YAMAHA YZF-R1 2001 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2001, Model line: YZF-R1, Model: YAMAHA YZF-R1 2001Pages: 116, PDF Size: 12.72 MB

Page 51 of 116

6

PERIODIC MAINTENANCE AND MINOR REPAIR

Owner’s tool kit ..................................................... 6-1

Periodic maintenance and lubrication chart ......... 6-2

Removing and installing cowlings and panels ..... 6-5

Checking the spark plugs .................................... 6-7

Engine oil and oil filter cartridge .......................... 6-9

Coolant .............................................................. 6-12

Cleaning the air filter element ............................ 6-15

Adjusting the carburetors ................................... 6-17

Adjusting the engine idling speed ...................... 6-18

Adjusting the throttle cable free play .................. 6-18

Adjusting the valve clearance ............................ 6-19

Tires .................................................................... 6-19

Wheels ................................................................ 6-22

Adjusting the clutch lever free play .................... 6-22

Adjusting the brake pedal position ..................... 6-23

Adjusting the rear brake light switch .................. 6-24

Checking the front and rear brake pads ............. 6-24

Checking the brake fluid level ............................ 6-25

Changing the brake fluid .................................... 6-26

Drive chain slack................................................. 6-27

Lubricating the drive chain ................................. 6-28Checking and lubricating the cables ................. 6-29

Checking and lubricating the throttle grip and

cable ............................................................... 6-29

Checking and lubricating the brake and

clutch levers .................................................... 6-30

Lubricating the brake pedal ............................... 6-30

Checking and lubricating the sidestand ............ 6-30

Lubricating the rear suspension ........................ 6-31

Checking the front fork ...................................... 6-31

Checking the steering ....................................... 6-32

Checking the wheel bearings ............................ 6-32

Battery ............................................................... 6-33

Replacing the fuses .......................................... 6-34

Replacing the headlight bulb ............................. 6-35

Replacing the tail/brake light bulb ..................... 6-37

Replacing a turn signal light bulb ...................... 6-37

Supporting the motorcycle ................................ 6-38

Front wheel ........................................................ 6-39

Rear wheel ........................................................ 6-41

Troubleshooting .................................................. 6-42

Troubleshooting charts ....................................... 6-43

E_5jj.book Page 1 Friday, September 8, 2000 3:33 PM

Page 52 of 116

6-1

6

EAU00462

6-PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00464

Safety is an obligation of the owner.

Periodic inspection, adjustment and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. The most important points of in-

spection, adjustment, and lubrication

are explained on the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, DEPENDING ON THE

WEATHER, TERRAIN, GEOGRAPHI-

CAL LOCATION, AND INDIVIDUAL

USE, THE MAINTENANCE INTER-

VALS MAY NEED TO BE

SHORTENED.

