engine YAMAHA YZ450F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 324 of 360

FUEL PUMP SYSTEM

8-34

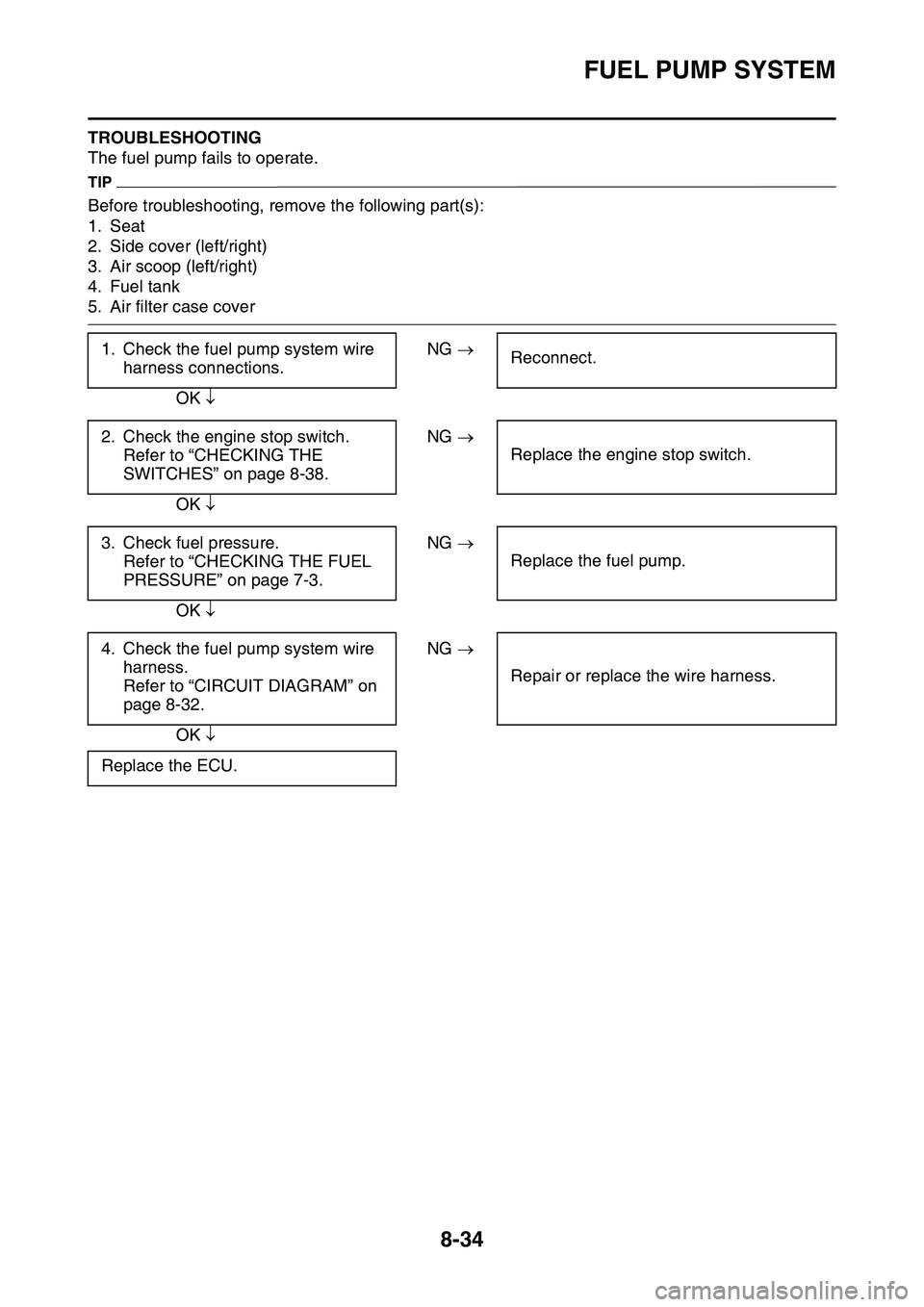

TROUBLESHOOTING

The fuel pump fails to operate.

TIP

Before troubleshooting, remove the following part(s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Air filter case cover

1. Check the fuel pump system wire

harness connections.NG Reconnect.

OK

2. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 8-38.

NG

Replace the engine stop switch.

OK

3. Check fuel pressure.

Refer to “CHECKING THE FUEL

PRESSURE” on page 7-3.

NG

Replace the fuel pump.

