warning YAMAHA YZ450F 2016 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ450F, Model: YAMAHA YZ450F 2016Pages: 362, PDF Size: 10.49 MB

Page 276 of 362

RADIATOR

6-3

EASB111295HANDLING NOTEEWA

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

EASB111296CHECKING THE RADIATOR

1. Check:

• Radiator fins “1”

Obstructions Clean.

Apply compressed air to the rear of the radi-

ator.

Damage Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

• Radiator hoses

• Radiator pipes

Crack/damage Replace.

Page 283 of 362

FUEL TANK

7-2

EASB111305REMOVING THE FUEL TANK

1. Extract the fuel in the fuel tank through the

fuel tank cap with a pump.

2. Remove:

• Fuel hose coupler

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcefully disconnect the

hose with tools.

TIP

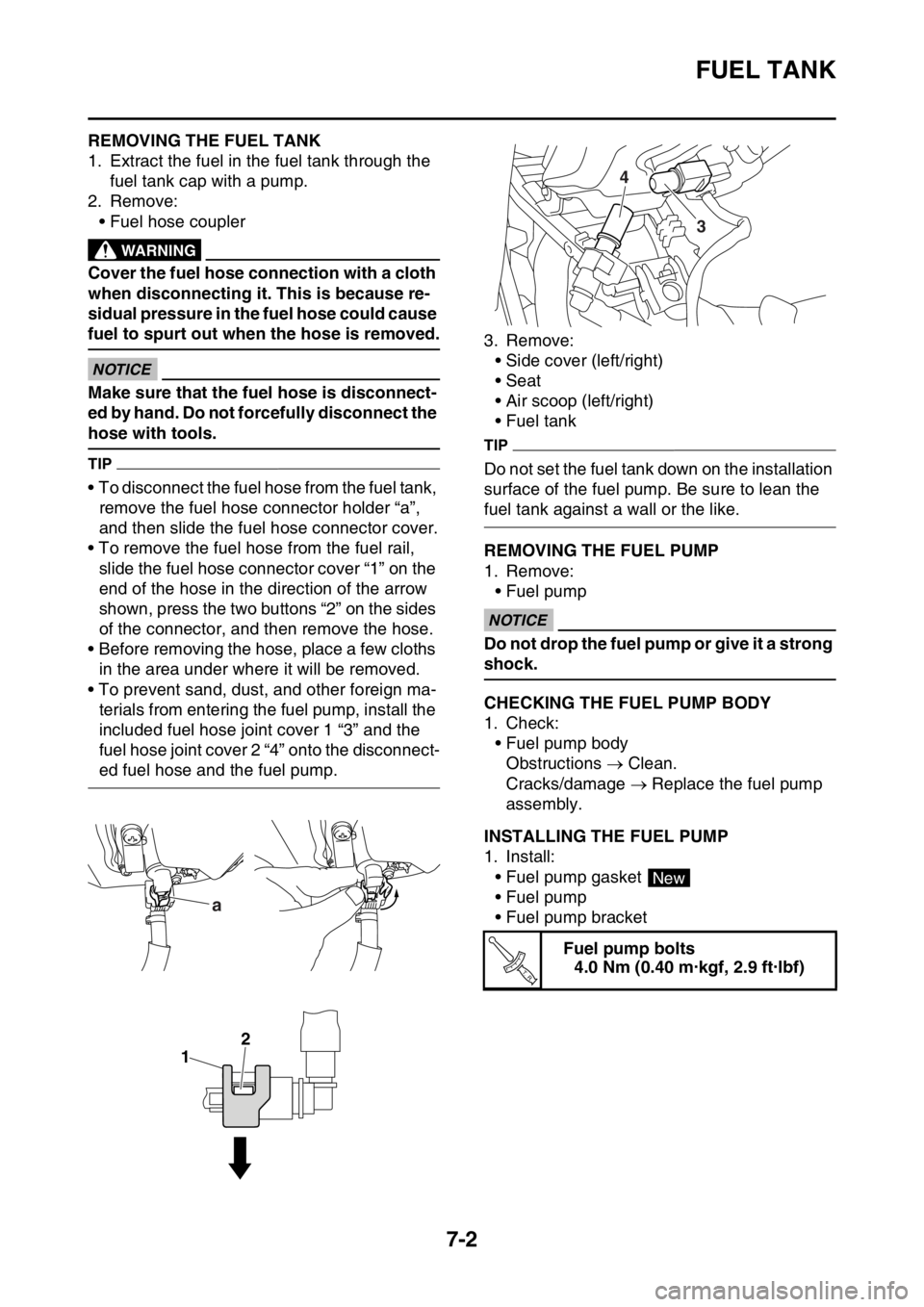

• To disconnect the fuel hose from the fuel tank,

remove the fuel hose connector holder “a”,

and then slide the fuel hose connector cover.

• To remove the fuel hose from the fuel rail,

slide the fuel hose connector cover “1” on the

end of the hose in the direction of the arrow

shown, press the two buttons “2” on the sides

of the connector, and then remove the hose.

• Before removing the hose, place a few cloths

in the area under where it will be removed.

