YAMAHA YZ65 2021 Owner's Guide

Manufacturer: YAMAHA, Model Year: 2021, Model line: YZ65, Model: YAMAHA YZ65 2021Pages: 92, PDF Size: 5.04 MB

Page 31 of 92

![YAMAHA YZ65 2021 Owners Guide Instrument and control functions

4-5

4

Gasoline

This model’s engine is designed to use

premium unleaded gasoline with a

pump octane number [(R+M)/2] of 91

or higher, or a research octane number

(RON YAMAHA YZ65 2021 Owners Guide Instrument and control functions

4-5

4

Gasoline

This model’s engine is designed to use

premium unleaded gasoline with a

pump octane number [(R+M)/2] of 91

or higher, or a research octane number

(RON](/img/51/54008/w960_54008-30.png)

Instrument and control functions

4-5

4

Gasoline

This model’s engine is designed to use

premium unleaded gasoline with a

pump octane number [(R+M)/2] of 91

or higher, or a research octane number

(RON) of 95 or higher. If knocking or

pinging occurs, try a gasoline of a dif-

ferent brand.

NOTICE

ECA15591

Use only unlea

ded g asoline. The use

of lead ed g asoline will cause severe

d ama ge to internal en gine parts,

such as the piston rin gs as well as to

the exhaust system.

Gasohol

There are two types of gasohol: gaso-

hol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol con-

tent does not exceed 10% (E10). Gas-

ohol containing methanol should not

be used as it can cause engine or fuel

system problems.

Fillin g the fuel tank

WARNING

EWA10882

Gasoline an d gasoline vapors are

extremely flamma ble. To avoi d fires

an d explosions an d to re duce the

risk of injury when refueling , follow

these instructions.

1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. Stop filling when the fuel reaches the

bottom of the filler tube. Because

fuel expands when it heats up,

heat from the engine or the sun

can cause fuel to spill out of the

fuel tank.

3. Wipe up any spilled fuel immedi- ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painte d surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can

cause injury or death. Han dle gaso-

line with care. Never siphon gasoline

b y mouth. If you shoul d swallow

some gasoline or inhale a lot of gas-

oline vapor, or get some gasoline in

your eyes, see your d octor immedi-

ately. If g asoline spills on your skin,

1. Maximum fuel level

2. Fuel tank filler tube

12

UBR882E0.book Page 5 Wednesd ay, February 26, 2020 11:39 AM

Page 32 of 92

Instrument and control functions

4-6

4 wash with soap an

d water. If gaso-

line spills on your clothin g, chan ge

your clothes.

