engine YAMAHA YZ85 2002 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 32 of 504

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is overhauled.

All gasket surfaces, oil seal lips, and O-

rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

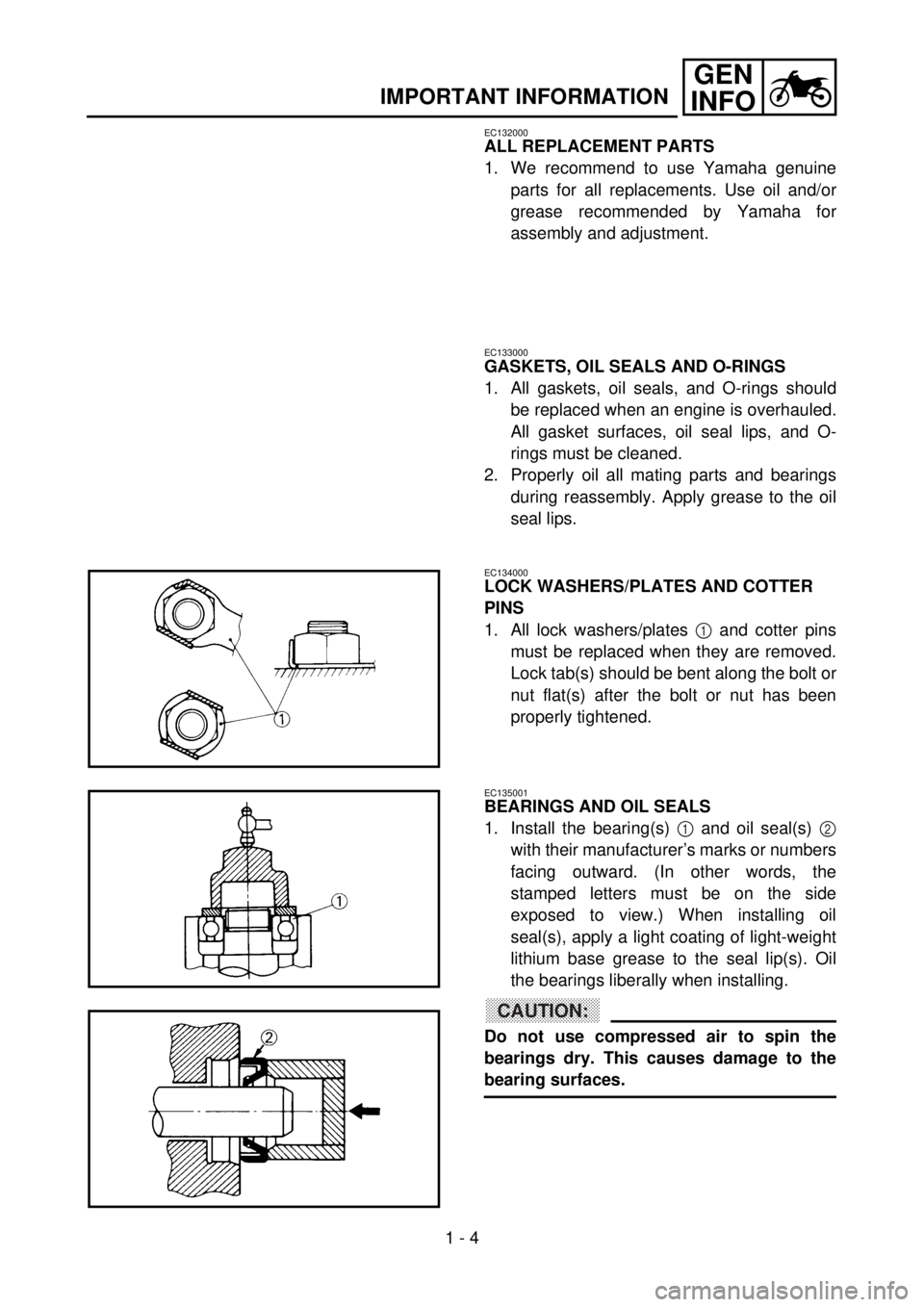

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

5PA10120

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

5PA10130

5PA10140

Page 44 of 504

1 - 9

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

ENGINE STOP SWITCH

The engine stop switch 1 is located on the left

handlebar. Continue pushing the engine stop

switch till the engine comes to a stop.