• To prevent sand, dust, and other foreign ma-

terials from entering the fuel pump, install the

included fuel hose joint cover 1 “3” and the

fuel hose joint cover 2 “4” onto the disconnect-

ed fuel hose and the fuel pump.3. Remove:

• Side cover (left/right)

• Seat

• Air scoop (left/right)

• Fuel tank

TIP

Do not set the fuel tank down on the installation

surface of the fuel pump. Be sure to lean the

fuel tank against a wall or the like.

EASB111306REMOVING THE FUEL PUMP

1. Remove:

• Fuel pump

ECA

NOTICE

Do not drop the fuel pump or give it a strong

shock.

EASB111307CHECKING THE FUEL PUMP BODY

1. Check:

• Fuel pump body

Obstructions Clean.

Cracks/damage Replace the fuel pump

assembly.

EASB111308INSTALLING THE FUEL PUMP

1. Install:

• Fuel pump gasket

• Fuel pump

• Fuel pump bracket

a

1

2

Fuel pump bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

3 4

New

T R..

Page 284 of 362

FUEL TANK

7-3

TIP

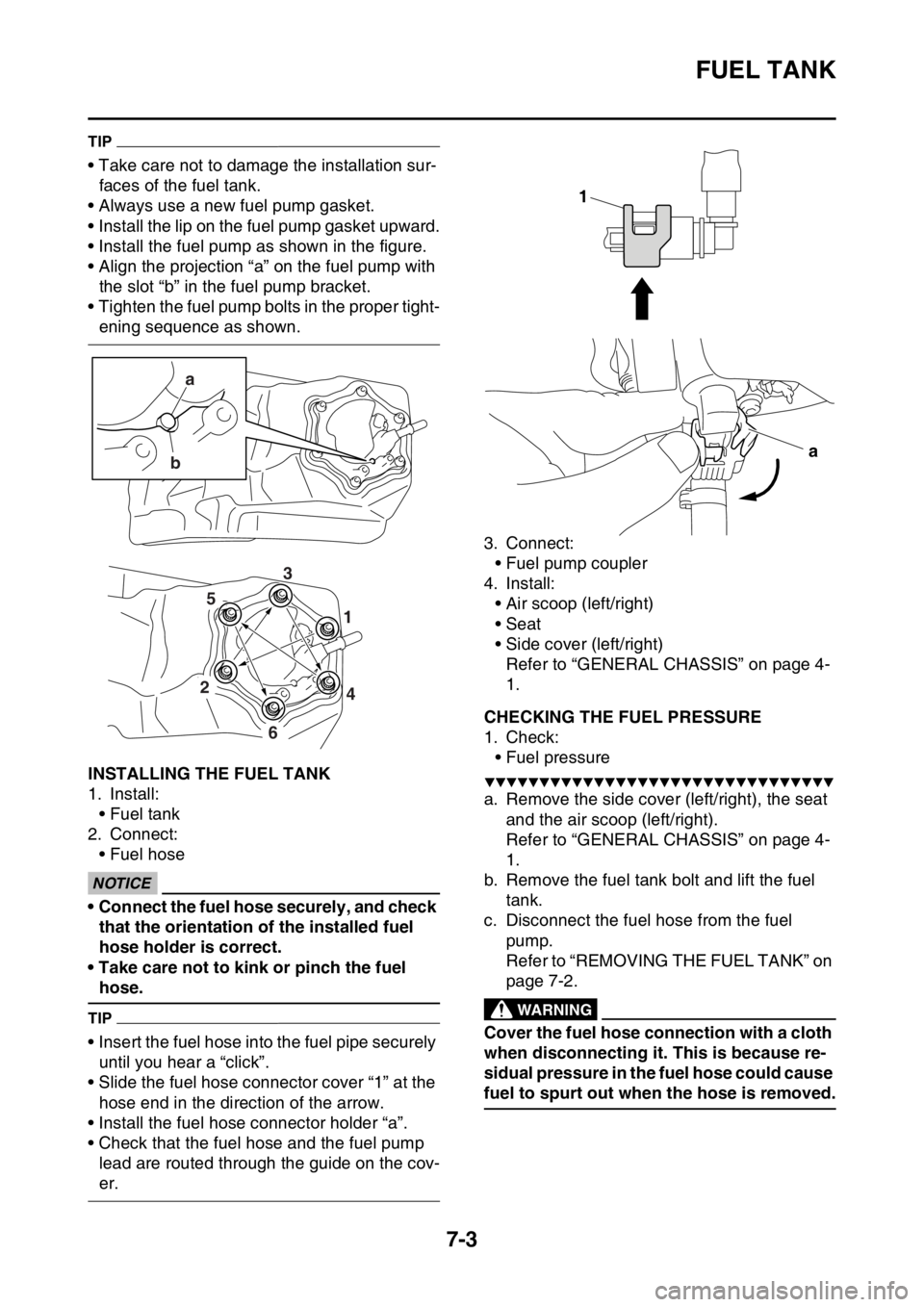

• Take care not to damage the installation sur-

faces of the fuel tank.

