YAMAHA YZ65 2021 Manual PDF

Manufacturer: YAMAHA, Model Year: 2021, Model line: YZ65, Model: YAMAHA YZ65 2021Pages: 92, PDF Size: 5.04 MB

Page 71 of 92

Periodic maintenance an d a djustment

7-21

7

EAU22762

Drive chain slack

The drive chain slack should be

checked before each ride and adjusted

if necessary.

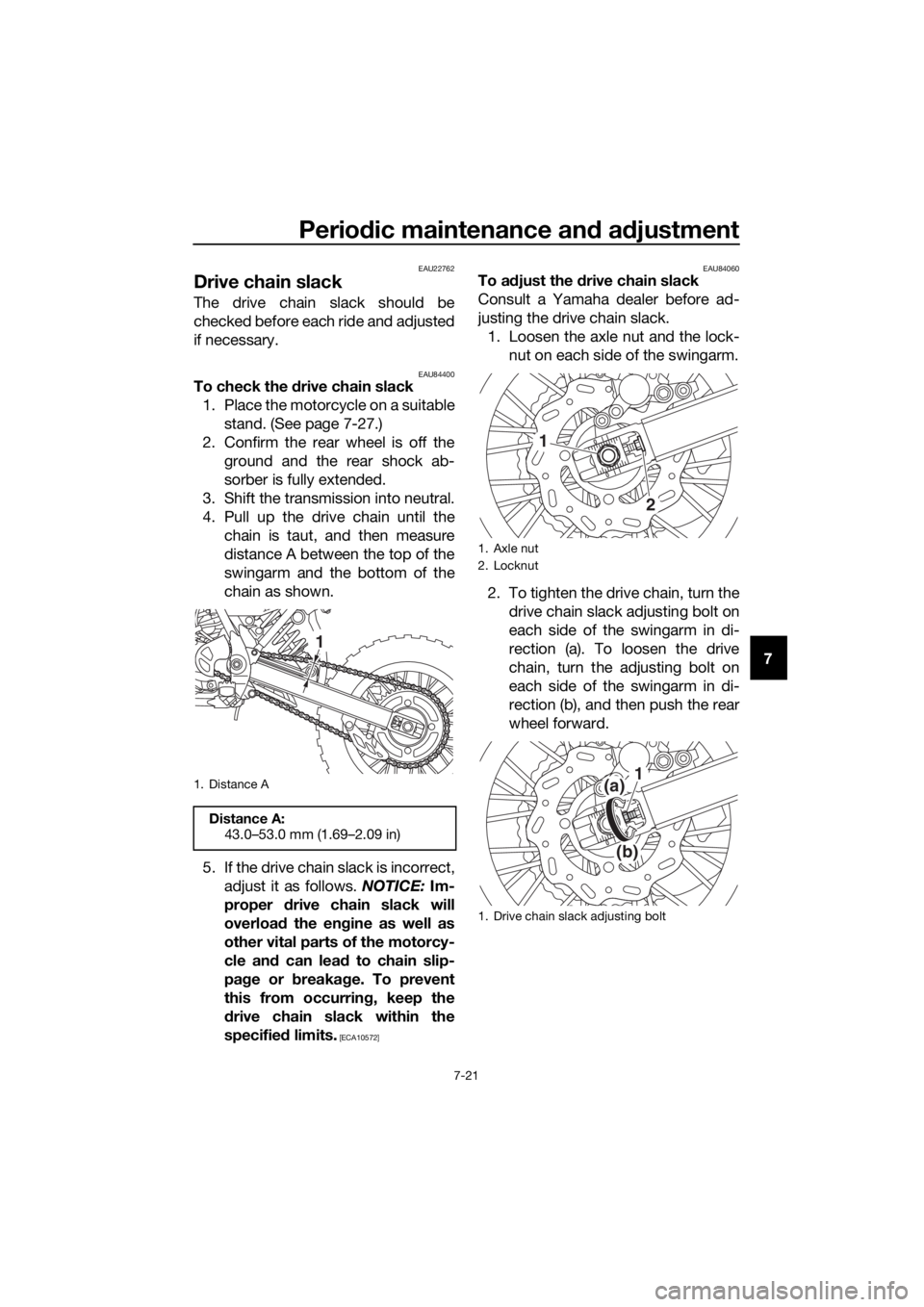

EAU84400To check the d rive chain slack

1. Place the motorcycle on a suitable stand. (See page 7-27.)

2. Confirm the rear wheel is off the ground and the rear shock ab-

sorber is fully extended.

3. Shift the transmission into neutral.

4. Pull up the drive chain until the chain is taut, and then measure

distance A between the top of the

swingarm and the bottom of the

chain as shown.

5. If the drive chain slack is incorrect, adjust it as follows. NOTICE: Im-

proper drive chain slack will

overloa d the en gine as well as

other vital parts of the motorcy-

cle an d can lead to chain slip-

pa ge or b reakag e. To prevent

this from occurrin g, keep the

d rive chain slack within the

specified limits.

