YAMAHA YZ450F 2014 Owners Manual

Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 251 of 360

OIL PUMP AND BALANCER GEAR

5-56

EAS1SL1266REMOVING THE BALANCER

1. Straighten the lock washer tab.

2. Loosen:

• Balancer nut “1”

• Primary drive gear nut “2”

• Balancer weight gear nut “3”

TIP

Place an aluminum plate “a” between the teeth

of the balancer drive gear “4” and balancer

weight gear “5”.

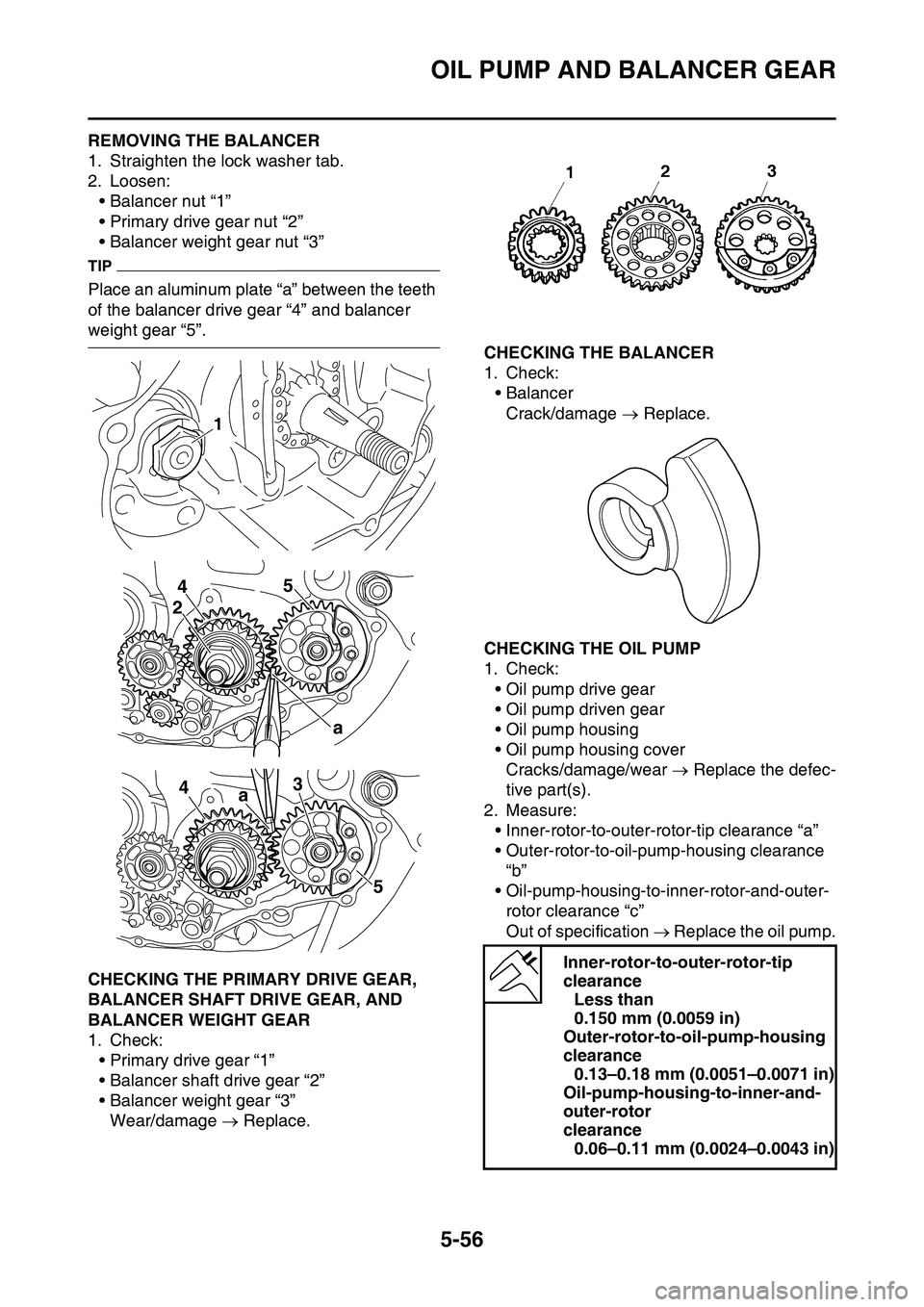

EAS1SL1267CHECKING THE PRIMARY DRIVE GEAR,

BALANCER SHAFT DRIVE GEAR, AND

BALANCER WEIGHT GEAR

1. Check:

• Primary drive gear “1”

• Balancer shaft drive gear “2”

• Balancer weight gear “3”

Wear/damage Replace.

EAS1SL1268CHECKING THE BALANCER

1. Check:

•Balancer

Crack/damage Replace.

EAS1SL1269CHECKING THE OIL PUMP

1. Check:

• Oil pump drive gear

• Oil pump driven gear

• Oil pump housing

• Oil pump housing cover

Cracks/damage/wear Replace the defec-

tive part(s).

