ignition YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 198 of 360

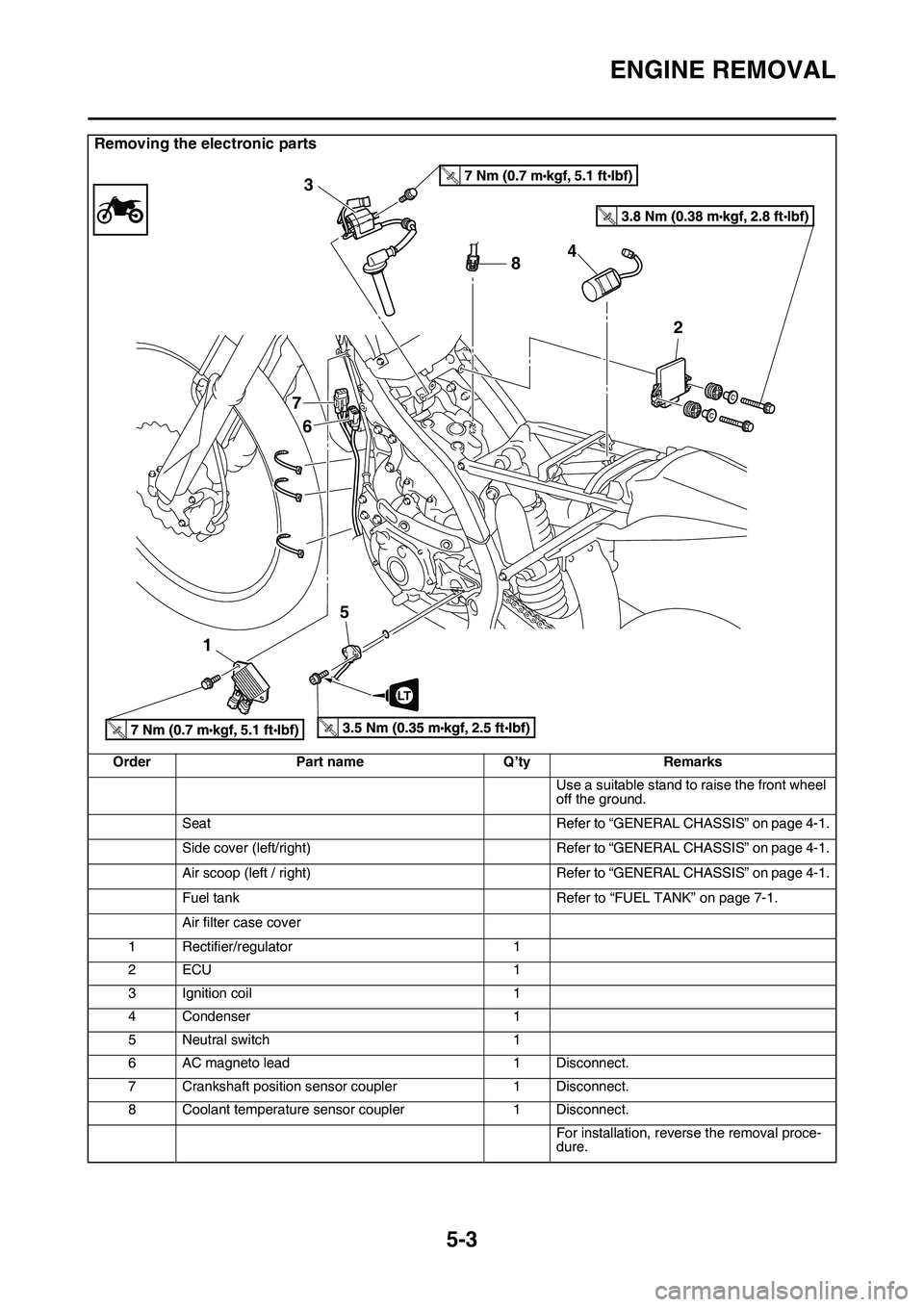

ENGINE REMOVAL

5-3

Removing the electronic parts

OrderPart nameQ’tyRemarks

Use a suitable stand to raise the front wheel

off the ground.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

Air filter case cover

1Rectifier/regulator1

2ECU1

3Ignition coil1

4Condenser1

5Neutral switch1

6AC magneto lead1Disconnect.

7Crankshaft position sensor coupler1Disconnect.

8Coolant temperature sensor coupler1Disconnect.

For installation, reverse the removal proce-dure.

T.R.

T.R.

T.R.T.R.