[ECA10572] EAU84060

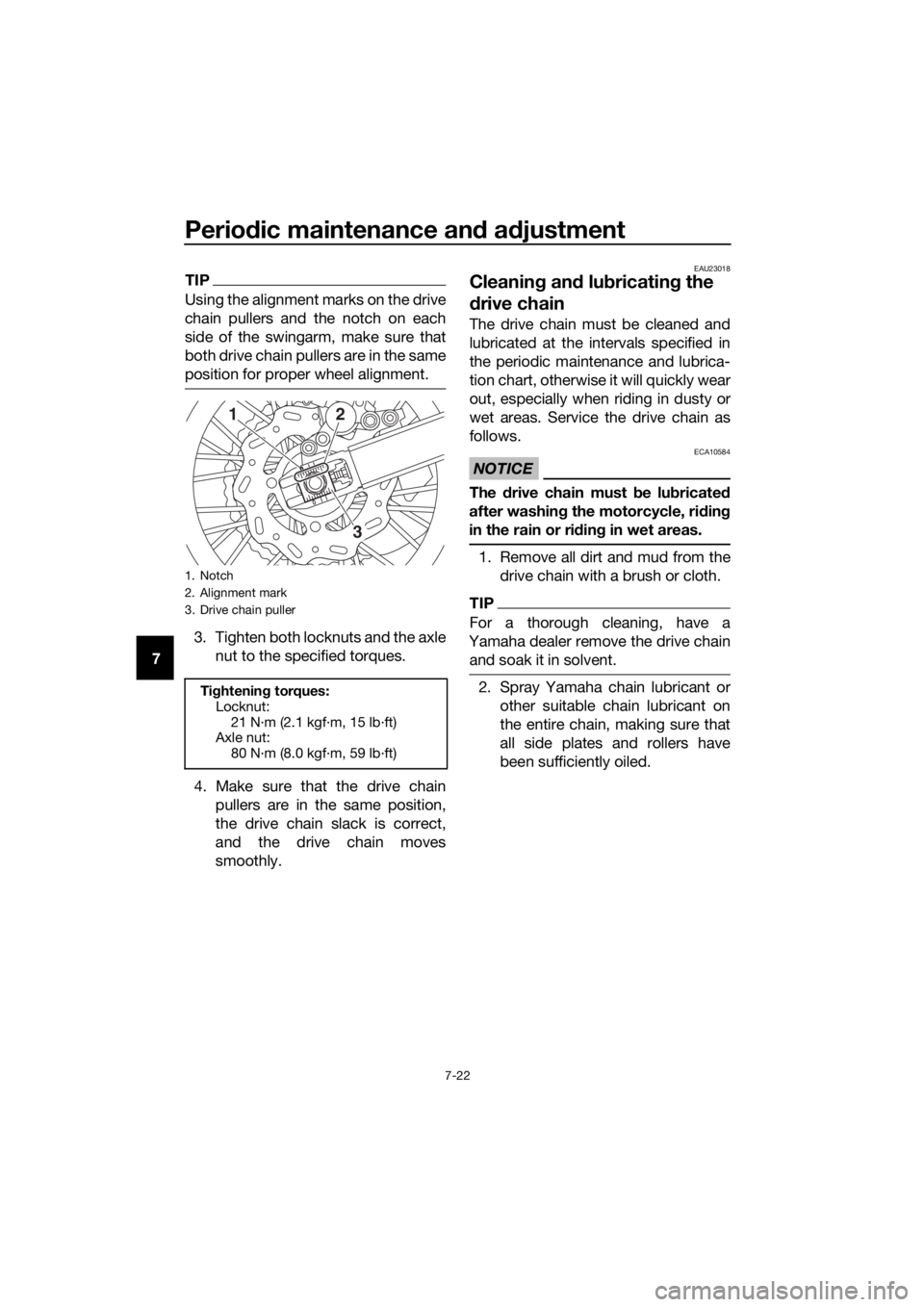

To a

djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward.

1. Distance A

Distance A:43.0–53.0 mm (1.69–2.09 in)

1

1. Axle nut

2. Locknut

1. Drive chain slack adjusting bolt

1

2

(b)

(a) 1

UBR882E0.book Page 21 Wednesday, February 26, 2020 11:39 AM

Page 72 of 92

Periodic maintenance an d a djustment

7-22

7

TIP

Using the alignment marks on the drive

chain pullers and the notch on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

3. Tighten both locknuts and the axle

nut to the specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23018

Cleanin g an d lu bricatin g the

d rive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

NOTICE

ECA10584

The drive chain must b e lubricate d

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.

1. Remove all dirt and mud from the

drive chain with a brush or cloth.

TIP

For a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.