2. Measure:

• Inner-rotor-to-outer-rotor-tip clearance “a”

• Outer-rotor-to-oil-pump-housing clearance

“b”

• Oil-pump-housing-to-inner-rotor-and-outer-

rotor clearance “c”

Out of specification Replace the oil pump.

1

5

4

2

a

43

a

5

Inner-rotor-to-outer-rotor-tip

clearance

Less than

0.150 mm (0.0059 in)

Outer-rotor-to-oil-pump-housing

clearance

0.13–0.18 mm (0.0051–0.0071 in)

Oil-pump-housing-to-inner-and-

outer-rotor

clearance

0.06–0.11 mm (0.0024–0.0043 in)

Page 252 of 360

OIL PUMP AND BALANCER GEAR

5-57

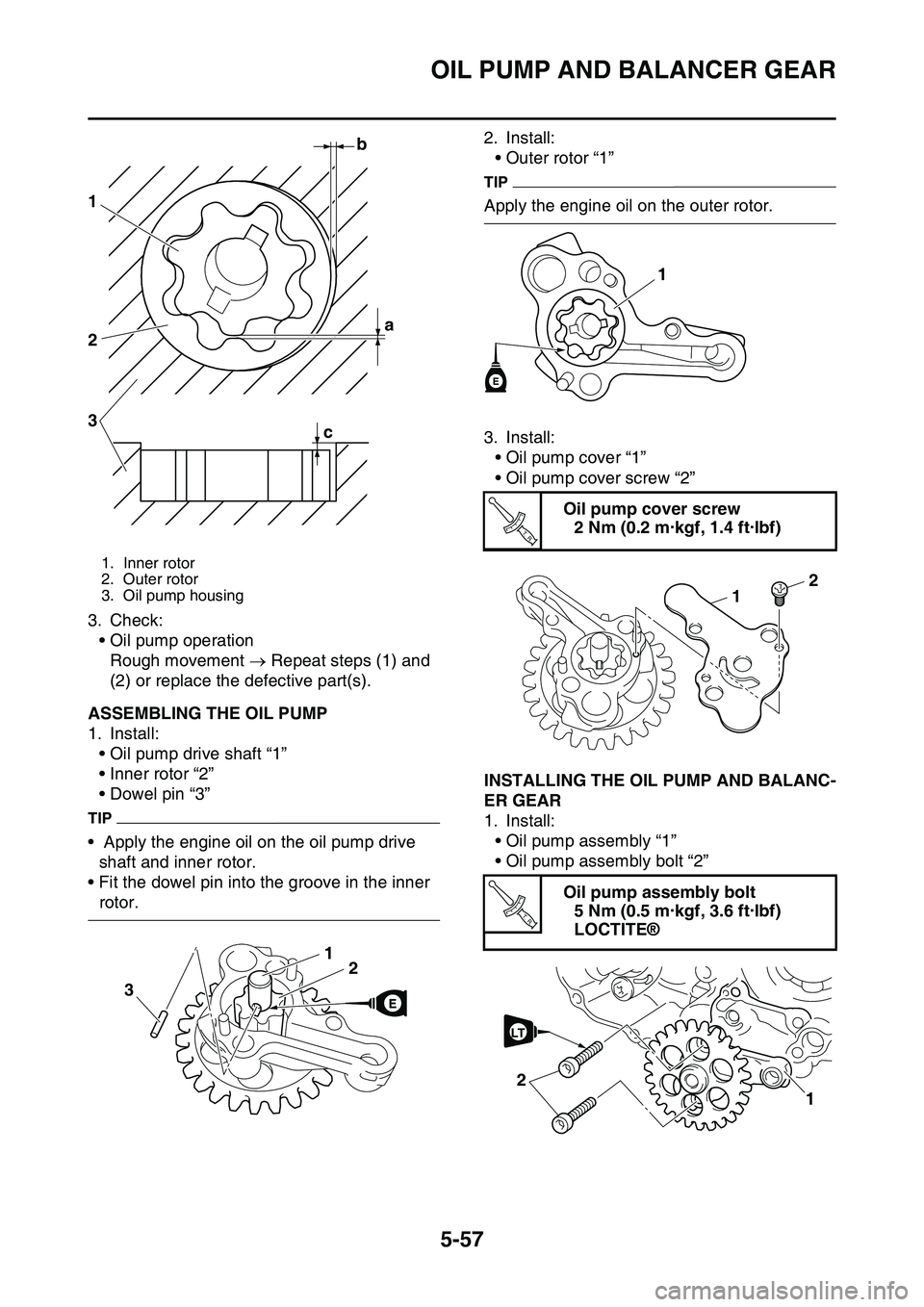

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS1SL1270ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.

2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2”

EAS1SL1271INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA1DX1023

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

21

3

Oil pump cover screw

2 Nm (0.2 m·kgf, 1.4 ft·lbf)

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

1

E

T R..

2

1

T R..

