTEUR DE POSITION DE PAPILLON DES GAZ)

DROSSELKLAPPENSENSOR

REMARQUES CONCERNANT LA

MANIPULATION

ATTENTION:

Ne pas desserrer les vis {TPS (capteur de position

de papillon des gaz)} 1 sauf en cas de remplace-

ment du TPS (capteur de position de papillon des

gaz) en raison d’une panne, car cela provoquerait

une baisse des performances du moteur.

CONTROLE DES CONNEXIONS DES

FICHES RAPIDES ET DES FILS

1. Contrôler:

Connexion des fiches rapides et des fils

Rouille/poussière/jeu/court-circuit → Répa-

rer ou remplacer.

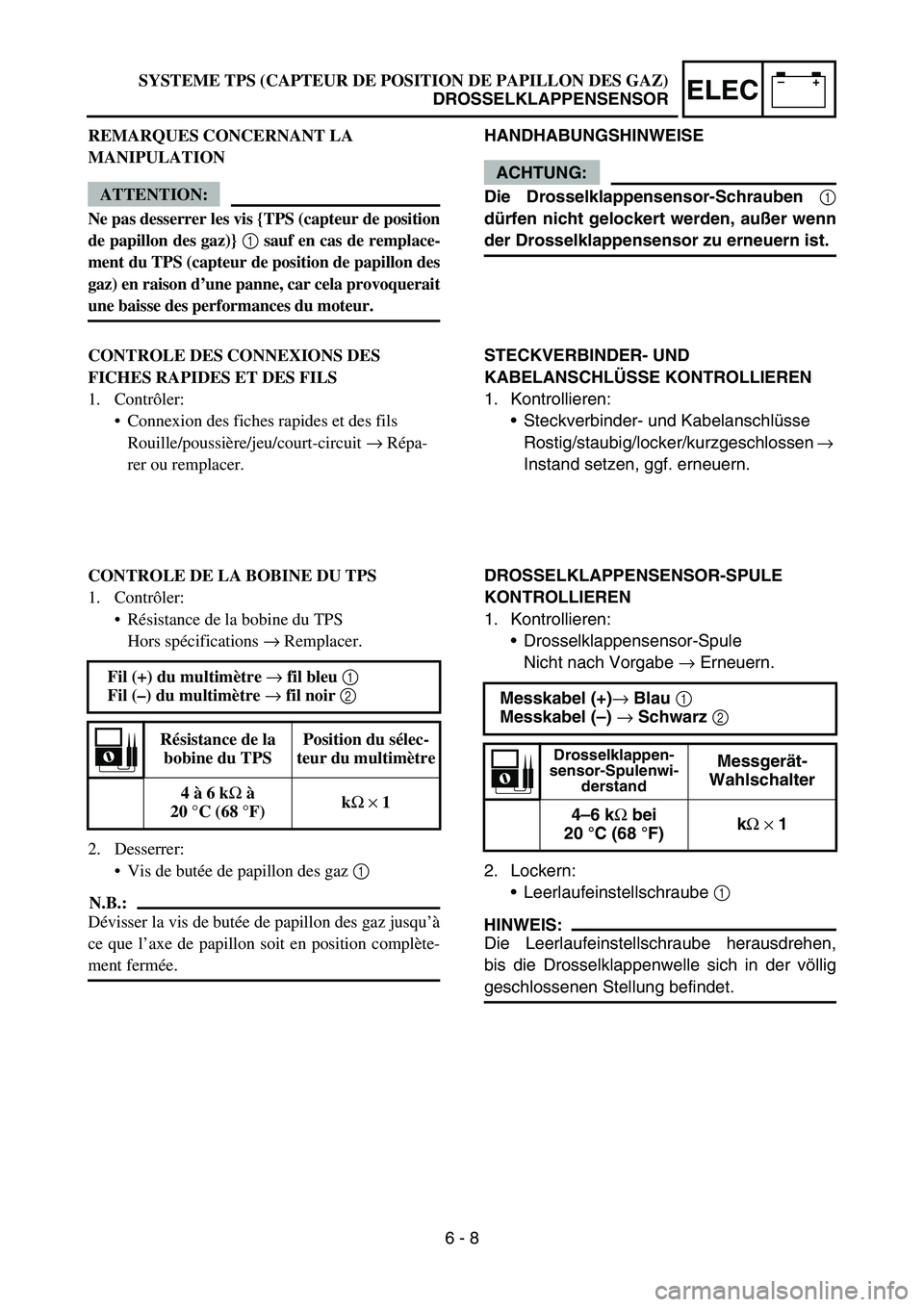

CONTROLE DE LA BOBINE DU TPS

1. Contrôler:

Résistance de la bobine du TPS

Hors spécifications → Remplacer.

