YAMAHA YZ85 2013 Manual PDF

Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ85, Model: YAMAHA YZ85 2013Pages: 88, PDF Size: 1.74 MB

Page 71 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-26

7

EAUM1652

Lubricating the swingarm piv-

ots The swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23272

Checking the front fork The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10751]

2. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

NOTICE

ECA10590

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

Recommended lubricant:Lithium-soap-based grease

U1SN81E0.book Page 26 Tuesday, June 12, 2012 3:17 PM

Page 72 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-27

7

EAU23283

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.1. Place a stand under the engine to raise the front wheel off the

ground. (See page 7-27 for more

information.) WARNING! To

avoid injury, securely support

the vehicle so there is no danger

of it falling over.

[EWA10751]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

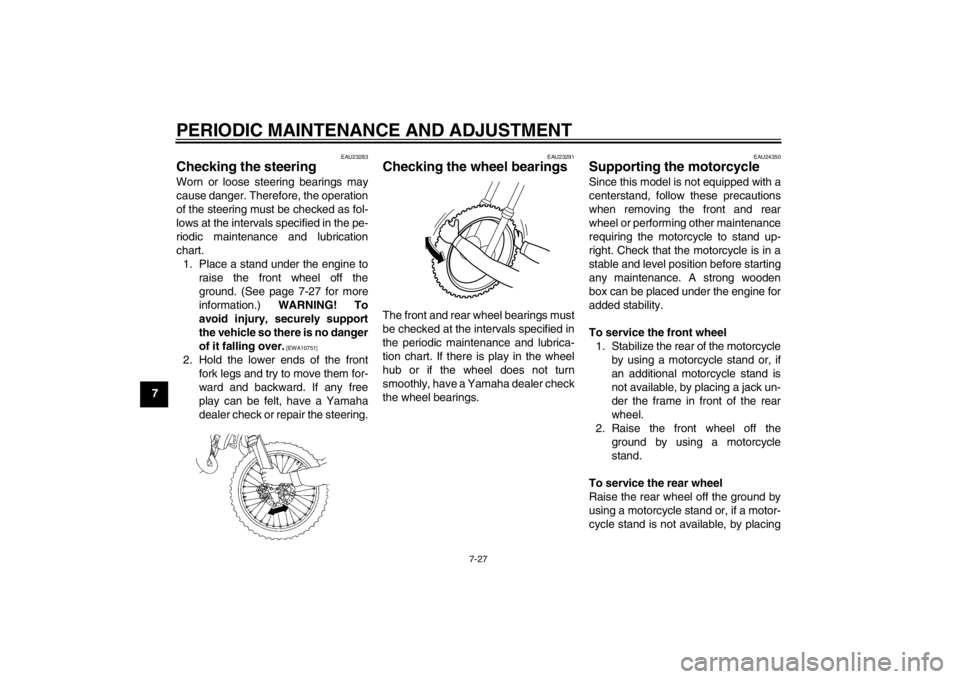

EAU23291

Checking the wheel bearings The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

EAU24350

Supporting the motorcycle Since this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other maintenance

requiring the motorcycle to stand up-

right. Check that the motorcycle is in a

stable and level position before starting

any maintenance. A strong wooden

box can be placed under the engine for

added stability.

To service the front wheel1. Stabilize the rear of the motorcycle by using a motorcycle stand or, if