8 3

7

6

154

2

LT

Page 284 of 360

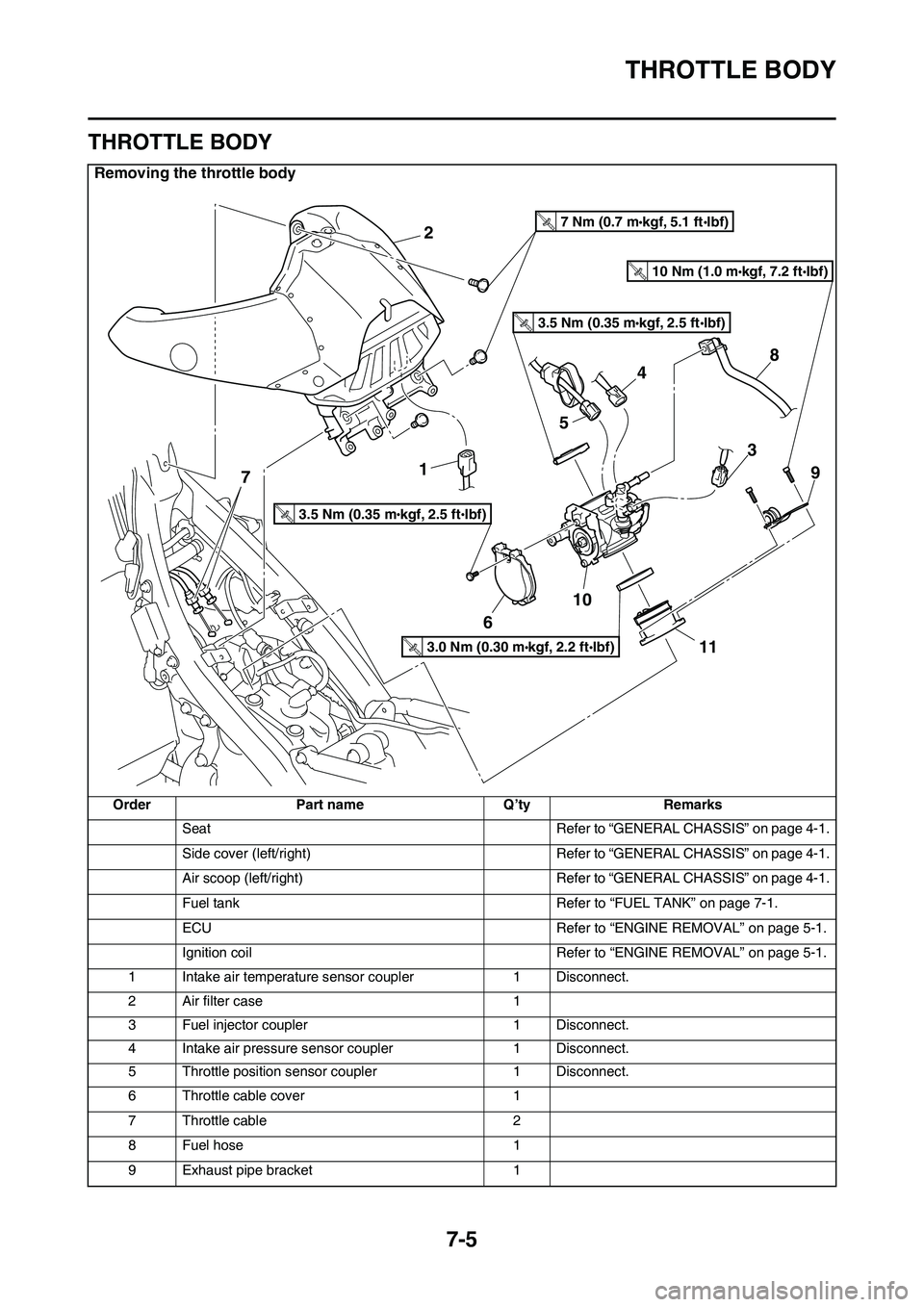

THROTTLE BODY

7-5

EAS1SL1314

THROTTLE BODY

Removing the throttle body

OrderPart nameQ’tyRemarks

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

ECURefer to “ENGINE REMOVAL” on page 5-1.

Ignition coilRefer to “ENGINE REMOVAL” on page 5-1.

1Intake air temperature sensor coupler1Disconnect.

2Air filter case1

3Fuel injector coupler1Disconnect.

4Intake air pressure sensor coupler1Disconnect.

5Throttle position sensor coupler1Disconnect.

