warning YAMAHA YZ450F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ450F, Model: YAMAHA YZ450F 2016Pages: 362, PDF Size: 10.49 MB

Page 118 of 362

CHASSIS

3-34

EASB111106CHECKING THE TIRES

1. Measure:

• Tire pressure

Out of specification Regulate.

TIP

• Check the tire while it is cold.

• Loose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

• If the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Cor-

rect the tire position.

EASB111107CHECKING AND TIGHTENING THE

SPOKES

1. Check:

• Spokes

Bend/damage Replace.

Loose Tighten.

TIP

A tight spoke will emit a clear, ringing tone; a

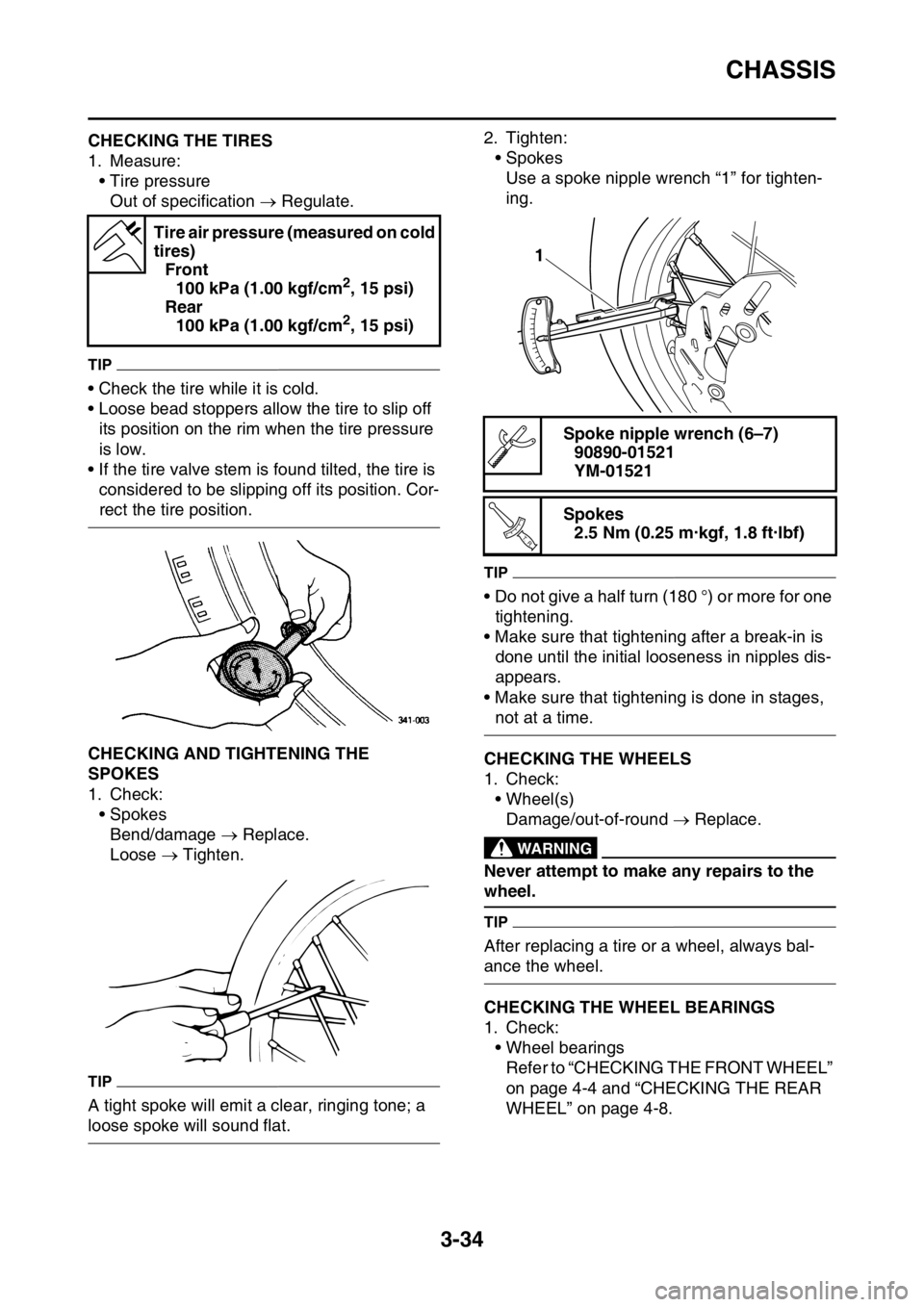

loose spoke will sound flat.2. Tighten:

• Spokes

Use a spoke nipple wrench “1” for tighten-

ing.

TIP

• Do not give a half turn (180 °) or more for one

tightening.

• Make sure that tightening after a break-in is

done until the initial looseness in nipples dis-

appears.

• Make sure that tightening is done in stages,

not at a time.

EASB111108CHECKING THE WHEELS

1. Check:

• Wheel(s)

Damage/out-of-round Replace.

EWA

WARNING

Never attempt to make any repairs to the

wheel.

TIP

After replacing a tire or a wheel, always bal-

ance the wheel.

EASB111109CHECKING THE WHEEL BEARINGS

1. Check:

• Wheel bearings

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4 and “CHECKING THE REAR

WHEEL” on page 4-8. Tire air pressure (measured on cold

tires)

Front

100 kPa (1.00 kgf/cm

2, 15 psi)

Rear

100 kPa (1.00 kgf/cm

2, 15 psi)

Spoke nipple wrench (6–7)

90890-01521

YM-01521

Spokes

2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

1

T R..

Page 119 of 362

CHASSIS

3-35

EASB111110CHECKING AND ADJUSTING THE STEER-

ING HEAD

1. Use a suitable stand to raise the front wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Steering head

Grasp the bottom of the front fork legs and

gently rock the front fork.

Blinding/looseness Adjust the steering

head.

3. Remove:

• Handlebar

Refer to “HANDLEBAR” on page 4-32.

• Upper bracket

Refer to “STEERING HEAD” on page 4-51.