1

2

LT

Page 253 of 360

OIL PUMP AND BALANCER GEAR

5-58

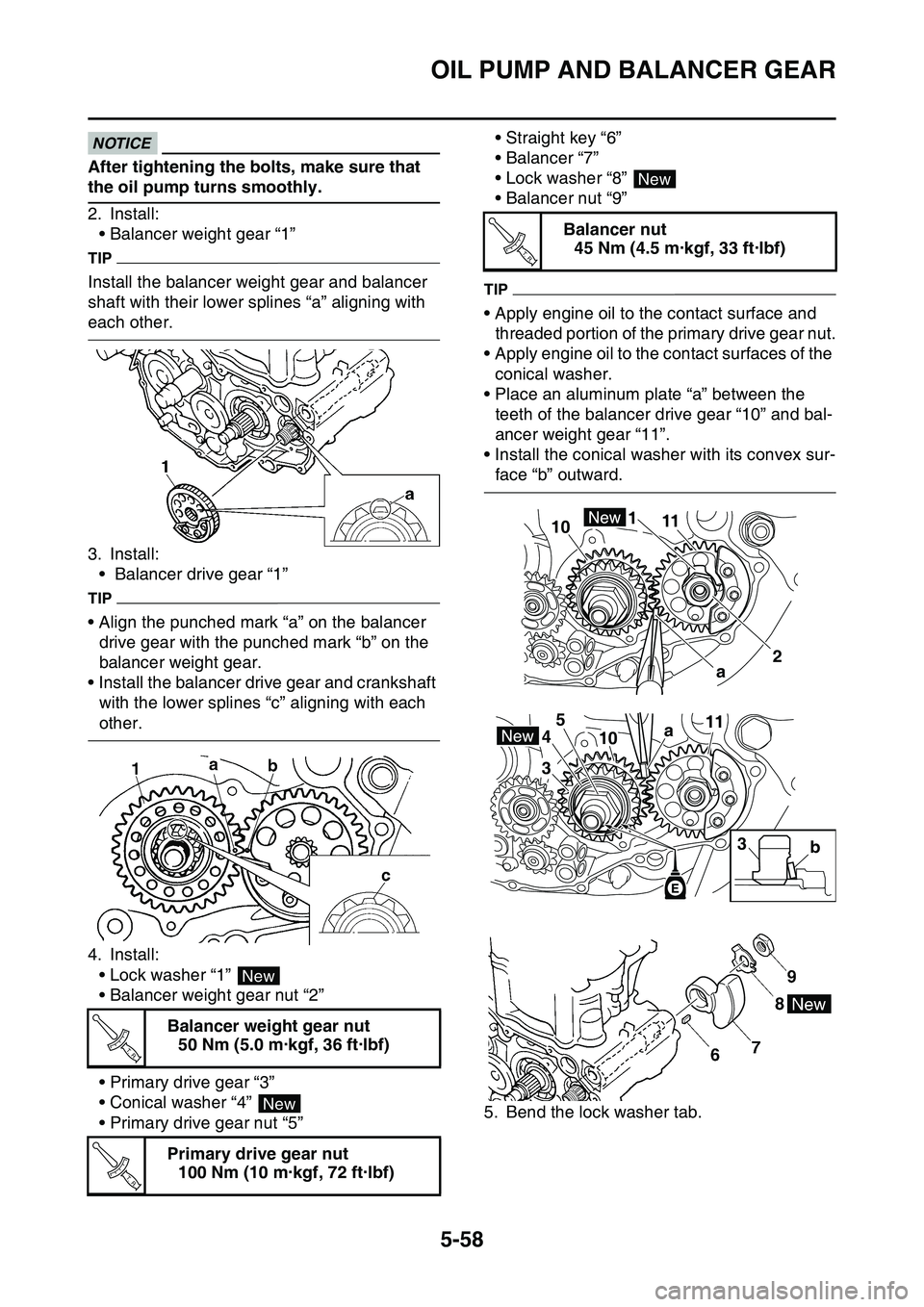

NOTICE

After tightening the bolts, make sure that

the oil pump turns smoothly.

2. Install:

• Balancer weight gear “1”

TIP

Install the balancer weight gear and balancer

shaft with their lower splines “a” aligning with

each other.

3. Install:

• Balancer drive gear “1”

TIP

• Align the punched mark “a” on the balancer

drive gear with the punched mark “b” on the

balancer weight gear.

• Install the balancer drive gear and crankshaft

with the lower splines “c” aligning with each

other.

4. Install:

• Lock washer “1”

• Balancer weight gear nut “2”

• Primary drive gear “3”

• Conical washer “4”

• Primary drive gear nut “5”

• Straight key “6”

•Balancer “7”

• Lock washer “8”

• Balancer nut “9”

TIP

• Apply engine oil to the contact surface and

threaded portion of the primary drive gear nut.

• Apply engine oil to the contact surfaces of the

conical washer.

• Place an aluminum plate “a” between the

teeth of the balancer drive gear “10” and bal

-

ancer weight gear “11”.

• Install the conical washer with its convex sur-

face “b” outward.

5. Bend the lock washer tab.

Balancer weight gear nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

Primary drive gear nut

100 Nm (10 m·kgf, 72 ft·lbf)

New

T R..