6Throttle cable cover1

7Throttle cable2

8Fuel hose1

9Exhaust pipe bracket1

2

1

6

10

11

9

8

3

7

5

4

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

3.0 Nm (0.30 mkgf, 2.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

Page 289 of 360

8

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 8-2

CIRCUIT DIAGRAM ................................................................................... 8-2

TROUBLESHOOTING ............................................................................... 8-4

CHARGING SYSTEM....................................................................................... 8-6

CIRCUIT DIAGRAM ................................................................................... 8-6

TROUBLE SHOOTING .............................................................................. 8-8

FUEL INJECTION SYSTEM........................................................................... 8-10

CIRCUIT DIAGRAM ................................................................................. 8-10

YAMAHA DIAGNOSTIC TOOL ................................................................ 8-12

TROUBLESHOOTING DETAILS ............................................................. 8-13

FUEL PUMP SYSTEM.................................................................................... 8-32

CIRCUIT DIAGRAM ................................................................................. 8-32

TROUBLESHOOTING ............................................................................. 8-34

ELECTRICAL COMPONENTS....................................................................... 8-36

CHECKING THE SWITCHES .................................................................. 8-38

CHECKING THE IGNITION SPARK GAP................................................ 8-41

CHECKING THE SPARK PLUG CAP ...................................................... 8-41

CHECKING THE IGNITION COIL ............................................................ 8-41

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 8-42

CHECKING THE ECU .............................................................................. 8-43

CHECKING THE STATOR COIL ............................................................. 8-43

CHECKING THE RECTIFIER/REGULATOR ........................................... 8-43

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 8-44

CHECKING THE THROTTLE POSITION SENSOR ................................ 8-44

CHECKING THE THROTTLE POSITION SENSOR

INPUT VOLTAGE .................................................................................... 8-43

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 8-46

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 8-46

CHECKING THE NEUTRAL SWITCH ..................................................... 8-46

CHECKING THE FUEL INJECTOR ......................................................... 8-47

Page 292 of 360

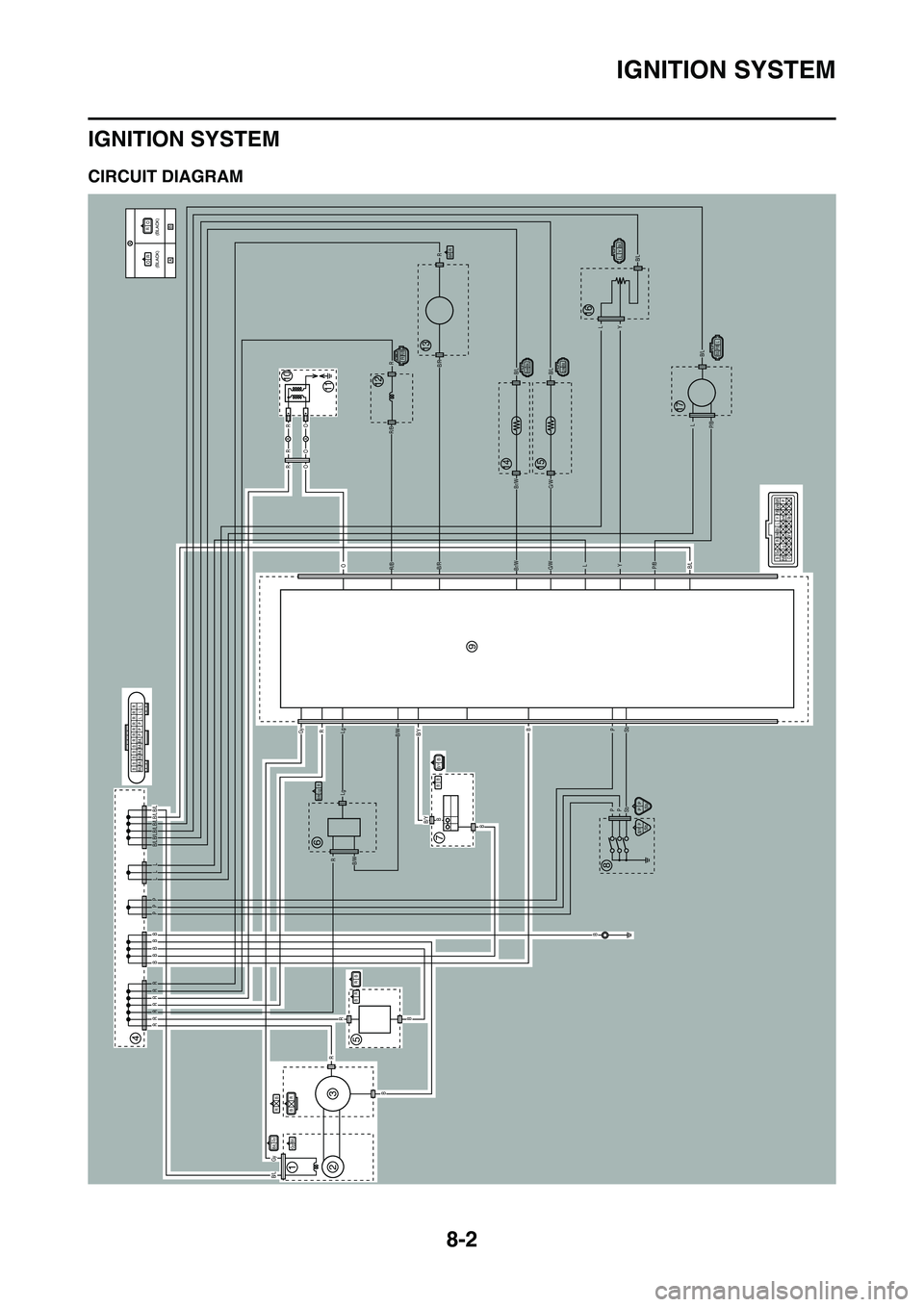

IGNITION SYSTEM

8-2

IGNITION SYSTEM

EAS1SL1321CIRCUIT DIAGRAM

B/LGy

BR

A

A

AA

B

RR R R R R R

B

B

B

RR

R

Lg

LgB/WB/Y

B/YB

B

BP

PP

Sb

B/LP/B

P/B

YL

YL

L

G/WBr/W

G/WBr/W

B/LB/L

B/L

B/L

B/R

B/R

R/B

R/B

O

OROR

OR

R

R

SbB

GyR

B/W

P L B/L

B/L Gy B/L B/L B/L B/L B/L

LL

PP

BBBB

PP

Sb

RB

B/RR

RB

B/Y PSb

BB

RR/B

LYB/L

B/W RLg

B/LBr/W

B/L P/B LB/LG/W

BB/Y

BB/L B/L B/L B/L B/L B/LBBBBRR

PPPL L LRR RR R

B

O P

Gy

R

B/Y Sb

P/B

R/B Lg B/RG/WBr/WB/L L Y

RB

B/L

Gy

R

O

O

R(BLACK) (BLACK)