5PA10420

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disen-

gage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

5PA10430

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 6 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

5PA10440

KICKSTARTER CRANK

Rotate the kickstarter crank 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kickstarter crank so the engine

can be started in any gear if the clutch is disen-

gaged. In normal practices, however, shift to

neutral before starting.

5PA10450

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

5PA10460

Page 46 of 504

1 - 10

GEN

INFO

CONTROL FUNCTIONS

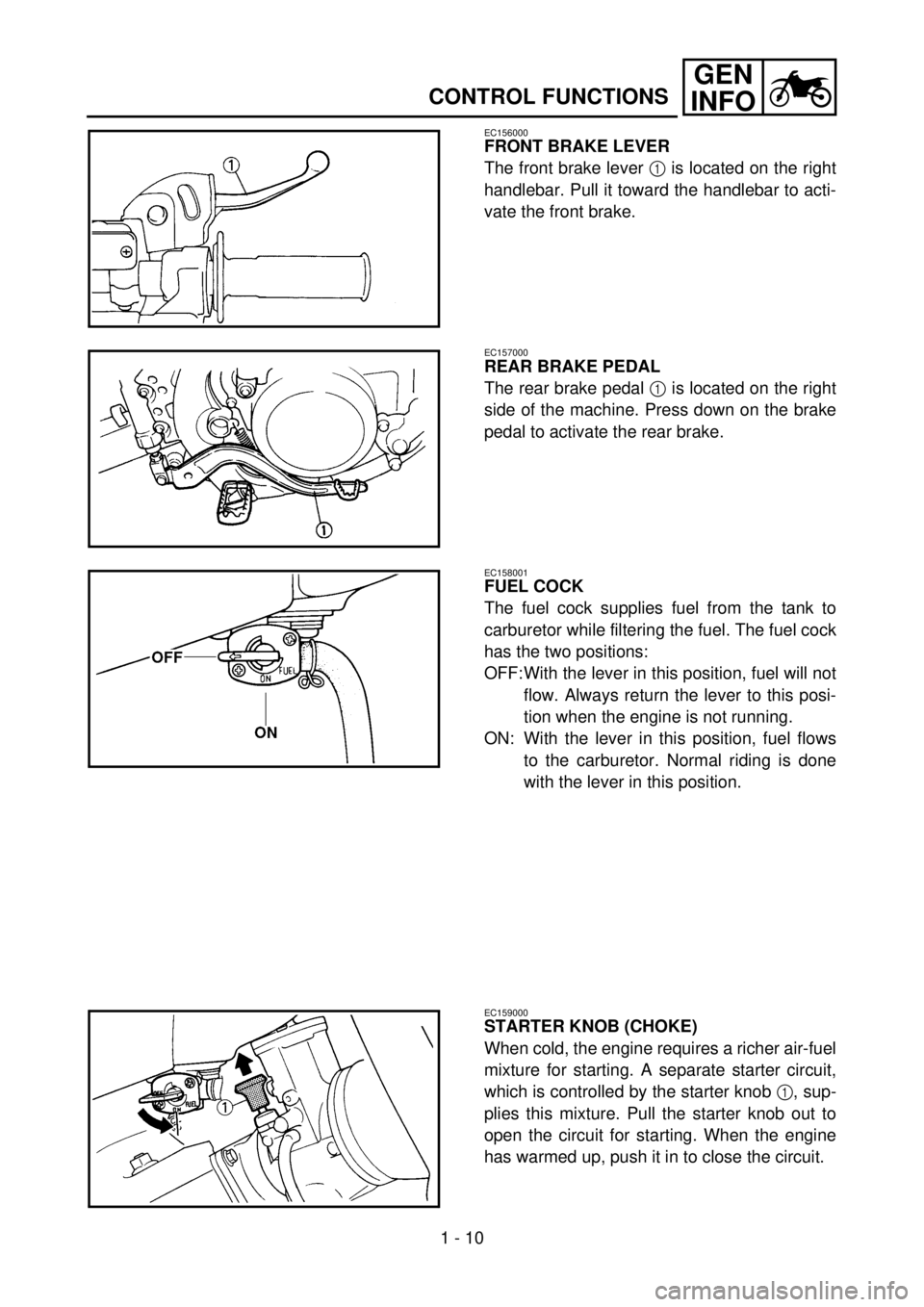

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

5PA10470

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

5PA10480

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the two positions:

OFF:With the lever in this position, fuel will not

flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

5PA10490

EC159000

STARTER KNOB (CHOKE)

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter knob 1, sup-

plies this mixture. Pull the starter knob out to

open the circuit for starting. When the engine

has warmed up, push it in to close the circuit.