• Always use a new fuel pump gasket.

• Install the lip on the fuel pump gasket upward.

• Install the fuel pump as shown in the figure.

• Align the projection “a” on the fuel pump with

the slot “b” in the fuel pump bracket.

• Tighten the fuel pump bolts in the proper tight-

ening sequence as shown.

EASB111309INSTALLING THE FUEL TANK

1. Install:

• Fuel tank

2. Connect:

• Fuel hose

ECA

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click”.

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a”.

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov-

er.3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EASB111310CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 4-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 7-2.

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

a

b

4 1

2

6

53

1

a

Page 290 of 362

THROTTLE BODY

7-9

EASB111317ADJUSTING THE THROTTLE POSITION

SENSOR

EWA

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check:

• Throttle position sensor

Refer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 8-44.

2. Adjust:

• Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

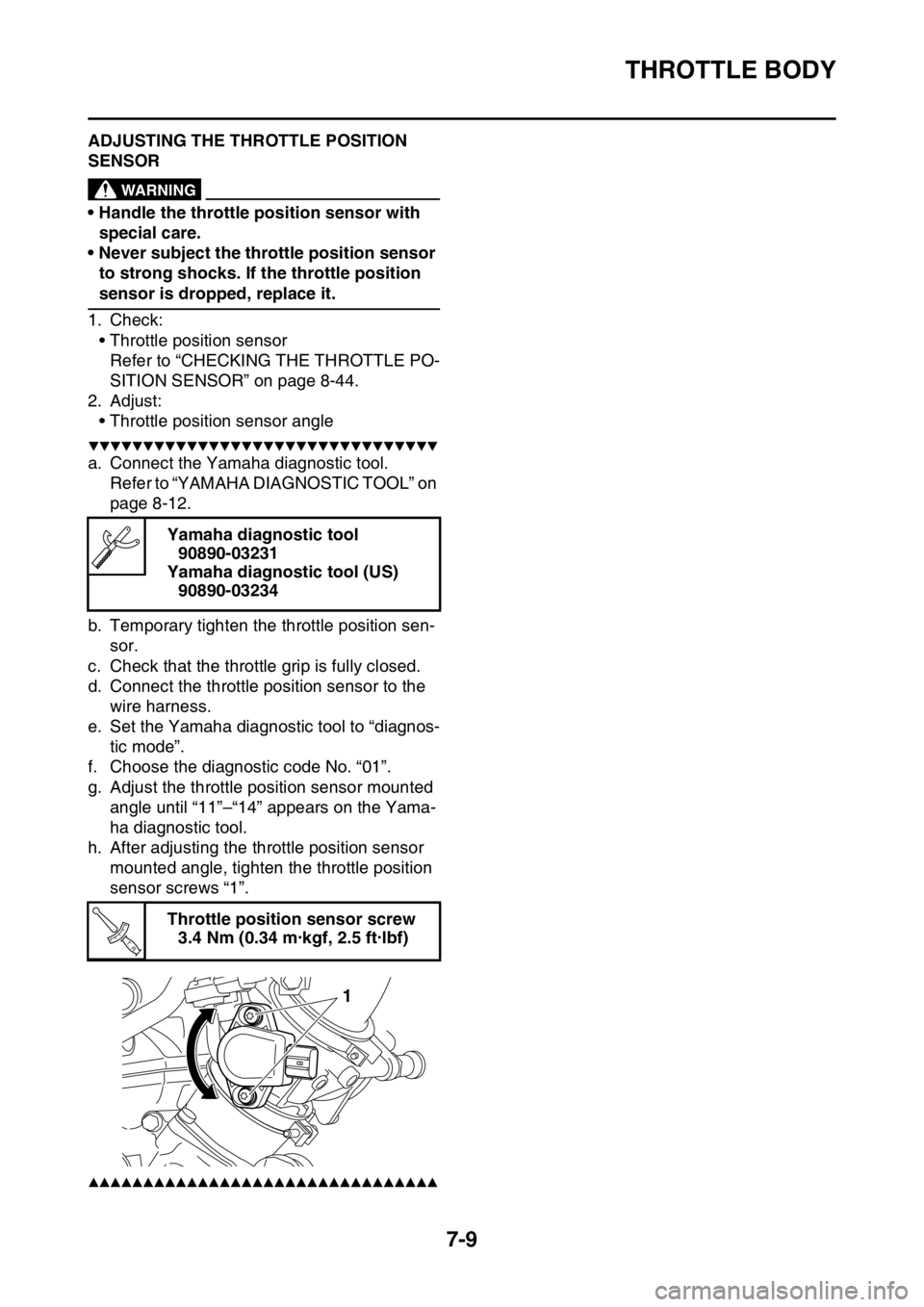

a. Connect the Yamaha diagnostic tool.

Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 8-12.

b. Temporary tighten the throttle position sen-

sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the

wire harness.

e. Set the Yamaha diagnostic tool to “diagnos-

tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11”–“14” appears on the Yama-

ha diagnostic tool.

h. After adjusting the throttle position sensor

mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234

Throttle position sensor screw

3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

T R..

