ignition YAMAHA YZ450F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 20 of 360

FEATURES

1-6

EAS20170

FEATURES

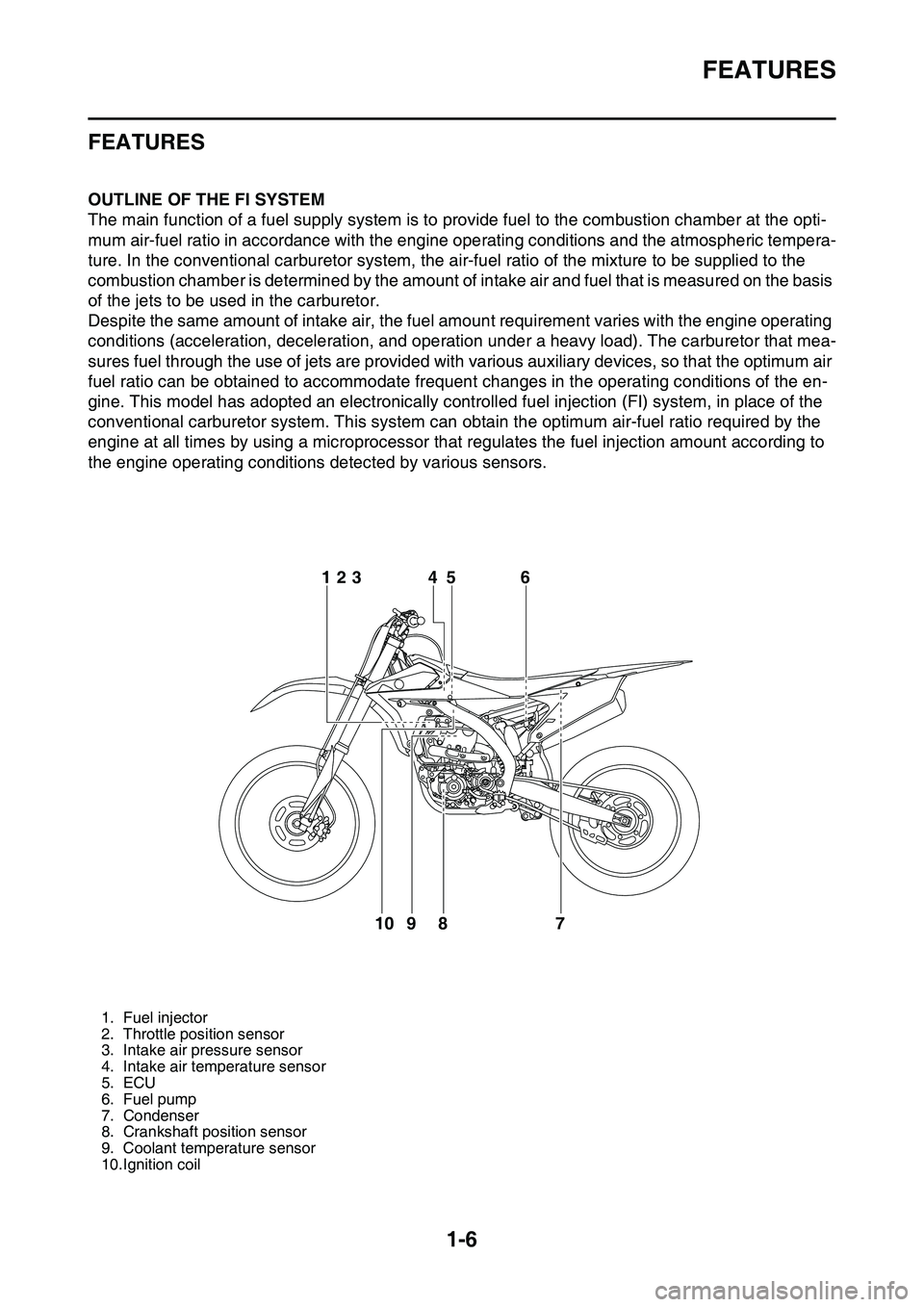

EAS1SL1014OUTLINE OF THE FI SYSTEM

The main function of a fuel supply system is to provide fuel to the combustion chamber at the opti-

mum air-fuel ratio in accordance with the engine operating conditions and the atmospheric tempera-

ture. In the conventional carburetor system, the air-fuel ratio of the mixture to be supplied to the

combustion chamber is determined by the amount of intake air and fuel that is measured on the basis

of the jets to be used in the carburetor.

Despite the same amount of intake air, the fuel amount requirement varies with the engine operating

conditions (acceleration, deceleration, and operation under a heavy load). The carburetor that mea

-

sures fuel through the use of jets are provided with various auxiliary devices, so that the optimum air

fuel ratio can be obtained to accommodate frequent changes in the operating conditions of the en

-

gine. This model has adopted an electronically controlled fuel injection (FI) system, in place of the

conventional carburetor system. This system can obtain the optimum air-fuel ratio required by the

engine at all times by using a microprocessor that regulates the fuel injection amount according to

the engine operating conditions detected by various sensors.