2. Desserrer:

Vis de butée de papillon des gaz 1

N.B.:

Dévisser la vis de butée de papillon des gaz jusqu’à

ce que l’axe de papillon soit en position complète-

ment fermée. Fil (+) du multimètre → fil bleu 1

Fil (–) du multimètre → fil noir 2

Résistance de la

bobine du TPSPosition du sélec-

teur du multimètre

4 à 6 kΩ à

20 °C (68 °F)kΩ × 1

6 - 8

Page 597 of 650

–+ELEC

3. Kontrollieren:

Drosselklappensensor-Widerstand

Darauf achten, dass der Widerstand all-

mählich ansteigt, während der Gasdreh-

griff geöffnet wird.

Nicht nach Vorgabe → Erneuern.

Messkabel (+) → Gelb 1

Messkabel (–) → Schwarz 2

Drosselklappensen-

sor-WiderstandMessgerät-

Wahlschal-

ter

Ganz

geschlossenGanz

geöffnet

kΩ × 1

0–2 kΩ

bei 20 °C

(68°F)4–6 kΩ

bei 20 °C

(68°F)

DROSSELKLAPPENSENSOR ERNEUERN

UND EINSTELLEN

1. Demontieren:

Drosselklappensensor-Steckverbinder

Vergaser

2. Demontieren:

Schraube (Drosselklappensensor) 1

Drosselklappensensor 2

HINWEIS:

Die Drosselklappensensor-Schrauben mit

einem T25-Einsatz lockern.

3. Erneuern:

Drosselklappensensor

4. Montieren:

Drosselklappensensor 1

Schraube (Drosselklappensensor) 2

HINWEIS:

Die Haltenase b am Vergaser muss in der

Nut a im Drosselklappensensor sitzen.

Die Drosselklappensensor-Schrauben provi-

sorisch festziehen.

5. Montieren:

Vergaser

Drosselklappensensor-Steckverbinder SYSTEME TPS (CAPTEUR DE POSITION DE PAPILLON DES GAZ)