B/W

4

1

3

2

5

67

8

10

9

1211

13

1415

16

17

Page 293 of 360

IGNITION SYSTEM

8-3

EAS1SL1322

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

9. ECU

10.Ignition coil

11.Spark plug

Page 294 of 360

IGNITION SYSTEM

8-4

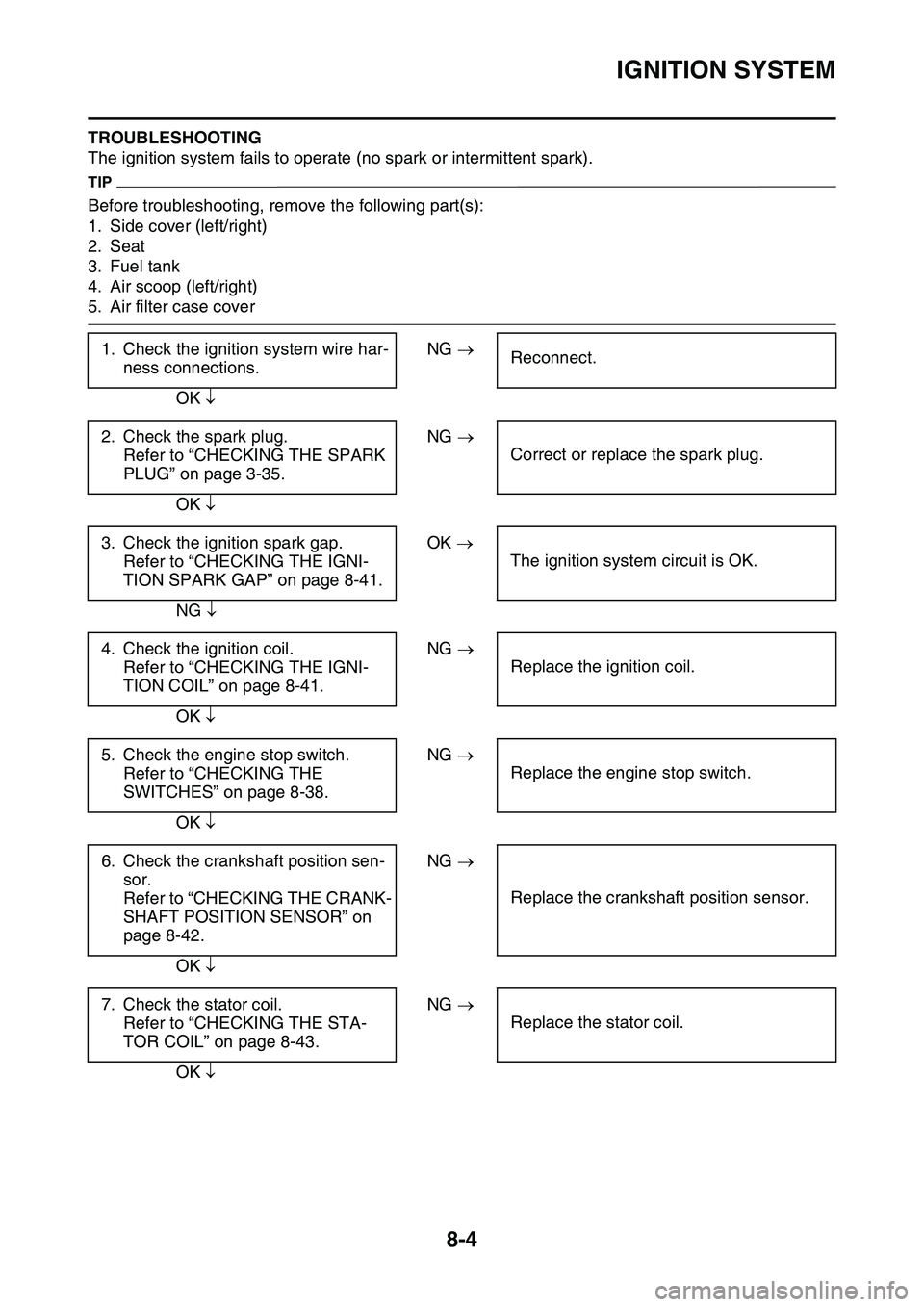

TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part(s):

1. Side cover (left/right)

2. Seat

3. Fuel tank

4. Air scoop (left/right)

5. Air filter case cover

1. Check the ignition system wire har-

ness connections.

NG Reconnect.

OK

2. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-35.

NG

Correct or replace the spark plug.

OK

3. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 8-41.

OK

The ignition system circuit is OK.

NG

4. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 8-41.

NG

Replace the ignition coil.

OK

5. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 8-38.

NG

Replace the engine stop switch.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 8-42.

NG

Replace the crankshaft position sensor.

OK

7. Check the stator coil.

Refer to “CHECKING THE STA-

TOR COIL” on page 8-43.

NG

Replace the stator coil.

OK

Page 295 of 360

IGNITION SYSTEM

8-5

8. Check the ignition system wire har-

ness.

Refer to “CIRCUIT DIAGRAM” on

page 8-2.

NG

Repair or replace the wire harness.

OK

Replace the ECU.