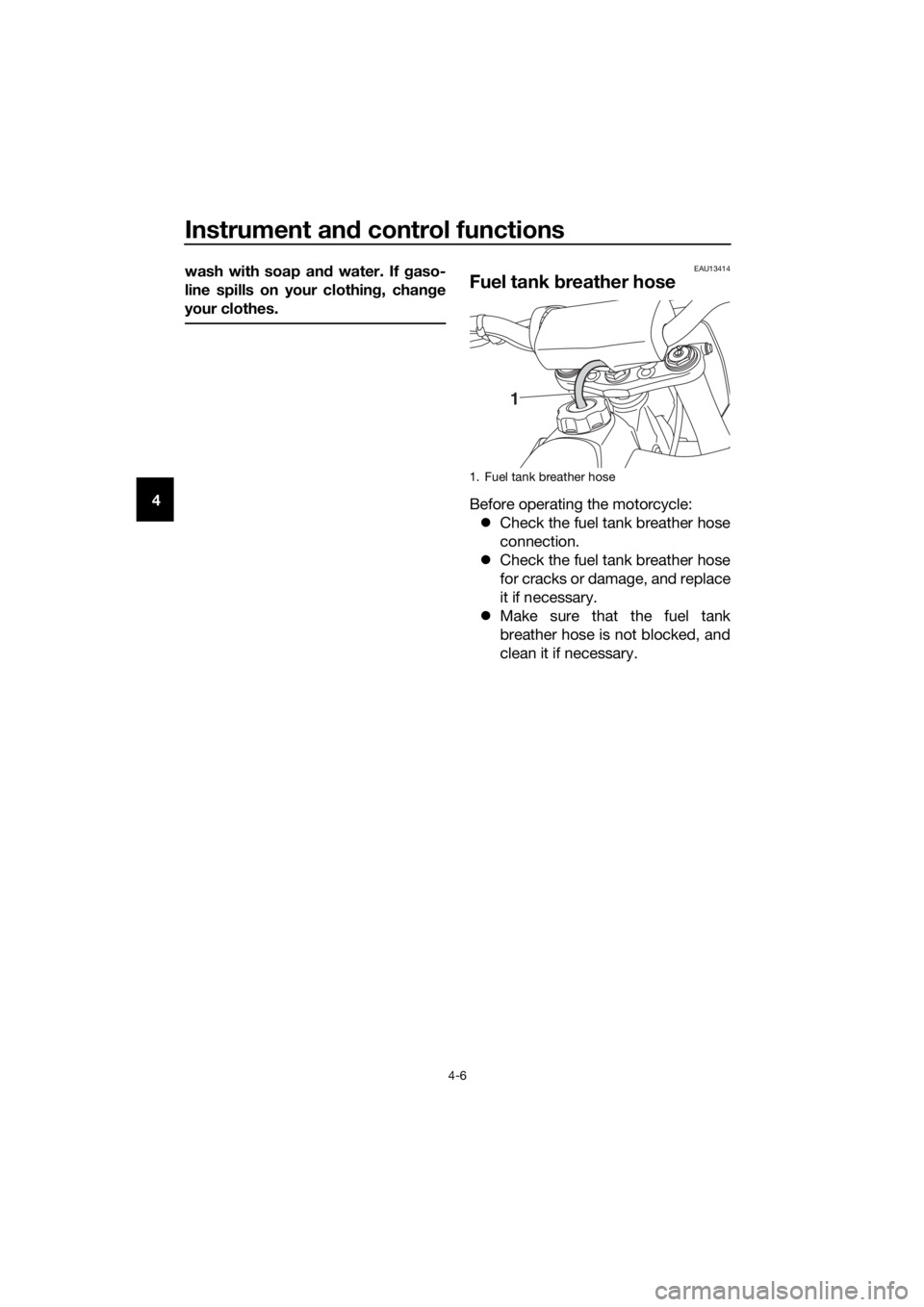

EAU13414

Fuel tank breather hose

Before operating the motorcycle:

Check the fuel tank breather hose

connection.

Check the fuel tank breather hose

for cracks or damage, and replace

it if necessary.

Make sure that the fuel tank

breather hose is not blocked, and

clean it if necessary.