EW000060

WARNING

@ If you are not familiar with motor-

cycle maintenance work, have a

Yamaha dealer do it for you. @

EAU01575

Owner’s tool kitThe tool kit is located inside the storage

compartment under the passenger

seat. (See page 3-14 for passenger

seat removal procedures.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

NOTE:@ If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you. @

EW000063

WARNING

@ Modifications not approved by

Yamaha may cause loss of perfor-

mance and render the vehicle un-

safe for use. Consult a Yamaha

dealer before attempting any

changes. @

1. Owner’s tool kit

E_5jj.book Page 1 Friday, September 8, 2000 3:33 PM

Page 53 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-2

6

EAU03540

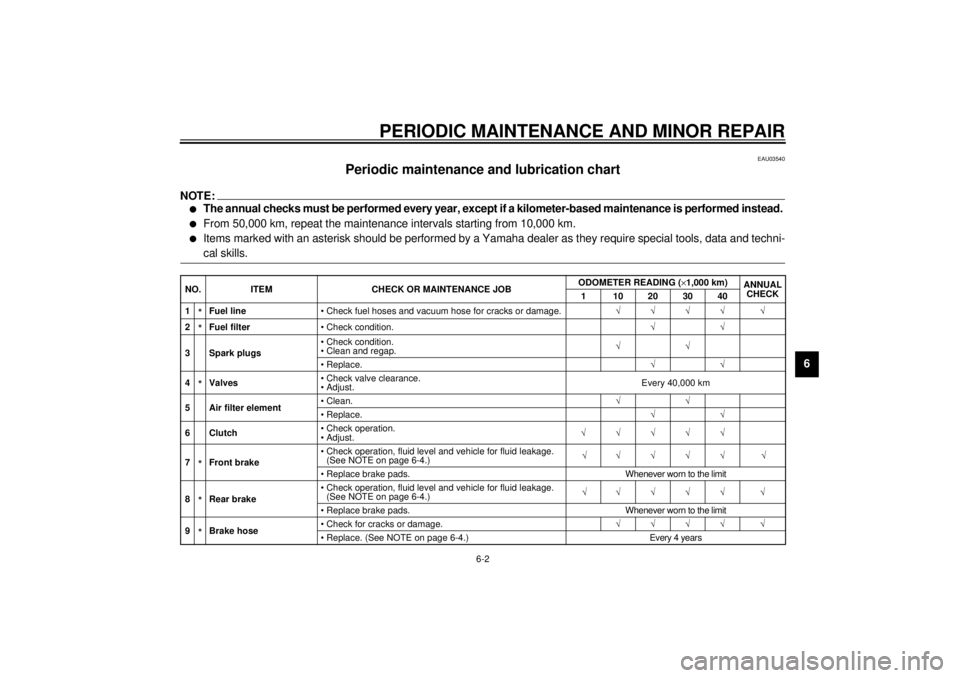

Periodic maintenance and lubrication chart

NOTE:@ l

The annual checks must be performed every year, except if a kilometer-based maintenance is performed instead.

l

From 50,000 km, repeat the maintenance intervals starting from 10,000 km.

l

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and techni-

cal skills.

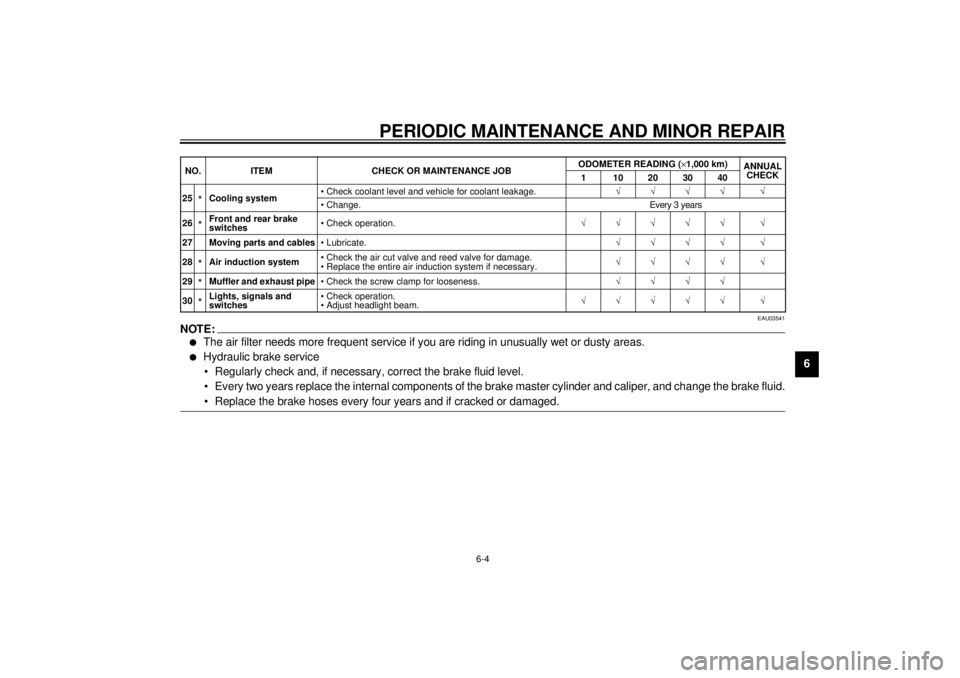

@CP-03ENO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

1

*Fuel line• Check fuel hoses and vacuum hose for cracks or damage.ÖÖÖÖ Ö

2*Fuel filter• Check condition.ÖÖ

3 Spark plugs• Check condition.

• Clean and regap.ÖÖ

• Replace.ÖÖ

4*Valves• Check valve clearance.