OK

4. Check the fuel pump system wire

harness.

Refer to “CIRCUIT DIAGRAM” on

page 8-32.

NG

Repair or replace the wire harness.

OK

Replace the ECU.

Page 329 of 360

ELECTRICAL COMPONENTS

8-39

1. Engine stop switch

2. Neutral switch

Page 331 of 360

ELECTRICAL COMPONENTS

8-41

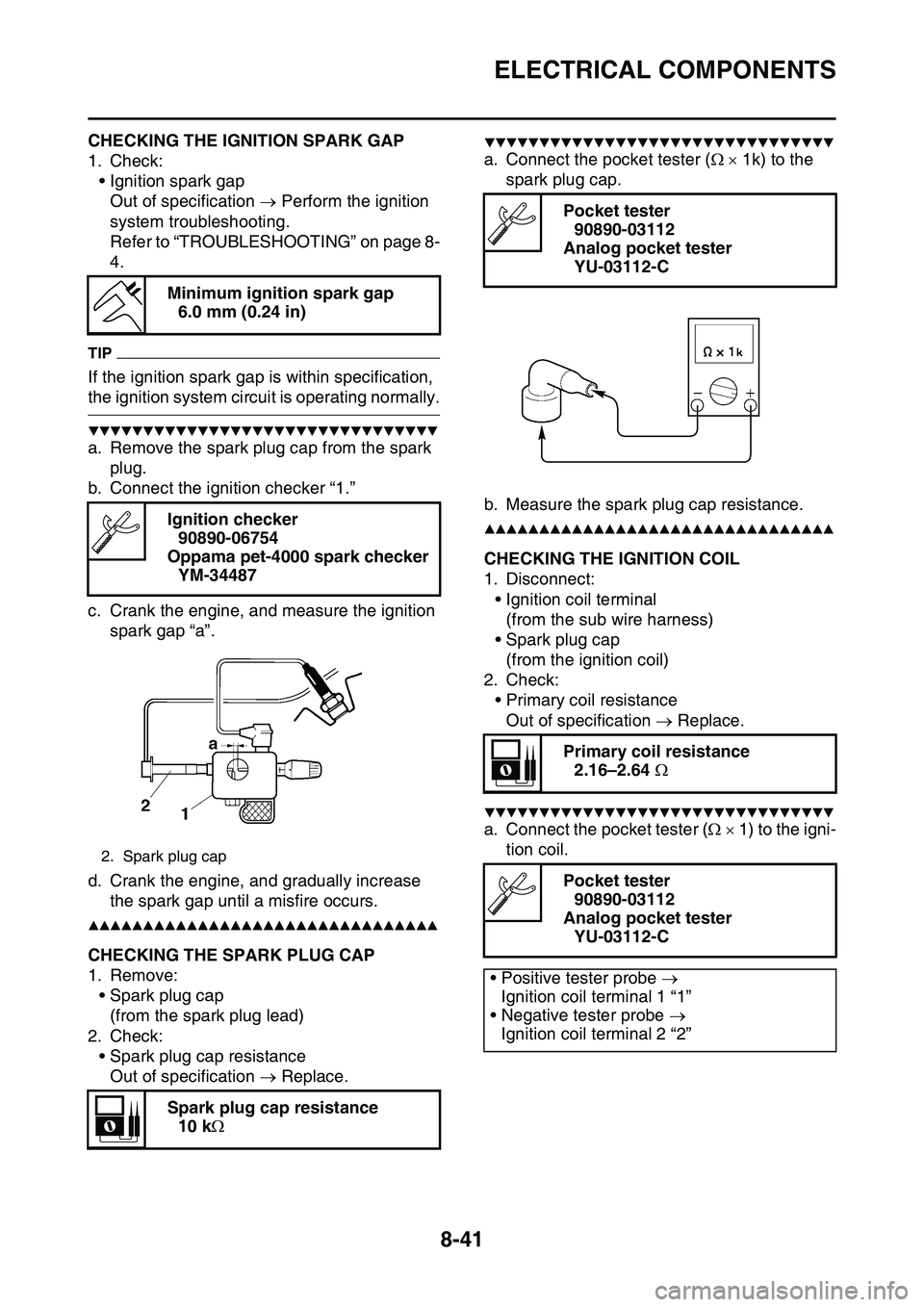

EAS1SL1335CHECKING THE IGNITION SPARK GAP

1. Check:

• Ignition spark gap

Out of specification Perform the ignition

system troubleshooting.

