tow YAMAHA YZ450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ450F, Model: YAMAHA YZ450F 2008Pages: 188, PDF Size: 11.75 MB

Page 18 of 188

1-8

CONTROL FUNCTIONS

CONTROL FUNCTIONS

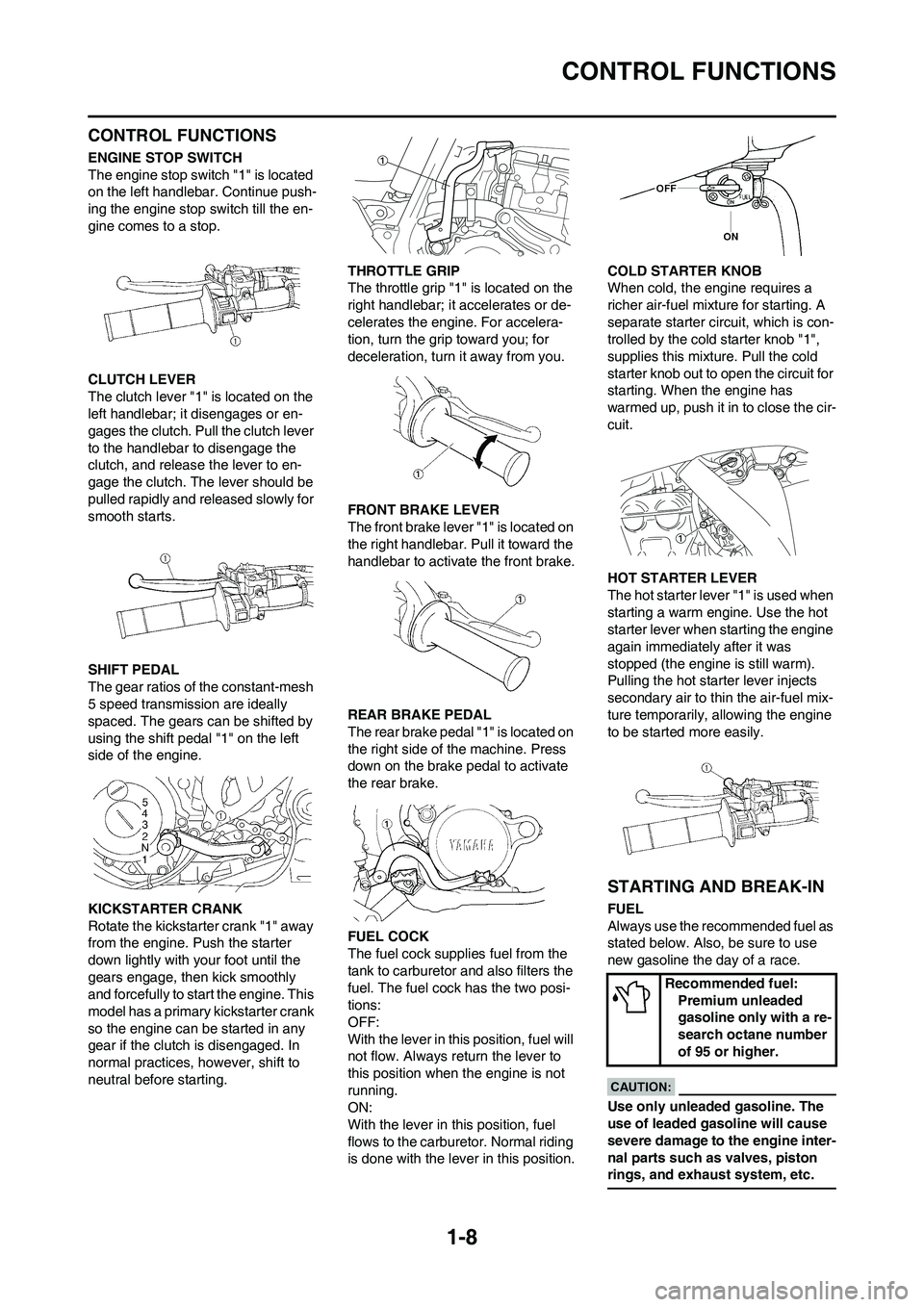

ENGINE STOP SWITCH

The engine stop switch "1" is located

on the left handlebar. Continue push-

ing the engine stop switch till the en-

gine comes to a stop.

CLUTCH LEVER

The clutch lever "1" is located on the

left handlebar; it disengages or en-

gages the clutch. Pull the clutch lever

to the handlebar to disengage the

clutch, and release the lever to en-

gage the clutch. The lever should be

pulled rapidly and released slowly for

smooth starts.

SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal "1" on the left

side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank "1" away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine. This

model has a primary kickstarter crank

so the engine can be started in any

gear if the clutch is disengaged. In

normal practices, however, shift to

neutral before starting.THROTTLE GRIP

The throttle grip "1" is located on the

right handlebar; it accelerates or de-

celerates the engine. For accelera-

tion, turn the grip toward you; for

deceleration, turn it away from you.

FRONT BRAKE LEVER

The front brake lever "1" is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

REAR BRAKE PEDAL

The rear brake pedal "1" is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.

FUEL COCK

The fuel cock supplies fuel from the

tank to carburetor and also filters the

fuel. The fuel cock has the two posi-

tions:

OFF:

With the lever in this position, fuel will

not flow. Always return the lever to

this position when the engine is not

running.

ON:

With the lever in this position, fuel

flows to the carburetor. Normal riding

is done with the lever in this position.COLD STARTER KNOB

When cold, the engine requires a

richer air-fuel mixture for starting. A

separate starter circuit, which is con-

trolled by the cold starter knob "1",

supplies this mixture. Pull the cold

starter knob out to open the circuit for

starting. When the engine has

warmed up, push it in to close the cir-

cuit.

HOT STARTER LEVER

The hot starter lever "1" is used when

starting a warm engine. Use the hot

starter lever when starting the engine

again immediately after it was

stopped (the engine is still warm).

Pulling the hot starter lever injects

secondary air to thin the air-fuel mix-

ture temporarily, allowing the engine

to be started more easily.

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline the day of a race.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Page 22 of 188

1-12

CLEANING AND STORAGE

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and ex-

tend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

Excessive hose pressure may

cause water seepage and contami-

nation of wheel bearings, front

forks, brakes and transmission

seals. Many expensive repair bills

have resulted from improper high

pressure detergent applications

such as those available in coin-op-

erated car washers.

4. After the majority of the dirt has

been hosed off, wash all surfaces

with warm water and a mild deter-

gent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediate-

ly with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, re-

move excess water from the

chain with a paper towel and lubri-

cate the chain to prevent rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed surfac-

es. Avoid combination cleaner-

waxes, as they may contain abra-

sives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.

STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the carburetor float bowl.

2. Remove the spark plug, pour a ta-

blespoon of SAE 10W-30 motor

oil in the spark plug hole, and re-

install the plug. With the engine

stop switch pushed in, kick the en-

gine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and lubri-

cate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust

pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cov-

er.

Make any necessary repairs before

the machine is stored.