Page 302 of 360

FUEL INJECTION SYSTEM

8-12

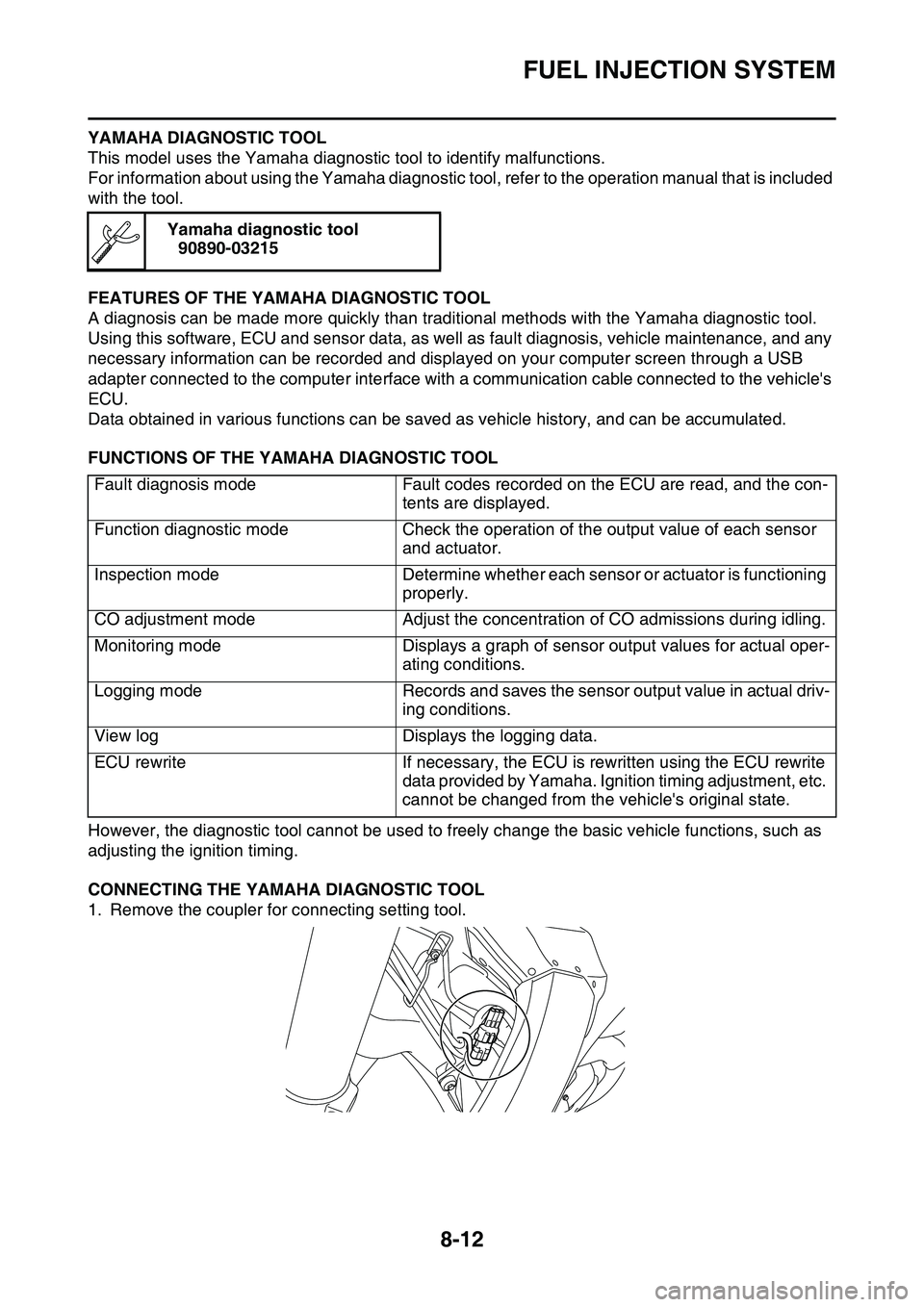

YAMAHA DIAGNOSTIC TOOL

This model uses the Yamaha diagnostic tool to identify malfunctions.

For information about using the Yamaha diagnostic tool, refer to the operation manual that is included

with the tool.

FEATURES OF THE YAMAHA DIAGNOSTIC TOOL

A diagnosis can be made more quickly than traditional methods with the Yamaha diagnostic tool.

Using this software, ECU and sensor data, as well as fault diagnosis, vehicle maintenance, and any

necessary information can be recorded and displayed on your computer screen through a USB

adapter connected to the computer interface with a communication cable connected to the vehicle's

ECU.

Data obtained in various functions can be saved as vehicle history, and can be accumulated.

FUNCTIONS OF THE YAMAHA DIAGNOSTIC TOOL

However, the diagnostic tool cannot be used to freely change the basic vehicle functions, such as

adjusting the ignition timing.

CONNECTING THE YAMAHA DIAGNOSTIC TOOL

1. Remove the coupler for connecting setting tool.

Yamaha diagnostic tool

90890-03215

Fault diagnosis modeFault codes recorded on the ECU are read, and the con-

tents are displayed.

Function diagnostic modeCheck the operation of the output value of each sensor

and actuator.

Inspection modeDetermine whether each sensor or actuator is functioning

properly.

CO adjustment modeAdjust the concentration of CO admissions during idling.

Monitoring modeDisplays a graph of sensor output values for actual oper-

ating conditions.

Logging modeRecords and saves the sensor output value in actual driv-

ing conditions.

View logDisplays the logging data.

ECU rewriteIf necessary, the ECU is rewritten using the ECU rewrite

data provided by Yamaha. Ignition timing adjustment, etc.

cannot be changed from the vehicle's original state.