Refer to “TROUBLESHOOTING” on page 8-

4.

TIP

If the ignition spark gap is within specification,

the ignition system circuit is operating normally.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap from the spark

plug.

b. Connect the ignition checker “1.”

c. Crank the engine, and measure the ignition

spark gap “a”.

d. Crank the engine, and gradually increase

the spark gap until a misfire occurs.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1336CHECKING THE SPARK PLUG CAP

1. Remove:

• Spark plug cap

(from the spark plug lead)

2. Check:

• Spark plug cap resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

spark plug cap.

b. Measure the spark plug cap resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1337CHECKING THE IGNITION COIL

1. Disconnect:

• Ignition coil terminal

(from the sub wire harness)

• Spark plug cap

(from the ignition coil)

2. Check:

• Primary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the igni-

tion coil.

Minimum ignition spark gap

6.0 mm (0.24 in)

Ignition checker

90890-06754

Oppama pet-4000 spark checker

YM-34487

2. Spark plug cap

Spark plug cap resistance

10 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Primary coil resistance

2.16–2.64

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Ignition coil terminal 2 “2”

Page 333 of 360

ELECTRICAL COMPONENTS

8-43

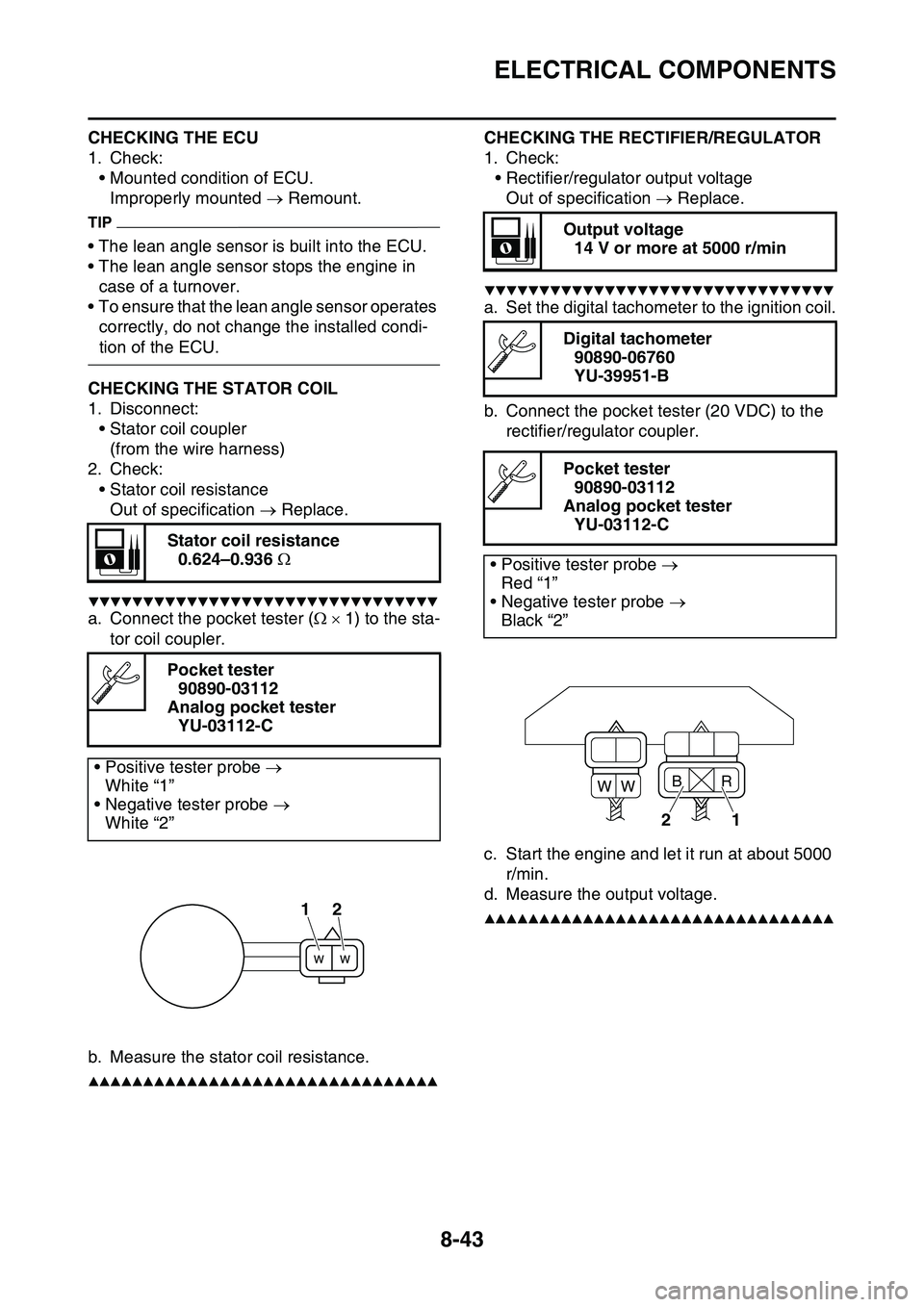

CHECKING THE ECU

1. Check:

• Mounted condition of ECU.

Improperly mounted Remount.

TIP

• The lean angle sensor is built into the ECU.

• The lean angle sensor stops the engine in

case of a turnover.

• To ensure that the lean angle sensor operates

correctly, do not change the installed condi

-

tion of the ECU.

EAS1SL1340CHECKING THE STATOR COIL

1. Disconnect:

• Stator coil coupler

(from the wire harness)

2. Check:

• Stator coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the sta-

tor coil coupler.

b. Measure the stator coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1341

CHECKING THE RECTIFIER/REGULATOR

1. Check:

• Rectifier/regulator output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Set the digital tachometer to the ignition coil.

b. Connect the pocket tester (20 VDC) to the

rectifier/regulator coupler.

c. Start the engine and let it run at about 5000

r/min.

d. Measure the output voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1342

Stator coil resistance

0.624–0.936

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

White “1”

• Negative tester probe

White “2”

12

Output voltage

14 V or more at 5000 r/min

Digital tachometer

90890-06760

YU-39951-B

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Red “1”

• Negative tester probe

Black “2”