1

Page 315 of 362

FUEL INJECTION SYSTEM

8-23

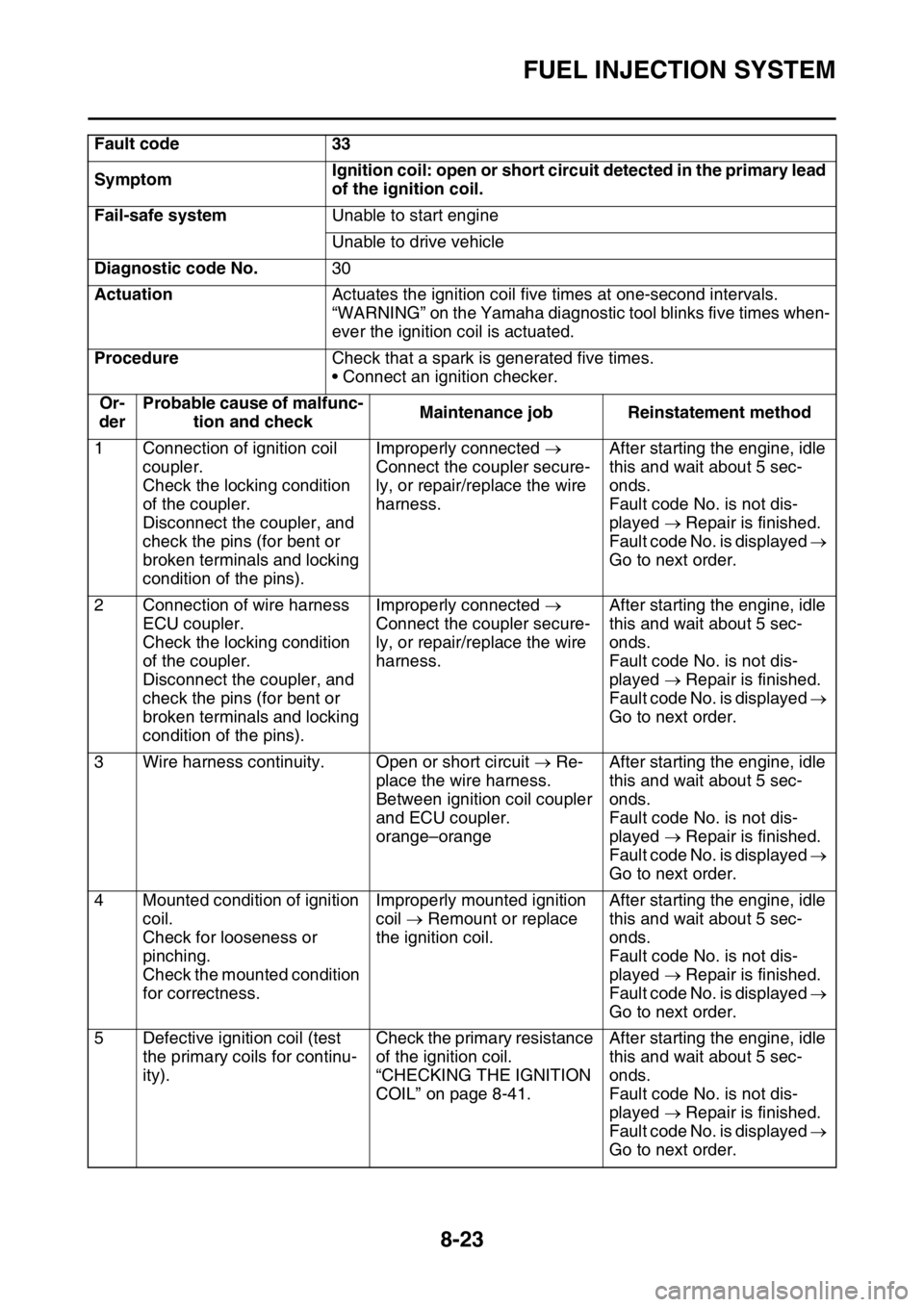

Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when-

ever the ignition coil is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between ignition coil coupler

and ECU coupler.

orange–orangeAfter starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4 Mounted condition of ignition

coil.

Check for looseness or

pinching.

Check the mounted condition

for correctness.Improperly mounted ignition

coil Remount or replace

the ignition coil.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5 Defective ignition coil (test

the primary coils for continu-

ity).Check the primary resistance

of the ignition coil.

“CHECKING THE IGNITION

COIL” on page 8-41.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Page 316 of 362

FUEL INJECTION SYSTEM

8-24

TIP

Disconnect the fuel pump coupler when this diagnostic tool is used. 6 Faulty ECU Execute the diagnostic mode.

(Code No. 30)

No spark Replace the

ECU.

Fault code 39

Symptom Injector: open or short circuit detected.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.36

ActuationActuates injector five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when

the injector is actuated.

ProcedureCheck that injector is actuated five times by listening for the oper-

ating sound.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of injector cou-

pler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Defective injector. Check the injector.