2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

1. Notch

2. Alignment mark

3. Drive chain puller

Tightenin g torques:

Locknut: 21 N·m (2.1 kgf·m, 15 lb·ft)

Axle nut:

80 N·m (8.0 kgf·m, 59 lb·ft)

12

3

UBR882E0.book Page 22 Wednesday, February 26, 2020 11:39 AM

Page 73 of 92

Periodic maintenance an d a djustment

7-23

7

EAU23098

Checkin g an d lu bricatin g the

ca bles

The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or re-

place it. WARNING! Dama ge to the

outer housin g of cab les may result

in internal rustin g an d cause inter-

ference with cab le movement. Re-

place dama ged cab les as soon as

possi ble to prevent unsafe con di-

tions.

[EWA10712] EAU23115

Checkin

g an d lu bricatin g the

throttle grip an d ca ble

The operation of the throttle grip

should be checked before each ride. In

addition, the cable should be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

chart.

The throttle cable is equipped with a

rubber cover. Make sure that the cover

is securely installed. Even though the

cover is installed correctly, it does not

completely protect the cable from wa-

ter entry. Therefore, use care not to

pour water directly onto the cover or

cable when washing the vehicle. If the

cable or cover becomes dirty, wipe

clean with a moist cloth.

Recommen ded lu bricant:

Yamaha cable lubricant or other

suitable cable lubricant

UBR882E0.book Page 23 Wednesday, February 26, 2020 11:39 AM

Page 74 of 92

Periodic maintenance an d a djustment

7-24

7

EAU23144

Checkin g an d lu bricatin g the

b rake an d clutch levers

The operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Brake lever

Clutch lever

EAU23185

Checkin g an d lu bricatin g the

b rake pe dal

The operation of the brake pedal

should be checked before each ride,

and the pedal pivot should be lubricat-

ed if necessary.

Recommen ded lu bricants:

Brake lever: Silicone grease

Clutch lever: Lithium-soap-based grease

Recommen ded lu bricant:

Lithium-soap-based grease

UBR882E0.book Page 24 Wednesday, February 26, 2020 11:39 AM

Page 75 of 92

Periodic maintenance an d a djustment

7-25

7

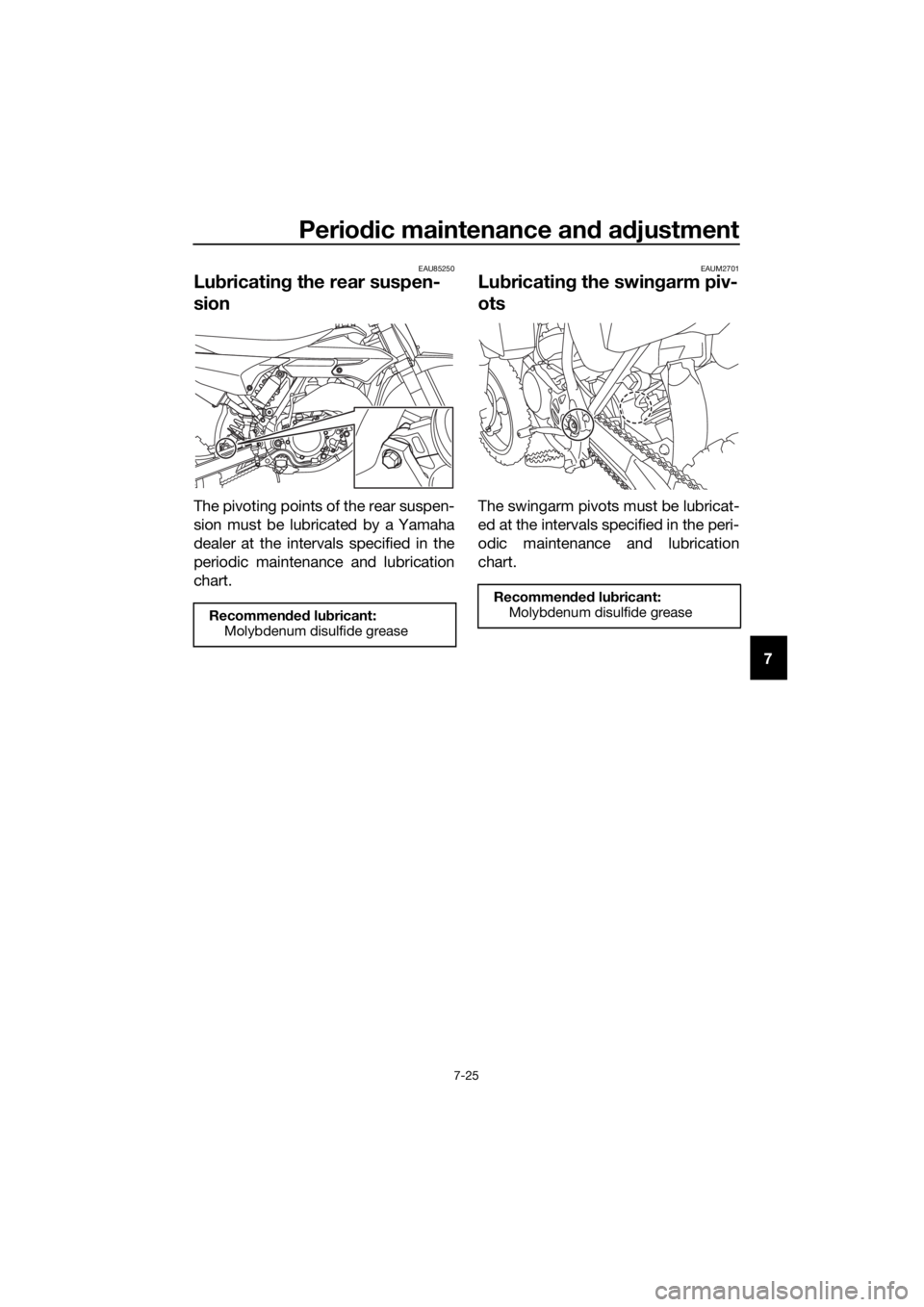

EAU85250

Lub ricatin g the rear suspen-

sion

The pivoting points of the rear suspen-

sion must be lubricated by a Yamaha

dealer at the intervals specified in the

periodic maintenance and lubrication

chart.

EAUM2701

Lu bricatin g the swin garm piv-

ots

The swingarm pivots must be lubricat-

ed at the intervals specified in the peri-

odic maintenance and lubrication

chart.

Recommen ded lu bricant:

Molybdenum disulfide grease

Recommen ded lu bricant:

Molybdenum disulfide grease

UBR882E0.book Page 25 Wednesday, February 26, 2020 11:39 AM

Page 76 of 92

Periodic maintenance an d a djustment

7-26

7

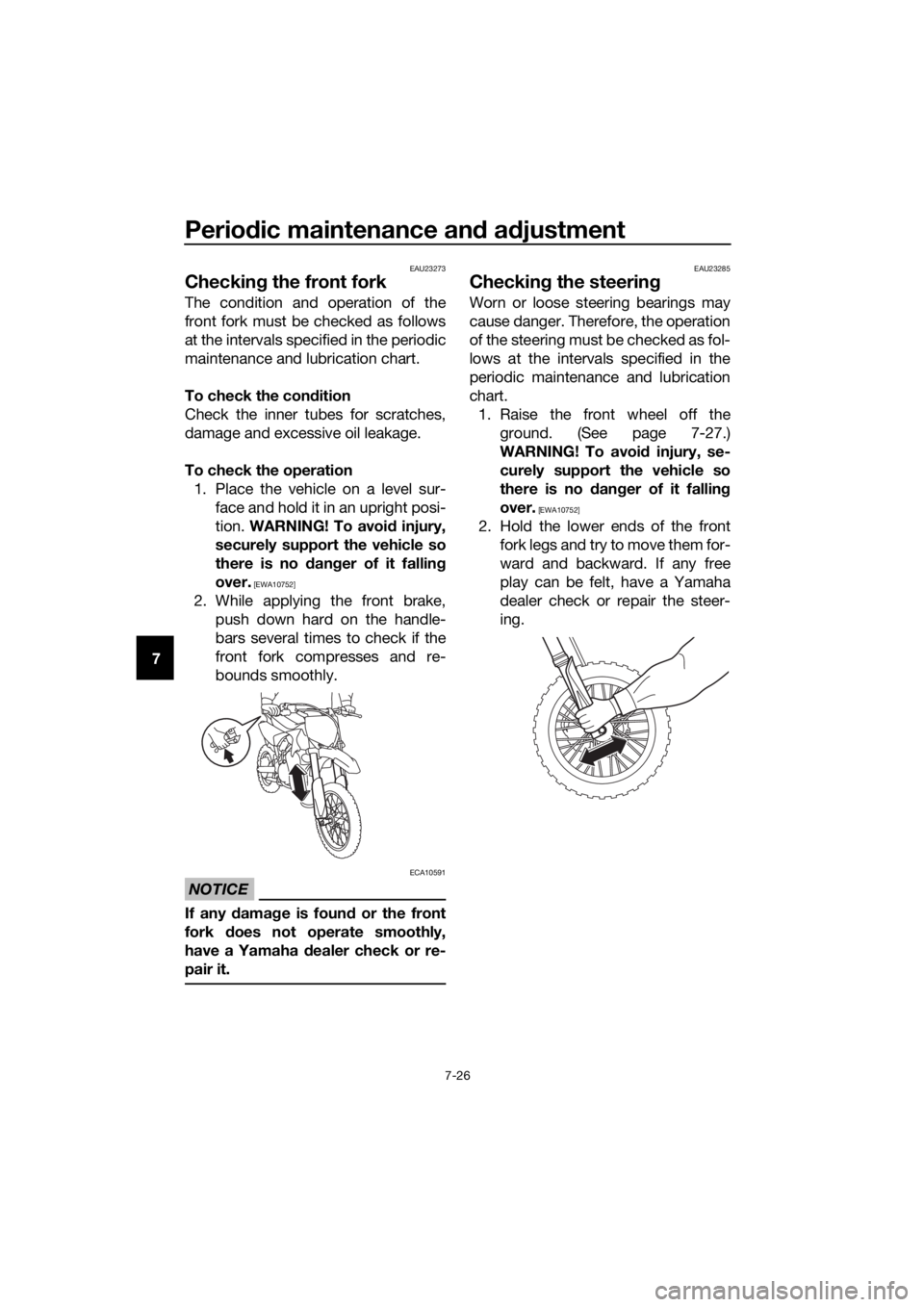

EAU23273

Checkin g the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any d amage is foun d or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAU23285

Checkin g the steerin g

Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Raise the front wheel off the ground. (See page 7-27.)