21

B

WWR

Page 335 of 360

ELECTRICAL COMPONENTS

8-45

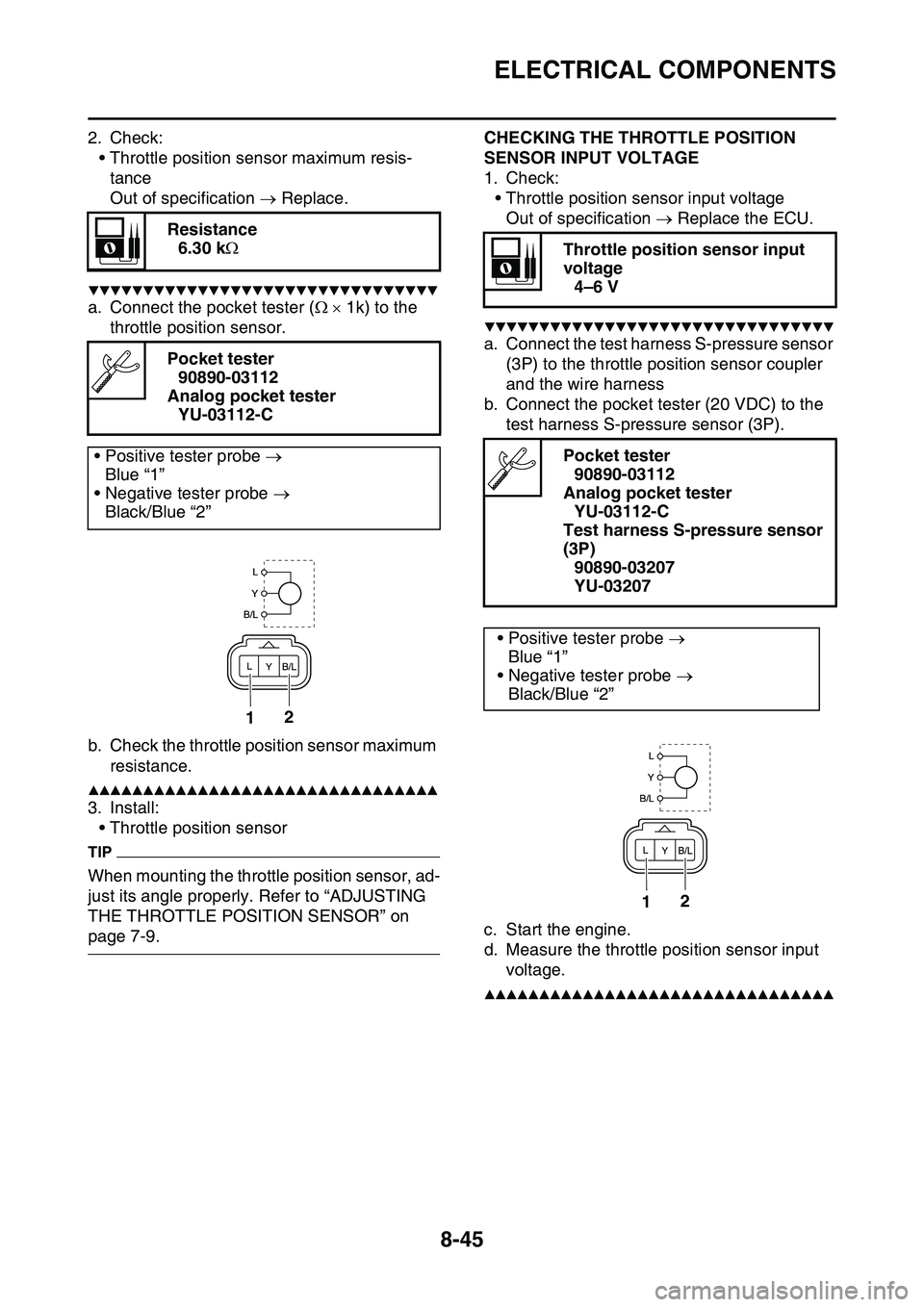

2. Check:

• Throttle position sensor maximum resis-

tance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

throttle position sensor.

b. Check the throttle position sensor maximum

resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Throttle position sensor

TIP

When mounting the throttle position sensor, ad-

just its angle properly. Refer to “ADJUSTING

THE THROTTLE POSITION SENSOR” on

page 7-9.

EAS1SL1344

CHECKING THE THROTTLE POSITION

SENSOR INPUT VOLTAGE

1. Check:

• Throttle position sensor input voltage

Out of specification Replace the ECU.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness S-pressure sensor

(3P) to the throttle position sensor coupler

and the wire harness

b. Connect the pocket tester (20 VDC) to the

test harness S-pressure sensor (3P).

c. Start the engine.

d. Measure the throttle position sensor input

voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1345

Resistance

6.30 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

21

Throttle position sensor input

voltage

4–6 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness S-pressure sensor

(3P)