New

T R..

Balancer nut

45 Nm (4.5 m·kgf, 33 ft·lbf)

New

T R..

1

2 11

10

a

3 45

1011

a

b

3

Page 254 of 360

AC MAGNETO

5-59

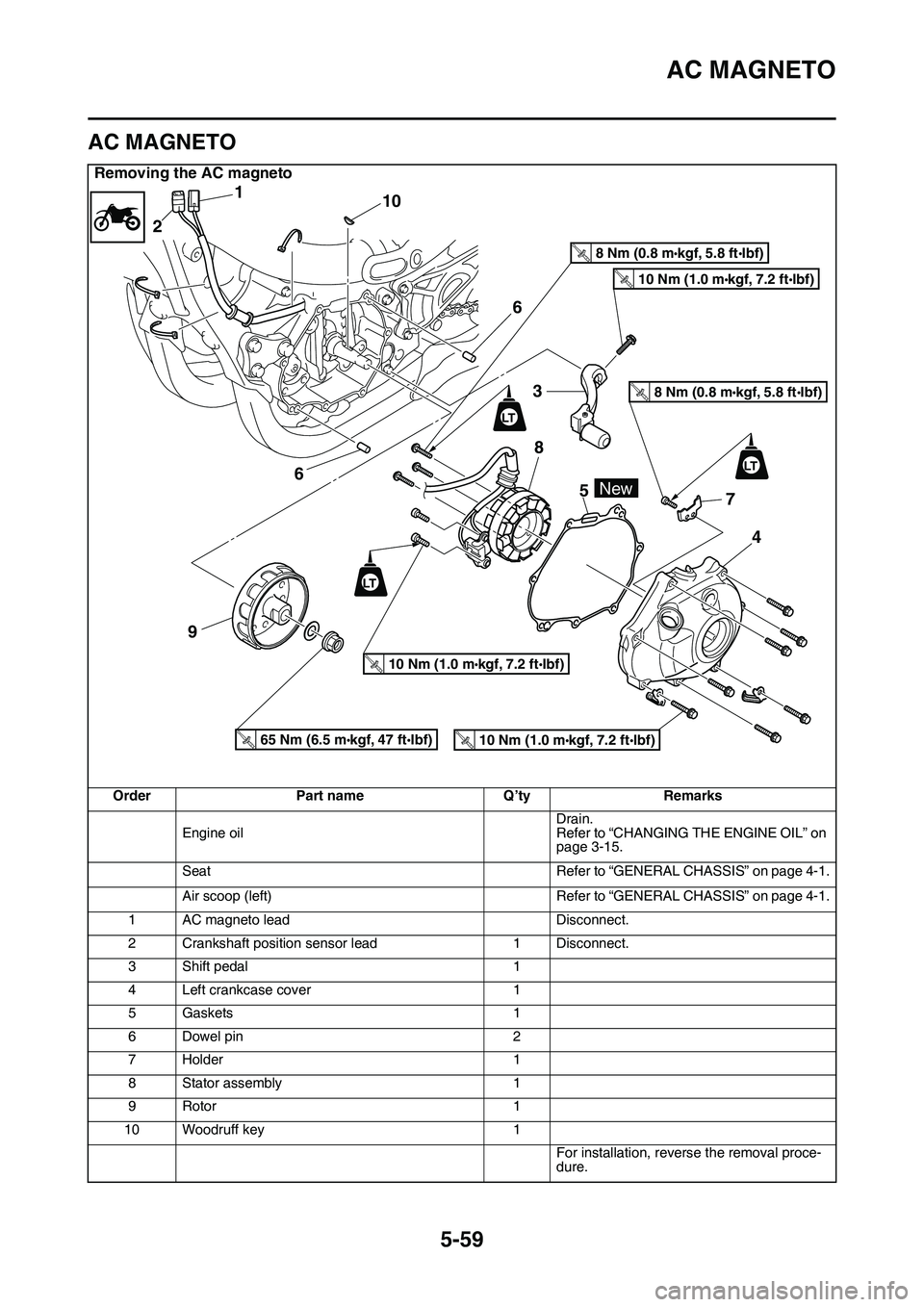

EAS1SL1272

AC MAGNETO

Removing the AC magneto

OrderPart nameQ’tyRemarks

Engine oilDrain.Refer to “CHANGING THE ENGINE OIL” on page 3-15.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left)Refer to “GENERAL CHASSIS” on page 4-1.

1AC magneto leadDisconnect.

2Crankshaft position sensor lead1Disconnect.

3Shift pedal1

4Left crankcase cover1

5Gaskets1

6Dowel pin2

7Holder1

8Stator assembly1

9Rotor1

10Woodruff key1

For installation, reverse the removal proce-dure.