WARNING! To avoi d injury, se-

curely support the vehicle so

there is no d anger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

UBR882E0.book Page 26 Wednesday, February 26, 2020 11:39 AM

Page 77 of 92

Periodic maintenance an d a djustment

7-27

7

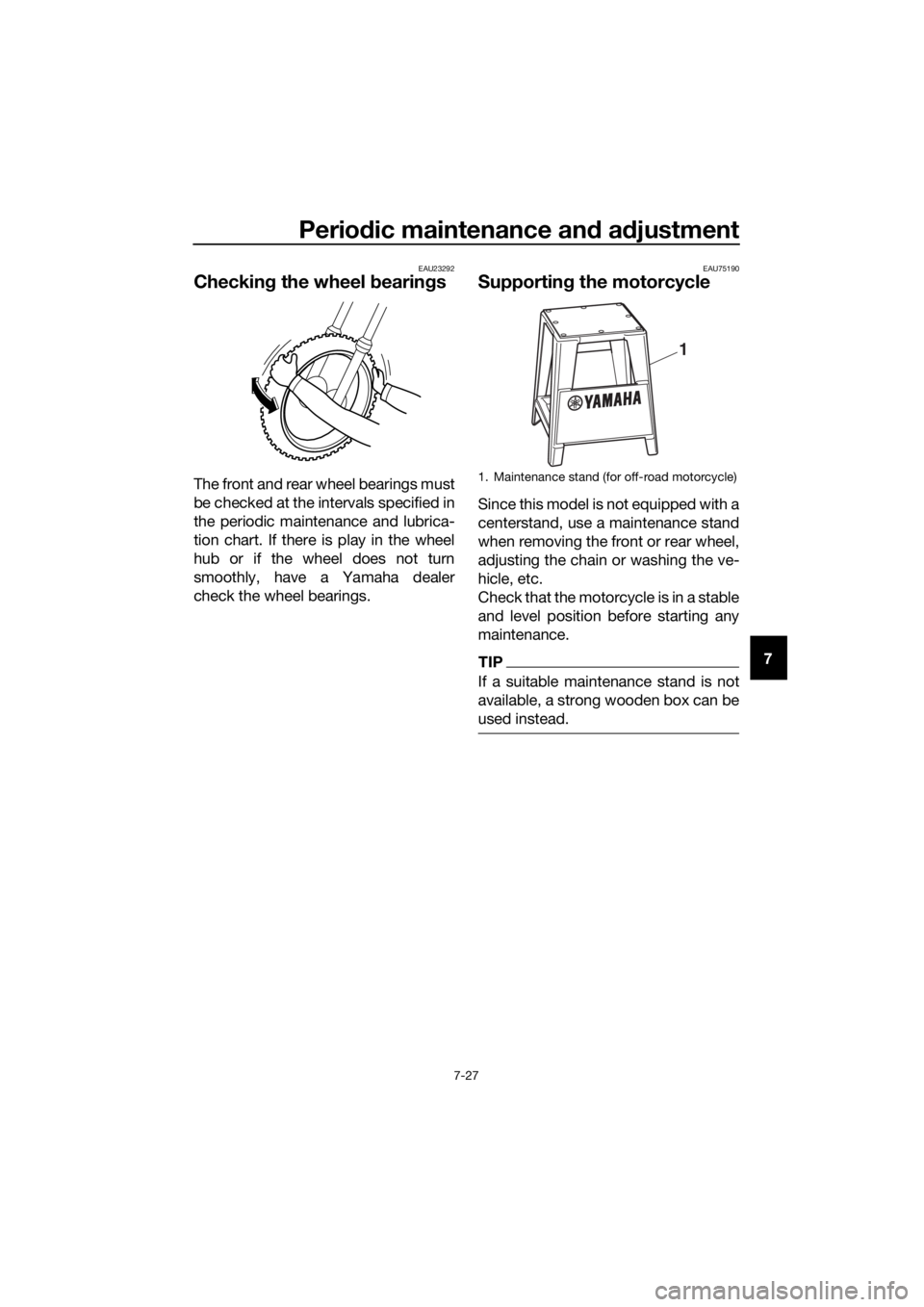

EAU23292

Checkin g the wheel b earings

The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU75190

Supportin g the motorcycle

Since this model is not equipped with a

centerstand, use a maintenance stand

when removing the front or rear wheel,

adjusting the chain or washing the ve-

hicle, etc.

Check that the motorcycle is in a stable

and level position before starting any

maintenance.

TIP

If a suitable maintenance stand is not

available, a strong wooden box can be

used instead.