DROSSELKLAPPENSENSOR

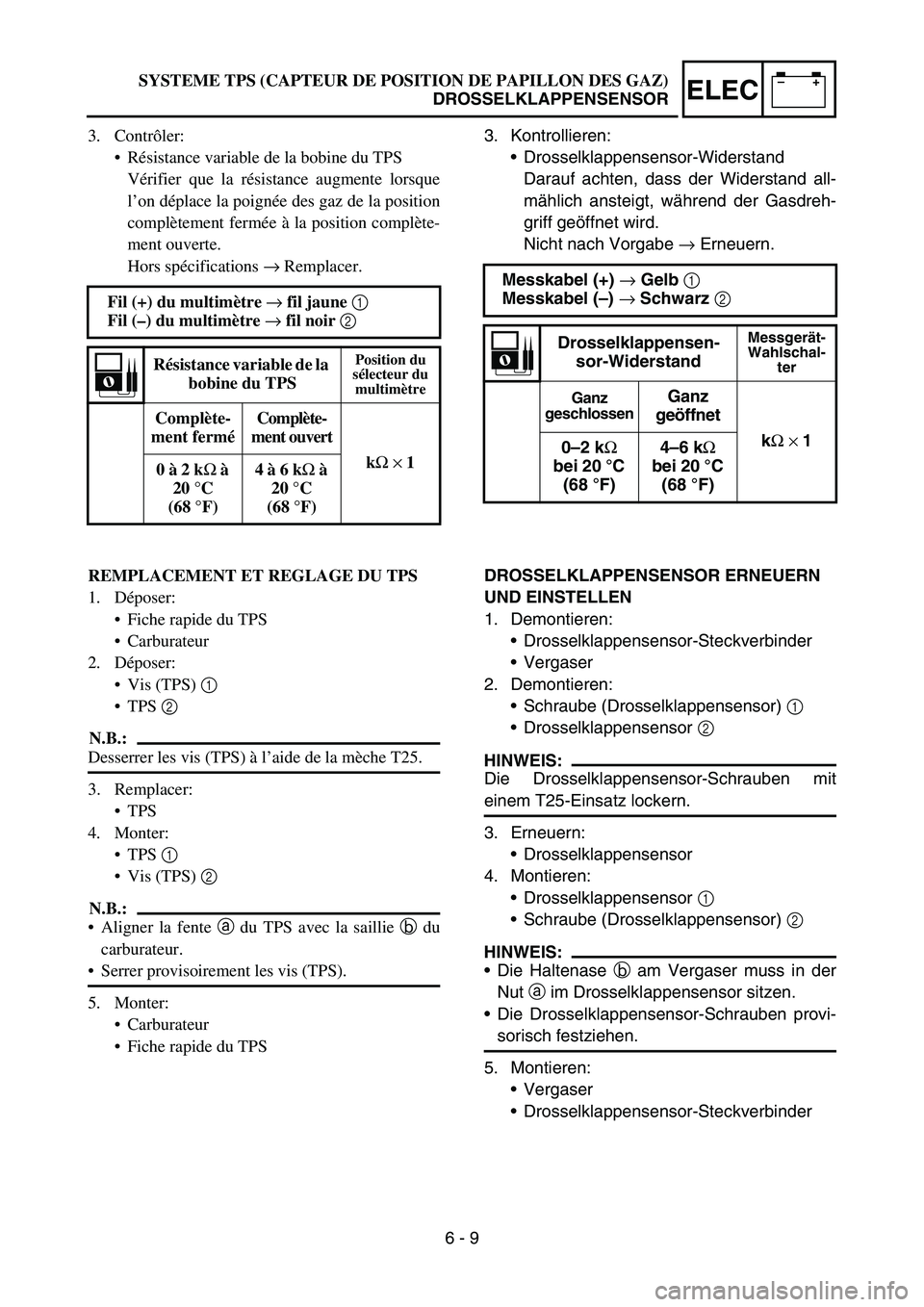

3. Contrôler:

Résistance variable de la bobine du TPS

Vérifier que la résistance augmente lorsque

l’on déplace la poignée des gaz de la position

complètement fermée à la position complète-

ment ouverte.

Hors spécifications → Remplacer.

Fil (+) du multimètre → fil jaune 1

Fil (–) du multimètre → fil noir 2

Résistance variable de la

bobine du TPSPosition du

sélecteur du

multimètre

Complète-

ment ferméComplète-

ment ouvert

kΩ × 1

0 à 2 kΩ à

20 °C

(68°F)4 à 6 kΩ à

20 °C

(68°F)

REMPLACEMENT ET REGLAGE DU TPS

1. Déposer:

Fiche rapide du TPS

Carburateur

2. Déposer:

Vis (TPS) 1

TPS 2

N.B.:

Desserrer les vis (TPS) à l’aide de la mèche T25.

3. Remplacer:

TPS

4. Monter:

TPS 1

Vis (TPS) 2

N.B.:

Aligner la fente a du TPS avec la saillie b du

carburateur.

Serrer provisoirement les vis (TPS).