110

2

4 7 5 8 3

96

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

65 Nm (6.5 mkgf, 47 ftIbf)T.R.

New

LT

6

LT

LT

Page 255 of 360

AC MAGNETO

5-60

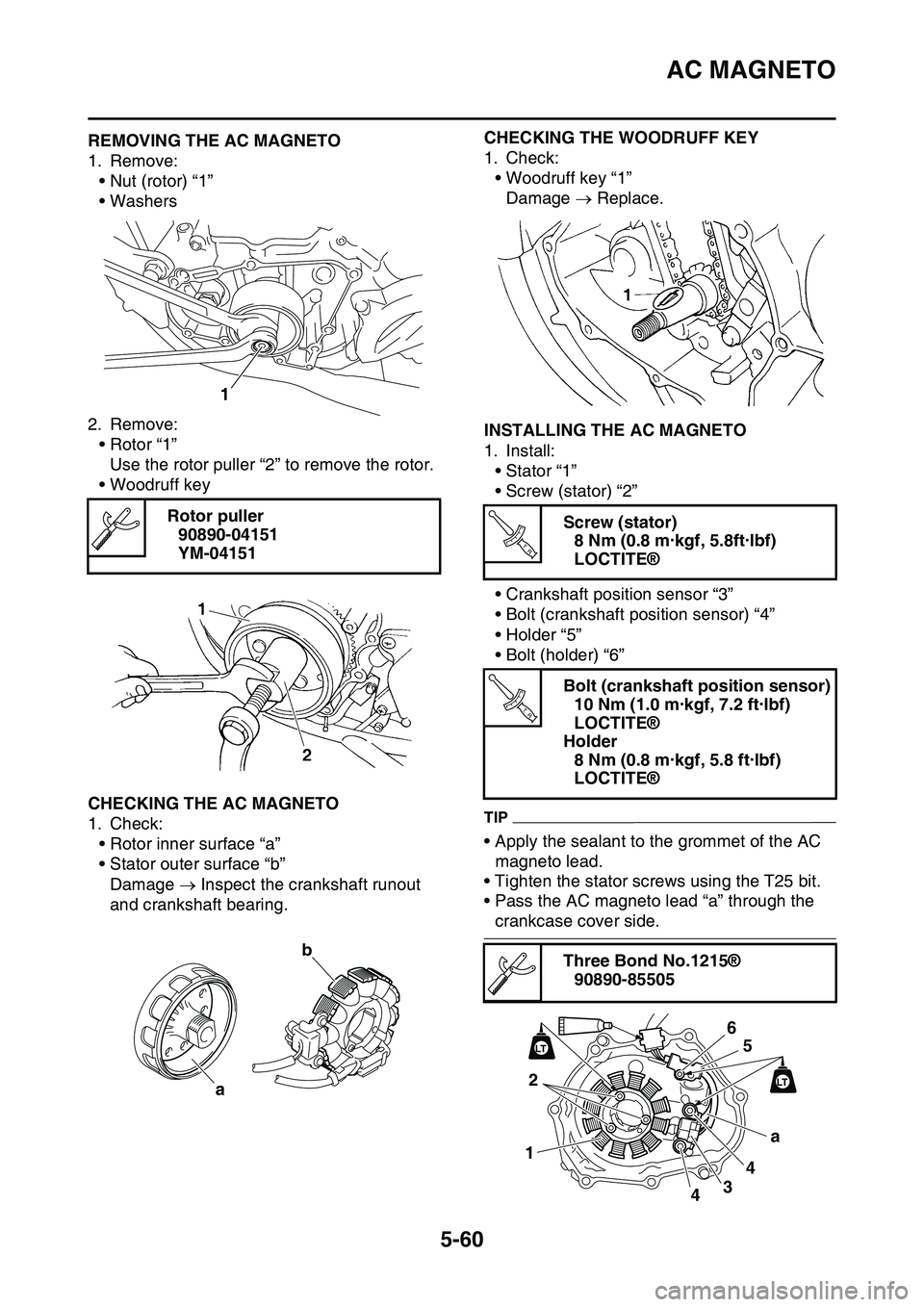

EAS1SL1273REMOVING THE AC MAGNETO

1. Remove:

• Nut (rotor) “1”

• Washers

2. Remove:

• Rotor “1”

Use the rotor puller “2” to remove the rotor.

• Woodruff key

EAS1SL1274CHECKING THE AC MAGNETO

1. Check:

• Rotor inner surface “a”

• Stator outer surface “b”

Damage Inspect the crankshaft runout

and crankshaft bearing.

EAS1SL1275

CHECKING THE WOODRUFF KEY

1. Check:

• Woodruff key “1”

Damage Replace.

EAS1SL1276INSTALLING THE AC MAGNETO

1. Install:

• Stator “1”

• Screw (stator) “2”

• Crankshaft position sensor “3”

• Bolt (crankshaft position sensor) “4”

• Holder “5”

• Bolt (holder) “6”

TIP

• Apply the sealant to the grommet of the AC

magneto lead.

• Tighten the stator screws using the T25 bit.

• Pass the AC magneto lead “a” through the

crankcase cover side.

Rotor puller

90890-04151

YM-04151

1

ab

Screw (stator)

8 Nm (0.8 m·kgf, 5.8ft·lbf)

LOCTITE®

Bolt (crankshaft position sensor)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Holder

8 Nm (0.8 m·kgf, 5.8 ft·lbf)

LOCTITE®

Three Bond No.1215®

90890-85505

T R..