1. Maintenance stand (for off-road motorcycle)

1

UBR882E0.book Page 27 Wednesday, February 26, 2020 11:39 AM

Page 78 of 92

Periodic maintenance an d a djustment

7-28

7

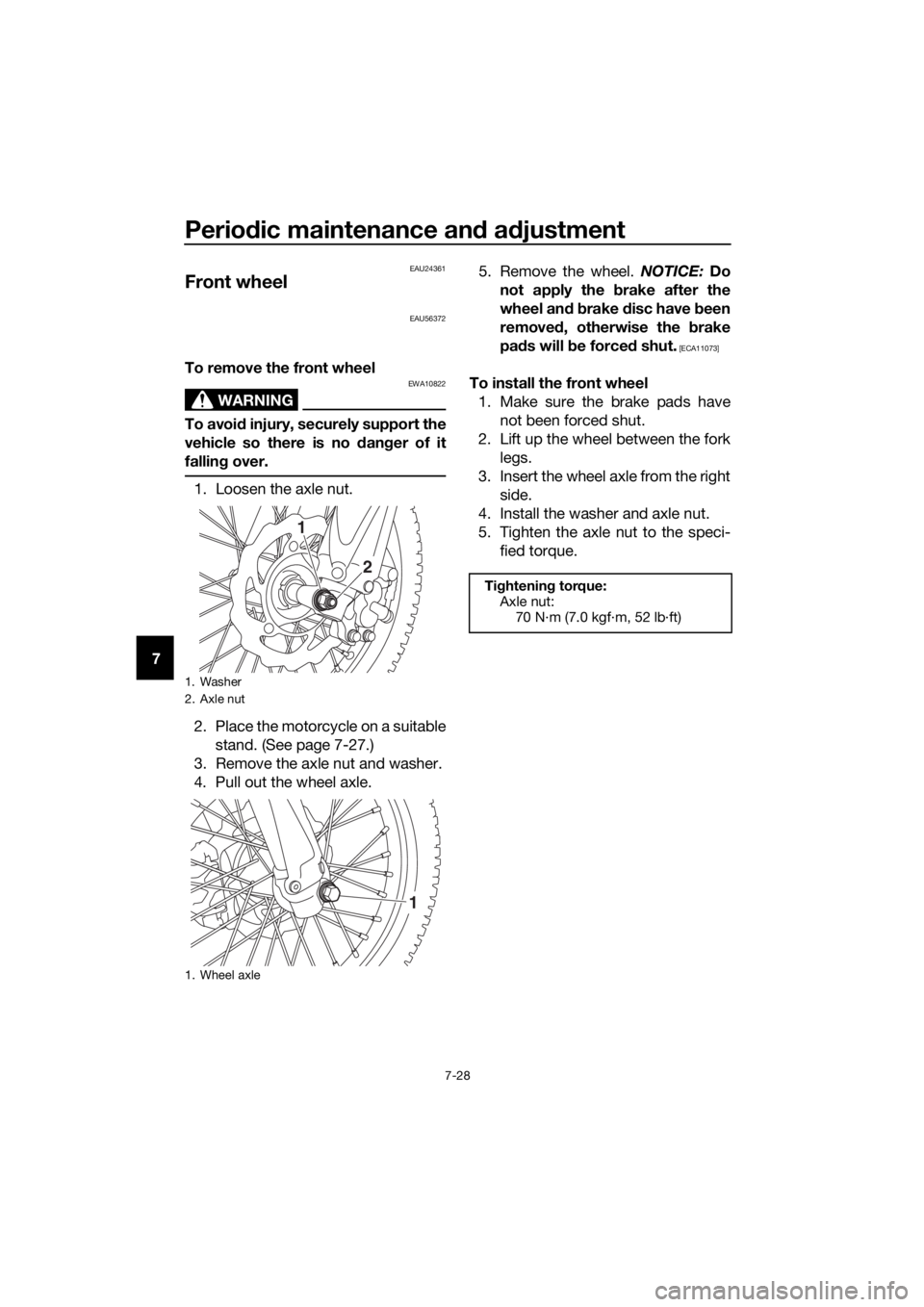

EAU24361

Front wheel

EAU56372

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no d anger of it

fallin g over.

1. Loosen the axle nut.

2. Place the motorcycle on a suitable

stand. (See page 7-27.)

3. Remove the axle nut and washer.

4. Pull out the wheel axle. 5. Remove the wheel.

NOTICE: Do

not apply the brake after the

wheel an d b rake disc have been

remove d, otherwise the brake

pa ds will be forced shut.