“CHECKING THE FUEL IN-

JECTOR” on page 8-46.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order. Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Page 335 of 362

ELECTRICAL COMPONENTS

8-43

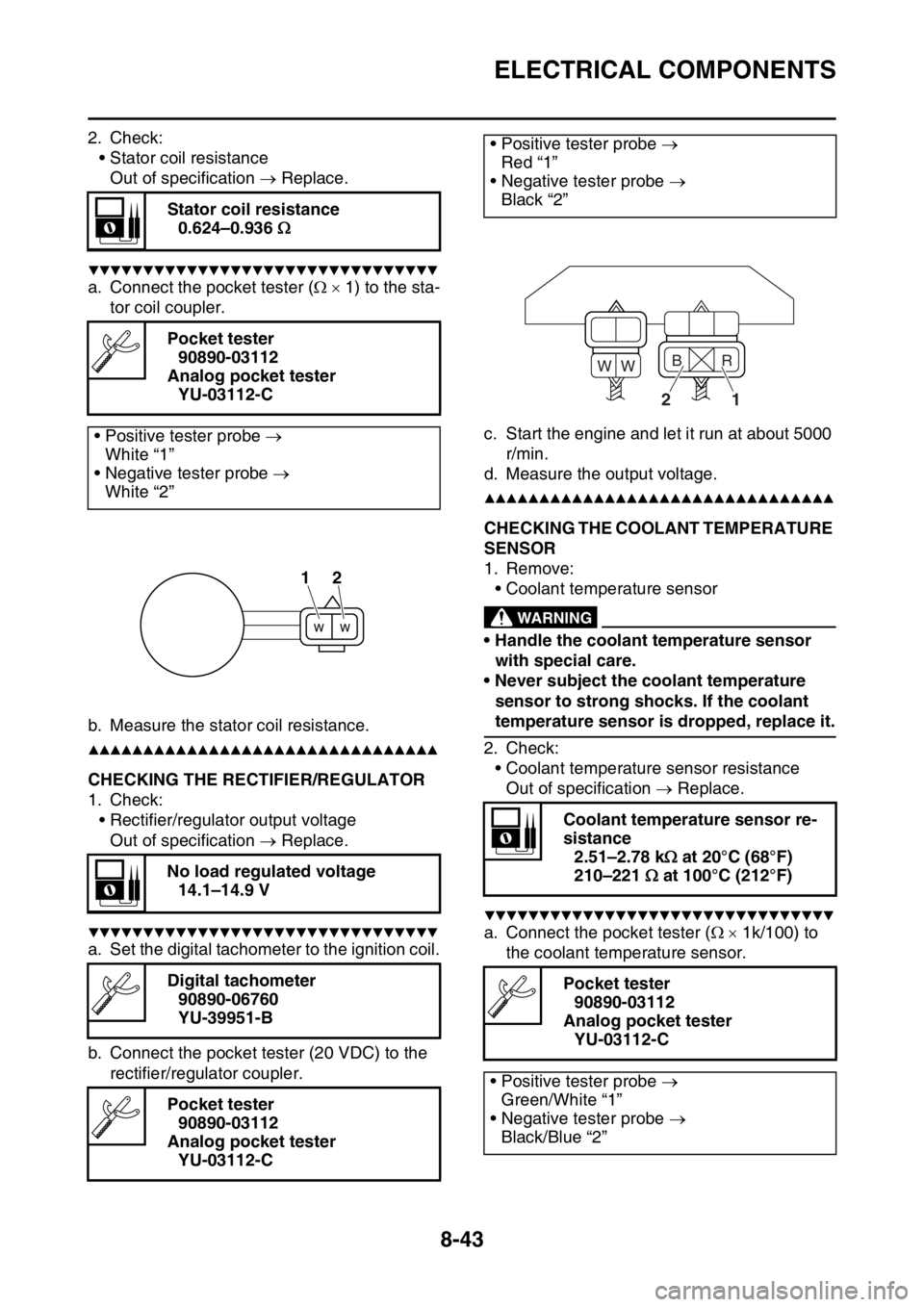

2. Check:

• Stator coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the sta-

tor coil coupler.

b. Measure the stator coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111340CHECKING THE RECTIFIER/REGULATOR

1. Check:

• Rectifier/regulator output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Set the digital tachometer to the ignition coil.

b. Connect the pocket tester (20 VDC) to the

rectifier/regulator coupler.c. Start the engine and let it run at about 5000

r/min.

d. Measure the output voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111341CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensor

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.