90890-03207

YU-03207

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

21

Page 336 of 360

ELECTRICAL COMPONENTS

8-46

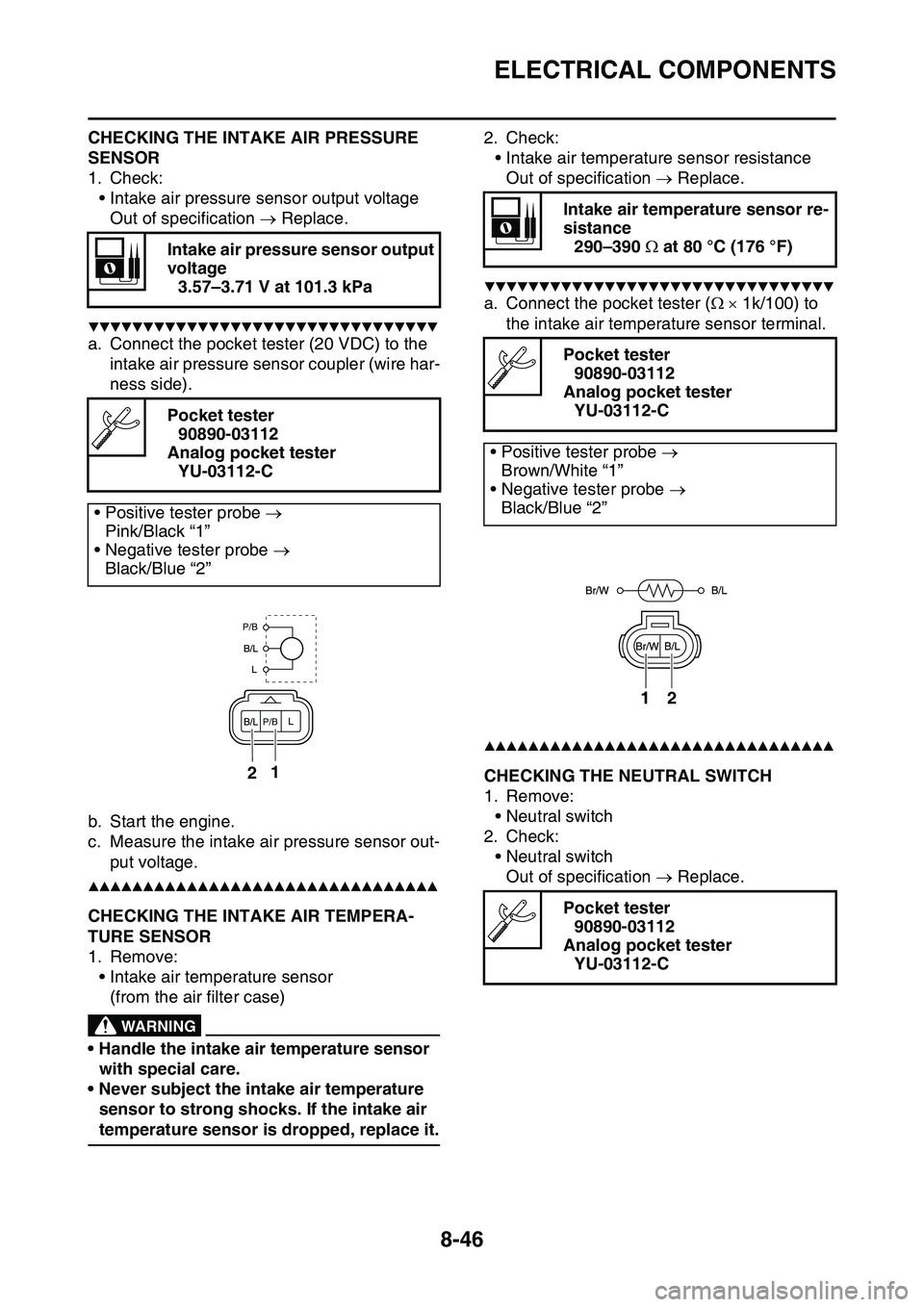

CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (20 VDC) to the

intake air pressure sensor coupler (wire har

-

ness side).

b. Start the engine.