[ECA11073]

To install the front wheel

1. Make sure the brake pads have not been forced shut.

2. Lift up the wheel between the fork legs.

3. Insert the wheel axle from the right side.

4. Install the washer and axle nut.

5. Tighten the axle nut to the speci- fied torque.

1. Washer

2. Axle nut

1. Wheel axle

2

1

1

Tightening torque:

Axle nut: 70 N·m (7.0 kgf·m, 52 lb·ft)

UBR882E0.book Page 28 Wednesday, February 26, 2020 11:39 AM

Page 79 of 92

Periodic maintenance an d a djustment

7-29

7

EAU25081

Rear wheel

EAU84051

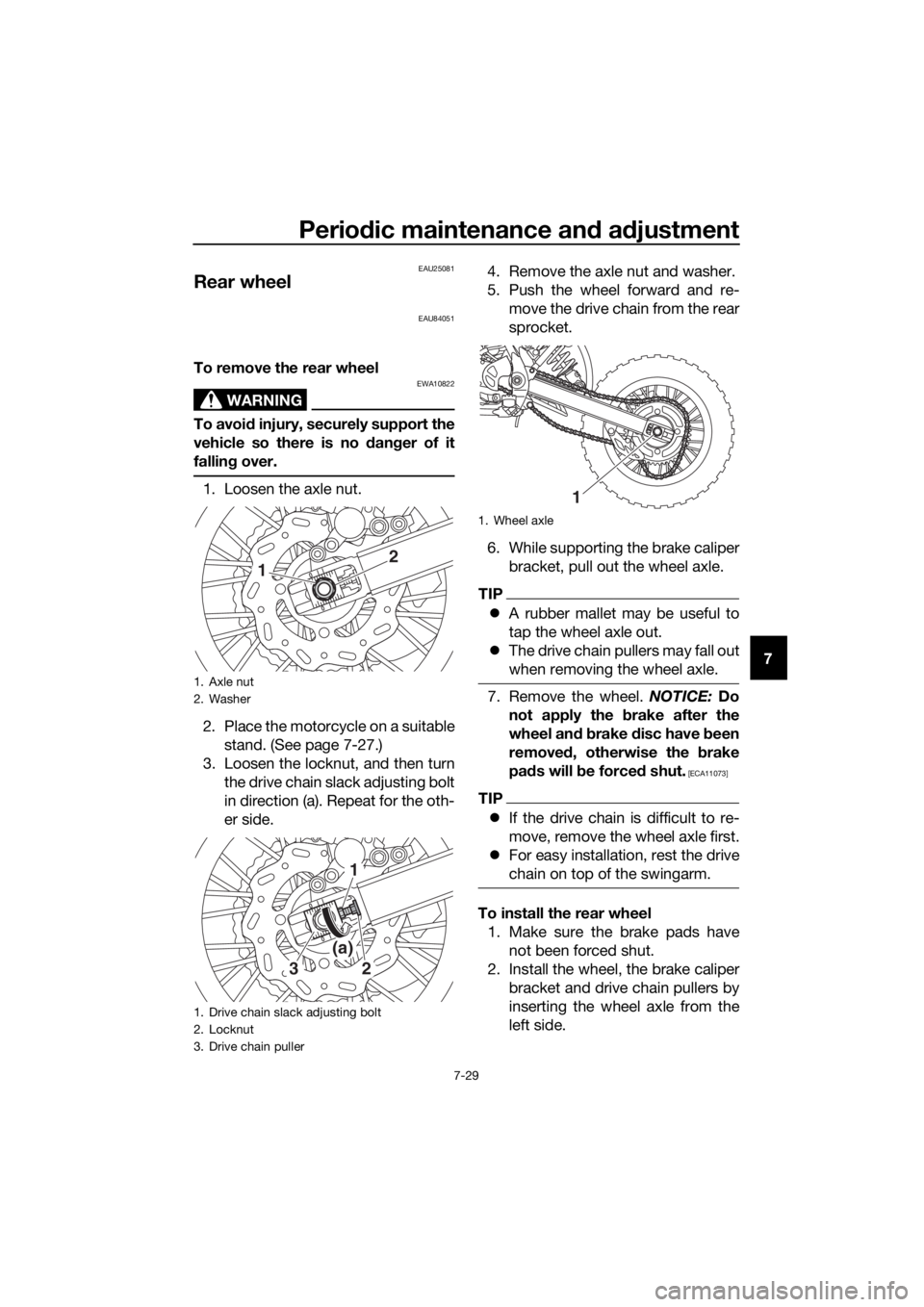

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no d anger of it

fallin g over.

1. Loosen the axle nut.

2. Place the motorcycle on a suitable

stand. (See page 7-27.)

3. Loosen the locknut, and then turn the drive chain slack adjusting bolt

in direction (a). Repeat for the oth-

er side. 4. Remove the axle nut and washer.

5. Push the wheel forward and re-

move the drive chain from the rear

sprocket.

6. While supporting the brake caliper bracket, pull out the wheel axle.

TIP

A rubber mallet may be useful to

tap the wheel axle out.

The drive chain pullers may fall out

when removing the wheel axle.

7. Remove the wheel. NOTICE: Do

not apply the b rake after the

wheel an d b rake disc have been

remove d, otherwise the brake

pa ds will be forced shut.

[ECA11073]

TIP

If the drive chain is difficult to re-

move, remove the wheel axle first.