T R..

26

5

4

3

4a

1

LT

LT

Page 256 of 360

AC MAGNETO

5-61

2. Install:

• Woodruff key “1”

• Rotor “2”

TIP

• Clean the contact surfaces of the tapered por-

tions of the crankshaft and rotor.

• When installing the woodruff key, make sure

that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the rotor, align the keyway “c”

of the rotor with the woodruff key.

3. Install:

• Washers

• Nut (rotor) “1”

4. Install:

• Dowel pin “1”

• Gasket (left crankcase cover) “2”

• Left crankcase cover “3”

• Lead holder “4”

• Bolt (left crankcase cover) “5”

TIP

Tighten the bolts in stages and in a crisscross

pattern.

5. Connect:

• AC magneto lead

Refer to “CABLE ROUTING DIAGRAM” on

page 2-33.

Nut (rotor)

65 Nm (6.5 m·kgf, 47 ft·lbf)

Bolt (left crankcase cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

b11

c

2 a

T R..

1

New

T R..

1

1

2

3

5

5

5

5

4

45

Page 257 of 360

CRANKCASE

5-62

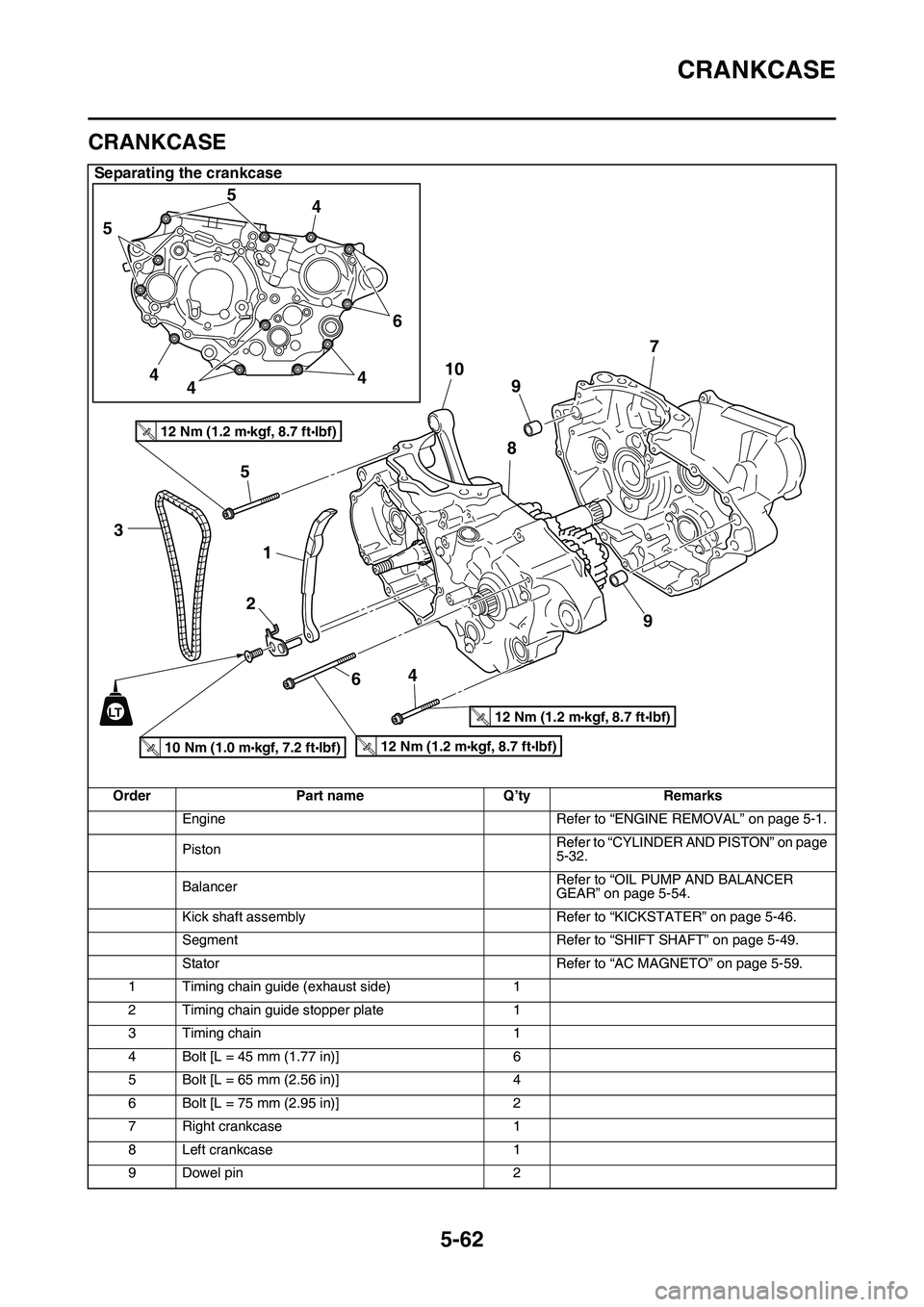

EAS1SL1277

CRANKCASE

Separating the crankcase

OrderPart nameQ’tyRemarks

EngineRefer to “ENGINE REMOVAL” on page 5-1.