c. Measure the intake air pressure sensor out-

put voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

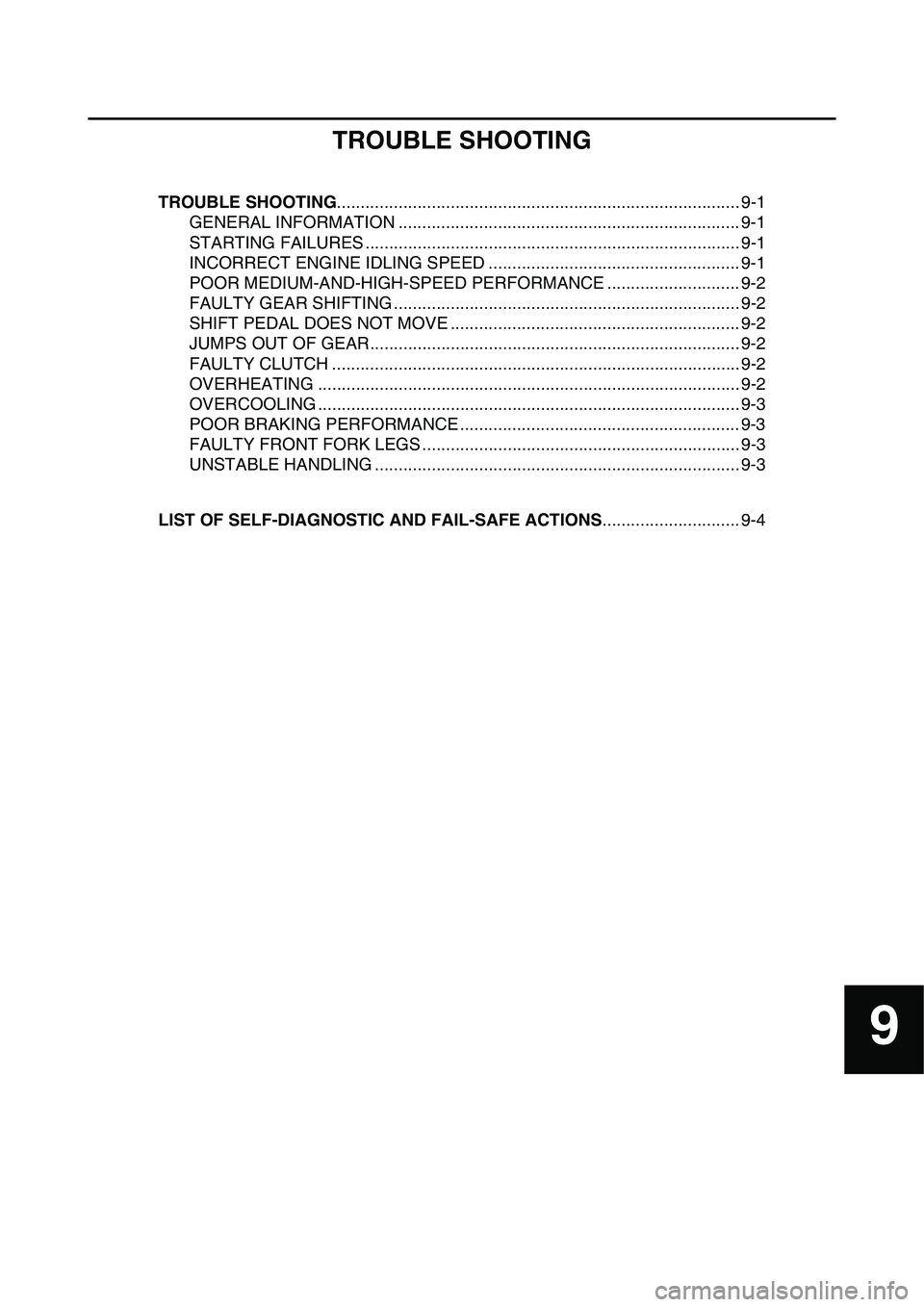

EAS1SL1346CHECKING THE INTAKE AIR TEMPERA-

TURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case)EWA1DX1010

WARNING

• Handle the intake air temperature sensor

with special care.

• Never subject the intake air temperature

sensor to strong shocks. If the intake air

temperature sensor is dropped, replace it.

2. Check:

• Intake air temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the intake air temperature sensor terminal.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1347CHECKING THE NEUTRAL SWITCH

1. Remove:

• Neutral switch

2. Check:

• Neutral switch

Out of specification Replace.

Intake air pressure sensor output

voltage

3.57–3.71 V at 101.3 kPa

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Pink/Black “1”

• Negative tester probe

Black/Blue “2”

12

P/B

P/B

Intake air temperature sensor re-

sistance

290–390 at 80 °C (176 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Brown/White “1”

• Negative tester probe

Black/Blue “2”

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

12

Page 339 of 360

9

TROUBLE SHOOTING

TROUBLE SHOOTING..................................................................................... 9-1

GENERAL INFORMATION ........................................................................ 9-1

STARTING FAILURES ............................................................................... 9-1

INCORRECT ENGINE IDLING SPEED ..................................................... 9-1

POOR MEDIUM-AND-HIGH-SPEED PERFORMANCE ............................ 9-2

FAULTY GEAR SHIFTING ......................................................................... 9-2

SHIFT PEDAL DOES NOT MOVE ............................................................. 9-2

JUMPS OUT OF GEAR.............................................................................. 9-2

FAULTY CLUTCH ...................................................................................... 9-2

OVERHEATING ......................................................................................... 9-2

OVERCOOLING ......................................................................................... 9-3

POOR BRAKING PERFORMANCE ........................................................... 9-3

FAULTY FRONT FORK LEGS ................................................................... 9-3

UNSTABLE HANDLING ............................................................................. 9-3

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS............................. 9-4

Page 340 of 360

TROUBLE SHOOTING

9-1

EAS1SL1349

TROUBLE SHOOTING

EAS1SL1350GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re

-

placement of parts.

EAS1SL1351STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in air

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

2. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

4. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

EAS1SL1352INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

• Faulty spark plug cap

2. Ignition coil

• Broken or shorted primary or secondary

coils

• Cracked or broken ignition coil

Page 341 of 360

TROUBLE SHOOTING

9-2

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

EAS1SL1353POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 9-1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EAS1SL1354FAULTY GEAR SHIFTING

Shifting is difficult

Refer to “CLUTCH” on page 5-37.