2. Check:

• Coolant temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the coolant temperature sensor. Stator coil resistance

0.624–0.936

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

White “1”

• Negative tester probe

White “2”

No load regulated voltage

14.1–14.9 V

Digital tachometer

90890-06760

YU-39951-B

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

12

• Positive tester probe

Red “1”

• Negative tester probe

Black “2”

Coolant temperature sensor re-

sistance

2.51–2.78 k at 20°C (68°F)

210–221 at 100°C (212°F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green/White “1”

• Negative tester probe

Black/Blue “2”

21

B

WWR

Page 336 of 362

ELECTRICAL COMPONENTS

8-44

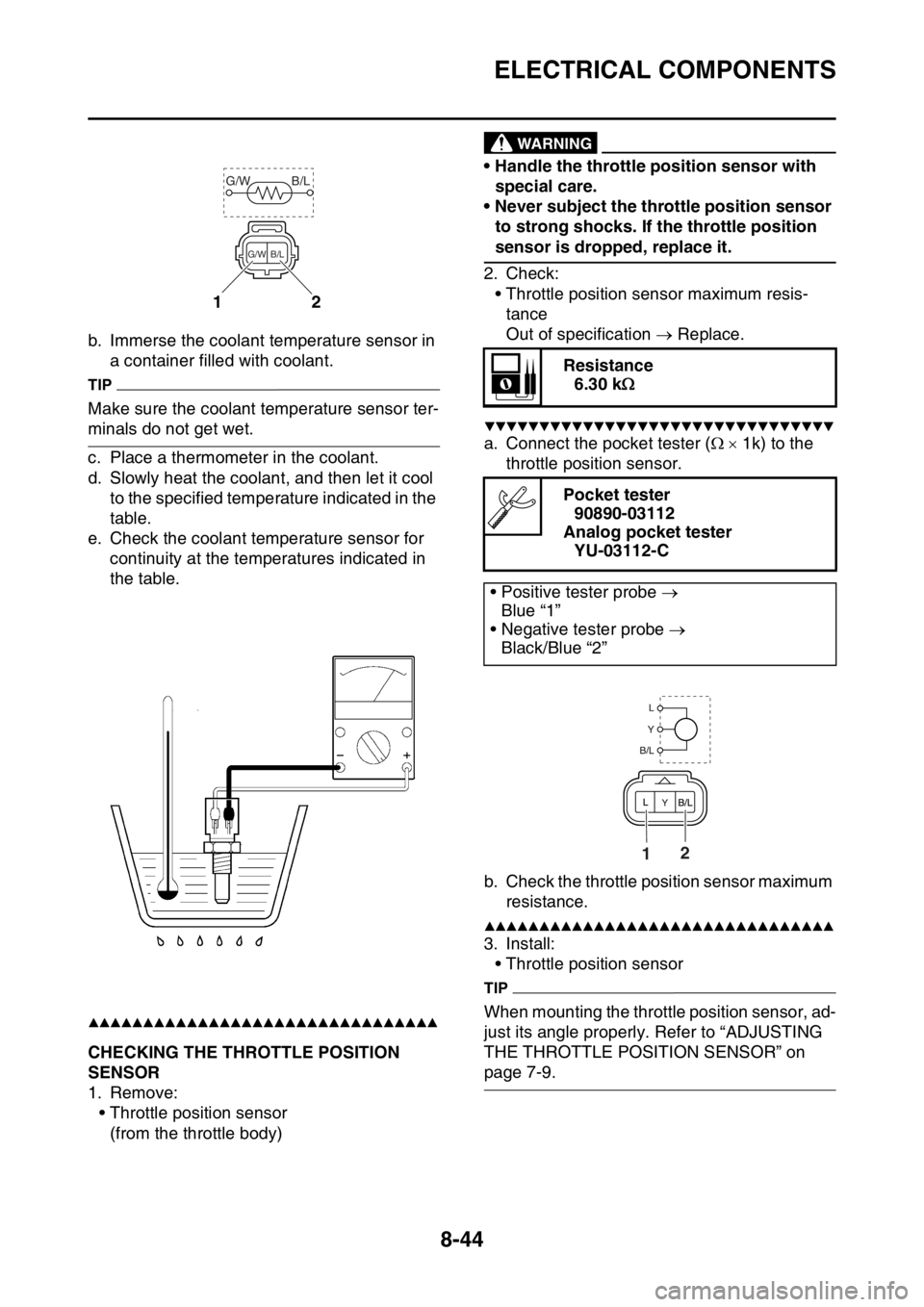

b. Immerse the coolant temperature sensor in

a container filled with coolant.

TIP

Make sure the coolant temperature sensor ter-

minals do not get wet.

c. Place a thermometer in the coolant.

d. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

e. Check the coolant temperature sensor for

continuity at the temperatures indicated in

the table.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111342CHECKING THE THROTTLE POSITION

SENSOR

1. Remove:

• Throttle position sensor

(from the throttle body)

EWA

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

2. Check:

• Throttle position sensor maximum resis-

tance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

throttle position sensor.

b. Check the throttle position sensor maximum

resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Throttle position sensor

TIP

When mounting the throttle position sensor, ad-

just its angle properly. Refer to “ADJUSTING

THE THROTTLE POSITION SENSOR” on

page 7-9.