4. Adjust:

• Steering head

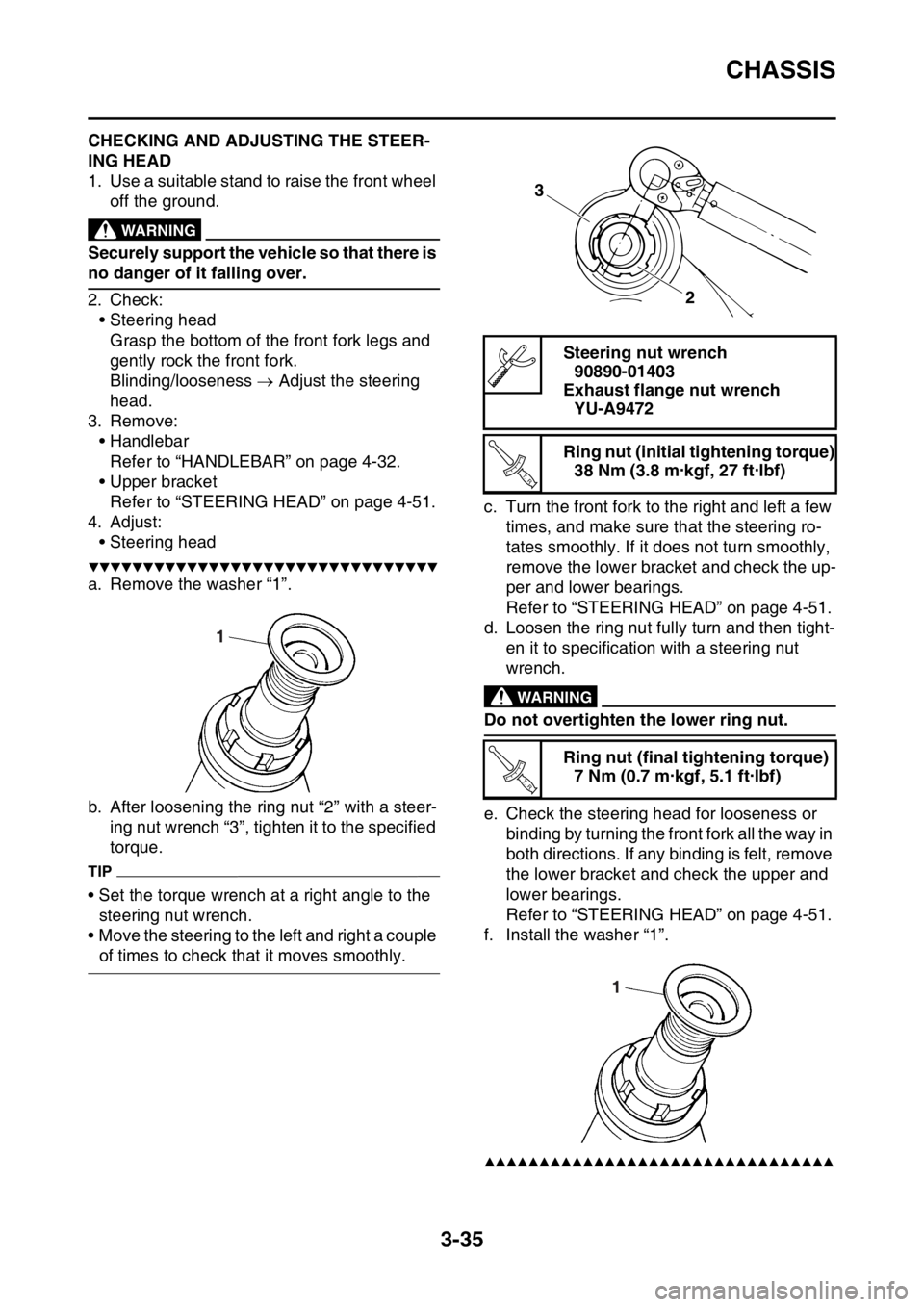

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the washer “1”.

b. After loosening the ring nut “2” with a steer-

ing nut wrench “3”, tighten it to the specified

torque.

TIP

• Set the torque wrench at a right angle to the

steering nut wrench.

• Move the steering to the left and right a couple

of times to check that it moves smoothly.c. Turn the front fork to the right and left a few

times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 4-51.

d. Loosen the ring nut fully turn and then tight-

en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or

binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 4-51.

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

1

Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

Ring nut (initial tightening torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

3

2

T R..

T R..

1

Page 128 of 362

FRONT WHEEL

4-4

EASB111122REMOVING THE FRONT WHEEL

1. Use a suitable stand to raise the front wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Front wheel

EASB111123CHECKING THE FRONT WHEEL

1. Check:

• Front wheel axle

Roll the front wheel axle on a flat surface.

Bends Replace.

EWA

WARNING

Do not attempt to straighten a bent wheel

axle.

2. Check:

•Tire(s)

• Front wheel

Damage/wear Replace.

Refer to “CHECKING THE TIRES” on page

3-34 and “CHECKING THE WHEELS” on

page 3-34.

3. Check:

• Spokes

Bend/damage Replace.

Loose Tighten.

Tap the spokes with a screwdriver.

TIP

A tight spoke will emit a clear, ringing tone; a

loose spoke will sound flat.

4. Tighten:

• Spokes

Refer to “CHECKING AND TIGHTENING

THE SPOKES” on page 3-34.

TIP

After tightening the spokes, measure the wheel

runout.