EAS1SL1015

1. Fuel injector

2. Throttle position sensor

3. Intake air pressure sensor

4. Intake air temperature sensor

5. ECU

6. Fuel pump

7. Condenser

8. Crankshaft position sensor

9. Coolant temperature sensor

10.Ignition coil

6

7 8 95 4 123

10

Page 31 of 360

SPECIAL TOOLS

1-17

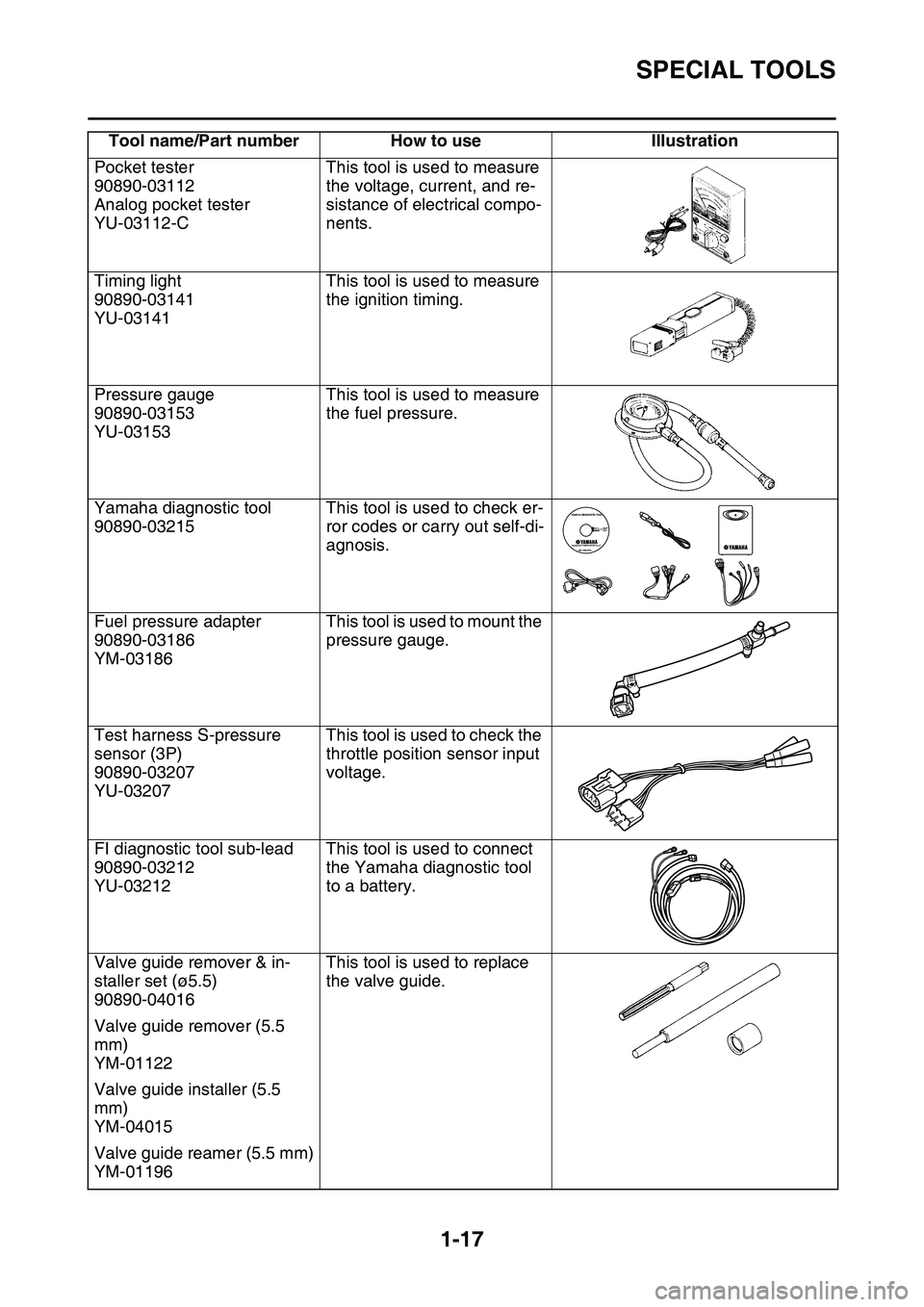

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

This tool is used to measure

the voltage, current, and re

-

sistance of electrical compo-

nents.

Timing light

90890-03141

YU-03141

This tool is used to measure

the ignition timing.

Pressure gauge

90890-03153

YU-03153

This tool is used to measure

the fuel pressure.

Yamaha diagnostic tool

90890-03215

This tool is used to check er-

ror codes or carry out self-di-

agnosis.

Fuel pressure adapter

90890-03186

YM-03186

This tool is used to mount the

pressure gauge.

Test harness S-pressure

sensor (3P)

90890-03207

YU-03207

This tool is used to check the

throttle position sensor input

voltage.

FI diagnostic tool sub-lead

90890-03212

YU-03212

This tool is used to connect

the Yamaha diagnostic tool

to a battery.

Valve guide remover & in-

staller set (ø5.5)

90890-04016

This tool is used to replace

the valve guide.