1. Fuel tank breather hose

1

UBR882E0.book Page 6 Wednesd ay, February 26, 2020 11:39 AM

Page 33 of 92

Instrument and control functions

4-7

4

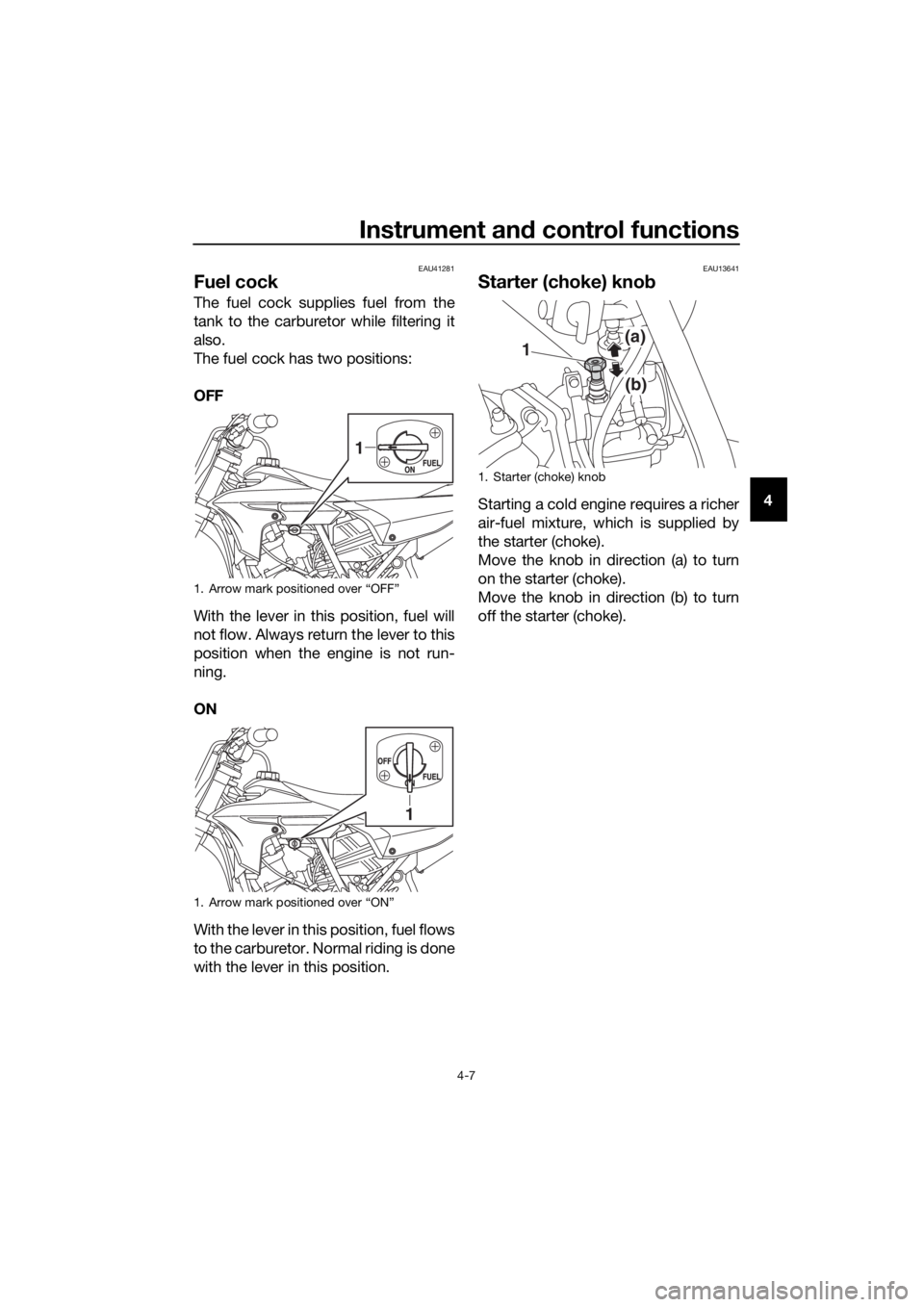

EAU41281

Fuel cock

The fuel cock supplies fuel from the

tank to the carburetor while filtering it

also.

The fuel cock has two positions:

OFF

With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not run-

ning.

ON

With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

EAU13641

Starter (choke) kno b

Starting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the knob in direction (a) to turn

on the starter (choke).

Move the knob in direction (b) to turn

off the starter (choke).

1. Arrow mark positioned over “OFF”

1. Arrow mark positioned over “ON”

1

1

1. Starter (choke) knob

1(a)

(b)