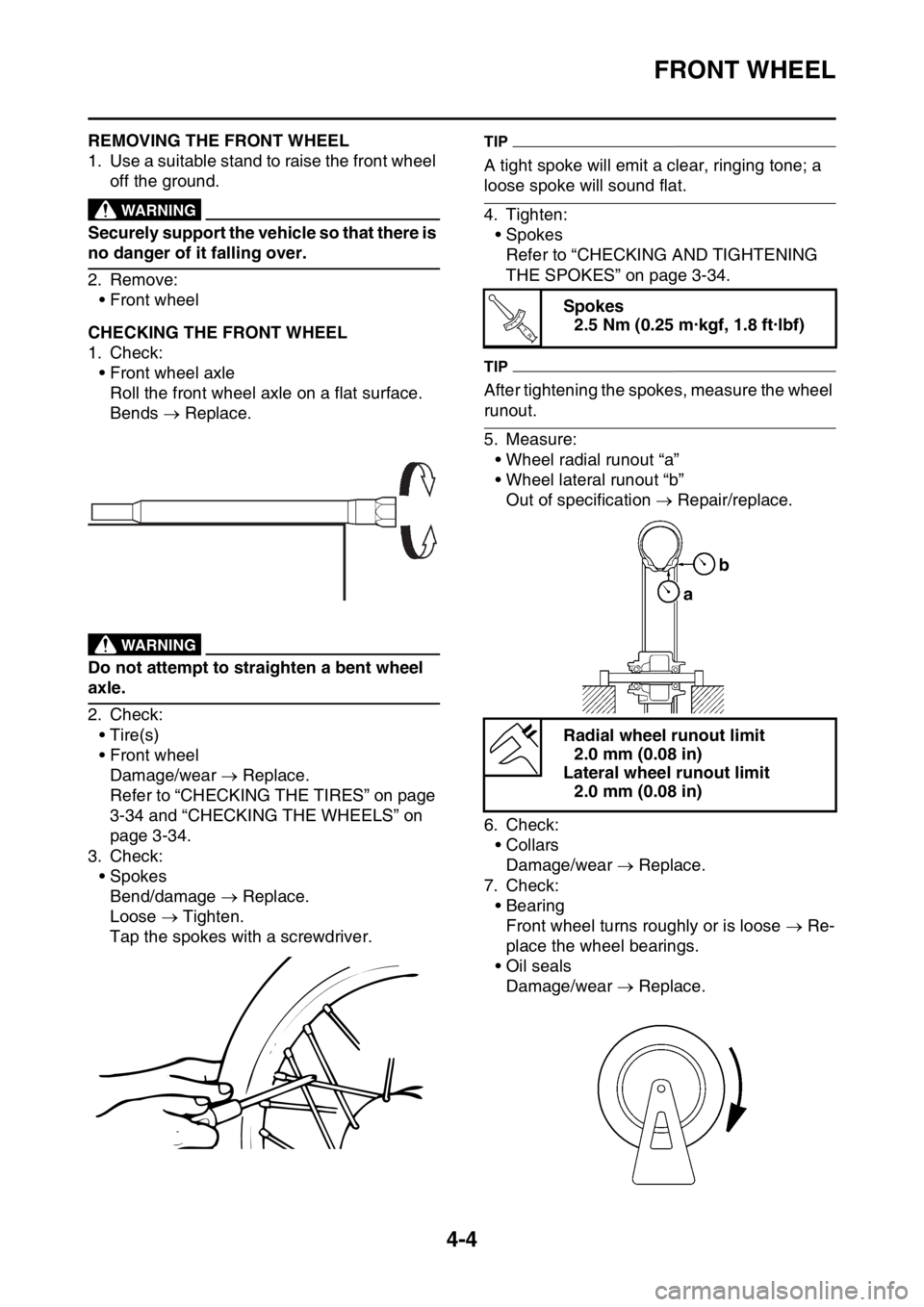

5. Measure:

• Wheel radial runout “a”

• Wheel lateral runout “b”

Out of specification Repair/replace.

6. Check:

•Collars

Damage/wear Replace.

7. Check:

• Bearing

Front wheel turns roughly or is loose Re-

place the wheel bearings.

• Oil seals

Damage/wear Replace.

Spokes

2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Radial wheel runout limit

2.0 mm (0.08 in)

Lateral wheel runout limit

2.0 mm (0.08 in)

T R..

ab

Page 132 of 362

REAR WHEEL

4-8

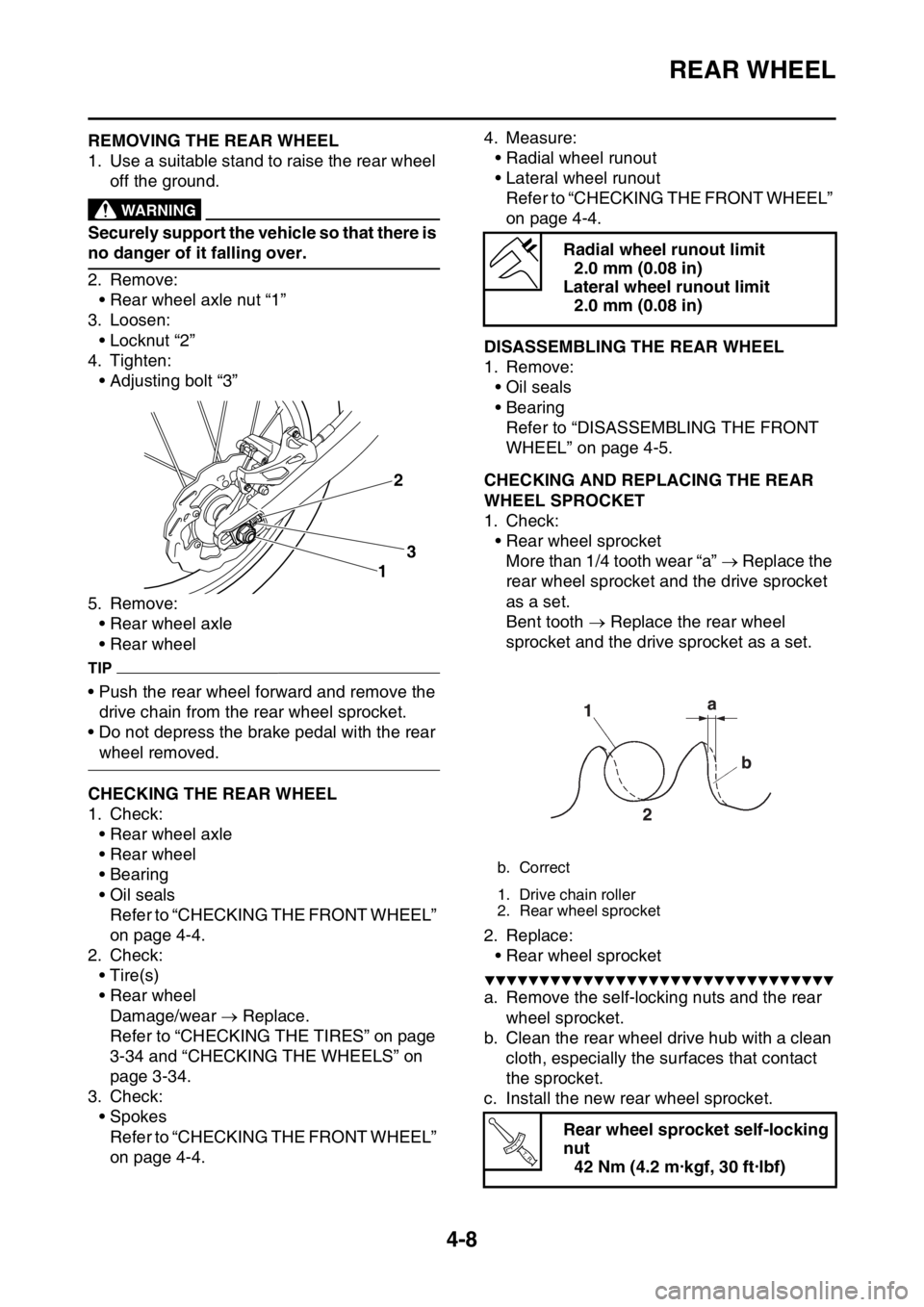

EASB111128REMOVING THE REAR WHEEL

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear wheel axle nut “1”

3. Loosen:

• Locknut “2”

4. Tighten:

• Adjusting bolt “3”

5. Remove:

• Rear wheel axle

• Rear wheel

TIP

• Push the rear wheel forward and remove the

drive chain from the rear wheel sprocket.