Valve guide remover (5.5

mm)

YM-01122

Valve guide installer (5.5

mm)

YM-04015

Valve guide reamer (5.5 mm)

YM-01196

Tool name/Part number How to use Illustration

Page 33 of 360

SPECIAL TOOLS

1-19

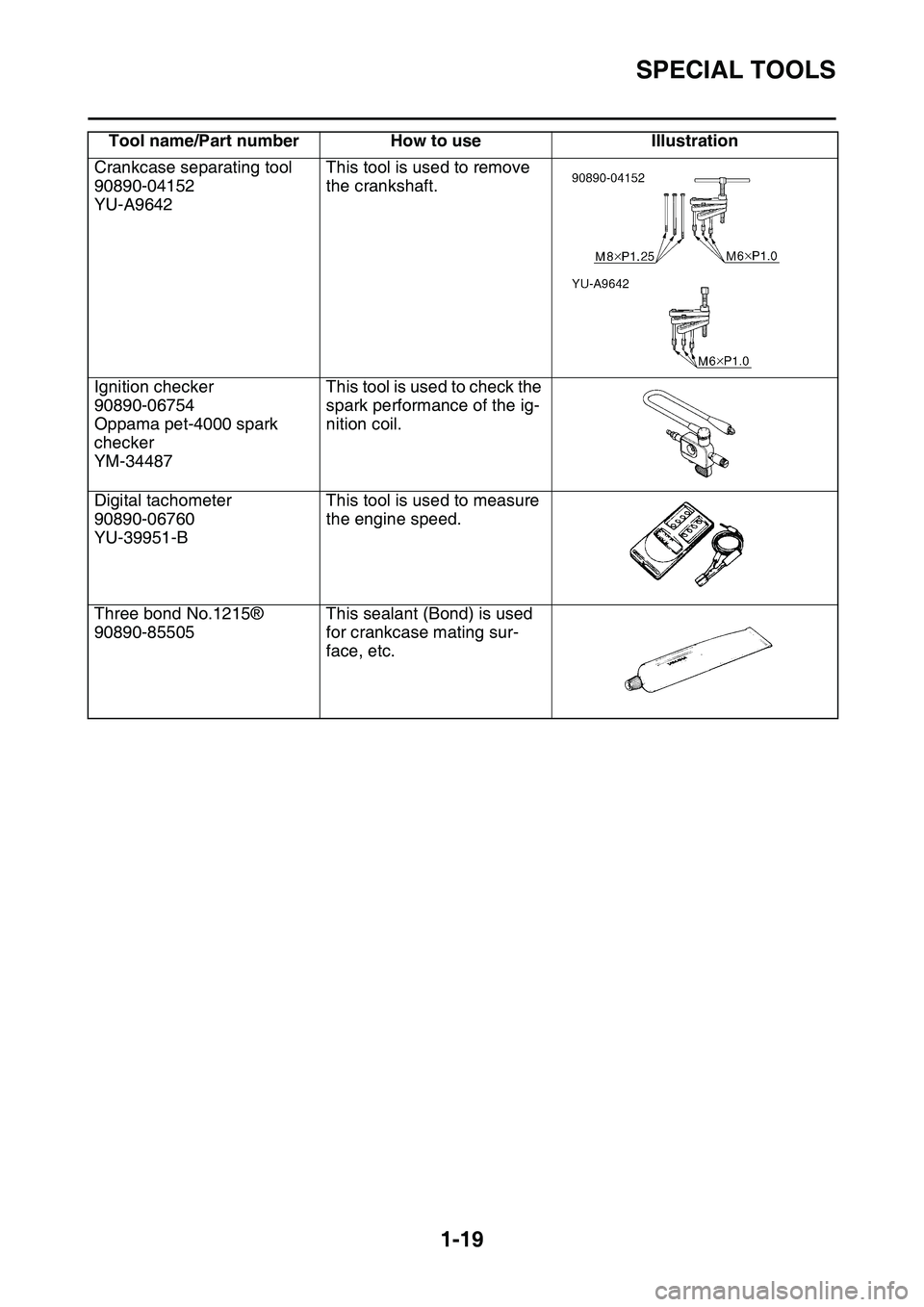

Crankcase separating tool

90890-04152

YU-A9642

This tool is used to remove

the crankshaft.

Ignition checker

90890-06754

Oppama pet-4000 spark

checker

YM-34487

This tool is used to check the

spark performance of the ig

-

nition coil.

Digital tachometer

90890-06760

YU-39951-B

This tool is used to measure

the engine speed.

Three bond No.1215®

90890-85505

This sealant (Bond) is used

for crankcase mating sur

-

face, etc.