5PA10500

Page 50 of 504

1 - 12

GEN

INFO

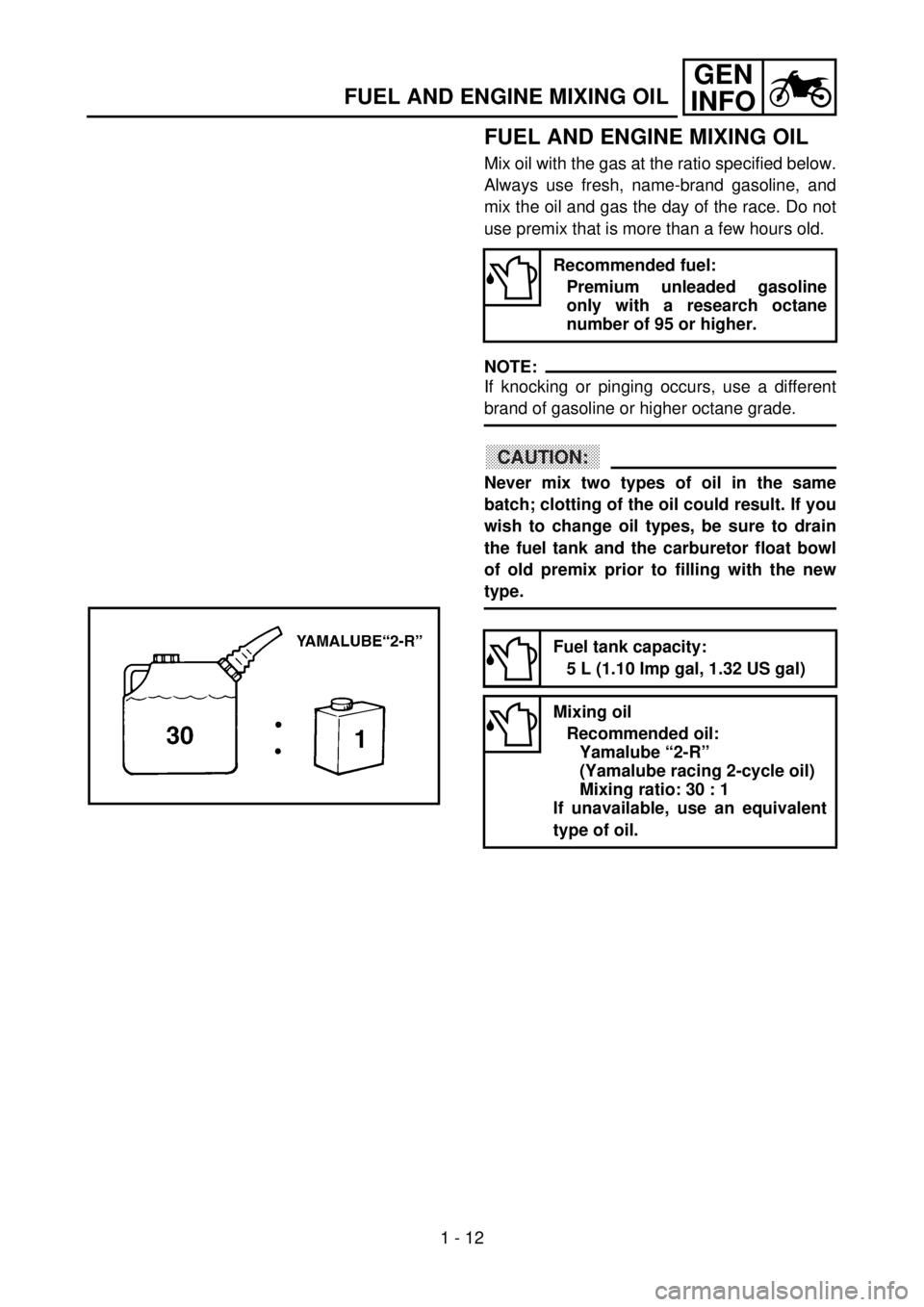

FUEL AND ENGINE MIXING OIL

FUEL AND ENGINE MIXING OIL

Mix oil with the gas at the ratio specified below.