• Do not depress the brake pedal with the rear

wheel removed.

EASB111129CHECKING THE REAR WHEEL

1. Check:

• Rear wheel axle

• Rear wheel

• Bearing

• Oil seals

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.

2. Check:

•Tire(s)

• Rear wheel

Damage/wear Replace.

Refer to “CHECKING THE TIRES” on page

3-34 and “CHECKING THE WHEELS” on

page 3-34.

3. Check:

• Spokes

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.4. Measure:

• Radial wheel runout

• Lateral wheel runout

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.

EASB111130DISASSEMBLING THE REAR WHEEL

1. Remove:

• Oil seals

• Bearing

Refer to “DISASSEMBLING THE FRONT

WHEEL” on page 4-5.

EASB111131CHECKING AND REPLACING THE REAR

WHEEL SPROCKET

1. Check:

• Rear wheel sprocket

More than 1/4 tooth wear “a” Replace the

rear wheel sprocket and the drive sprocket

as a set.

Bent tooth Replace the rear wheel

sprocket and the drive sprocket as a set.

2. Replace:

• Rear wheel sprocket

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the self-locking nuts and the rear

wheel sprocket.

b. Clean the rear wheel drive hub with a clean

cloth, especially the surfaces that contact

the sprocket.

c. Install the new rear wheel sprocket.

3

12

Radial wheel runout limit

2.0 mm (0.08 in)

Lateral wheel runout limit

2.0 mm (0.08 in)

b. Correct

1. Drive chain roller

2. Rear wheel sprocket

Rear wheel sprocket self-locking

nut

42 Nm (4.2 m·kgf, 30 ft·lbf)

T R..

Page 140 of 362

FRONT BRAKE

4-16

EASB111135INTRODUCTIONEWA

WARNING

If you need to disassemble the disc brake

components, observe the following precau-

tions.

• Never disassemble the brake components

unless absolutely necessary.

• If there is any problem with connections

on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing brake

components.

• Use new brake fluid for cleaning the brake

components.

• Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to

let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING

THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

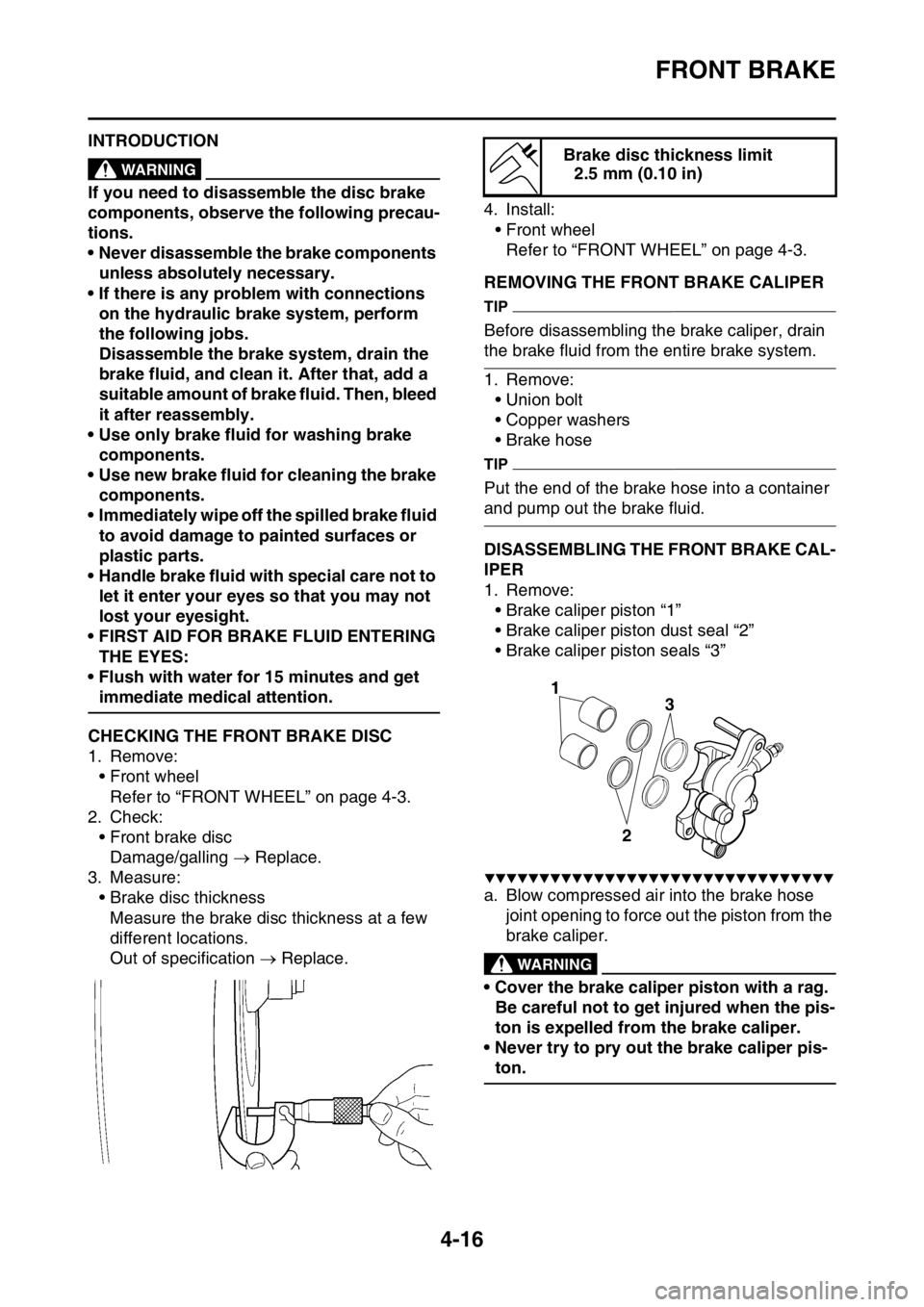

EASB111136CHECKING THE FRONT BRAKE DISC

1. Remove:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

2. Check:

• Front brake disc

Damage/galling Replace.

3. Measure:

• Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.4. Install:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

EASB111137REMOVING THE FRONT BRAKE CALIPER

TIP

Before disassembling the brake caliper, drain

the brake fluid from the entire brake system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

Put the end of the brake hose into a container

and pump out the brake fluid.