Tool name/Part number How to use Illustration

Page 55 of 360

ELECTRICAL SPECIFICATIONS

2-12

EAS1SL1055

ELECTRICAL SPECIFICATIONS

Voltage

System voltage 12 V

Ignition system

Ignition system TCI

Advancer type Digital

Ignition timing (B.T.D.C.) 10.0 ° at 2000 r/min

Engine control unit

Model/manufacturer 1SL0/YAMAHA (USA) (CAN)

1SL1/YAMAHA (EUR) (JPN) (AUS) (NZL)

(ZAF)

Ignition coil

Minimum ignition spark gap 6.0 mm (0.24 in)

Primary coil resistance 2.16–2.64

Secondary coil resistance 8.64–12.96 k

AC magneto

Standard output 14.0 V, 95 W at 5000 r/min

Stator coil resistance 0.624–0.936

Rectifier/regulator

Regulator type Semi conductor-short circuit

No load regulated voltage 14.1–14.9 V

Rectifier capacity (DC) 23.0 A

Page 59 of 360

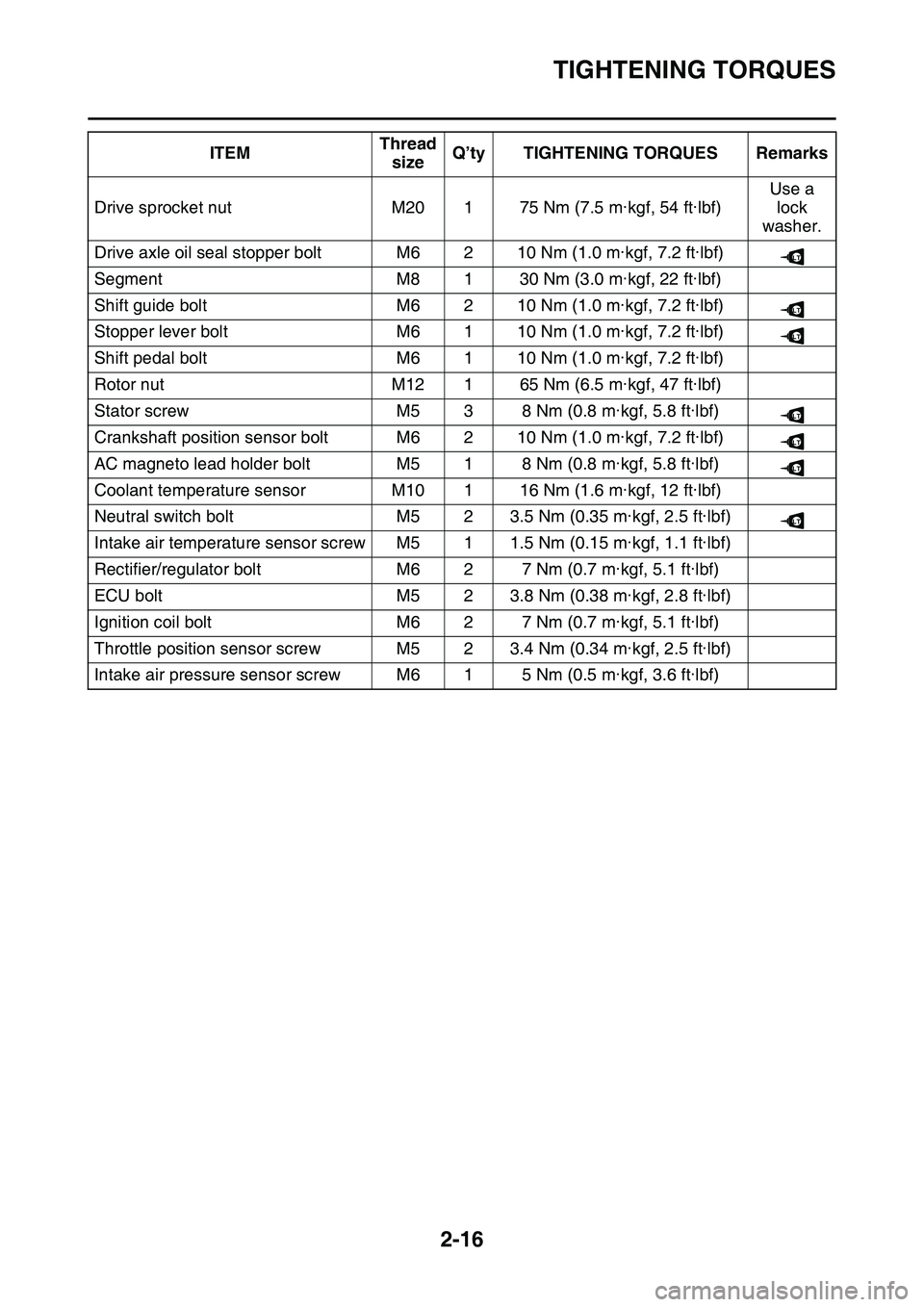

TIGHTENING TORQUES

2-16

Drive sprocket nutM20175 Nm (7.5 m·kgf, 54 ft·lbf)

Use a

lock

washer.