5. Monter:

Carburateur

Fiche rapide du TPS

6 - 9

Page 634 of 650

7 - 16

TUN

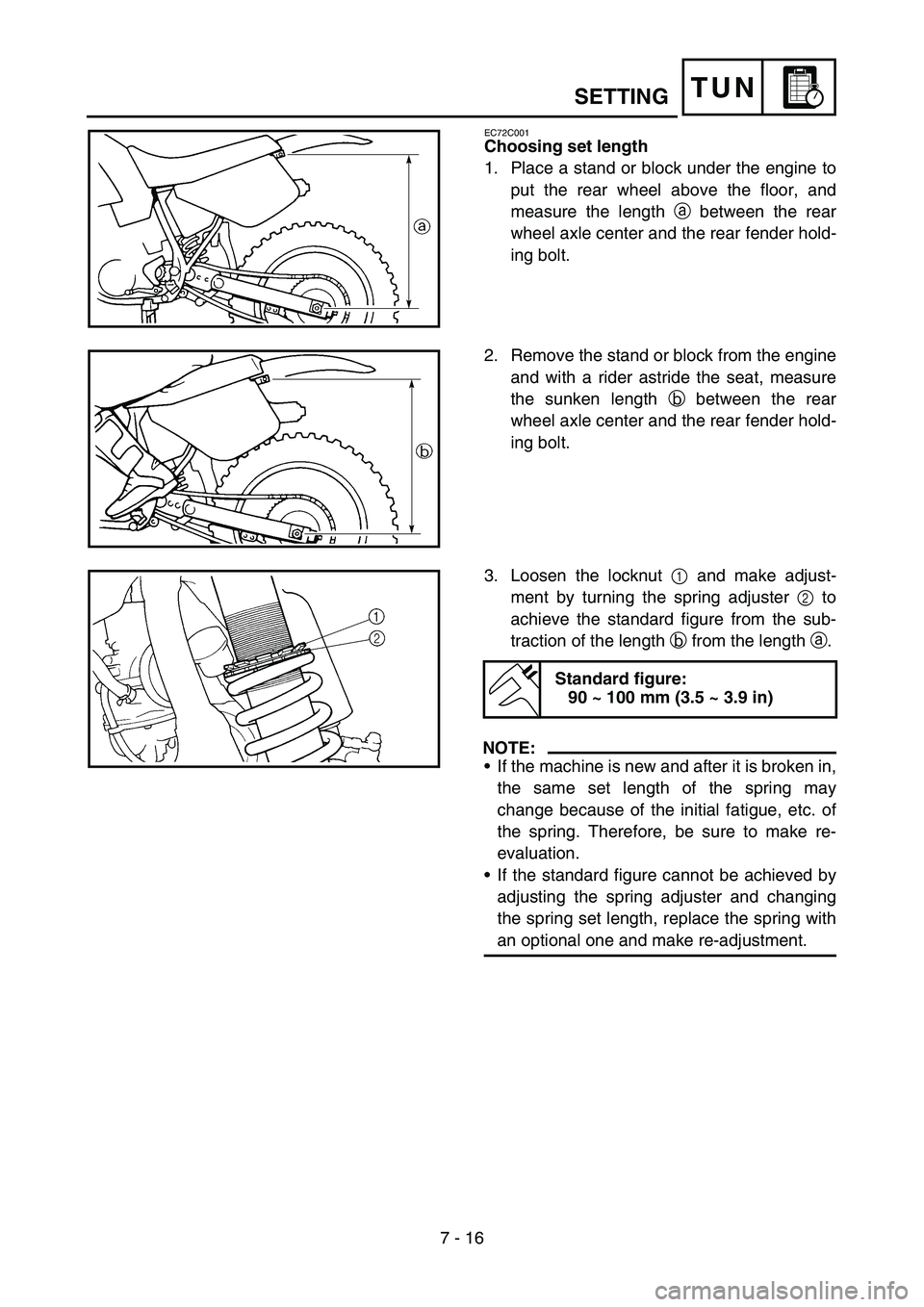

EC72C001

Choosing set length

1. Place a stand or block under the engine to

put the rear wheel above the floor, and

measure the length a between the rear

wheel axle center and the rear fender hold-

ing bolt.

2. Remove the stand or block from the engine

and with a rider astride the seat, measure

the sunken length b between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut 1 and make adjust-

ment by turning the spring adjuster 2 to

achieve the standard figure from the sub-

traction of the length b from the length a.

NOTE:

•If the machine is new and after it is broken in,

the same set length of the spring may

change because of the initial fatigue, etc. of

the spring. Therefore, be sure to make re-

evaluation.

•If the standard figure cannot be achieved by

adjusting the spring adjuster and changing

the spring set length, replace the spring with

an optional one and make re-adjustment.

Standard figure:

90 ~ 100 mm (3.5 ~ 3.9 in)

SETTING

Page 642 of 650

7 - 20

TUNSETTING

EC72H002

Suspension setting

•Front fork

NOTE:

•If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

•Before any change, set the rear shock absorber sunken length to the standard figure 90 ~ 100 mm

(3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire rangeCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil amount Decrease oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).

Spring Replace with soft spring.

Unsmooth movement

over entire rangeOuter tube Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Slide metal Replace with a new one for extended use.

Piston metal Replace with a new one for extended use.

Under bracket tightening

torqueRetighten to specified torque.

Poor initial

movementRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming outCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Oil amount Increase oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).

Spring Replace with stiff spring.

Stiff toward stroke

endOil amountDecrease oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

Soft toward stroke

end, bottoming outOil amountIncrease oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

Stiff initial movement Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front postureCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat (lower rear posture).

Oil amount Increase oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

“Obtrusive” front,

tending to upper front

postureCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in)

when one passenger is astride seat (upper rear pos-

ture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).

Page 643 of 650

7 - 21

TUNSETTING

•Rear shock absorber

NOTE:

•If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

•Adjust the rebound damping in 2-click increments or decrements.

•Adjust the low compression damping in 1-click increments or decrements.

•Adjust the high compression damping in 1/6 turn increments or decrements.

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff, tending to sinkRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Spring set length Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in)

when one passenger is astride seat.

Spongy and unstableRebound damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Low compression damp-

ingTurn adjuster clockwise (about 1 click) to increase

damping.

Spring Replace with stiff spring.

Heavy and draggingRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Spring Replace with soft spring.

Poor road grippingRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low compression damp-

ingTurn adjuster clockwise (about 1 clicks) to increase

damping.

High compression damp-

ingTurn adjuster clockwise (about 1/6 clicks) to

increase damping.

Spring set length Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in)

when one passenger is astride seat.

Spring Replace with soft spring.

Bottoming outHigh compression damp-

ingTurn adjuster clockwise (about 1/6 turn) to increase

damping.

Spring set length Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in)

when one passenger in astride seat.

Spring Replace with stiff spring.

BouncingRebound damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Spring Replace with soft spring.

Stiff travelHigh compression damp-

ingTurn adjuster counterclockwise (about 1/6 turn) to

decrease damping.

Spring set length Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in)

when one passenger is astride seat.

Spring Replace with soft spring.