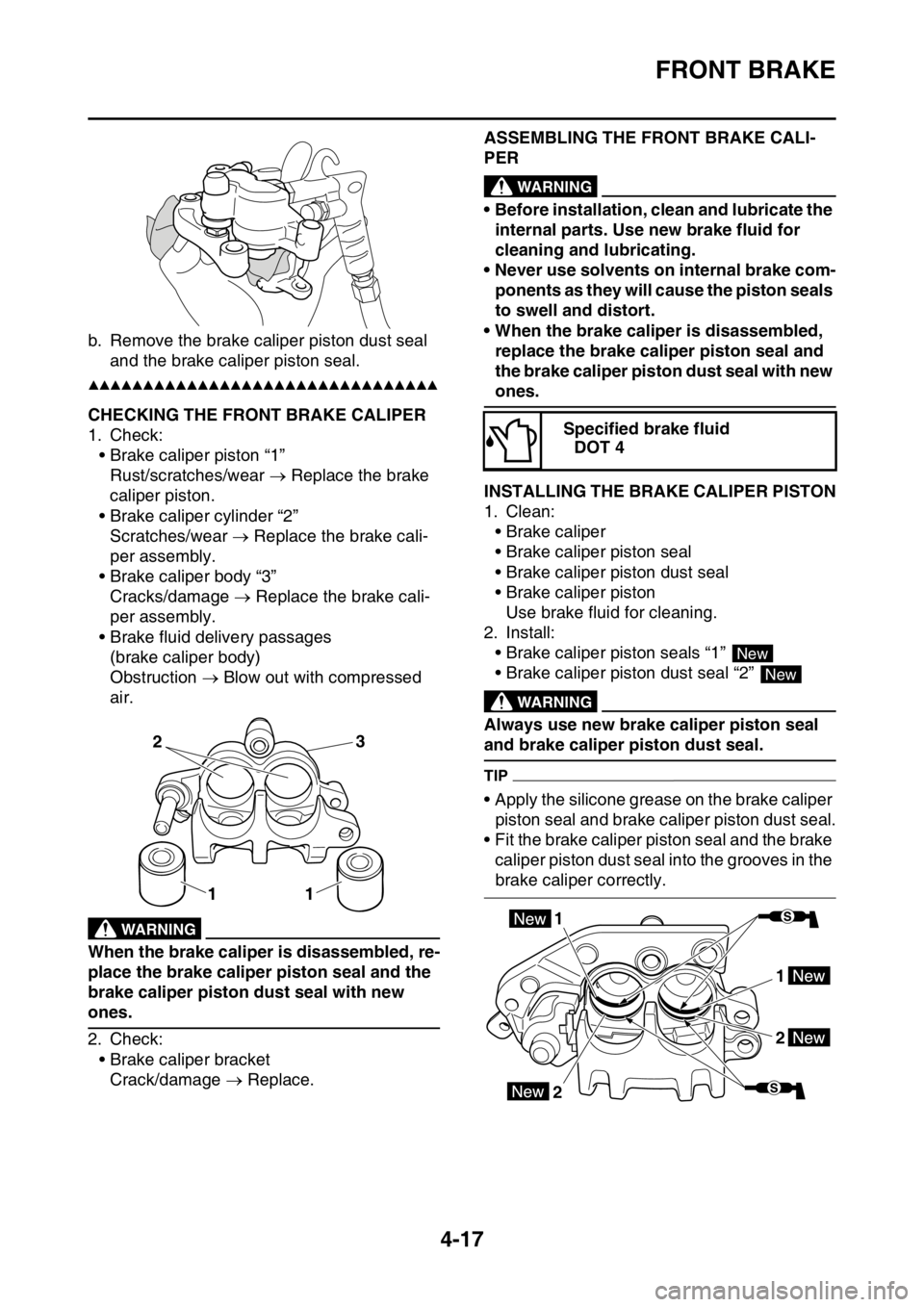

EASB111138DISASSEMBLING THE FRONT BRAKE CAL-

IPER

1. Remove:

• Brake caliper piston “1”

• Brake caliper piston dust seal “2”

• Brake caliper piston seals “3”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Blow compressed air into the brake hose

joint opening to force out the piston from the

brake caliper.

EWA

WARNING

• Cover the brake caliper piston with a rag.

Be careful not to get injured when the pis-

ton is expelled from the brake caliper.

• Never try to pry out the brake caliper pis-

ton.

Brake disc thickness limit

2.5 mm (0.10 in)

3

2

1

Page 141 of 362

FRONT BRAKE

4-17

b. Remove the brake caliper piston dust seal

and the brake caliper piston seal.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111139CHECKING THE FRONT BRAKE CALIPER

1. Check:

• Brake caliper piston “1”

Rust/scratches/wear Replace the brake

caliper piston.

• Brake caliper cylinder “2”

Scratches/wear Replace the brake cali-

per assembly.

• Brake caliper body “3”

Cracks/damage Replace the brake cali-

per assembly.

• Brake fluid delivery passages

(brake caliper body)

Obstruction Blow out with compressed

air.

EWA

WARNING

When the brake caliper is disassembled, re-

place the brake caliper piston seal and the

brake caliper piston dust seal with new

ones.

2. Check:

• Brake caliper bracket

Crack/damage Replace.

EASB111140

ASSEMBLING THE FRONT BRAKE CALI-

PER

EWA

WARNING

• Before installation, clean and lubricate the

internal parts. Use new brake fluid for

cleaning and lubricating.

• Never use solvents on internal brake com-

ponents as they will cause the piston seals

to swell and distort.

• When the brake caliper is disassembled,

replace the brake caliper piston seal and

the brake caliper piston dust seal with new

ones.