Page 313 of 360

FUEL INJECTION SYSTEM

8-23

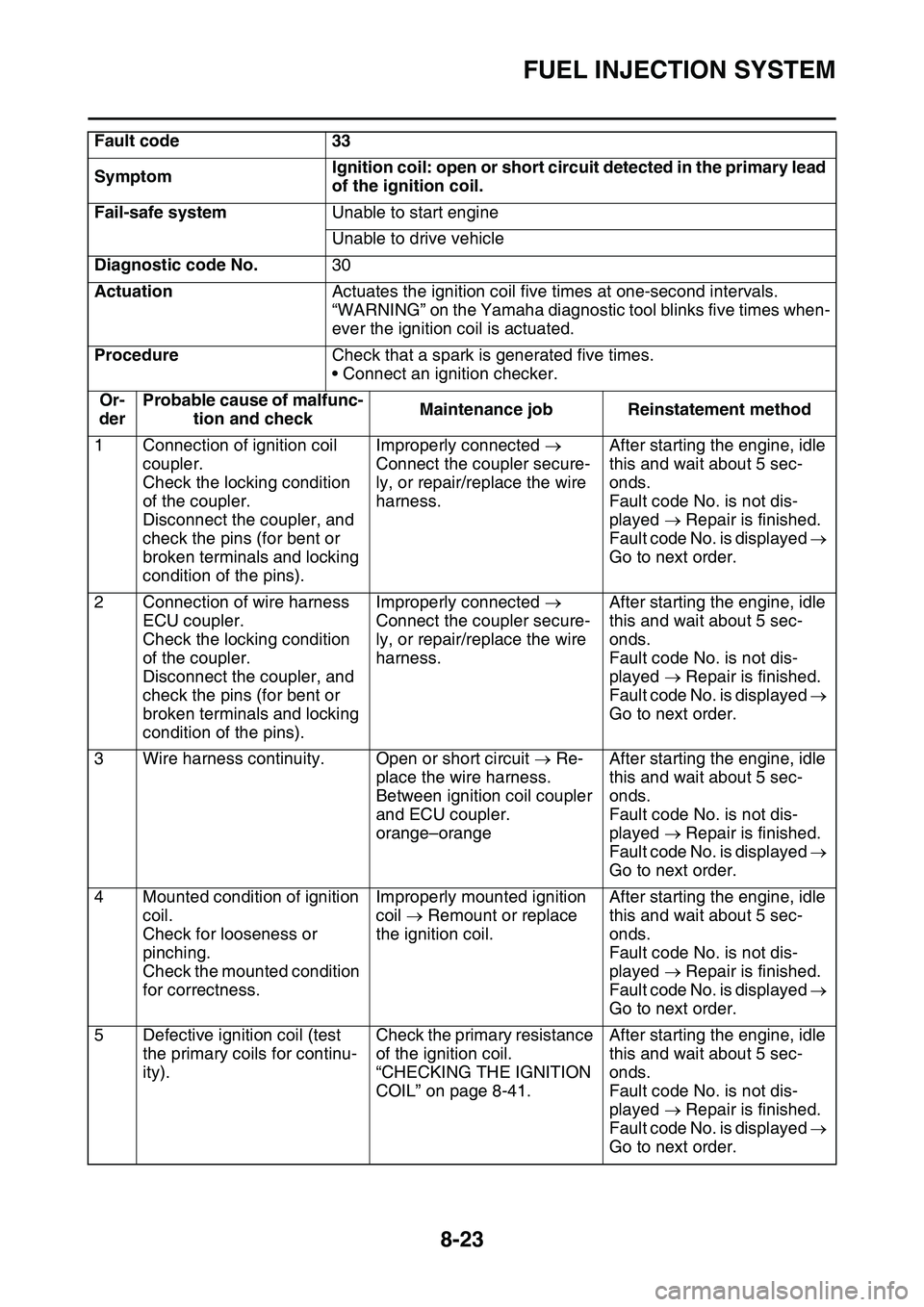

Fault code33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when-

ever the ignition coil is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

Or-

der

Probable cause of malfunc-

tion and checkMaintenance jobReinstatement method

1Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3Wire harness continuity.Open or short circuit Re-

place the wire harness.

Between ignition coil coupler

and ECU coupler.

orange–orange

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4Mounted condition of ignition

coil.

Check for looseness or

pinching.

Check the mounted condition

for correctness.

Improperly mounted ignition

coil Remount or replace

the ignition coil.After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5Defective ignition coil (test

the primary coils for continu

-

ity).

Check the primary resistance

of the ignition coil.