For easy installation, rest the drive

chain on top of the swingarm.

To install the rear wheel

1. Make sure the brake pads have not been forced shut.

2. Install the wheel, the brake caliper bracket and drive chain pullers by

inserting the wheel axle from the

left side.

1. Axle nut

2. Washer

1. Drive chain slack adjusting bolt

2. Locknut

3. Drive chain puller

12

23

(a)1

1. Wheel axle

1

UBR882E0.book Page 29 Wednesday, February 26, 2020 11:39 AM

Page 80 of 92

Periodic maintenance an d a djustment

7-30

7

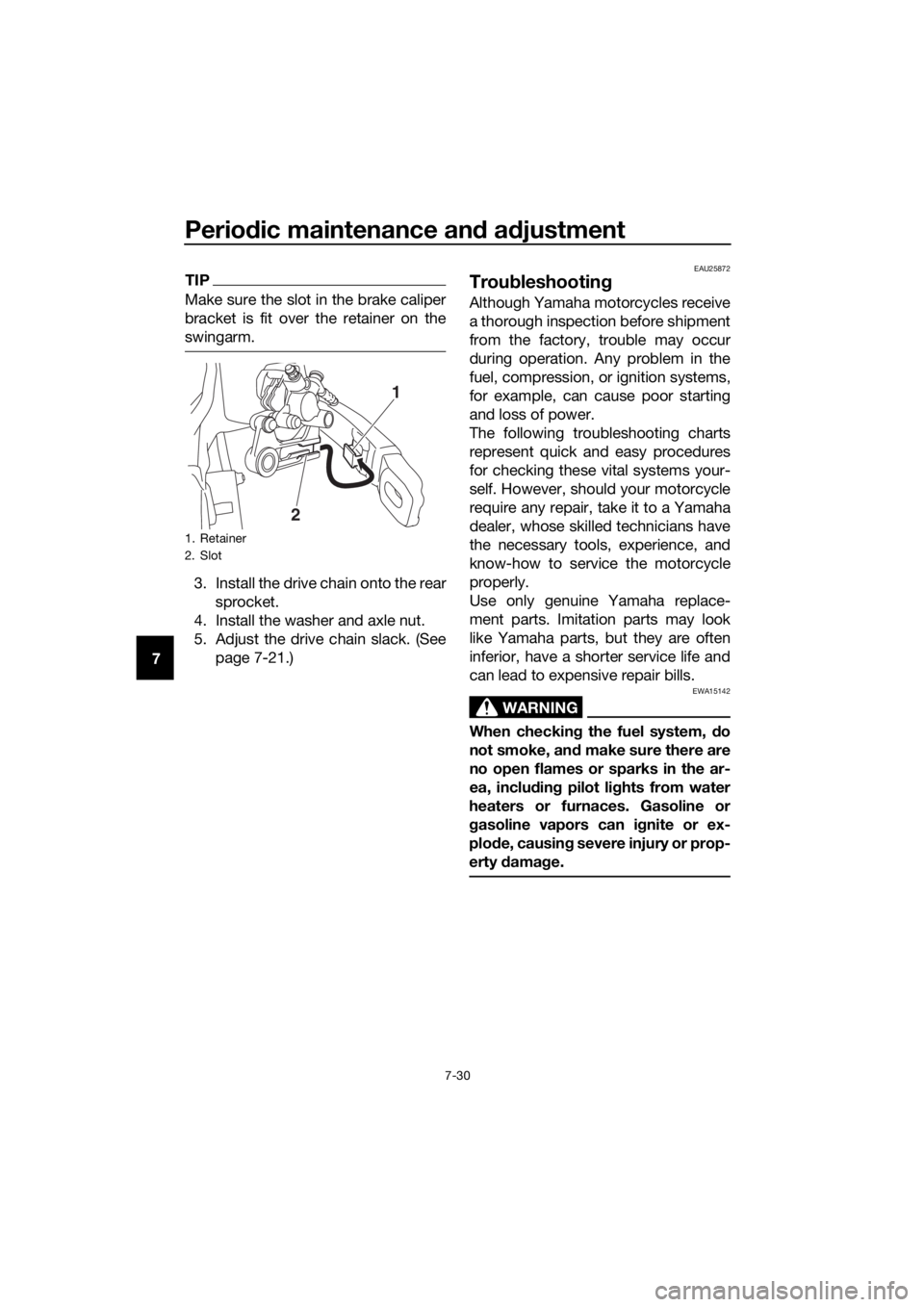

TIP

Make sure the slot in the brake caliper

bracket is fit over the retainer on the

swingarm.

3. Install the drive chain onto the rear

sprocket.

4. Install the washer and axle nut.

5. Adjust the drive chain slack. (See page 7-21.)

EAU25872

Trou bleshootin g

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

heaters or furnaces. Gasoline or

g asoline vapors can i gnite or ex-

plo de, causin g severe injury or prop-

erty damag e.

1. Retainer

2. Slot

1

2

UBR882E0.book Page 30 Wednesday, February 26, 2020 11:39 AM