Always use fresh, name-brand gasoline, and

mix the oil and gas the day of the race. Do not

use premix that is more than a few hours old.

NOTE:

If knocking or pinging occurs, use a different

brand of gasoline or higher octane grade.

CAUTION:

Never mix two types of oil in the same

batch; clotting of the oil could result. If you

wish to change oil types, be sure to drain

the fuel tank and the carburetor float bowl

of old premix prior to filling with the new

type.

Recommended fuel:

Premium unleaded gasoline

only with a research octane

number of 95 or higher.

Fuel tank capacity:

5 L (1.10 Imp gal, 1.32 US gal)

Mixing oil

Recommended oil:

Yamalube “2-R”

(Yamalube racing 2-cycle oil)

Mixing ratio: 30 : 1

If unavailable, use an equivalent

type of oil.

5PA10540

Page 52 of 504

1 - 13

GEN

INFO

STARTING AND BREAK-IN

STARTING AND BREAK-IN

CAUTION:

Before starting the machine, perform the

checks in the pre-operation check list.

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

STARTING A COLD ENGINE

1. Shift the transmission into neutral.

2. Turn the fuel cock to “ON” and full open the

starter knob (CHOKE).

3. With the throttle completely closed start the

engine by kicking the kickstarter crank

forthly with firm stroke.

4. Run the engine at idle or slightly higher

until it warms up: this usually takes about

one or two minutes.

5. The engine is warmed up when it responds

normally to the throttle with the starter knob

(CHOKE) turned off.

CAUTION:

Do not warm up the engine for extended

periods.

STARTING A WARM ENGINE

Do not operate the starter knob (CHOKE).

Open the throttle slightly and start the engine

by kicking the kickstarter crank forcefully with

firm stroke.

CAUTION:

Observe the following break-in procedures

during initial operation to ensure optimum

performance and avoid engine damage.