UBR882E0.book Page 7 Wednesd ay, February 26, 2020 11:39 AM

Page 34 of 92

Instrument and control functions

4-8

4

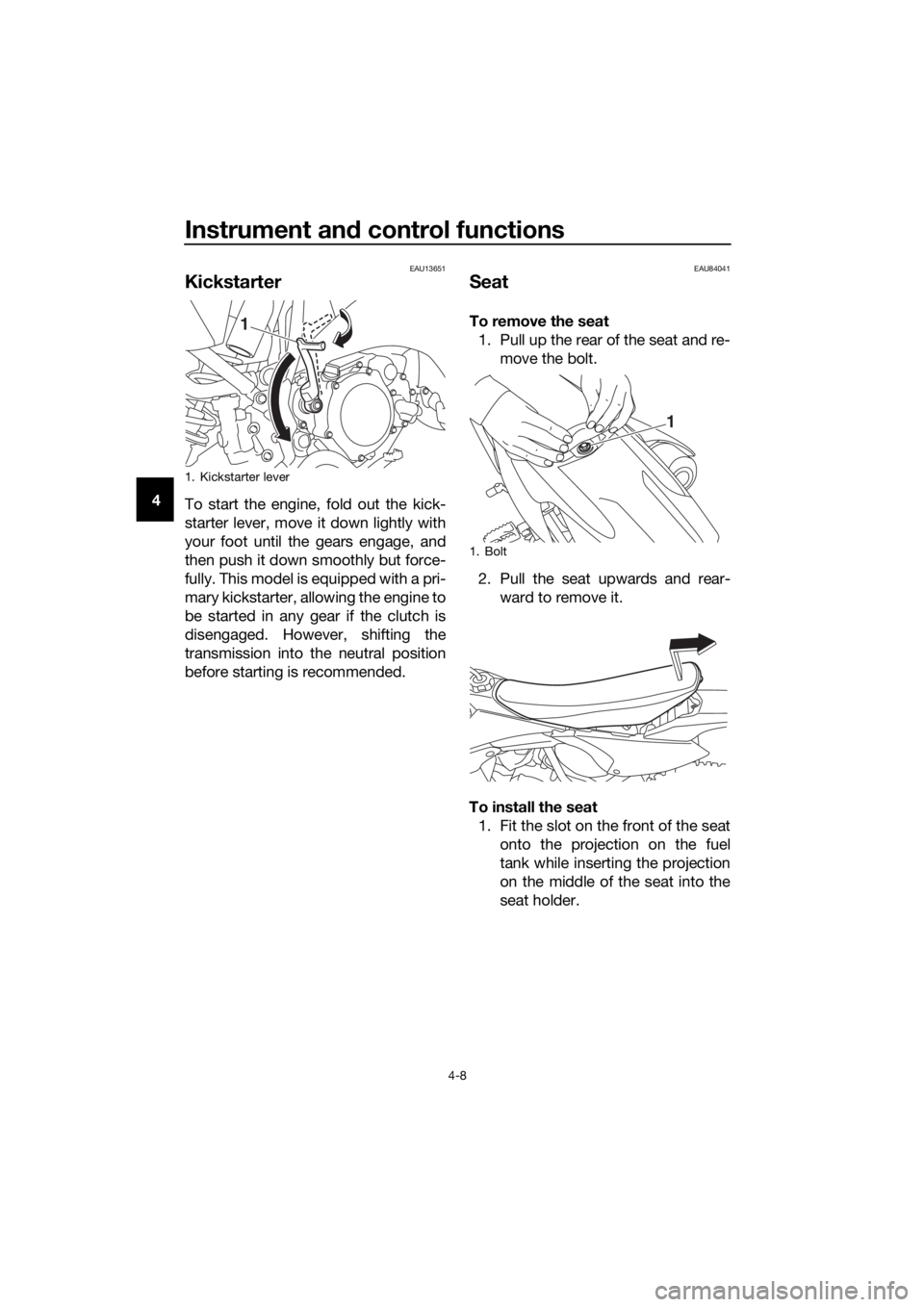

EAU13651

Kickstarter

To start the engine, fold out the kick-

starter lever, move it down lightly with

your foot until the gears engage, and

then push it down smoothly but force-

fully. This model is equipped with a pri-

mary kickstarter, allowing the engine to

be started in any gear if the clutch is

disengaged. However, shifting the

transmission into the neutral position

before starting is recommended.

EAU84041

Seat

To remove the seat

1. Pull up the rear of the seat and re- move the bolt.

2. Pull the seat upwards and rear- ward to remove it.

To install the seat 1. Fit the slot on the front of the seat onto the projection on the fuel

tank while inserting the projection

on the middle of the seat into the

seat holder.

1. Kickstarter lever

1

1. Bolt

1

UBR882E0.book Page 8 Wednesd ay, February 26, 2020 11:39 AM

Page 35 of 92

Instrument and control functions

4-9

4

2. Make sure the seat is in its original

position.

3. Install the bolt at the rear of the seat.

TIP

When removing and installing the

seat, be careful not to damage the

seat with a tool.

Make sure that the seat is properly

secured before riding.

EAU84383

Adjustin g the front fork

WARNING

EWA10181

Always a djust both fork le gs equally,

otherwise poor han dlin g an d loss of

stab ility may result.

This front fork is equipped with re-

bound damping force adjusting screws

and compression damping force ad-

justing screws.

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.