Page 51 of 188

3-5

ENGINE

ENGINE

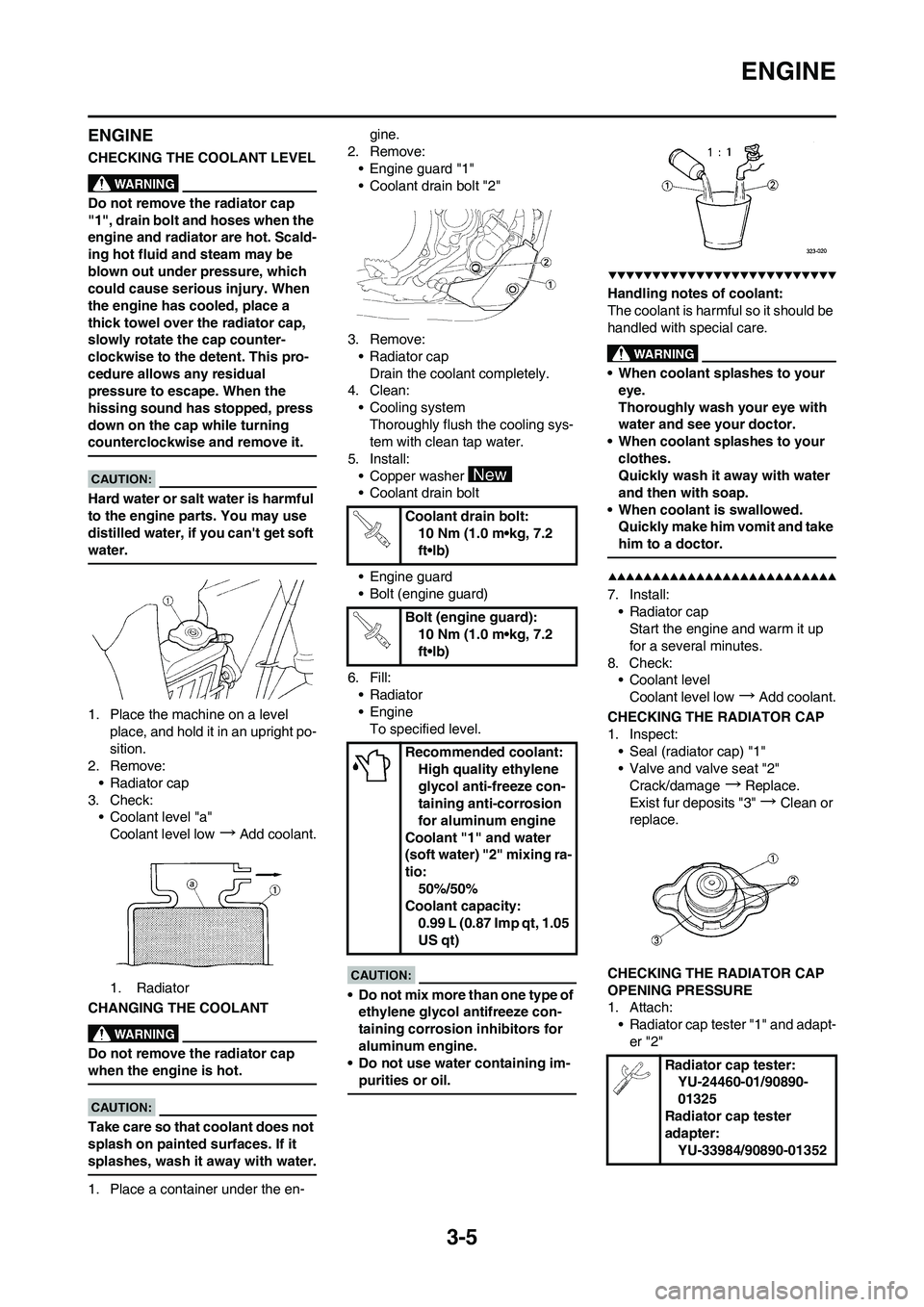

CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove:

• Radiator cap

3. Check:

• Coolant level "a"

Coolant level low

→Add coolant.

1. Radiator

CHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-gine.

2. Remove:

• Engine guard "1"

• Coolant drain bolt "2"

3. Remove:

• Radiator cap

Drain the coolant completely.

4. Clean:

• Cooling system

Thoroughly flush the cooling sys-

tem with clean tap water.

5. Install:

• Copper washer

• Coolant drain bolt

• Engine guard

• Bolt (engine guard)

6. Fill:

• Radiator

•Engine

To specified level.

• Do not mix more than one type of

ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your

eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your

clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed.

Quickly make him vomit and take

him to a doctor.

7. Install:

• Radiator cap

Start the engine and warm it up

for a several minutes.

8. Check:

• Coolant level

Coolant level low

→Add coolant.

CHECKING THE RADIATOR CAP

1. Inspect:

• Seal (radiator cap) "1"

• Valve and valve seat "2"

Crack/damage

→Replace.

Exist fur deposits "3"

→Clean or

replace.

CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (engine guard):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio:

50%/50%

Coolant capacity:

0.99 L (0.87 Imp qt, 1.05

US qt)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Page 72 of 188

4-4

EXHAUST PIPE AND SILENCER

CHECKING THE SILENCER AND

EXHAUST PIPE

1. Inspect:

• Gasket "1"

Damage

→Replace.

CHANGING THE SILENCER FIBER

1. Remove:

• Rivet (front) "1"

• Inner pipe "2"

Take care not to damage the rivet

fitting holes (ø4.9 mm) "a" in re-

moval.

Pull out the inner pipe while lightly

tapping the stay "b" on the silencer

using a soft hammer.

2. Replace:

• Fiber "1" (for EUROPE)

3. Replace:

• Fiber "1" (except for EUROPE)

Wrap around the inner pipe the fiber

as is vinyl packaged, then secure it

with pieces of tape "2".

4. Install:

• Inner pipe "1"

• Rivet (front) "2"

• Band "3"

• Apply heat resistant sealant along

the plate edge "a" on the inside of

the silencer and also along the si-

lencer edge "b" as shown.

• Take care not to allow the fiber out

of place when installing the inner

pipe.

• Install the band "3" with the mating

ends "c" positioned as shown.