an additional motorcycle stand is

not available, by placing a jack un-

der the frame in front of the rear

wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

U1SN81E0.book Page 27 Tuesday, June 12, 2012 3:17 PM

Page 73 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-28

7

a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

EAU24360

Front wheel

EAU41343

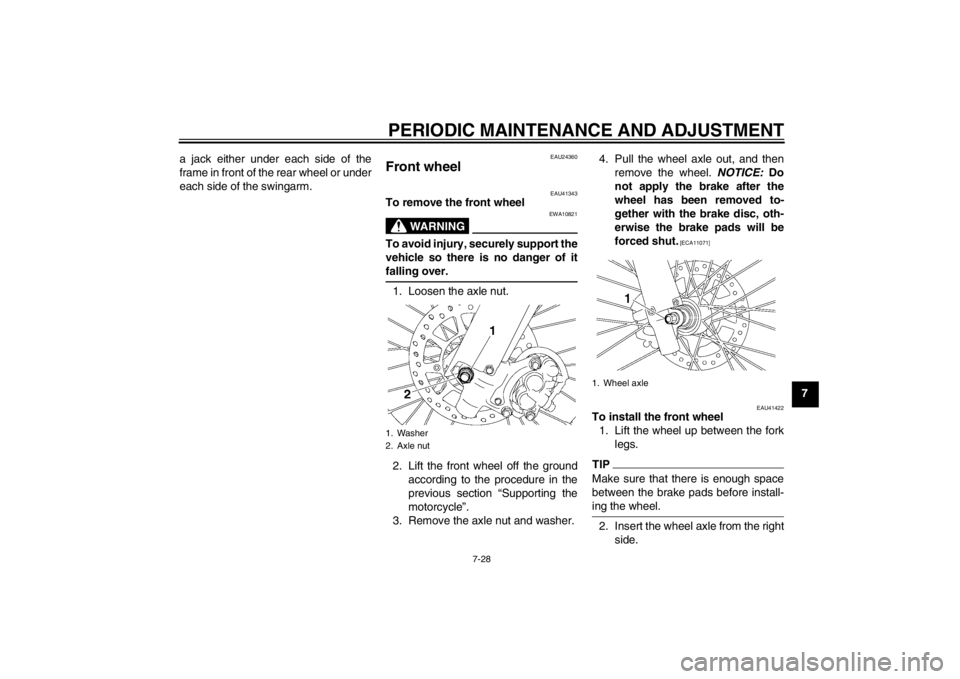

To remove the front wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Loosen the axle nut.

2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the axle nut and washer. 4. Pull the wheel axle out, and then

remove the wheel. NOTICE: Do

not apply the brake after the

wheel has been removed to-

gether with the brake disc, oth-

erwise the brake pads will be

forced shut.

[ECA11071]

EAU41422

To install the front wheel1. Lift the wheel up between the fork legs.TIPMake sure that there is enough space

between the brake pads before install-

ing the wheel.2. Insert the wheel axle from the rightside.

1. Washer

2. Axle nut

1. Wheel axle

U1SN81E0.book Page 28 Tuesday, June 12, 2012 3:17 PM

Page 74 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-29

73. Lower the front wheel so that it is

on the ground, install the remov-

able sidestand, and then rest the

motorcycle on it.

4. Install the washer and axle nut, and then tighten the axle nut to the

specified torque.

EAU25080

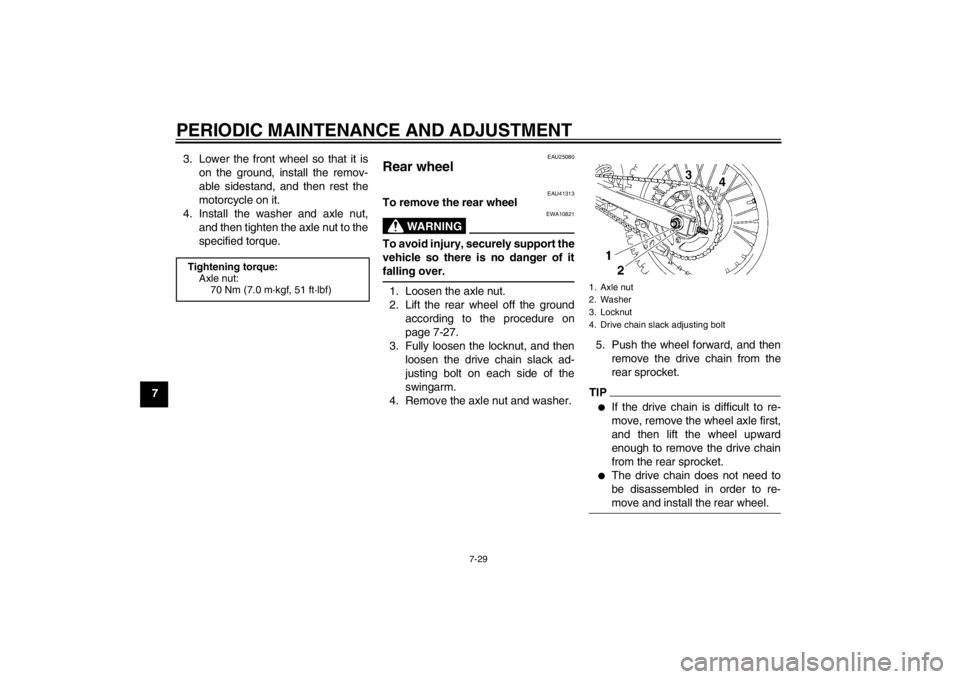

Rear wheel

EAU41313

To remove the rear wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Loosen the axle nut.

2. Lift the rear wheel off the groundaccording to the procedure on

page 7-27.

3. Fully loosen the locknut, and then loosen the drive chain slack ad-

justing bolt on each side of the

swingarm.

4. Remove the axle nut and washer. 5. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

TIP●

If the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

●

The drive chain does not need to

be disassembled in order to re-

move and install the rear wheel.