Page 54 of 504

1 - 14

GEN

INFO

STARTING AND BREAK-IN

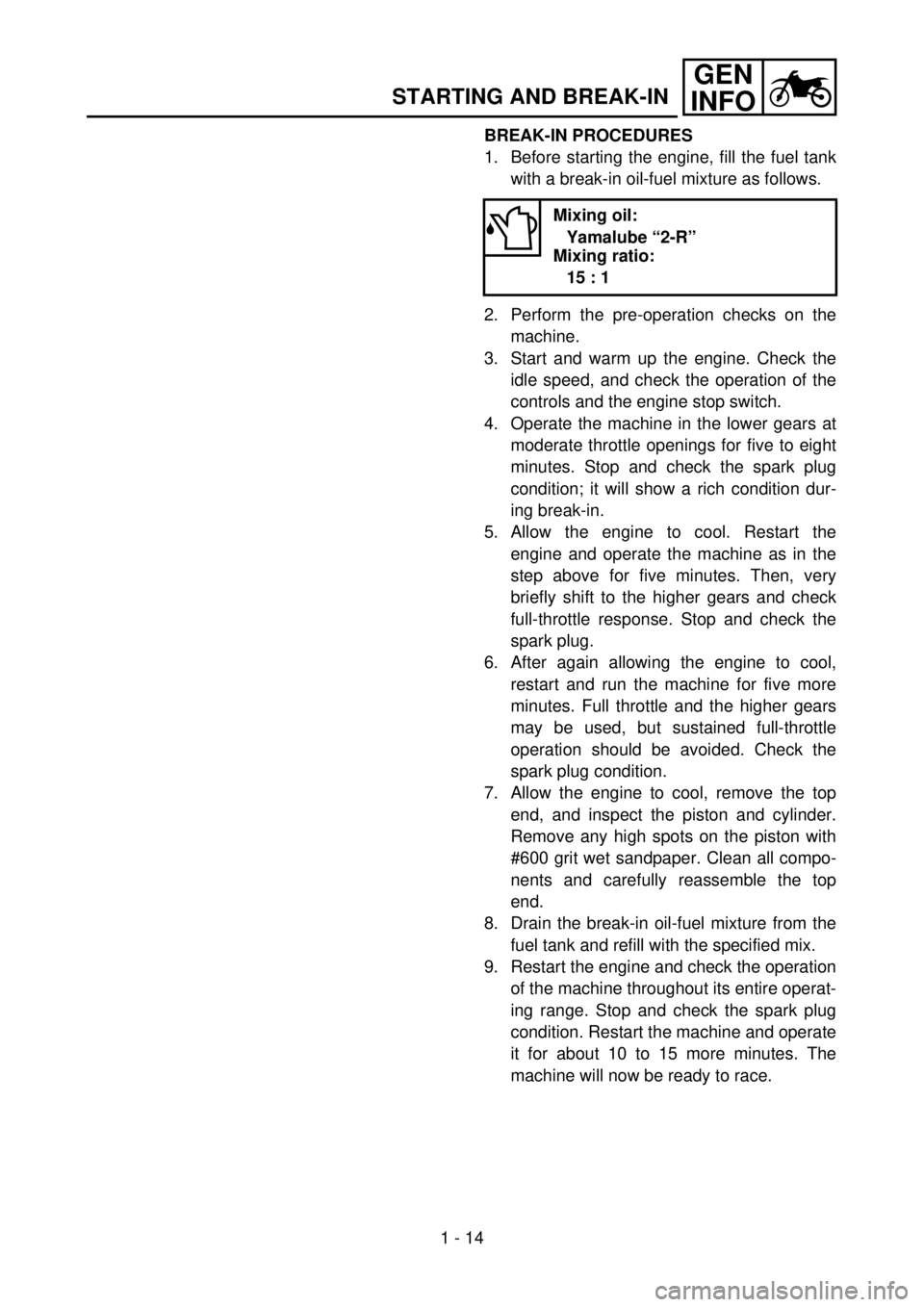

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with a break-in oil-fuel mixture as follows.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the engine stop switch.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes. Stop and check the spark plug

condition; it will show a rich condition dur-

ing break-in.

5. Allow the engine to cool. Restart the

engine and operate the machine as in the

step above for five minutes. Then, very

briefly shift to the higher gears and check

full-throttle response. Stop and check the

spark plug.

6. After again allowing the engine to cool,

restart and run the machine for five more

minutes. Full throttle and the higher gears

may be used, but sustained full-throttle

operation should be avoided. Check the

spark plug condition.

7. Allow the engine to cool, remove the top

end, and inspect the piston and cylinder.

Remove any high spots on the piston with

#600 grit wet sandpaper. Clean all compo-

nents and carefully reassemble the top

end.

8. Drain the break-in oil-fuel mixture from the

fuel tank and refill with the specified mix.

9. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Stop and check the spark plug

condition. Restart the machine and operate

it for about 10 to 15 more minutes. The

machine will now be ready to race.

Mixing oil:

Yamalube “2-R”

Mixing ratio:

15 : 1

Page 56 of 504

1 - 15

GEN

INFO

STARTING AND BREAK-IN

CAUTION:

lAfter the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

lWhen any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

Page 58 of 504

GEN

INFO

1 - 16

TORQUE-CHECK POINTS

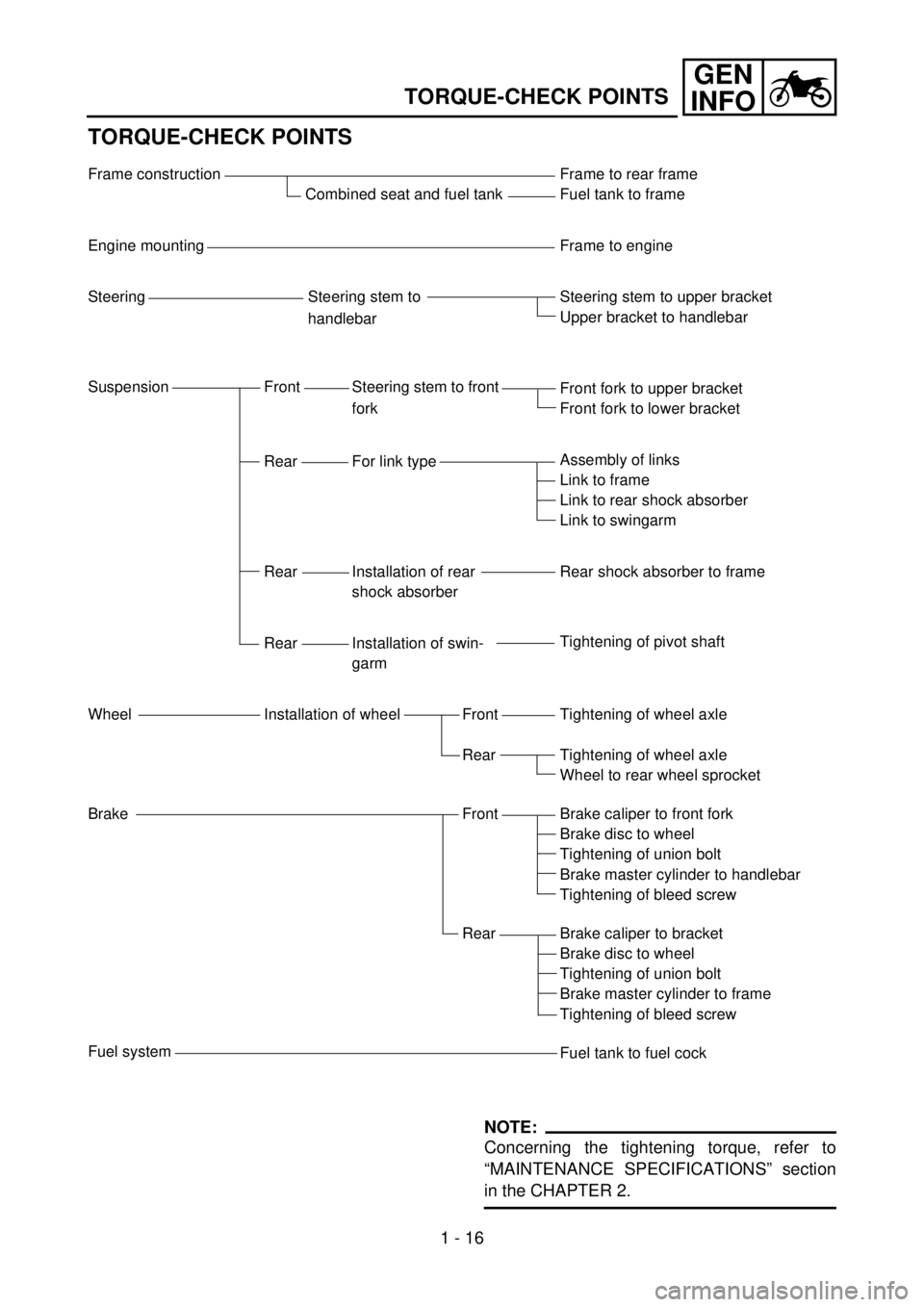

TORQUE-CHECK POINTS

Frame construction

Combined seat and fuel tank

Engine mounting

Steering Steering stem to

handlebar

Suspension Front Steering stem to front

fork

Rear For link type

Rear Installation of rear

shock absorber

Rear Installation of swin-

garm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel systemFrame to rear frame

Fuel tank to frame

Frame to engine

Steering stem to upper bracket

Upper bracket to handlebar

Front fork to upper bracket

Front fork to lower bracket

Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear shock absorber to frame

Tightening of pivot shaft

Tightening of wheel axle

Tightening of wheel axle

Wheel to rear wheel sprocket

Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Brake caliper to bracket

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Page 62 of 504

1 - 17

GEN

INFO

CLEANING AND STORAGE

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will

enhance its appearance, maintain good overall

performance, and extend the life of many com-

ponents.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering. A plastic bag secured with a

rubber band may be used for this purpose.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprock-

ets, or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

CAUTION:

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been

hosed off, wash all surfaces with warm

water and a mild detergent. Use an old

toothbrush to clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel

and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery

cleaner to keep the cover pliable and

glossy.

8. Automotive wax may be applied to all

painted or chromed surfaces. Avoid combi-

nation cleaner-waxes, as they may contain

abrasives.

9. After completing the above, start the

engine and allow it to idle for several min-

utes.

Page 64 of 504

1 - 18

GEN

INFO

CLEANING AND STORAGE

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.