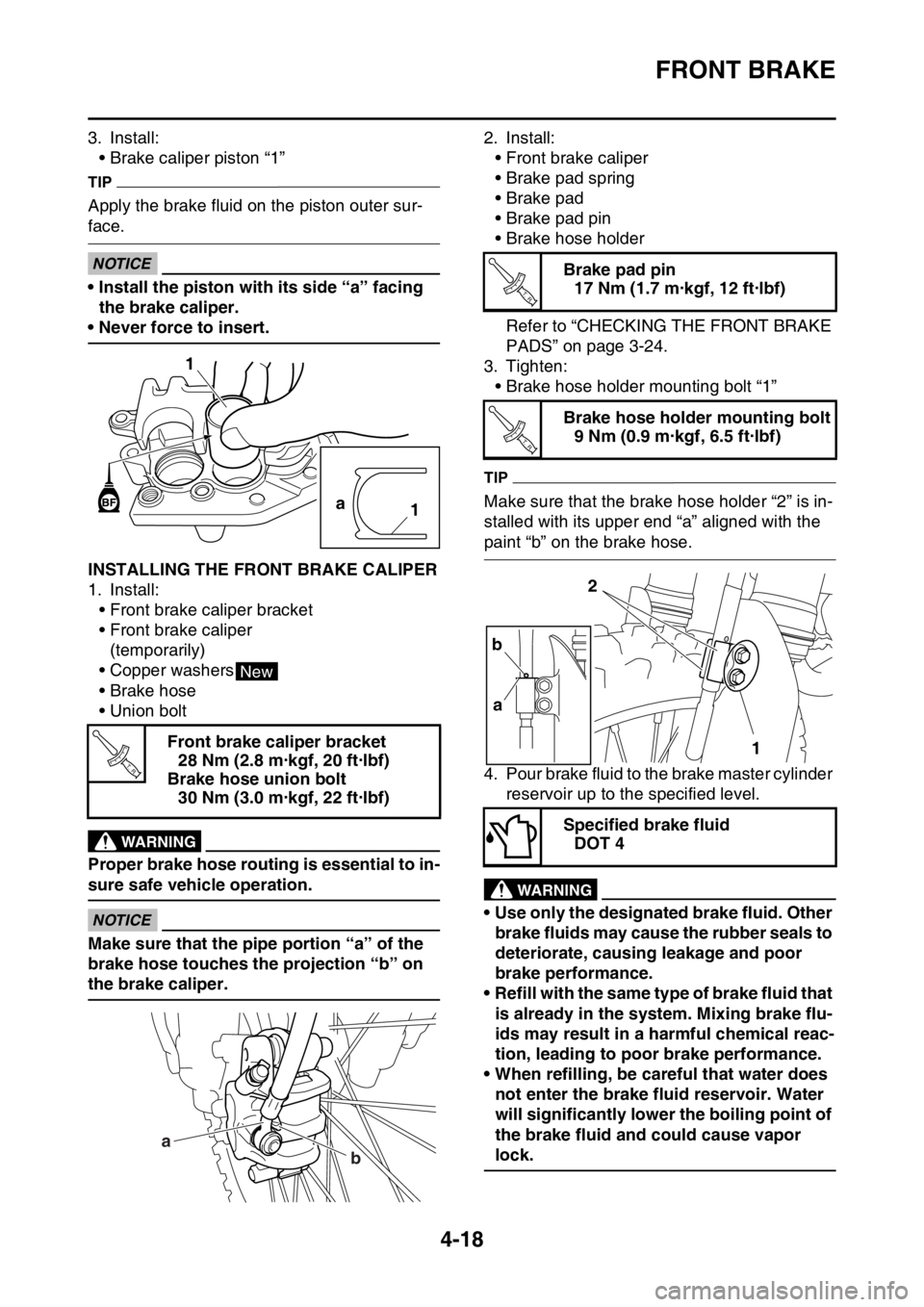

EASB111141INSTALLING THE BRAKE CALIPER PISTON

1. Clean:

• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper piston

Use brake fluid for cleaning.

2. Install:

• Brake caliper piston seals “1”

• Brake caliper piston dust seal “2”

EWA

WARNING

Always use new brake caliper piston seal

and brake caliper piston dust seal.

TIP

• Apply the silicone grease on the brake caliper

piston seal and brake caliper piston dust seal.

• Fit the brake caliper piston seal and the brake

caliper piston dust seal into the grooves in the

brake caliper correctly.

2

113

Specified brake fluid

DOT 4

New

New

1

1

22

Page 142 of 362

FRONT BRAKE

4-18

3. Install:

• Brake caliper piston “1”

TIP

Apply the brake fluid on the piston outer sur-

face.

ECA

NOTICE

• Install the piston with its side “a” facing

the brake caliper.

• Never force to insert.