Tightening torque:Axle nut:70 Nm (7.0 m·kgf, 51 ft·lbf)

1. Axle nut

2. Washer

3. Locknut

4. Drive chain slack adjusting bolt

U1SN81E0.book Page 29 Tuesday, June 12, 2012 3:17 PM

Page 75 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-30

7

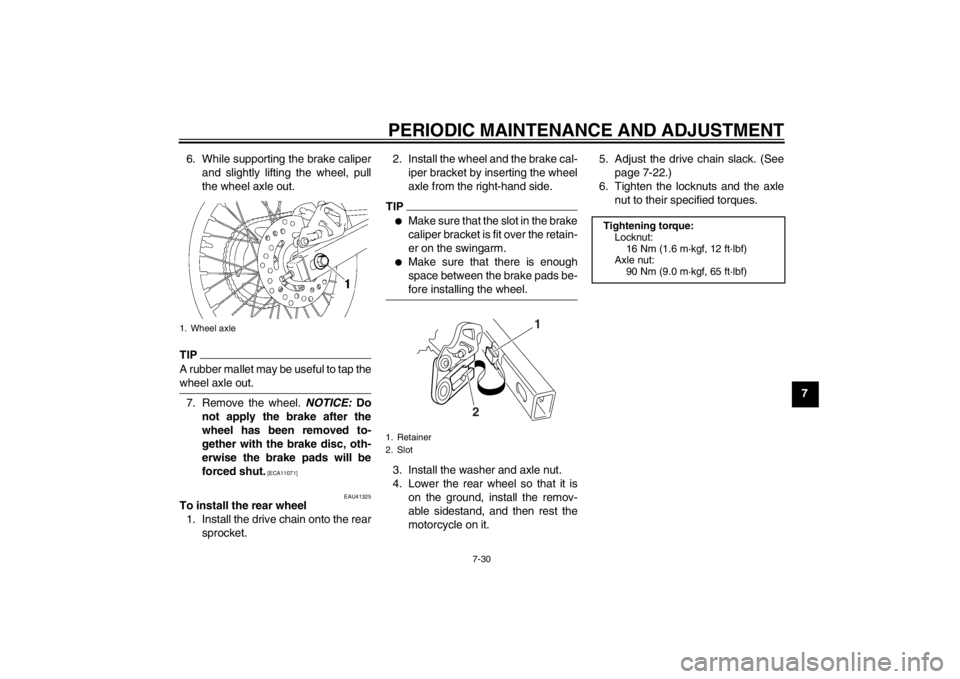

6. While supporting the brake caliper

and slightly lifting the wheel, pull

the wheel axle out.

TIPA rubber mallet may be useful to tap the

wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the brake after the

wheel has been removed to-

gether with the brake disc, oth-

erwise the brake pads will be

forced shut.

[ECA11071]

EAU41325

To install the rear wheel1. Install the drive chain onto the rear sprocket. 2. Install the wheel and the brake cal-

iper bracket by inserting the wheel

axle from the right-hand side.

TIP●

Make sure that the slot in the brake

caliper bracket is fit over the retain-

er on the swingarm.

●

Make sure that there is enough

space between the brake pads be-

fore installing the wheel.

3. Install the washer and axle nut.

4. Lower the rear wheel so that it ison the ground, install the remov-

able sidestand, and then rest the

motorcycle on it. 5. Adjust the drive chain slack. (See

page 7-22.)

6. Tighten the locknuts and the axle nut to their specified torques.

1. Wheel axle

1. Retainer

2. Slot

2 1

Tightening torque:

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

Axle nut:

90 Nm (9.0 m·kgf, 65 ft·lbf)

U1SN81E0.book Page 30 Tuesday, June 12, 2012 3:17 PM

Page 76 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-31

7

EAU25871

Troubleshooting Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi- or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15141

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.U1SN81E0.book Page 31 Tuesday, June 12, 2012 3:17 PM

Page 77 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-32

7

EAU41493

Troubleshooting charts Starting problems or poor engine performance

Check the fuel level in

the fuel tank.1. Fuel

There is

enough fuel.

There is

no fuel.

Supply fuel.

Operate the kickstarter.2. Compression

There is compression.

There is

no compression. Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wet

Dry Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer check the vehicle.

Open the throttle halfway and operate

the kickstarter.

Check the compression.

The engine does not start.

Check the compression.