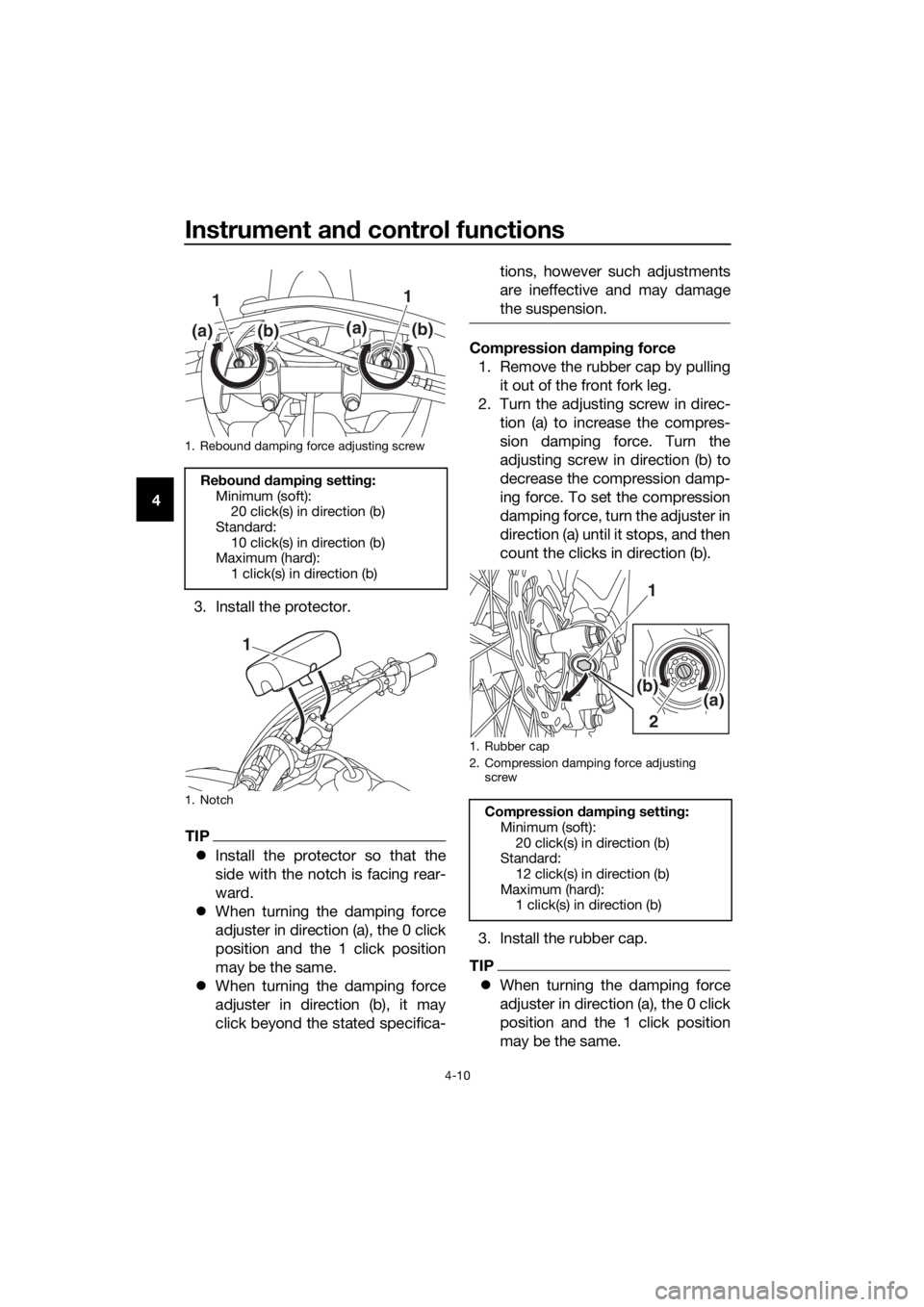

Re boun d d ampin g force

1. Remove the protector.

2. Turn the adjusting screw in direc- tion (a) to increase the rebound

damping force. Turn the adjusting

screw in direction (b) to decrease

the rebound damping force. To

set the rebound damping force,

turn the adjuster in direction (a)

until it stops, and then count the

clicks in direction (b).

1. Slot

2. Projection

3. Seat holder

3

2

1

2

1. Protector

1

UBR882E0.book Page 9 Wednesd

ay, February 26, 2020 11:39 AM

Page 36 of 92

Instrument and control functions

4-10

4

3. Install the protector.

TIP

Install the protector so that the

side with the notch is facing rear-

ward.

When turning the damping force

adjuster in direction (a), the 0 click

position and the 1 click position

may be the same.

When turning the damping force

adjuster in direction (b), it may

click beyond the stated specifica- tions, however such adjustments

are ineffective and may damage

the suspension.

Compression

dampin g force

1. Remove the rubber cap by pulling it out of the front fork leg.

2. Turn the adjusting screw in direc- tion (a) to increase the compres-

sion damping force. Turn the

adjusting screw in direction (b) to

decrease the compression damp-

ing force. To set the compression

damping force, turn the adjuster in

direction (a) until it stops, and then

count the clicks in direction (b).

3. Install the rubber cap.

TIP

When turning the damping force

adjuster in direction (a), the 0 click

position and the 1 click position

may be the same.

1. Rebound damping force adjusting screw

Reboun d d ampin g setting :

Minimum (soft): 20 click(s) in direction (b)

Standard: 10 click(s) in direction (b)

Maximum (hard):

1 click(s) in direction (b)

1. Notch

1 1

(a)

(b)(a)(b)

1

1. Rubber cap

2. Compression damping force adjusting screw

Compression dampin g settin g:

Minimum (soft): 20 click(s) in direction (b)

Standard:

12 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

2

1

(a)(b)

UBR882E0.book Page 10 Wednesday, February 26, 2020 11:39 AM

Page 37 of 92

Instrument and control functions

4-11

4

When turning the damping force

adjuster in direction (b), it may

click beyond the stated specifica-

tions, however such adjustments

are ineffective and may damage

the suspension.

EAU84390

Front fork b leedin g

When riding in extremely rough condi-

tions, the air temperature and pressure

in the front fork will rise. This will in-

crease the spring preload and harden

the front suspension. If this occurs,

bleed the air from each front fork leg.

WARNING

EWA10201

Always blee d b oth fork le gs, other-

wise poor han dlin g an d loss of sta-

b ility may result.

To bleed the front fork legs

1. Remove the protector.

2. Place the motorcycle on a suitable

stand. (See page 7-27.)

3. Make sure the front wheel is off the ground and the area near the

bleed screws is clean.

4. Remove the bleed screws.

1. Protector

1

UBR882E0.book Page 11 Wednesday, February 26, 2020 11:39 AM

Page 38 of 92

Instrument and control functions

4-12

4 5. Wait a few seconds, and then in-

stall the bleed screws.