EAS1SL1355SHIFT PEDAL DOES NOT MOVE

Shift shaft

• Bent shift shaft

Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EAS1SL1356JUMPS OUT OF GEAR

Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

Shift forks

• Worn shift fork

Shift drum

• Incorrect axial play

• Worn shift drum groove

Transmission

• Worn gear dog

EAS1SL1357FAULTY CLUTCH

Clutch slips

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

Clutch drags

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EAS1SL1358OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Page 350 of 360

CHASSIS

10-3

SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

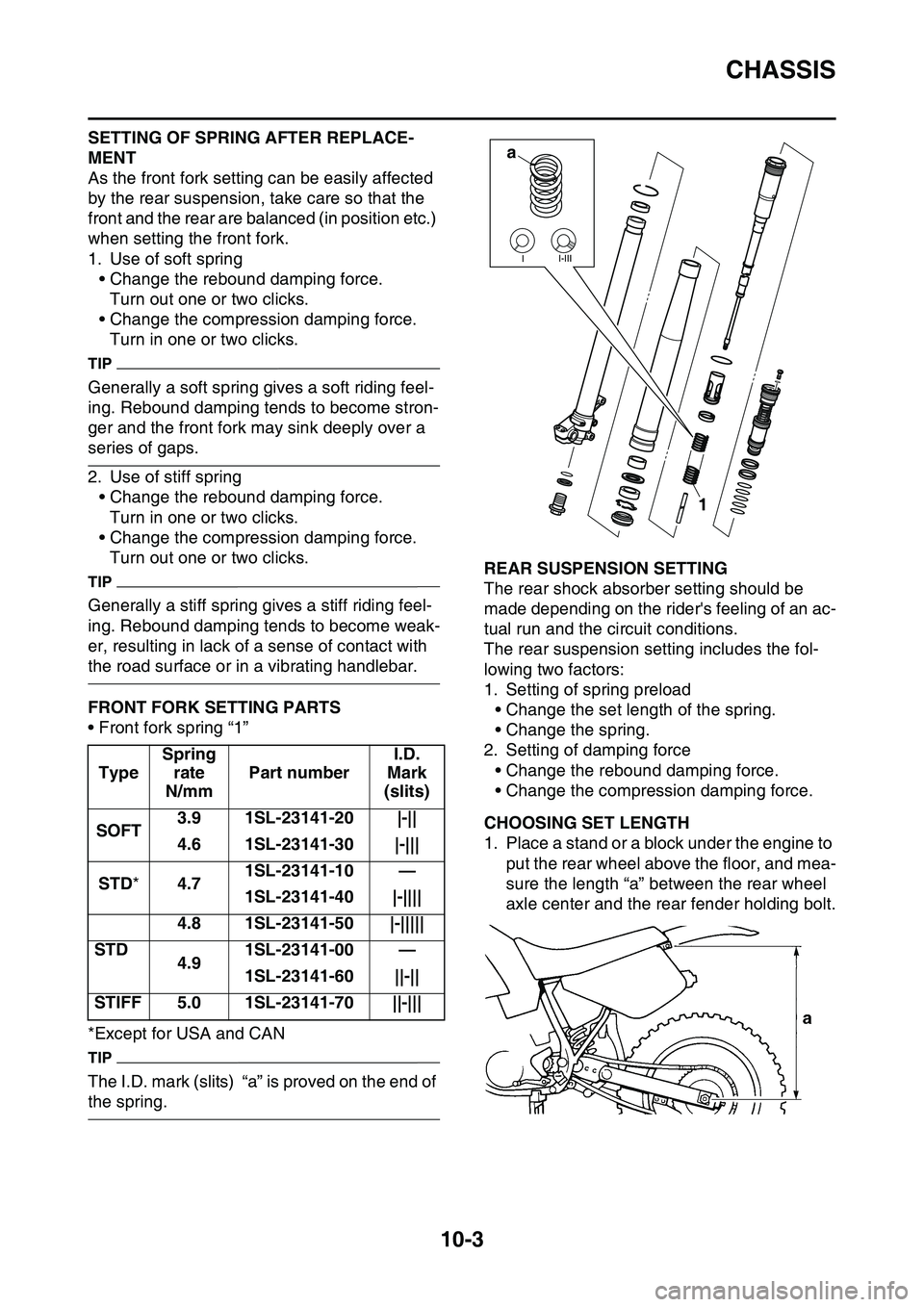

EAS1SL1372FRONT FORK SETTING PARTS

• Front fork spring “1”

*Except for USA and CAN

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS1SL1373REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider's feeling of an ac

-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS1SL1374CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea

-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

Type

Spring

rate

N/mm

Part number

I.D.

Mark

(slits)

SOFT3.91SL-23141-20|-||

4.61SL-23141-30|-|||

STD*4.71SL-23141-10—

1SL-23141-40|-||||

4.81SL-23141-50|-|||||

STD4.91SL-23141-00—

1SL-23141-60||-||

STIFF5.01SL-23141-70||-|||

a

1