Drive axle oil seal stopper boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

SegmentM8130 Nm (3.0 m·kgf, 22 ft·lbf)

Shift guide boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

Stopper lever boltM6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Shift pedal boltM6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rotor nutM12165 Nm (6.5 m·kgf, 47 ft·lbf)

Stator screwM538 Nm (0.8 m·kgf, 5.8 ft·lbf)

Crankshaft position sensor boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

AC magneto lead holder boltM518 Nm (0.8 m·kgf, 5.8 ft·lbf)

Coolant temperature sensorM10116 Nm (1.6 m·kgf, 12 ft·lbf)

Neutral switch boltM523.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Intake air temperature sensor screwM511.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rectifier/regulator boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

ECU boltM523.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Ignition coil boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle position sensor screwM523.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

Intake air pressure sensor screwM615 Nm (0.5 m·kgf, 3.6 ft·lbf)

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

LT

LT

LT

LT

Page 88 of 360

CHECKING THE WHEEL BEARINGS ..................................................... 3-33

CHECKING AND ADJUSTING THE STEERING HEAD .......................... 3-33

LUBRICATING THE LEVERS .................................................................. 3-34

LUBRICATING THE PEDAL .................................................................... 3-34

ELECTRICAL SYSTEM.................................................................................. 3-35

CHECKING THE SPARK PLUG .............................................................. 3-35

CHECKING THE IGNITION TIMING ........................................................ 3-35

Page 95 of 360

PRE-OPERATION INSPECTION AND MAINTENANCE

3-7

EAS1SL1067

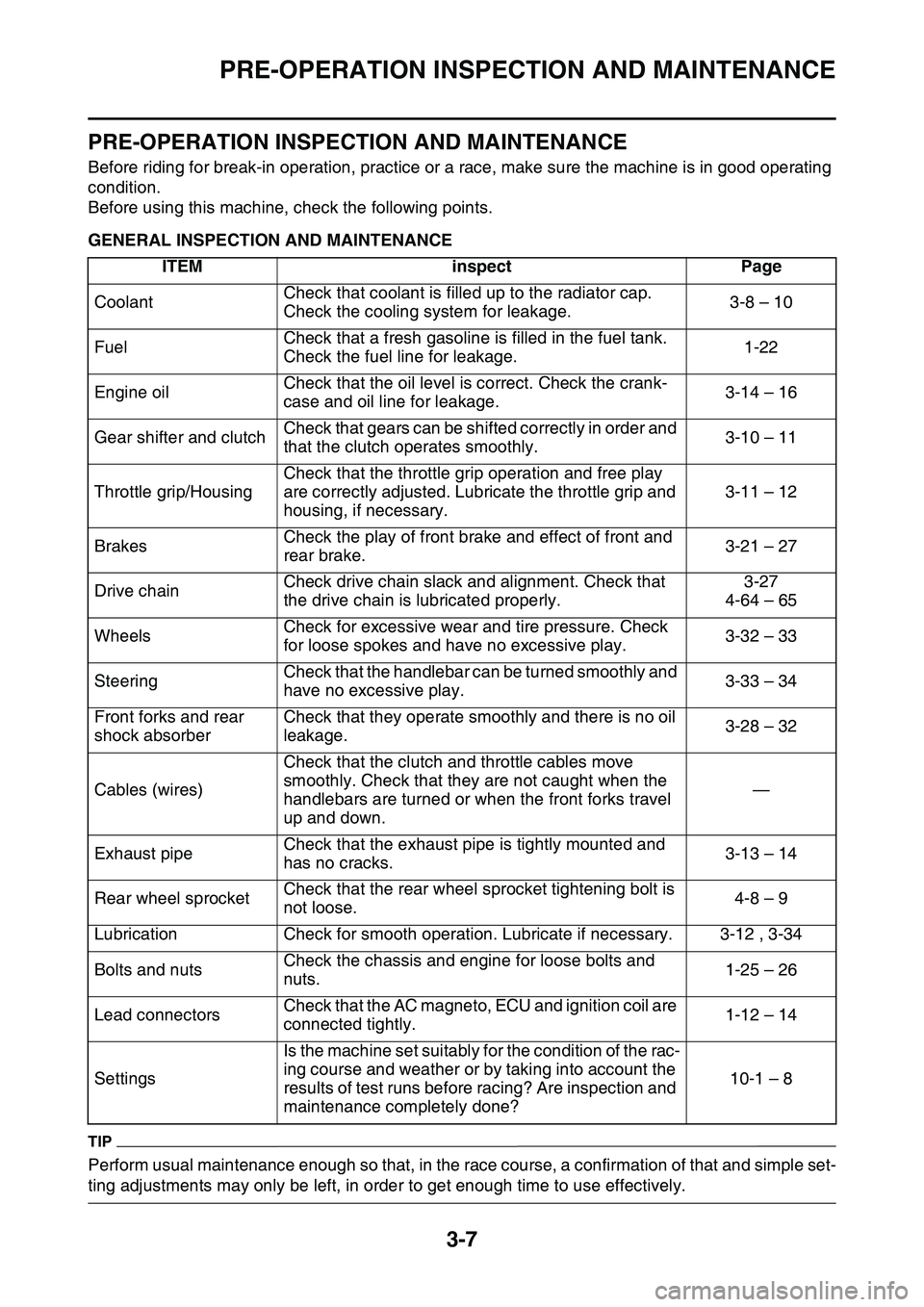

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS1SL1068GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.