6. Install the protector.

EAU84212

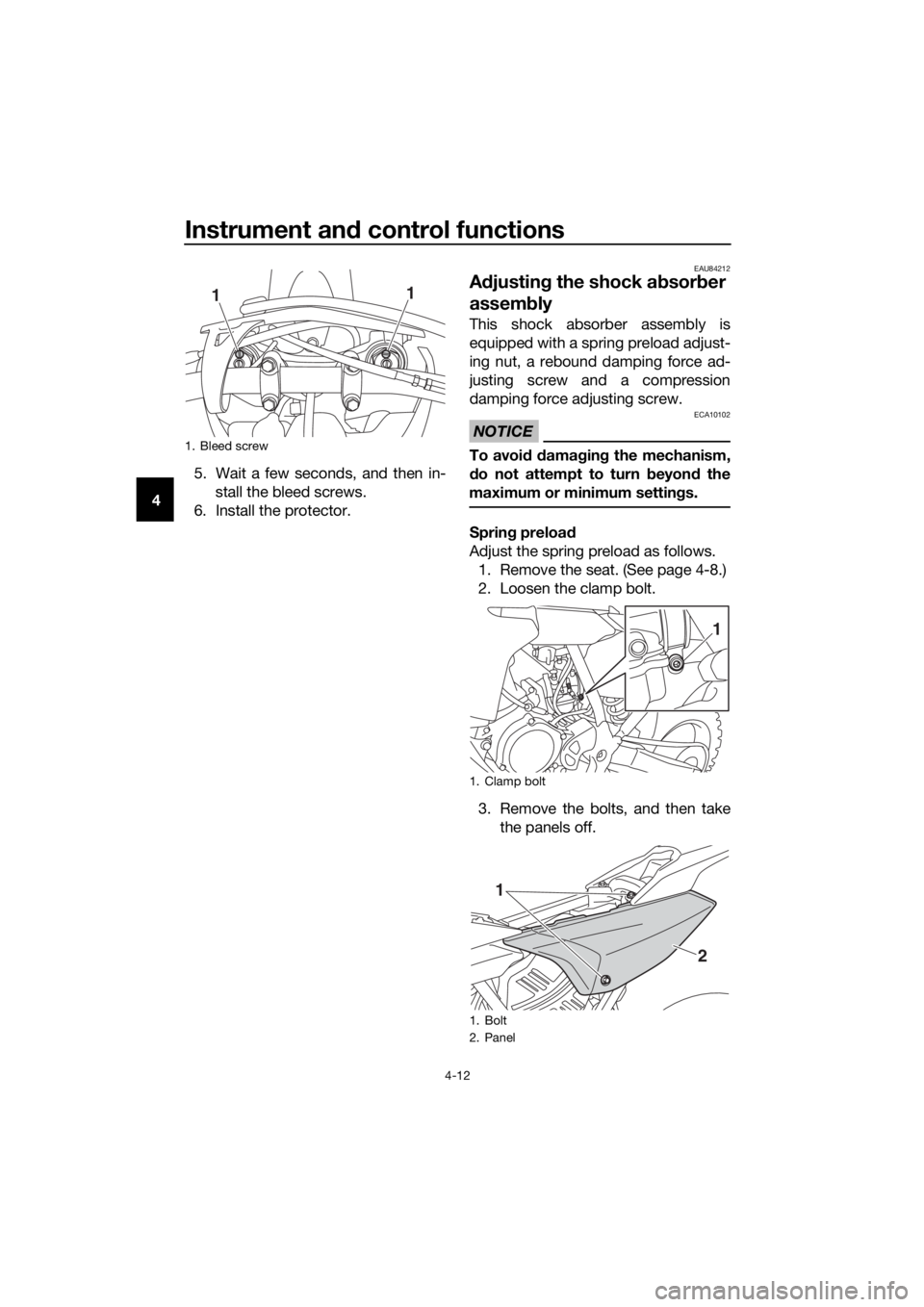

A djustin g the shock a bsor ber

assem bly

This shock absorber assembly is

equipped with a spring preload adjust-

ing nut, a rebound damping force ad-

justing screw and a compression

damping force adjusting screw.

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.

Sprin g preloa d

Adjust the spring preload as follows. 1. Remove the seat. (See page 4-8.)