•Adjust.Every 40,000 km

5 Air filter element•Clean.ÖÖ

• Replace.ÖÖ

6Clutch• Check operation.

•Adjust.ÖÖÖÖÖ

7*Front brake• Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-4.)ÖÖÖÖÖ Ö

• Replace brake pads. Whenever worn to the limit

8*Rear brake• Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-4.)ÖÖÖÖÖ Ö

• Replace brake pads. Whenever worn to the limit

9*Brake hose• Check for cracks or damage.ÖÖÖÖ Ö

• Replace. (See NOTE on page 6-4.) Every 4 years

E_5jj.book Page 2 Friday, September 8, 2000 3:33 PM

Page 54 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-3

6

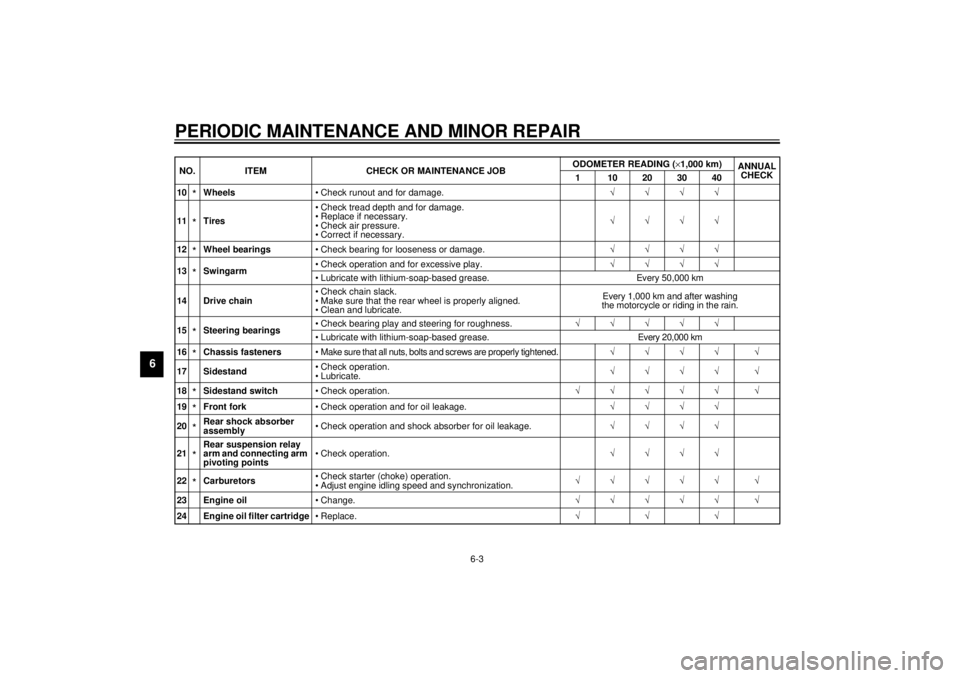

10

*Wheels• Check runout and for damage.ÖÖÖÖ

11*Tires• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.ÖÖÖÖ

12*Wheel bearings• Check bearing for looseness or damage.ÖÖÖÖ

13*Swingarm• Check operation and for excessive play.ÖÖÖÖ

• Lubricate with lithium-soap-based grease. Every 50,000 km

14 Drive chain• Check chain slack.

• Make sure that the rear wheel is properly aligned.

• Clean and lubricate.Every 1,000 km and after washing

the motorcycle or riding in the rain.