PistonRefer to “CYLINDER AND PISTON” on page 5-32.

BalancerRefer to “OIL PUMP AND BALANCER GEAR” on page 5-54.

Kick shaft assemblyRefer to “KICKSTATER” on page 5-46.

SegmentRefer to “SHIFT SHAFT” on page 5-49.

StatorRefer to “AC MAGNETO” on page 5-59.

1Timing chain guide (exhaust side)1

2Timing chain guide stopper plate1

3Timing chain1

4Bolt [L = 45 mm (1.77 in)]6

5Bolt [L = 65 mm (2.56 in)]4

6Bolt [L = 75 mm (2.95 in)]2

7Right crankcase1

8Left crankcase1

9Dowel pin2

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

3

1 5

2

6410 55

4

4

446

97

8

9

LT

Page 258 of 360

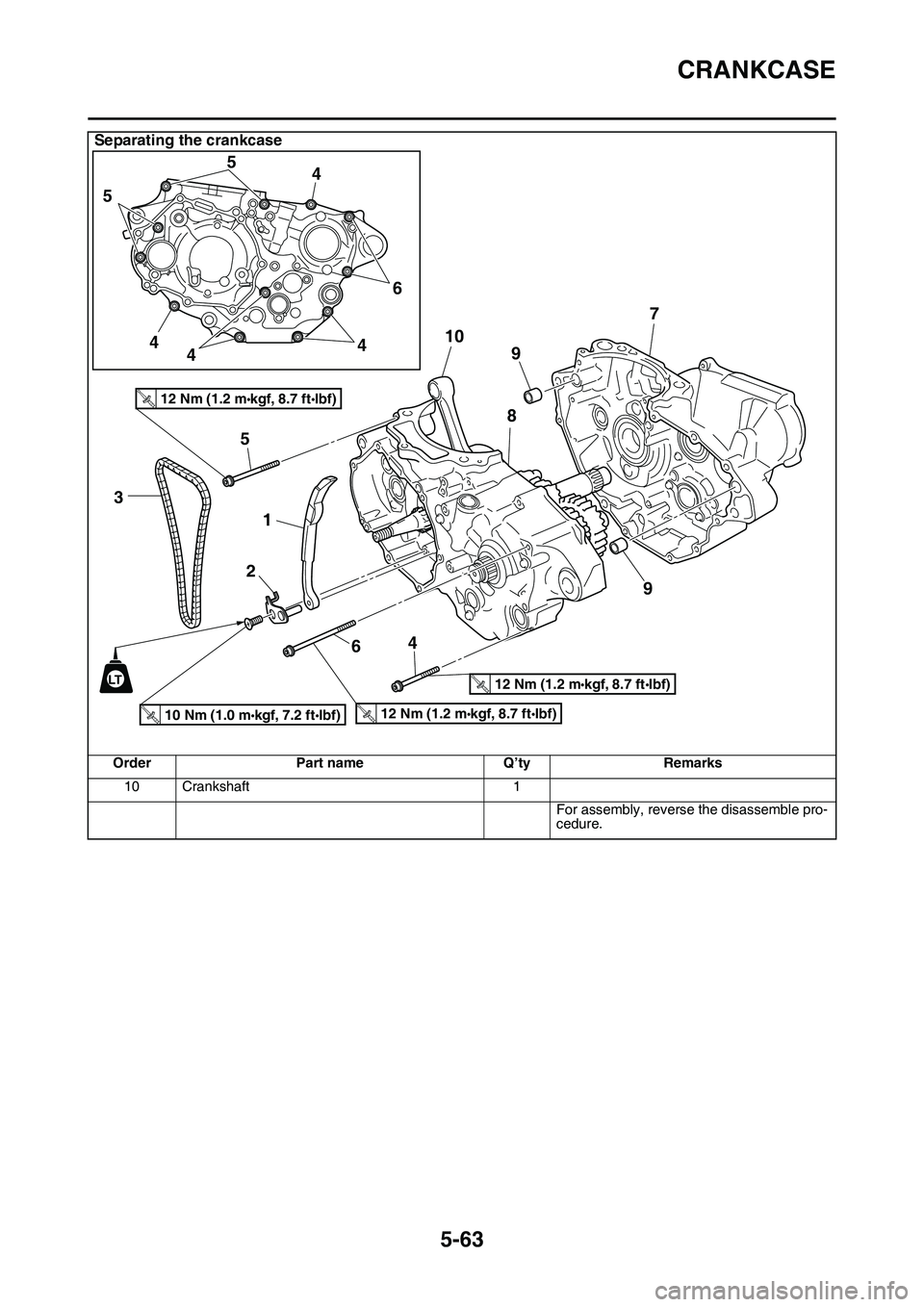

CRANKCASE

5-63

10Crankshaft1

For assembly, reverse the disassemble pro-cedure.