ITEMinspectPage

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.3-8 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage.1-22

Engine oilCheck that the oil level is correct. Check the crank-

case and oil line for leakage.3-14 – 16

Gear shifter and clutchCheck that gears can be shifted correctly in order and

that the clutch operates smoothly.3-10 – 11

Throttle grip/Housing

Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary.

3-11 – 12

BrakesCheck the play of front brake and effect of front and

rear brake.3-21 – 27

Drive chainCheck drive chain slack and alignment. Check that

the drive chain is lubricated properly.3-27

4-64 – 65

WheelsCheck for excessive wear and tire pressure. Check

for loose spokes and have no excessive play.3-32 – 33

SteeringCheck that the handlebar can be turned smoothly and

have no excessive play.3-33 – 34

Front forks and rear

shock absorberCheck that they operate smoothly and there is no oil

leakage.3-28 – 32

Cables (wires)

Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and

has no cracks.3-13 – 14

Rear wheel sprocketCheck that the rear wheel sprocket tightening bolt is

not loose.4-8 – 9

LubricationCheck for smooth operation. Lubricate if necessary. 3-12 , 3-34

Bolts and nutsCheck the chassis and engine for loose bolts and

nuts.1-25 – 26

Lead connectorsCheck that the AC magneto, ECU and ignition coil are

connected tightly.1-12 – 14

Settings

Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?10-1 – 8

Page 105 of 360

ENGINE

3-17

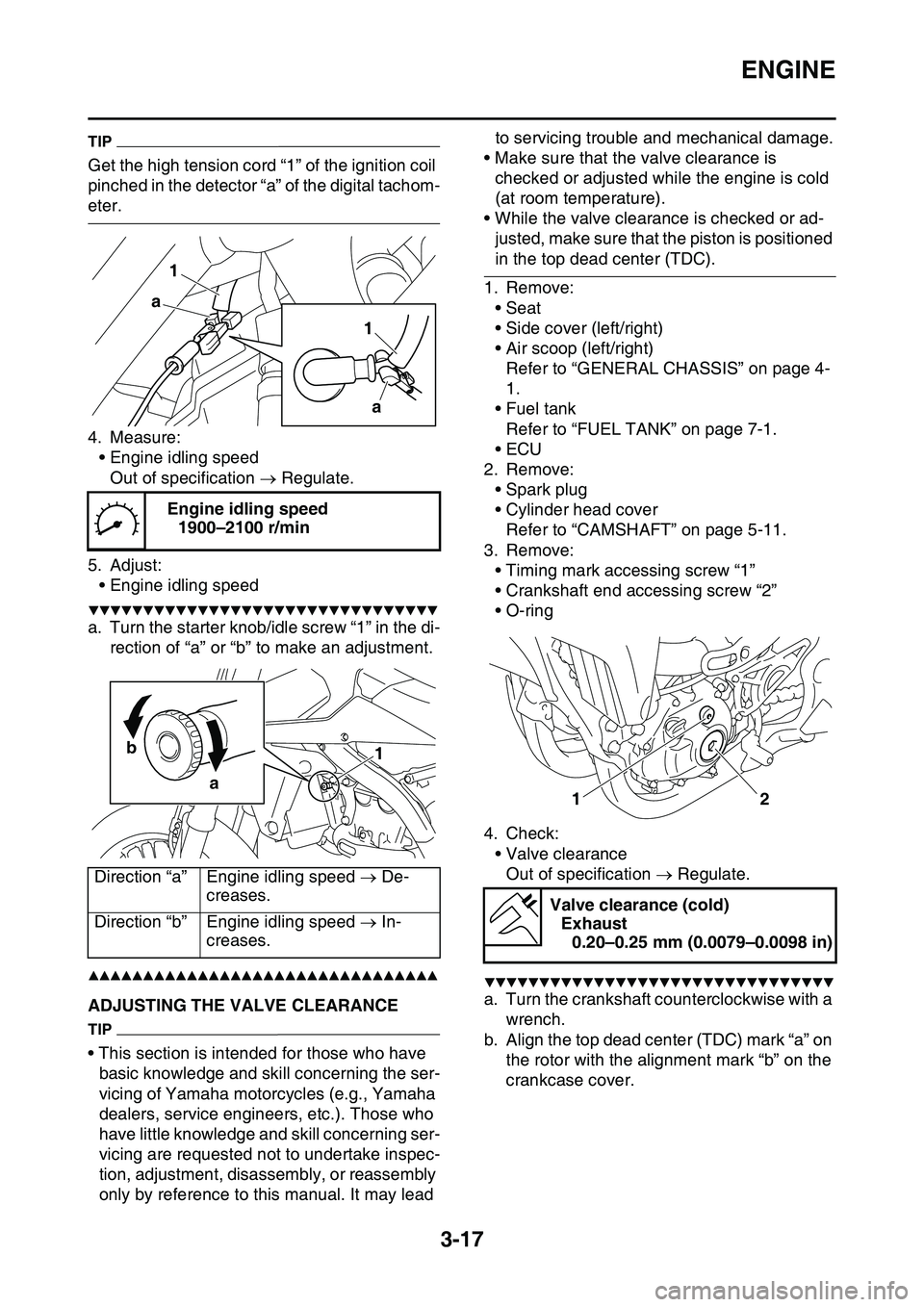

TIP

Get the high tension cord “1” of the ignition coil

pinched in the detector “a” of the digital tachom

-

eter.