15*Steering bearings• Check bearing play and steering for roughness.ÖÖÖÖÖ

• Lubricate with lithium-soap-based grease. Every 20,000 km

16*Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.ÖÖÖÖ Ö

17 Sidestand• Check operation.

• Lubricate.ÖÖÖÖ Ö

18*Sidestand switch• Check operation.ÖÖÖÖÖ Ö

19*Front fork• Check operation and for oil leakage.ÖÖÖÖ

20*Rear shock absorber

assembly• Check operation and shock absorber for oil leakage.ÖÖÖÖ

21*Rear suspension relay

arm and connecting arm

pivoting points• Check operation.ÖÖÖÖ

22*Carburetors• Check starter (choke) operation.

• Adjust engine idling speed and synchronization.ÖÖÖÖÖ Ö

23 Engine oil• Change.ÖÖÖÖÖ Ö

24 Engine oil filter cartridge•Replace.ÖÖÖ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

E_5jj.book Page 3 Friday, September 8, 2000 3:33 PM

Page 55 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-4

6

EAU03541

NOTE:@l

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

l

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinder and caliper, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

@25

*Cooling system• Check coolant level and vehicle for coolant leakage.ÖÖÖÖ Ö

• Change. Every 3 years

26*Front and rear brake

switches• Check operation.ÖÖÖÖÖ Ö

27 Moving parts and cables• Lubricate.ÖÖÖÖ Ö

28*Air induction system• Check the air cut valve and reed valve for damage.

• Replace the entire air induction system if necessary.ÖÖÖÖ Ö

29*Muffler and exhaust pipe• Check the screw clamp for looseness.ÖÖÖÖ

30*Lights, signals and

switches• Check operation.

• Adjust headlight beam.ÖÖÖÖÖ Ö NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

E_5jj.book Page 4 Friday, September 8, 2000 3:33 PM

Page 56 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-5

6

EAU01139

Removing and installing

cowlings and panels The cowlings and panels shown above

need to be removed to perform some

of the maintenance jobs described in

this chapter. Refer to this section each

time a cowling or panel needs to be re-

moved and installed.

EAU03536

Cowling A

To remove the cowlingRemove the screw, loosen the quick

fastener screws 1/4 turn counterclock-

wise, and then take the cowling off.To install the cowling

Place the cowling in the original posi-

tion, and then tighten the quick fastener

screws and install the screw.