“CHECKING THE IGNITION

COIL” on page 8-41.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Page 314 of 360

FUEL INJECTION SYSTEM

8-24

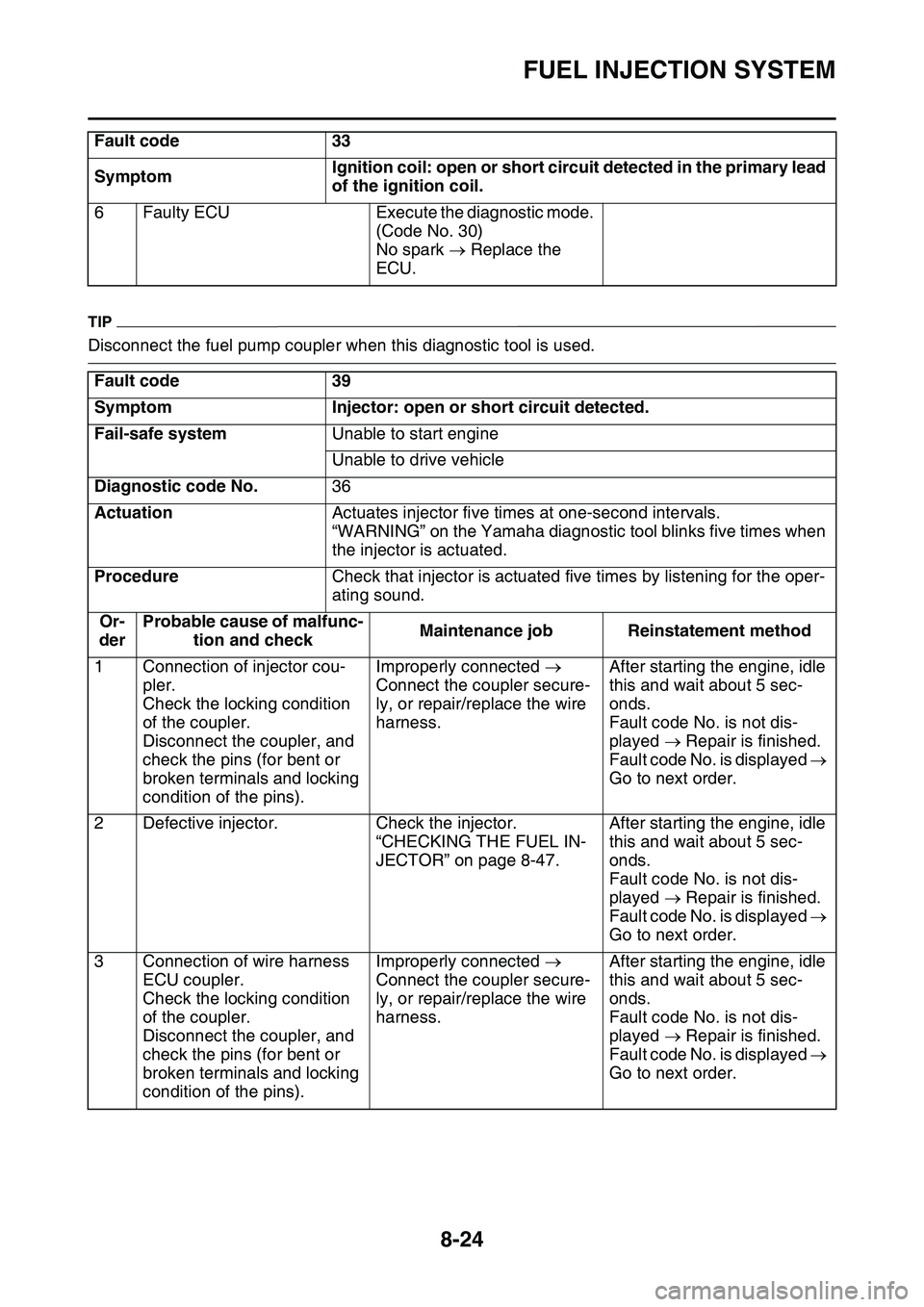

TIP

Disconnect the fuel pump coupler when this diagnostic tool is used.

6Faulty ECUExecute the diagnostic mode.

(Code No. 30)

No spark Replace the

ECU.

Fault code39

SymptomInjector: open or short circuit detected.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.36

ActuationActuates injector five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when

the injector is actuated.

ProcedureCheck that injector is actuated five times by listening for the oper-

ating sound.

Or-

der

Probable cause of malfunc-

tion and checkMaintenance jobReinstatement method

1Connection of injector cou-

pler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2Defective injector.Check the injector.

“CHECKING THE FUEL IN-

JECTOR” on page 8-47.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.