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1088ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser

-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser

-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 5-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

Engine idling speed

1900–2100 r/min

Direction “a”Engine idling speed De-

creases.

Direction “b”Engine idling speed In-

creases.

1 1

a a

1 b

a

Valve clearance (cold)

Exhaust

0.20–0.25 mm (0.0079–0.0098 in)

1

2

Page 123 of 360

ELECTRICAL SYSTEM

3-35

EAS1SL1114

ELECTRICAL SYSTEM

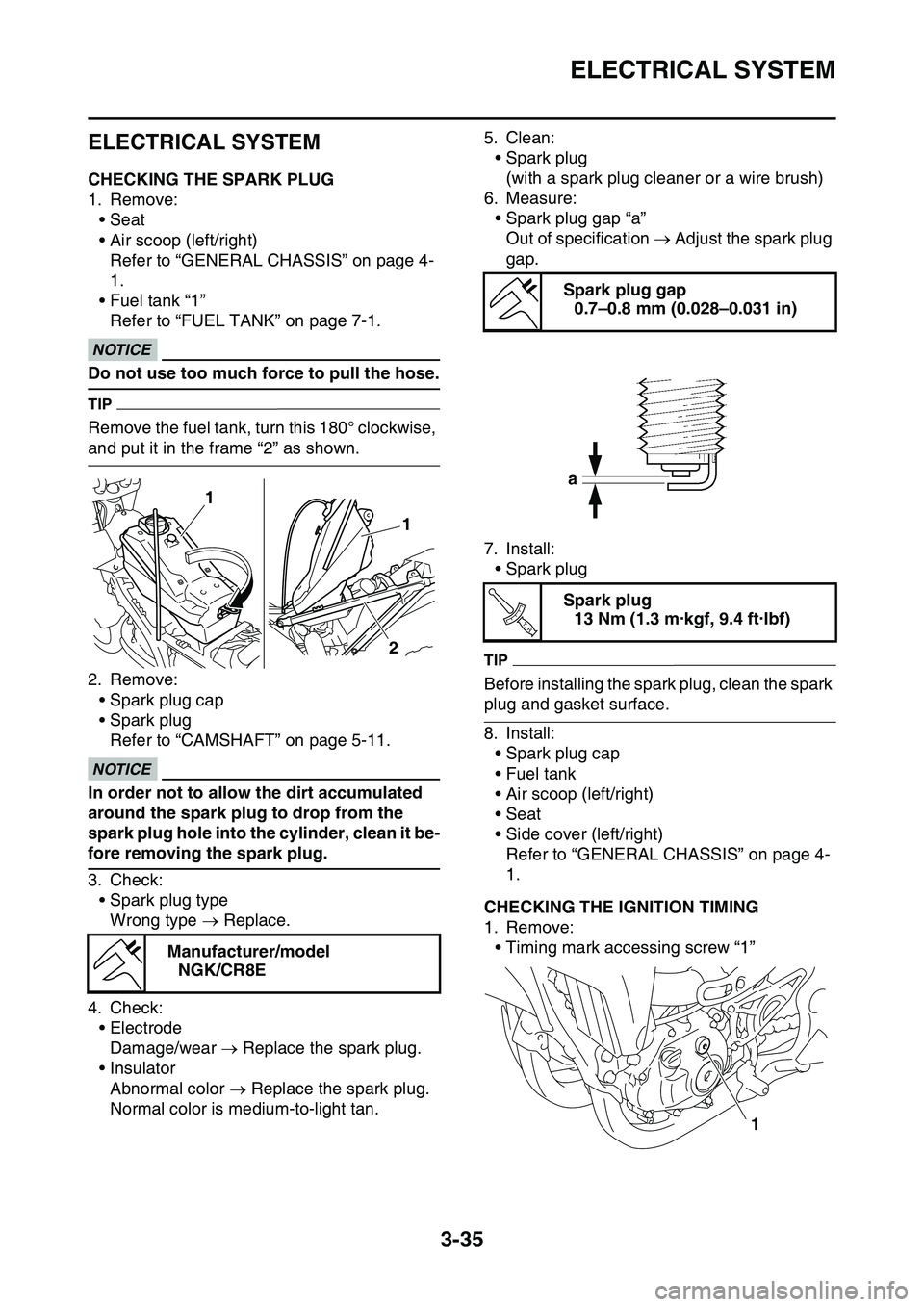

EAS1SL1115CHECKING THE SPARK PLUG

1. Remove:

• Seat

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank “1”

Refer to “FUEL TANK” on page 7-1.ECA1DX1001

NOTICE

Do not use too much force to pull the hose.

TIP

Remove the fuel tank, turn this 180° clockwise,

and put it in the frame “2” as shown.

2. Remove:

• Spark plug cap

• Spark plug

Refer to “CAMSHAFT” on page 5-11.ECA13330

NOTICE

In order not to allow the dirt accumulated

around the spark plug to drop from the

spark plug hole into the cylinder, clean it be

-

fore removing the spark plug.