U1SN81E0.book Page 32 Tuesday, June 12, 2012 3:17 PM

Page 78 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-33

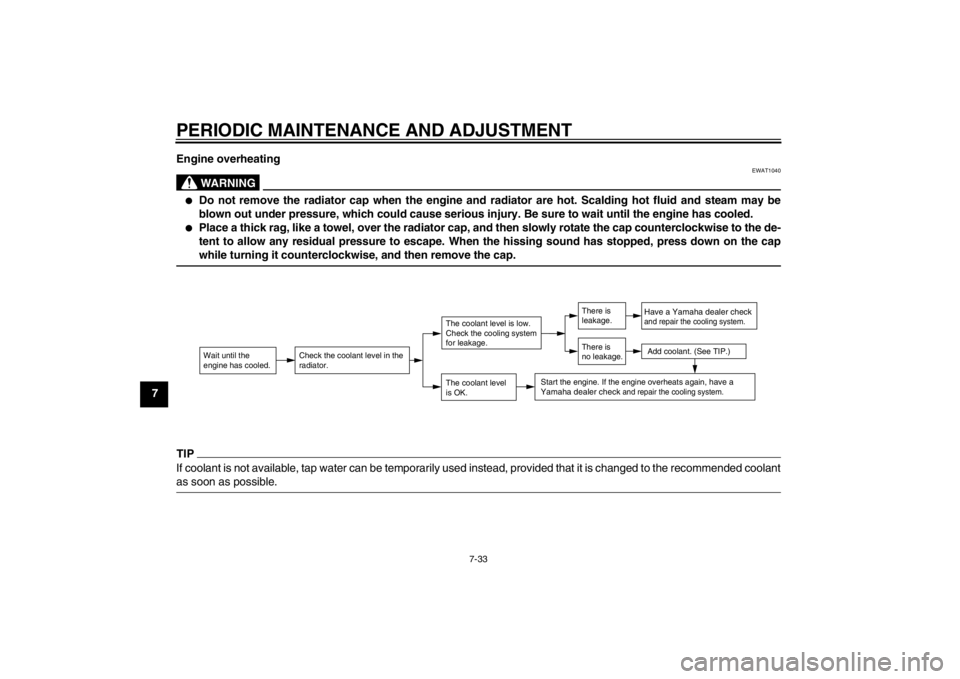

7Engine overheating

WARNING

EWAT1040

●

Do not remove the radiator cap when the engine and

radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

●

Place a thick rag, like a towel, over the radiator cap, and then slowly rotate the cap counterclockwise to the de-

tent to allow any residual pressure to escape. When the hissing sound has stopped, press down on the cap

while turning it counterclockwise, and then remove the cap.

TIPIf coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended coolant

as soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

U1SN81E0.book Page 33 Tuesday, June 12, 2012 3:17 PM

Page 79 of 88

MOTORCYCLE CARE AND STORAGE

8-1

8

EAU37833

Matte color caution NOTICE

ECA15192

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use be-

fore cleaning the vehicle. Using a

brush, harsh chemical products or

cleaning compounds when cleaning

these parts will scratch or damage

their surface. Wax also should not

be applied to any matte colored fin-

ished parts.

EAU41358

Care While the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a motor-

cycle. Frequent and proper care does

not only comply with the terms of the

warranty, but it will also keep your mo-

torcycle looking good, extend its life

and optimize its performance.

Before cleaning1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and covers as well as all electrical couplers

and connectors, including the

spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and de-

greaser off with water.

Cleaning

NOTICE

ECA17691

●

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the af-

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

●

Improper cleaning can damage

plastic parts (such as cowlings,

panels, etc.) and the mufflers.

Use only a soft, clean cloth or

sponge with water to clean plas-

tic. However, if the plastic parts

cannot be thoroughly cleaned

with water, diluted mild deter-

gent with water may be used. Be

U1SN81E0.book Page 1 Tuesday, June 12, 2012 3:17 PM

Page 80 of 88

MOTORCYCLE CARE AND STORAGE

8-2

8sure to rinse off any detergent

residue using plenty of water, as

it is harmful to plastic parts.

●

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

●

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, and switches),

breather hoses and vents.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain or near the sea

Since sea salt is extremely corrosive,

carry out the following steps after each

ride in the rain or near the sea.

1. Clean the motorcycle with cold wa- ter and a mild detergent, after the

engine has cooled down.

NOTICE: Do not use warm water

since it increases the corrosive

action of the salt.

[ECA10791]

2. Apply a corrosion protection spray on all metal, including chrome- and

nickel-plated, surfaces to prevent

corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. 4. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

5. Use spray oil as a universal clean- er to remove any remaining dirt.

6. Touch up minor paint damage caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA11131

Contaminants on the brakes or tires

can cause loss of control.●

Make sure that there is no oil or

wax on the brakes or tires.

●

If necessary, clean the brake

discs and brake linings with a

regular brake disc cleaner or ac-

etone, and wash the tires with

warm water and a mild deter-

gent. Before riding at higher

speeds, test the motorcycle’s

braking performance and cor-

nering behavior.

U1SN81E0.book Page 2 Tuesday, June 12, 2012 3:17 PM