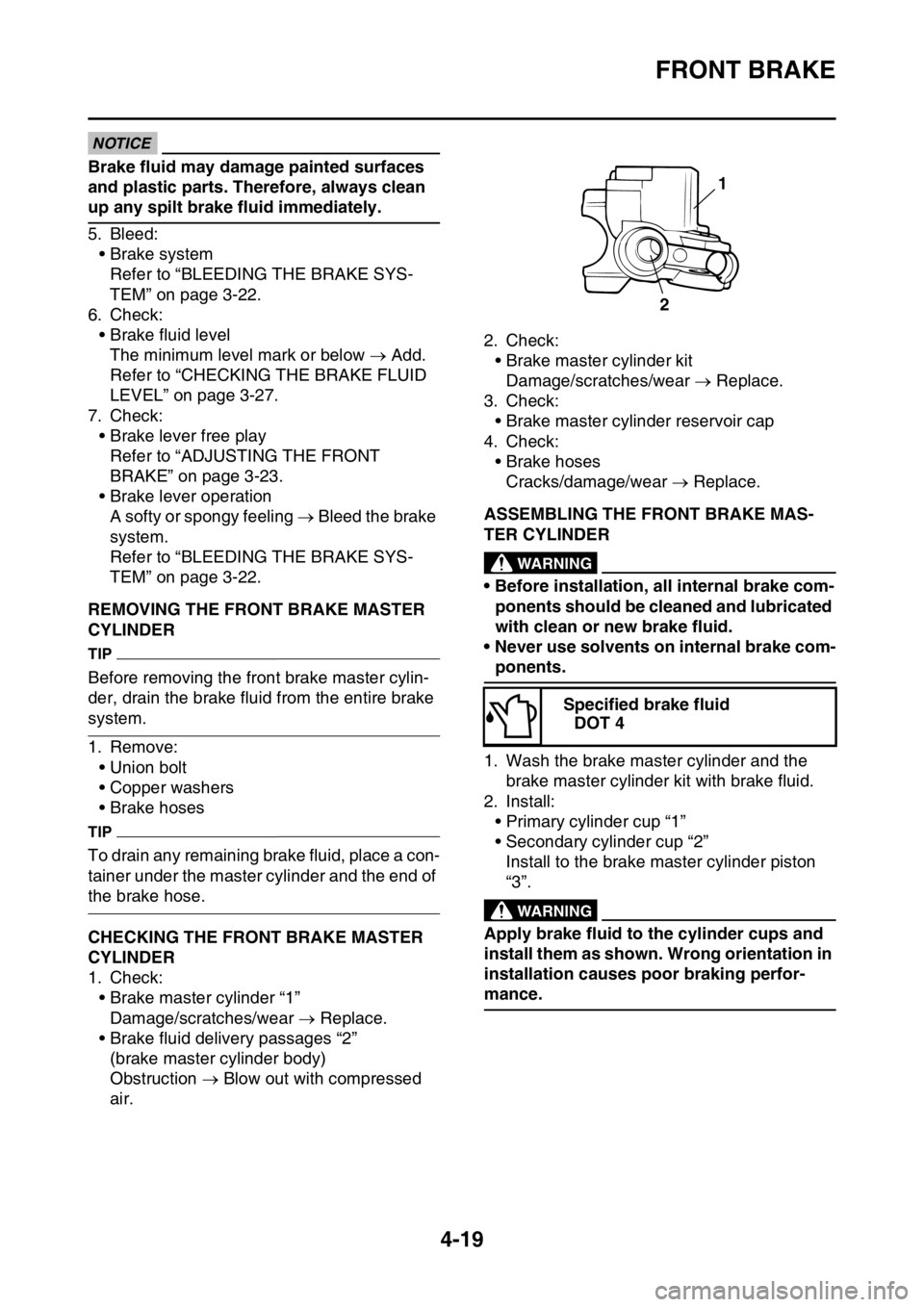

EASB111142INSTALLING THE FRONT BRAKE CALIPER

1. Install:

• Front brake caliper bracket

• Front brake caliper

(temporarily)

• Copper washers

• Brake hose

• Union bolt

EWA

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.

ECA

NOTICE

Make sure that the pipe portion “a” of the

brake hose touches the projection “b” on

the brake caliper.2. Install:

• Front brake caliper

• Brake pad spring

• Brake pad

• Brake pad pin

• Brake hose holder

Refer to “CHECKING THE FRONT BRAKE

PADS” on page 3-24.

3. Tighten:

• Brake hose holder mounting bolt “1”

TIP

Make sure that the brake hose holder “2” is in-

stalled with its upper end “a” aligned with the

paint “b” on the brake hose.

4. Pour brake fluid to the brake master cylinder

reservoir up to the specified level.

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

Front brake caliper bracket

28 Nm (2.8 m·kgf, 20 ft·lbf)

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

1

a

1

New

T R..

a

b

Brake pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Brake hose holder mounting bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Specified brake fluid

DOT 4

T R..

T R..

2

1 b

a

Page 143 of 362

FRONT BRAKE

4-19

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

6. Check:

• Brake fluid level

The minimum level mark or below Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-27.

7. Check:

• Brake lever free play

Refer to “ADJUSTING THE FRONT

BRAKE” on page 3-23.

• Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

EASB111143REMOVING THE FRONT BRAKE MASTER

CYLINDER

TIP

Before removing the front brake master cylin-

der, drain the brake fluid from the entire brake

system.

1. Remove:

• Union bolt

• Copper washers

• Brake hoses

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

EASB111144CHECKING THE FRONT BRAKE MASTER

CYLINDER

1. Check:

• Brake master cylinder “1”

Damage/scratches/wear Replace.

• Brake fluid delivery passages “2”

(brake master cylinder body)

Obstruction Blow out with compressed

air.2. Check:

• Brake master cylinder kit

Damage/scratches/wear Replace.

3. Check:

• Brake master cylinder reservoir cap

4. Check:

• Brake hoses

Cracks/damage/wear Replace.

EASB111145ASSEMBLING THE FRONT BRAKE MAS-

TER CYLINDER

EWA

WARNING

• Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

• Never use solvents on internal brake com-

ponents.

1. Wash the brake master cylinder and the

brake master cylinder kit with brake fluid.

2. Install:

• Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3”.

EWA

WARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor-

mance.Specified brake fluid

DOT 4

1

2

Page 144 of 362

FRONT BRAKE

4-20

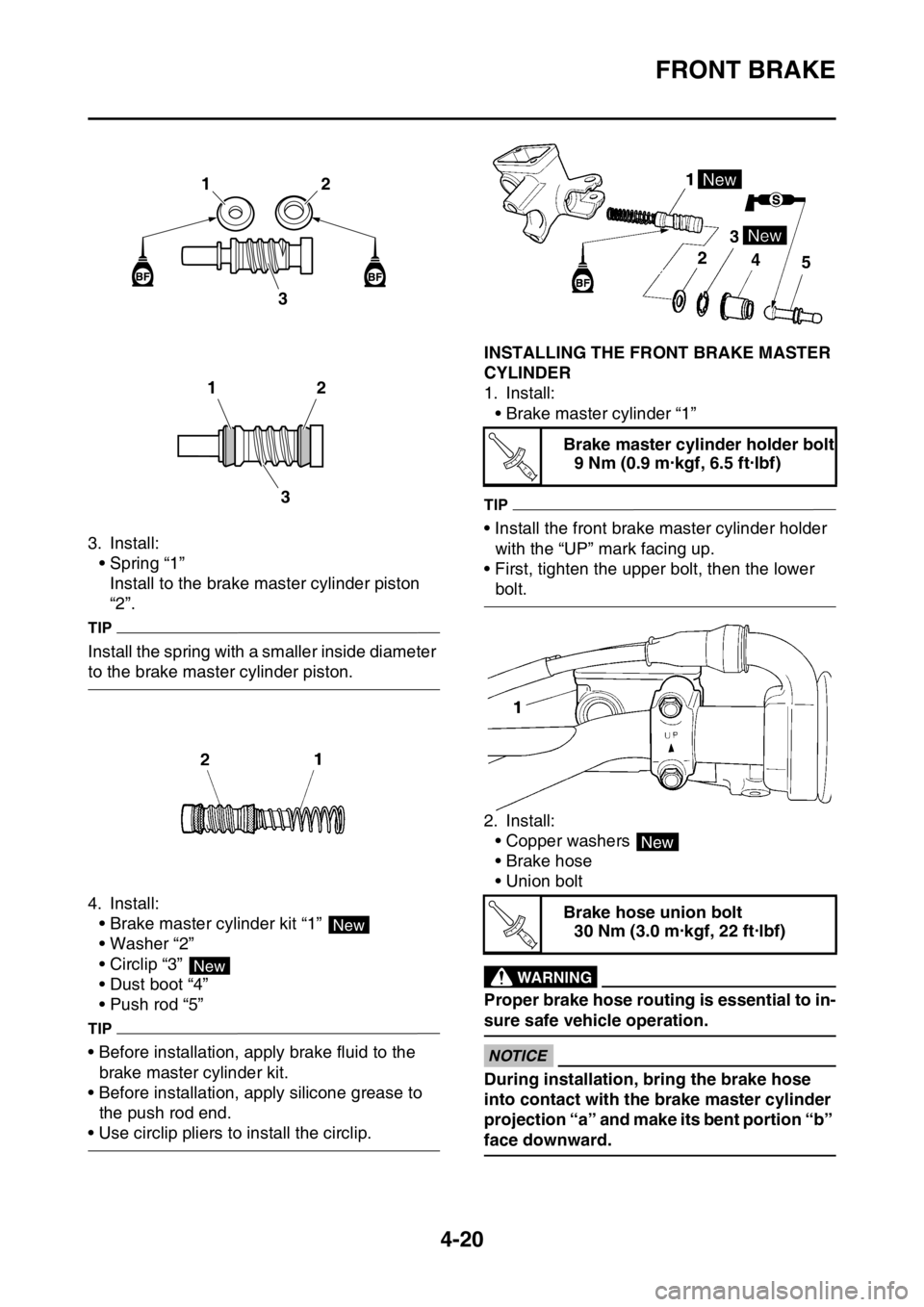

3. Install:

• Spring “1”