INSTALLING THE SILENCER AND

EXHAUST PIPE

1. Install:

• Gasket

• Exhaust pipe "1"

• Nut (exhaust pipe) "2"

• Bolt (exhaust pipe) "3"

First, temporarily tighten the nut (ex-

haust pipe), then tighten the bolt (ex-

haust pipe) 13 Nm (1.3 m•kg, 9.4

ft•lb). After that, retighten the nut (ex-

haust pipe) 20 Nm (2.0 m•kg, 14 ft•lb)

and then the bolt (exhaust pipe) 20

Nm (2.0 m•kg, 14 ft•lb).

2. Install:

• Silencer clamp "1"

• Gasket "2"

• Silencer "3"

• Washer "4"

• Bolt (silencer) "5"

• Install the gasket with its meshed

area "a" toward the exhaust pipe

side.

• The gasket should be installed ac-

cording to the dimension shown.

Nut (exhaust pipe):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (exhaust pipe):

20 Nm (2.0 m•kg, 14

ft•lb)

Silencer clamp:

14 Nm (1.4 m•kg, 10

ft•lb)

Bolt (silencer):

30 Nm (3.0 m•kg, 22

ft•lb)

New

Page 74 of 188

4-6

RADIATOR

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

CHECKING THE RADIATOR

1. Inspect:

• Radiator core "1"

Obstruction

→Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin

→Repair/replace.

INSTALLING THE RADIATOR

1. Install:

• Pipe 1 "1"

• Radiator hose 1 "2"

• Pipe 2 "3"

• Radiator hose 3 "4"

• Radiator hose 4 "5"2. Install:

• Radiator hose 2 "1"

• Left radiator "2"

3. Install:

• Radiator breather hose "1"

• Right radiator "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

Pipe 1:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Pipe 2:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 3:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 4:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 2:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Left radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Right radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 114 of 188

4-46

KICK SHAFT AND SHIFT SHAFT

5. Hook:

• Torsion spring "1"

Turn the torsion spring clockwise and

hook into the proper hole "a" in the

crankcase.

INSTALLING THE KICK IDLE

GEAR

1. Install:

• Kick idle gear "1"

• Washer "2"

• Circlip "3"

• Apply the engine oil on the kick idle

gear inner circumference.

• Install the kick idle gear with its de-

pressed side "a" toward you.

Page 183 of 188

7-6

CHASSIS

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-

ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the race, be sure to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to

achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the race result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary from machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or

slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface.

• Under a stony or hard road condi-

tion, the tire pressure should be

higher to prevent a flat tire.

FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris-

tics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damp-

ing.

• Change the rebound damping.

The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN AMOUNT AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil amount in 5 cm3 (0.2

Imp oz, 0.2 US oz) increments or

decrements. Too small oil amount

causes the front fork to produce a

noise at full rebound or the rider to

feel some pressure on his hands

or body. Alternatively, too large oil

amount will cause the air spring

characteristics to have a tendency

to be stiffer with the consequent

deteriorated performance and

characteristics. Therefore, adjust

the front fork within the specified

range.

A. Air spring characteristics in

relation to oil amount change

B. Load Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio49/13

(3.769)

Part name Size Part number

Drive

sprocket "1"

(STD) 13T 9383B-13233

Rear wheel

sprocket "2"

47T 1C3-25447-00

48T 1C3-25448-00

(STD) 49T 1C3-25449-00

50T 1C3-25450-00

51T 1C3-25451-00

52T 1C3-25452-00

Standard tire pressure:

100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment:

60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment:

100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil amount:

350 cm3 (12.3 Imp oz,

11.8 US oz)

Extent of adjustment:

300–375 cm

3(10.6–13.2

Imp oz, 10.1–12.7 US

oz)