1. Cowling A

2. Panel A

3. Cowling B

1. Quick fastener screw (´ 4)

2. ScrewRight side

1. Quick fastener screw (´ 4)

2. ScrewLeft side

E_5jj.book Page 5 Friday, September 8, 2000 3:33 PM

Page 57 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-6

6

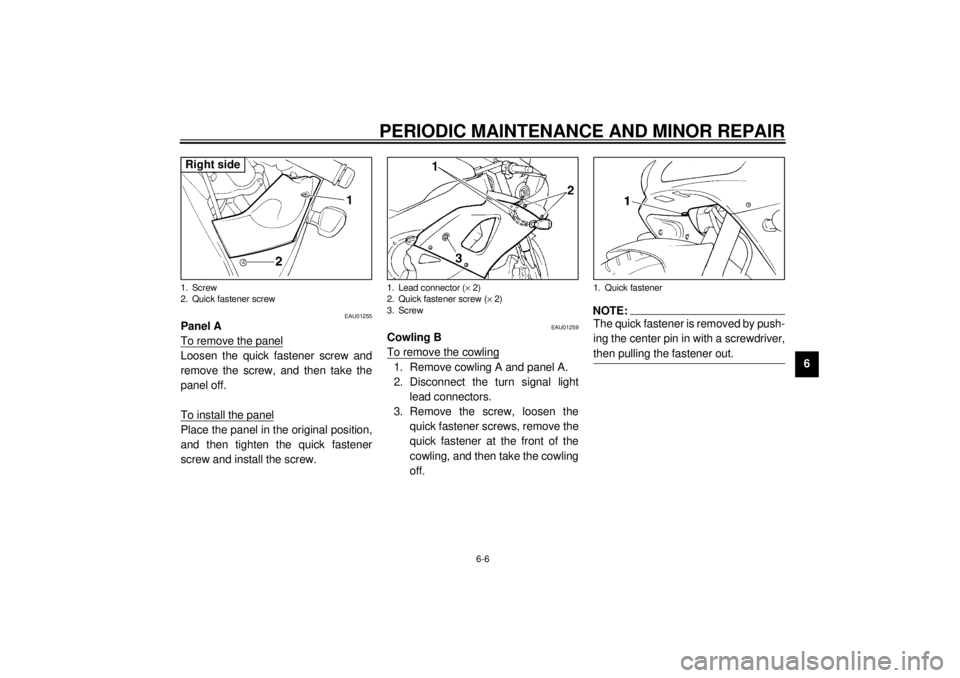

EAU01255

Panel A

To remove the panelLoosen the quick fastener screw and

remove the screw, and then take the

panel off.

To install the panelPlace the panel in the original position,

and then tighten the quick fastener

screw and install the screw.

EAU01259

Cowling B

To remove the cowling1. Remove cowling A and panel A.

2. Disconnect the turn signal light

lead connectors.

3. Remove the screw, loosen the

quick fastener screws, remove the

quick fastener at the front of the

cowling, and then take the cowling

off.

NOTE:@ The quick fastener is removed by push-

ing the center pin in with a screwdriver,

then pulling the fastener out. @

1. Screw

2. Quick fastener screwRight side

1. Lead connector (´ 2)

2. Quick fastener screw (´ 2)

3. Screw

1. Quick fastener

E_5jj.book Page 6 Friday, September 8, 2000 3:33 PM

Page 58 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-7

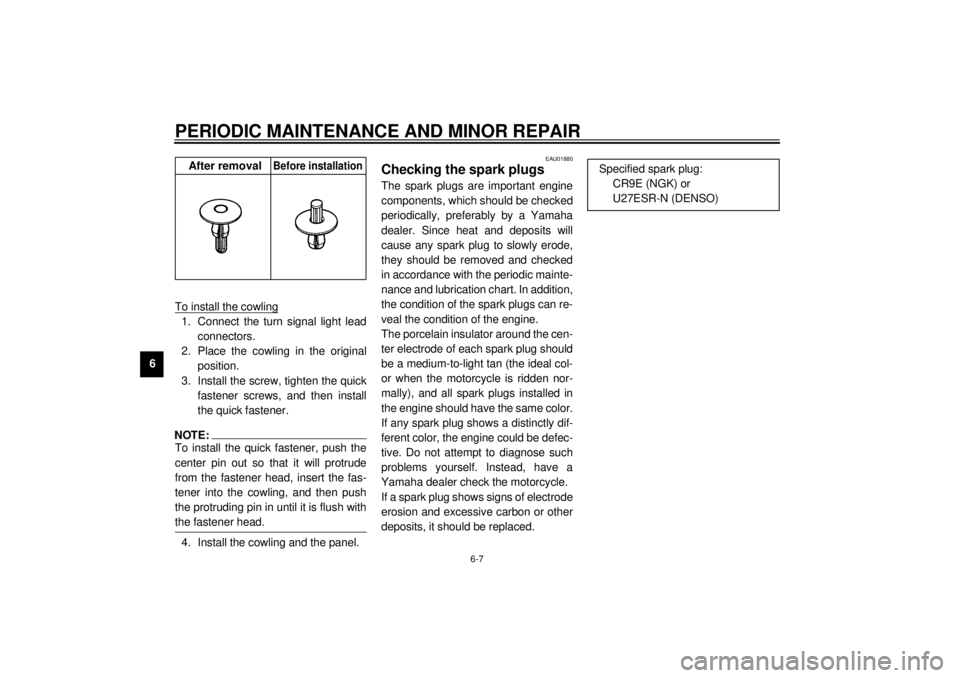

6To install the cowling

1. Connect the turn signal light lead

connectors.

2. Place the cowling in the original

position.