2. Loosen the clamp bolt.

3. Remove the bolts, and then take the panels off.

1. Bleed screw

1 1

1. Clamp bolt

1. Bolt

2. Panel

1

1

2

UBR882E0.book Page 12 Wednesday, February 26, 2020 11:39 AM

Page 39 of 92

Instrument and control functions

4-13

4

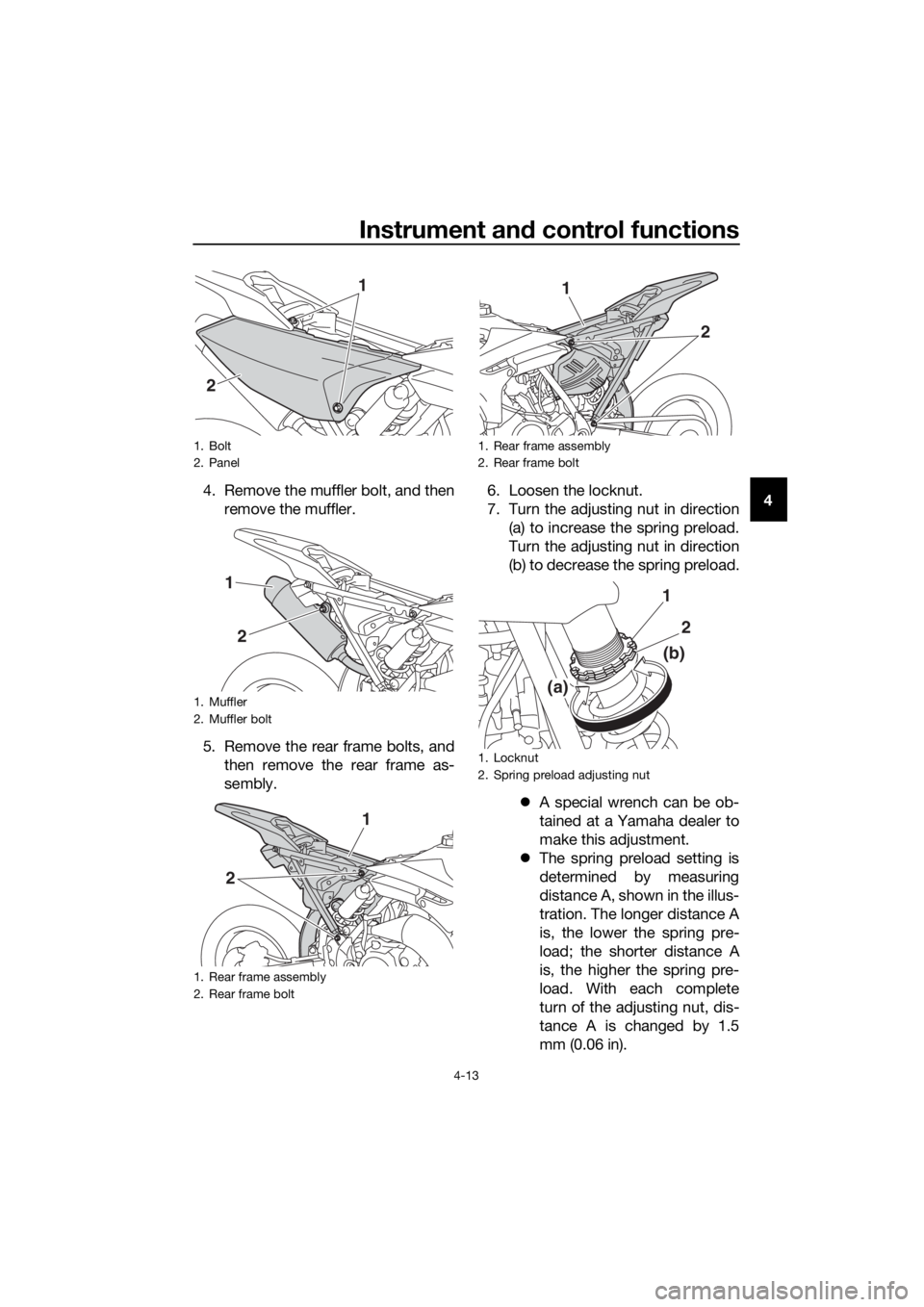

4. Remove the muffler bolt, and then

remove the muffler.

5. Remove the rear frame bolts, and then remove the rear frame as-

sembly. 6. Loosen the locknut.

7. Turn the adjusting nut in direction

(a) to increase the spring preload.

Turn the adjusting nut in direction

(b) to decrease the spring preload.

A special wrench can be ob-

tained at a Yamaha dealer to

make this adjustment.

The spring preload setting is

determined by measuring

distance A, shown in the illus-

tration. The longer distance A

is, the lower the spring pre-

load; the shorter distance A

is, the higher the spring pre-

load. With each complete

turn of the adjusting nut, dis-

tance A is changed by 1.5

mm (0.06 in).

1. Bolt

2. Panel

1. Muffler

2. Muffler bolt

1. Rear frame assembly

2. Rear frame bolt

1

2

2

1

2

1

1. Rear frame assembly

2. Rear frame bolt

1. Locknut

2. Spring preload adjusting nut

2

1

1

2

(a)

(b)