3. Check:

• Spark plug type

Wrong type Replace.

4. Check:

• Electrode

Damage/wear Replace the spark plug.

• Insulator

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.

5. Clean:

• Spark plug

(with a spark plug cleaner or a wire brush)

6. Measure:

• Spark plug gap “a”

Out of specification Adjust the spark plug

gap.

7. Install:

• Spark plug

TIP

Before installing the spark plug, clean the spark

plug and gasket surface.

8. Install:

• Spark plug cap

• Fuel tank

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1116CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw “1”Manufacturer/model

NGK/CR8E

1

1

2

Spark plug gap

0.7–0.8 mm (0.028–0.031 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)T R..

1

Page 124 of 360

ELECTRICAL SYSTEM

3-36

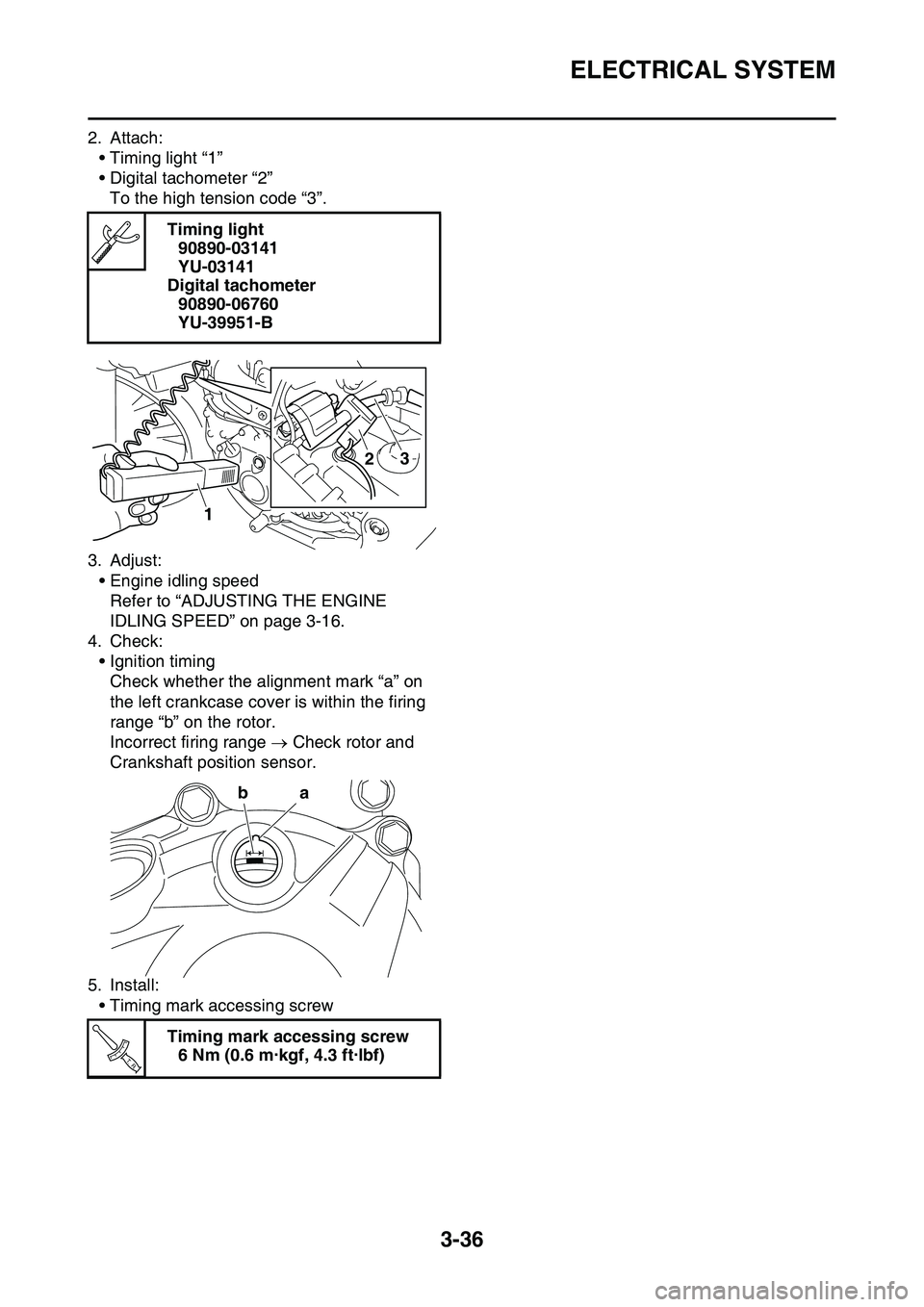

2. Attach:

• Timing light “1”

• Digital tachometer “2”

To the high tension code “3”.

3. Adjust:

• Engine idling speed

Refer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-16.

4. Check:

• Ignition timing

Check whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install:

• Timing mark accessing screw

Timing light

90890-03141

YU-03141

Digital tachometer

90890-06760

YU-39951-B

Timing mark accessing screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

a

b

T R..