Page 186 of 188

7-9

CHASSIS

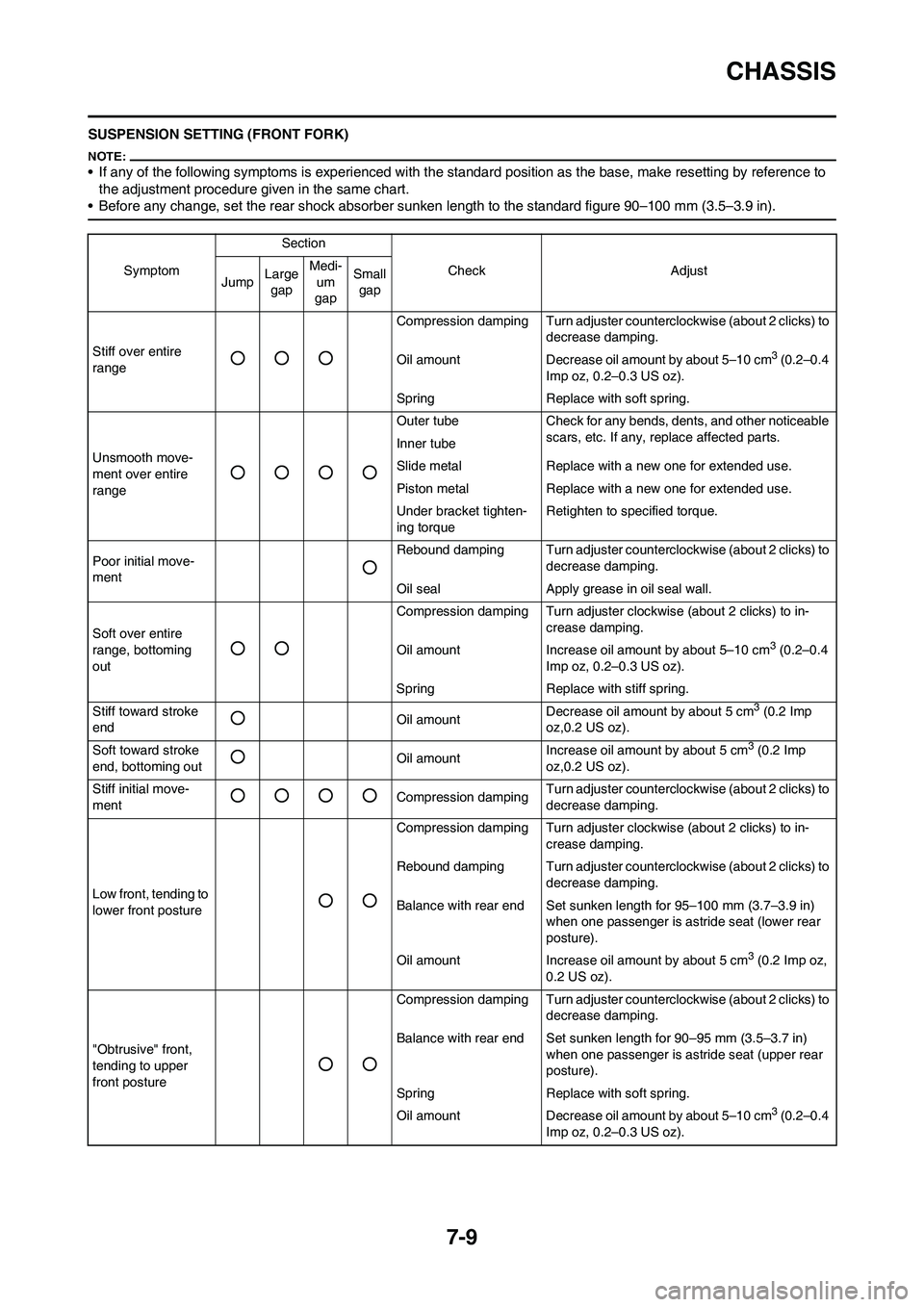

SUSPENSION SETTING (FRONT FORK)

• If any of the following symptoms is experienced with the standard position as the base, make resetting by reference to

the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm (3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

range

○○○

Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).

Spring Replace with soft spring.

Unsmooth move-

ment over entire

range

○○○○

Outer tube Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Slide metal Replace with a new one for extended use.

Piston metal Replace with a new one for extended use.

Under bracket tighten-

ing torqueRetighten to specified torque.

Poor initial move-

ment

○

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming

out

○○

Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Oil amount Increase oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).

Spring Replace with stiff spring.

Stiff toward stroke

end

○Oil amountDecrease oil amount by about 5 cm3 (0.2 Imp

oz,0.2 US oz).

Soft toward stroke

end, bottoming out

○Oil amountIncrease oil amount by about 5 cm3 (0.2 Imp

oz,0.2 US oz).

Stiff initial move-

ment

○○○○Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture

○○

Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95–100 mm (3.7–3.9 in)

when one passenger is astride seat (lower rear

posture).

Oil amount Increase oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

"Obtrusive" front,

tending to upper

front posture

○○

Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90–95 mm (3.5–3.7 in)

when one passenger is astride seat (upper rear

posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.4

Imp oz, 0.2–0.3 US oz).