3. Install the screw, tighten the quick

fastener screws, and then install

the quick fastener.NOTE:@ To install the quick fastener, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the cowling, and then push

the protruding pin in until it is flush with

the fastener head. @4. Install the cowling and the panel.

EAU01880

Checking the spark plugs The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal col-

or when the motorcycle is ridden nor-

mally), and all spark plugs installed in

the engine should have the same color.

If any spark plug shows a distinctly dif-

ferent color, the engine could be defec-

tive. Do not attempt to diagnose such

problems yourself. Instead, have a

Yamaha dealer check the motorcycle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced.

After removal

Before installation

Specified spark plug:

CR9E (NGK) or

U27ESR-N (DENSO)

E_5jj.book Page 7 Friday, September 8, 2000 3:33 PM

Page 59 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6 Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible. @

a. Spark plug gap

Spark plug gap:

0.7–0.8 mm

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kg)

E_5jj.book Page 8 Friday, September 8, 2000 3:33 PM

Page 60 of 116

PERIODIC MAINTENANCE AND MINOR REPAIR

6-9

6

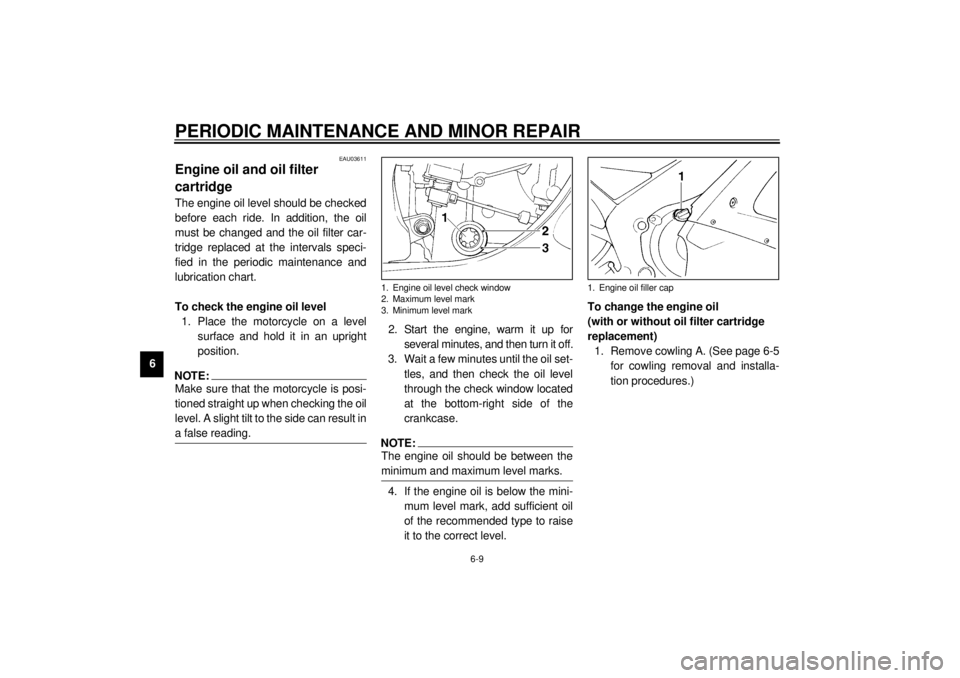

EAU03611

Engine oil and oil filter

cartridge The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:@ Make sure that the motorcycle is posi-

tioned straight up when checking the oil

level. A slight tilt to the side can result in

a false reading. @

2. Start the engine, warm it up for

several minutes, and then turn it off.

3. Wait a few minutes until the oil set-

tles, and then check the oil level

through the check window located

at the bottom-right side of the

crankcase.NOTE:@ The engine oil should be between the

minimum and maximum level marks. @4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.To change the engine oil

(with or without oil filter cartridge

replacement)

1. Remove cowling A. (See page 6-5

for cowling removal and installa-

tion procedures.)1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

1. Engine oil filler cap

E_5jj.book Page 9 Friday, September 8, 2000 3:33 PM