Install to the brake master cylinder piston

“2”.

TIP

Install the spring with a smaller inside diameter

to the brake master cylinder piston.

4. Install:

• Brake master cylinder kit “1”

• Washer “2”

• Circlip “3”

• Dust boot “4”

• Push rod “5”

TIP

• Before installation, apply brake fluid to the

brake master cylinder kit.

• Before installation, apply silicone grease to

the push rod end.

• Use circlip pliers to install the circlip.

EASB111146INSTALLING THE FRONT BRAKE MASTER

CYLINDER

1. Install:

• Brake master cylinder “1”

TIP

• Install the front brake master cylinder holder

with the “UP” mark facing up.

• First, tighten the upper bolt, then the lower

bolt.

2. Install:

• Copper washers

• Brake hose

• Union bolt

EWA13530

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.

ECA1DX1007

NOTICE

During installation, bring the brake hose

into contact with the brake master cylinder

projection “a” and make its bent portion “b”

face downward.

12

3

2 1

3

New

New

Brake master cylinder holder bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

T R..

New

T R..

Page 145 of 362

FRONT BRAKE

4-21

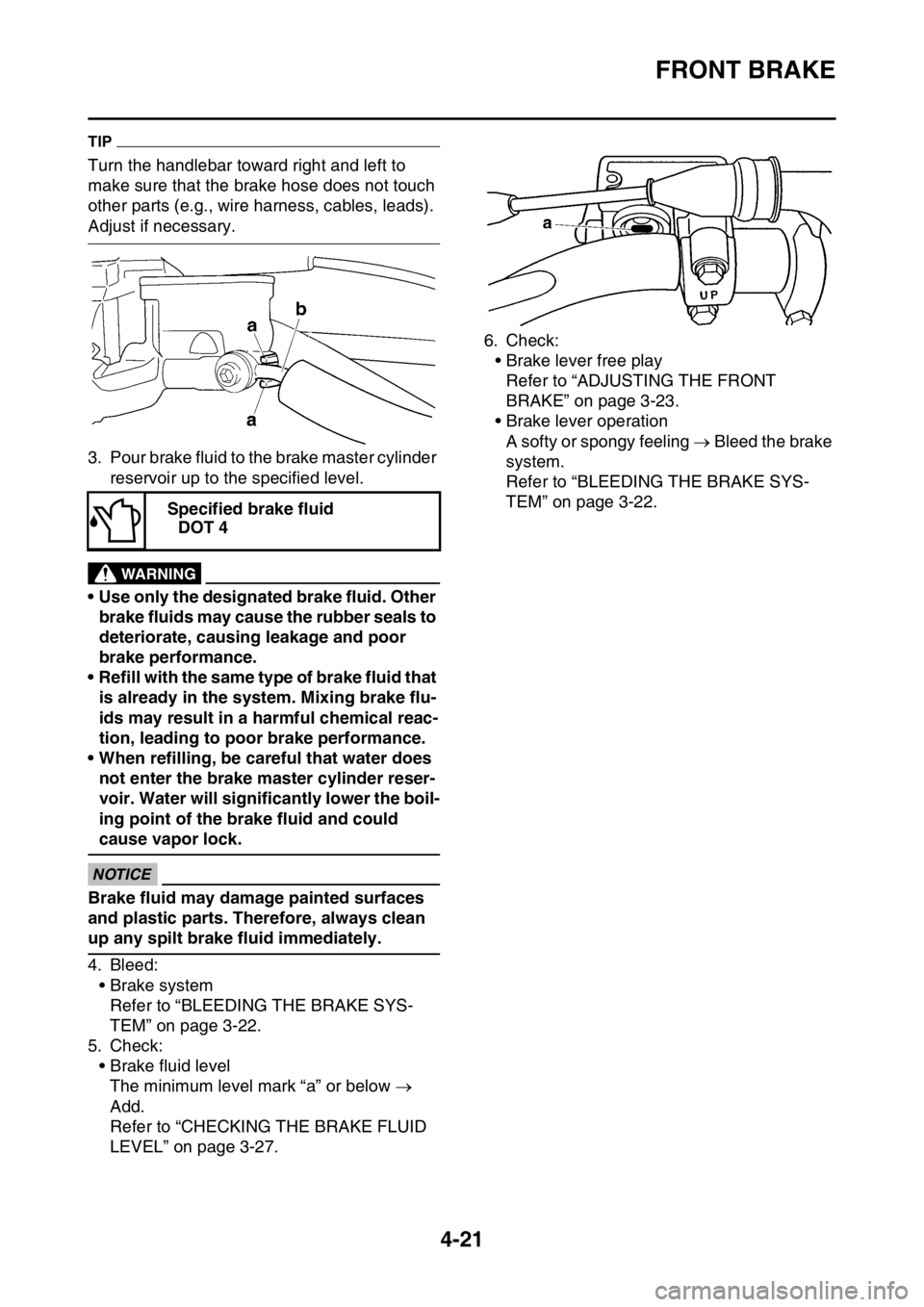

TIP

Turn the handlebar toward right and left to

make sure that the brake hose does not touch

other parts (e.g., wire harness, cables, leads).

Adjust if necessary.

3. Pour brake fluid to the brake master cylinder

reservoir up to the specified level.

EWA13540

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake master cylinder reser-

voir. Water will significantly lower the boil-

ing point of the brake fluid and could

cause vapor lock.

ECA13540

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

4. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

5. Check:

• Brake fluid level

The minimum level mark “a” or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-27.6. Check:

• Brake lever free play

Refer to “ADJUSTING THE FRONT

BRAKE” on page 3-23.

• Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

Specified brake fluid

DOT 4