12

G/W B/L

B/L G/W

Resistance

6.30 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

21

Page 337 of 362

ELECTRICAL COMPONENTS

8-45

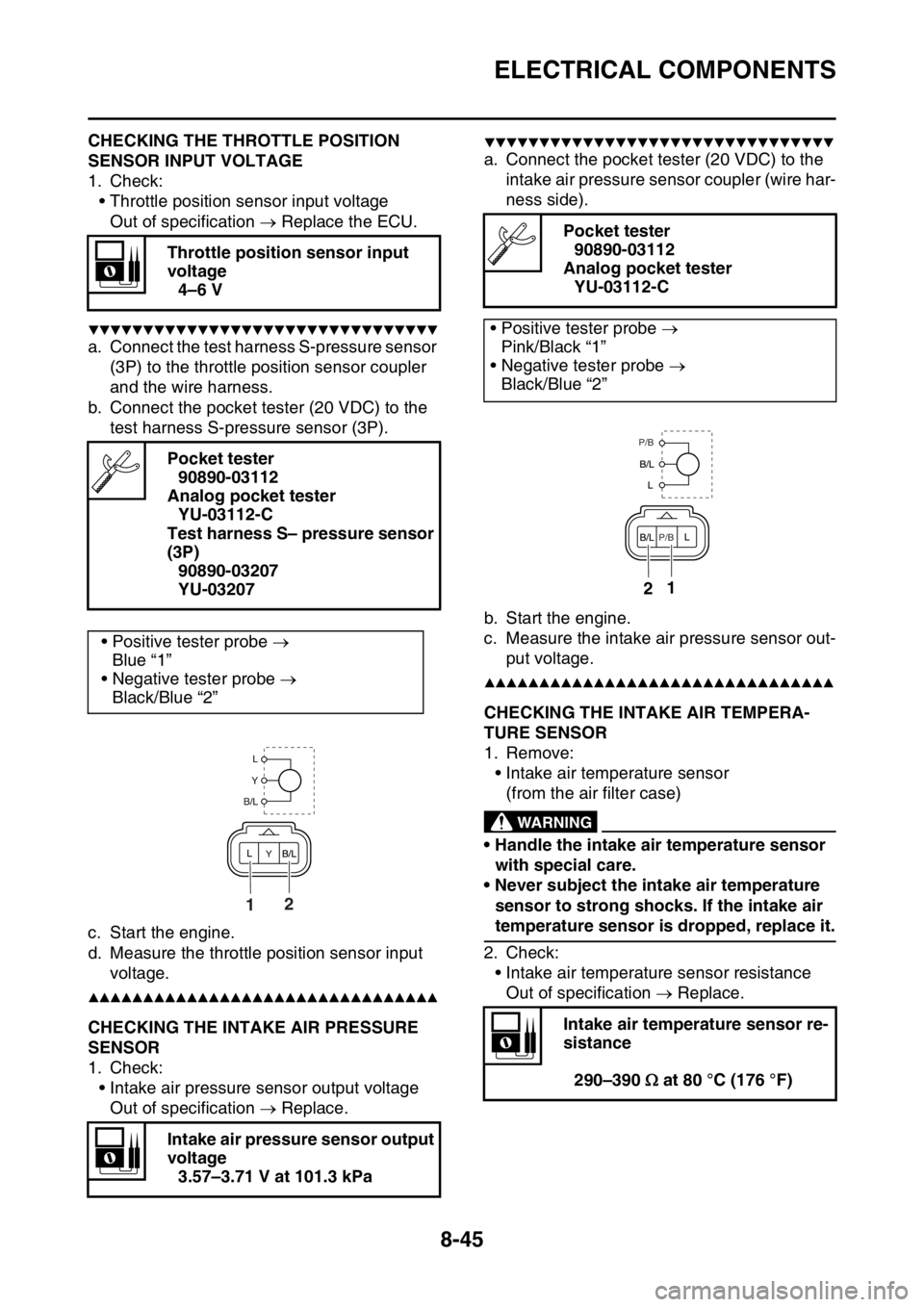

EASB111343CHECKING THE THROTTLE POSITION

SENSOR INPUT VOLTAGE

1. Check:

• Throttle position sensor input voltage

Out of specification Replace the ECU.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness S-pressure sensor

(3P) to the throttle position sensor coupler

and the wire harness.

b. Connect the pocket tester (20 VDC) to the

test harness S-pressure sensor (3P).

c. Start the engine.

d. Measure the throttle position sensor input

voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111344CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (20 VDC) to the

intake air pressure sensor coupler (wire har-

ness side).

b. Start the engine.

c. Measure the intake air pressure sensor out-

put voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB111345CHECKING THE INTAKE AIR TEMPERA-

TURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case)

EWA

WARNING

• Handle the intake air temperature sensor

with special care.

• Never subject the intake air temperature

sensor to strong shocks. If the intake air

temperature sensor is dropped, replace it.