UBR882E0.book Page 13 Wednesday, February 26, 2020 11:39 AM

Page 40 of 92

Instrument and control functions

4-14

4

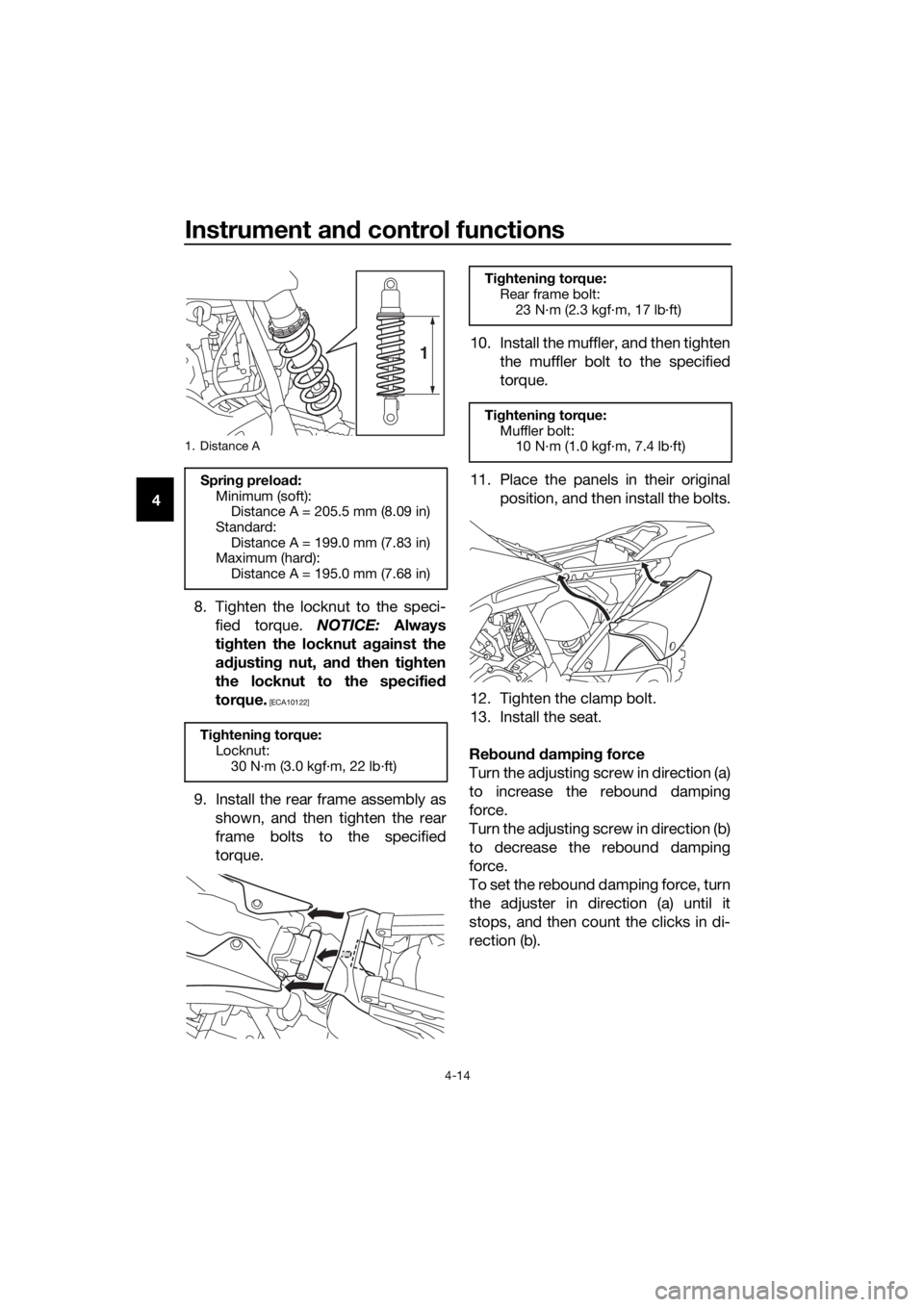

8. Tighten the locknut to the speci-fied torque. NOTICE: Always

ti g hten the locknut ag ainst the

a d justin g nut, and then tighten

the locknut to the specified

torque.

[ECA10122]

9. Install the rear frame assembly as shown, and then tighten the rear

frame bolts to the specified

torque. 10. Install the muffler, and then tighten

the muffler bolt to the specified

torque.

11. Place the panels in their original position, and then install the bolts.

12. Tighten the clamp bolt.

13. Install the seat.

Re boun d d ampin g force

Turn the adjusting screw in direction (a)

to increase the rebound damping

force.

Turn the adjusting screw in direction (b)

to decrease the rebound damping

force.

To set the rebound damping force, turn

the adjuster in direction (a) until it

stops, and then count the clicks in di-

rection (b).

1. Distance A

Sprin g preloa d:

Minimum (soft): Distance A = 205.5 mm (8.09 in)

Standard: Distance A = 199.0 mm (7.83 in)

Maximum (hard):

Distance A = 195.0 mm (7.68 in)

Ti ghtenin g torque:

Locknut: 30 N·m (3.0 kgf·m, 22 lb·ft)

1

Tightening torque:

Rear frame bolt: 23 N·m (2.3 kgf·m, 17 lb·ft)

Ti ghtening torque:

Muffler bolt: 10 N·m (1.0 kgf·m, 7.4 lb·ft)

UBR882E0.book Page 14 Wednesday, February 26, 2020 11:39 AM