Separating the crankcase

Order Part name Q’ty Remarks

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

12 Nm (1.2 m•kgf, 8.7 ft•Ibf)T.R.

3

1 5

2

6410 55

4

4

446

97

8

9

LT

Page 259 of 360

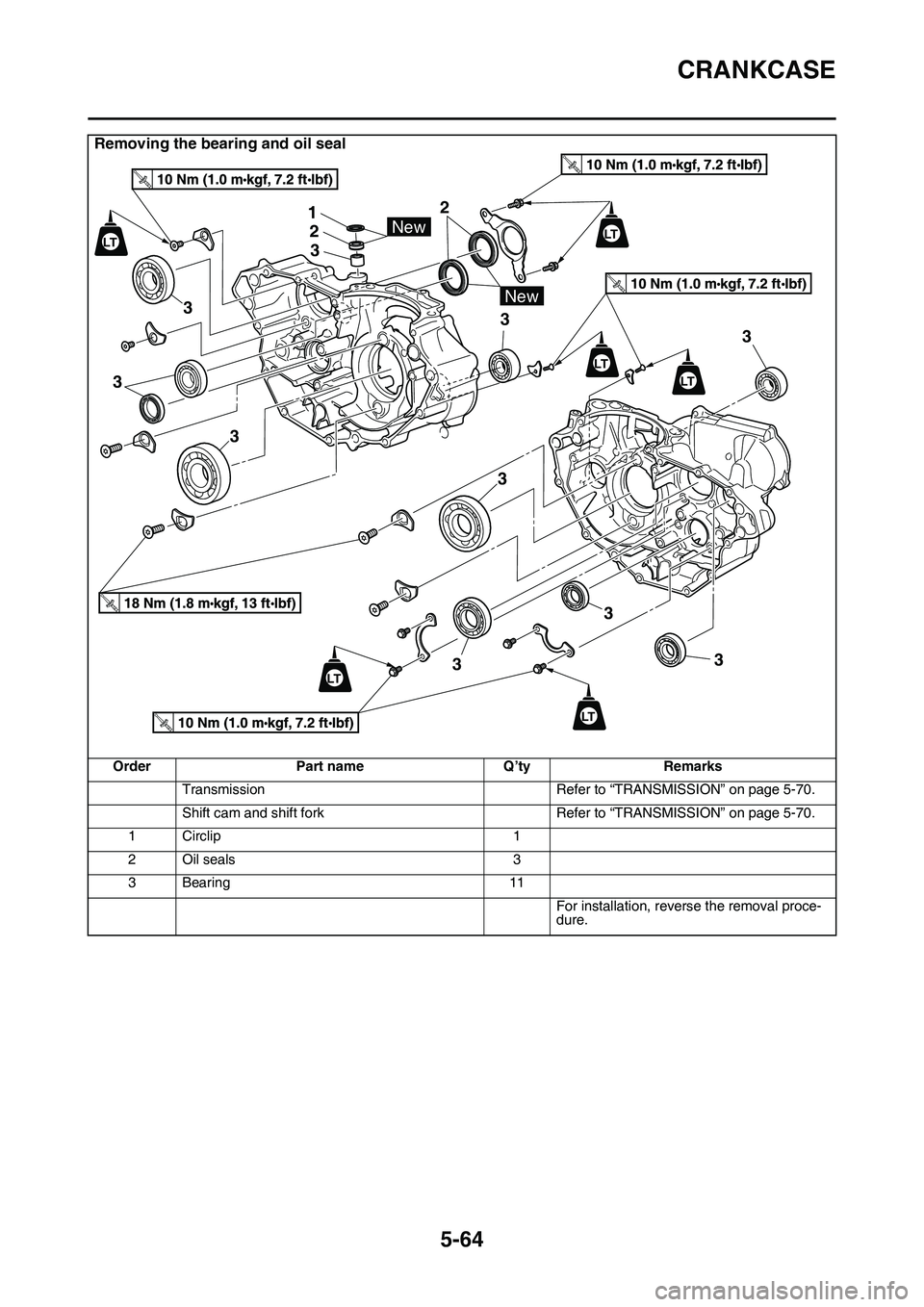

CRANKCASE

5-64

Removing the bearing and oil seal

OrderPart nameQ’tyRemarks

TransmissionRefer to “TRANSMISSION” on page 5-70.

Shift cam and shift forkRefer to “TRANSMISSION” on page 5-70.

1Circlip1

2Oil seals3

3Bearing11

For installation, reverse the removal proce-dure.

LT

LT

LT

LT

LT

1

22

3

3

33

3

3

3 3

33

New

NewLT

Page 260 of 360

CRANKCASE

5-65

EAS1SL1278DISASSEMBLING THE CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1.”

TIP

• Place the crankcase with its left side down-

ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA33DD041

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force.

c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1279REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by

pressing its inner race.

• Do not use the removed bearing.

EAS1SL1280CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:

• Timing chain

Stiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check:

• Timing chain guide

Damage/wear Replace

EAS1SL1281CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

1

a