2. Check:

• Intake air temperature sensor resistance

Out of specification Replace. Throttle position sensor input

voltage

4–6 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness S– pressure sensor

(3P)

90890-03207

YU-03207

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

Intake air pressure sensor output

voltage

3.57–3.71 V at 101.3 kPa

21

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Pink/Black “1”

• Negative tester probe

Black/Blue “2”

Intake air temperature sensor re-

sistance

290–390 at 80 °C (176 °F)

12

P/B

P/B

Page 347 of 362

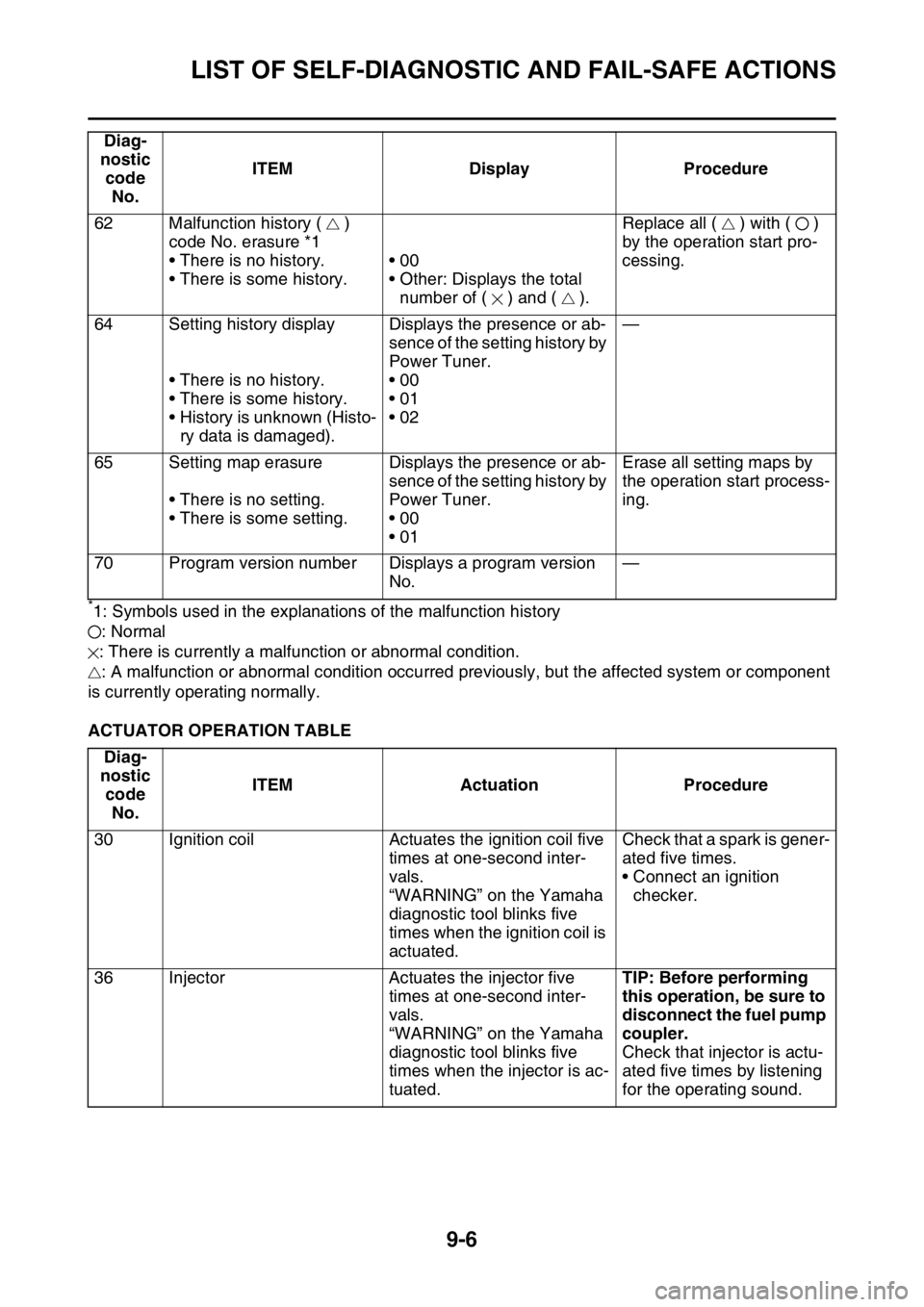

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-6

*1: Symbols used in the explanations of the malfunction history

: Normal

: There is currently a malfunction or abnormal condition.

: A malfunction or abnormal condition occurred previously, but the affected system or component

is currently operating normally.

ACTUATOR OPERATION TABLE62 Malfunction history ( )

code No. erasure *1

• There is no history.

• There is some history.•00

• Other: Displays the total

number of ( ) and ( ).Replace all ( ) with ( )

by the operation start pro-

cessing.

64 Setting history display

• There is no history.

• There is some history.

• History is unknown (Histo-

ry data is damaged).Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01

•02—

65 Setting map erasure

• There is no setting.

• There is some setting.Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01Erase all setting maps by

the operation start process-

ing.

70 Program version number Displays a program version

No.—

Diag-

nostic

code

No.ITEM Actuation Procedure

30 Ignition coil Actuates the ignition coil five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the ignition coil is

actuated.Check that a spark is gener-

ated five times.

• Connect an ignition

checker.

36 Injector Actuates the injector five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the injector is ac-

tuated.TIP: Before performing

this operation, be sure to

disconnect the fuel pump

coupler.

Check that injector is actu-

ated five times by listening

for the operating sound. Diag-

nostic

code

No.ITEM Display Procedure