YAMAHA YZF-R7 1999 Owners Manual

Manufacturer: YAMAHA, Model Year: 1999, Model line: YZF-R7, Model: YAMAHA YZF-R7 1999Pages: 381, PDF Size: 18.88 MB

Page 331 of 381

7 - 81

CHAS

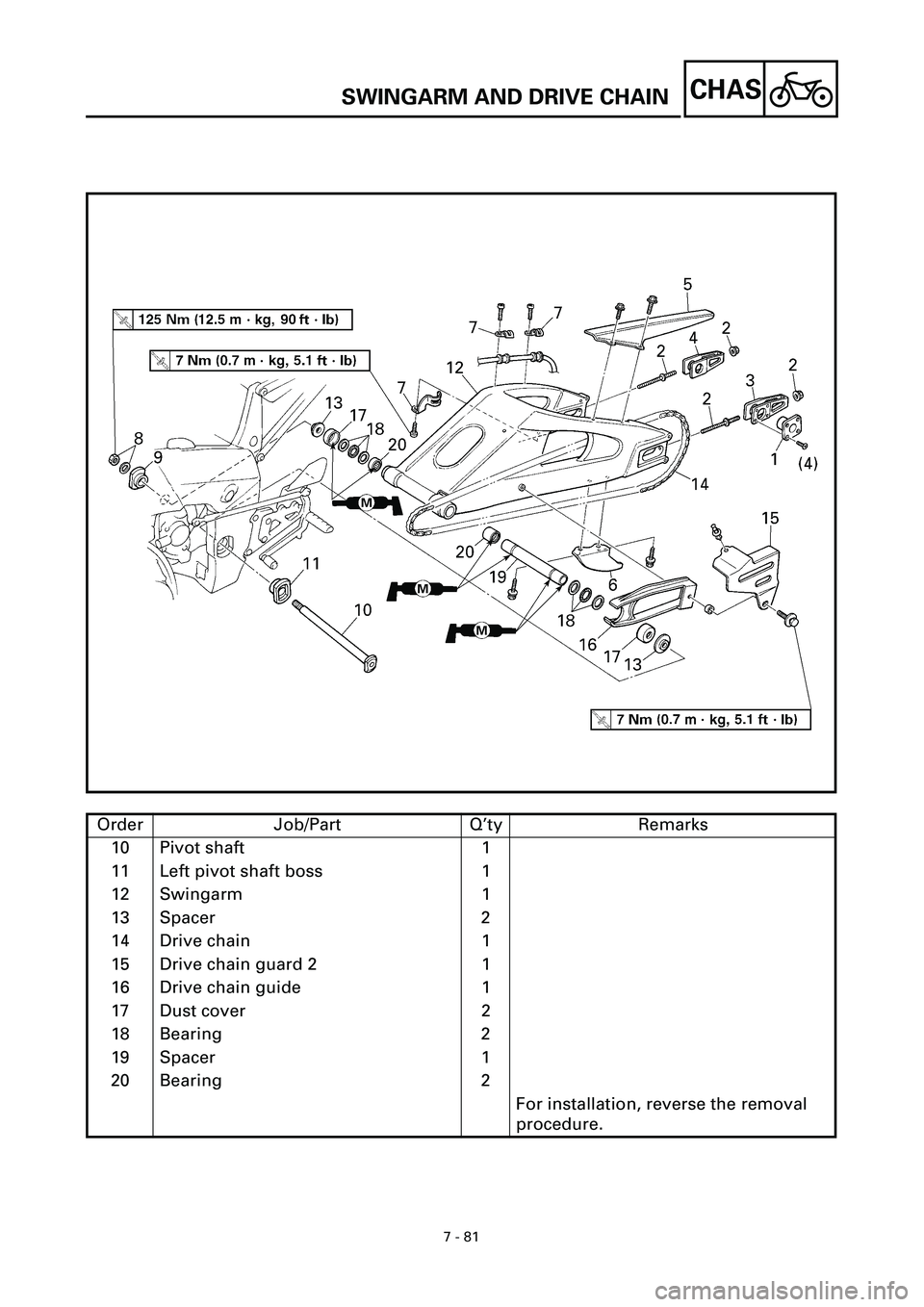

Order Job/Part Q’ty Remarks

10 Pivot shaft 1

11 Left pivot shaft boss 1

12 Swingarm 1

13 Spacer 2

14 Drive chain 1

15 Drive chain guard 2 1

16 Drive chain guide 1

17 Dust cover 2

18 Bearing 2

19 Spacer 1

20 Bearing 2

For installation, reverse the removal

procedure.

SWINGARM AND DRIVE CHAIN

Page 332 of 381

7 - 82

CHAS

EB707100

NOTE:

Before removing the drive sprocket,

drive chain, and rear wheel, measure the

drive chain slack and the length of a ten-

link section of the drive chain.

EB707111

REMOVING THE SWINGARM

1. Stand the motorcycle on a level surface.

WARNINGWARNING

Securely support the motorcycle so that

there is no danger of it falling over.

NOTE:

Place the motorcycle on a suitable stand

so that the rear wheel is elevated.

2. Measure:

• swingarm side play

• swingarm vertical movement

t t t t t t t t t t t t t t t t t t t t t t t t t t t

a. Measure the tightening torque of the

pivot shaft nut.

b. Measure the swingarm side play

by moving the swingarm from side to

side.

c. If the swingarm side play is out of

specification, check the spacers, bear-

ings, washers, and dust covers.

d. Check the swingarm vertical move-

ment

õ by moving the swingarm up

and down.

If swingarm vertical movement is not

smooth or if there is binding, check the

spacers, bearings, washers, and dust

covers.

s s s s s s s s s s s s s s s s s s s s s s s s s s s

T R..

Pivot shaft nut

125 Nm (12.5 m • kg, 90 ft • lb)

Swingarm side play (at the

end of the swingarm)

1.0 mm (0.04 in)

SWINGARM AND DRIVE CHAIN

Page 333 of 381

7 - 83

CHAS

EB707120

REMOVING THE DRIVE CHAIN

1. Remove:

• drive chain

(with the drive chain cutter)

NOTE:

Only cut the drive chain if it or the swin-

garm is to be replaced.

Drive chain cutter

90890-01286

EB707400

CHECKING THE SWINGARM

1. Check:

• swingarm

Bends/cracks/damage ® Replace.

NOTE:

If the swingarm must be replaced, the

drive chain must be cut with a drive

chain cutter.

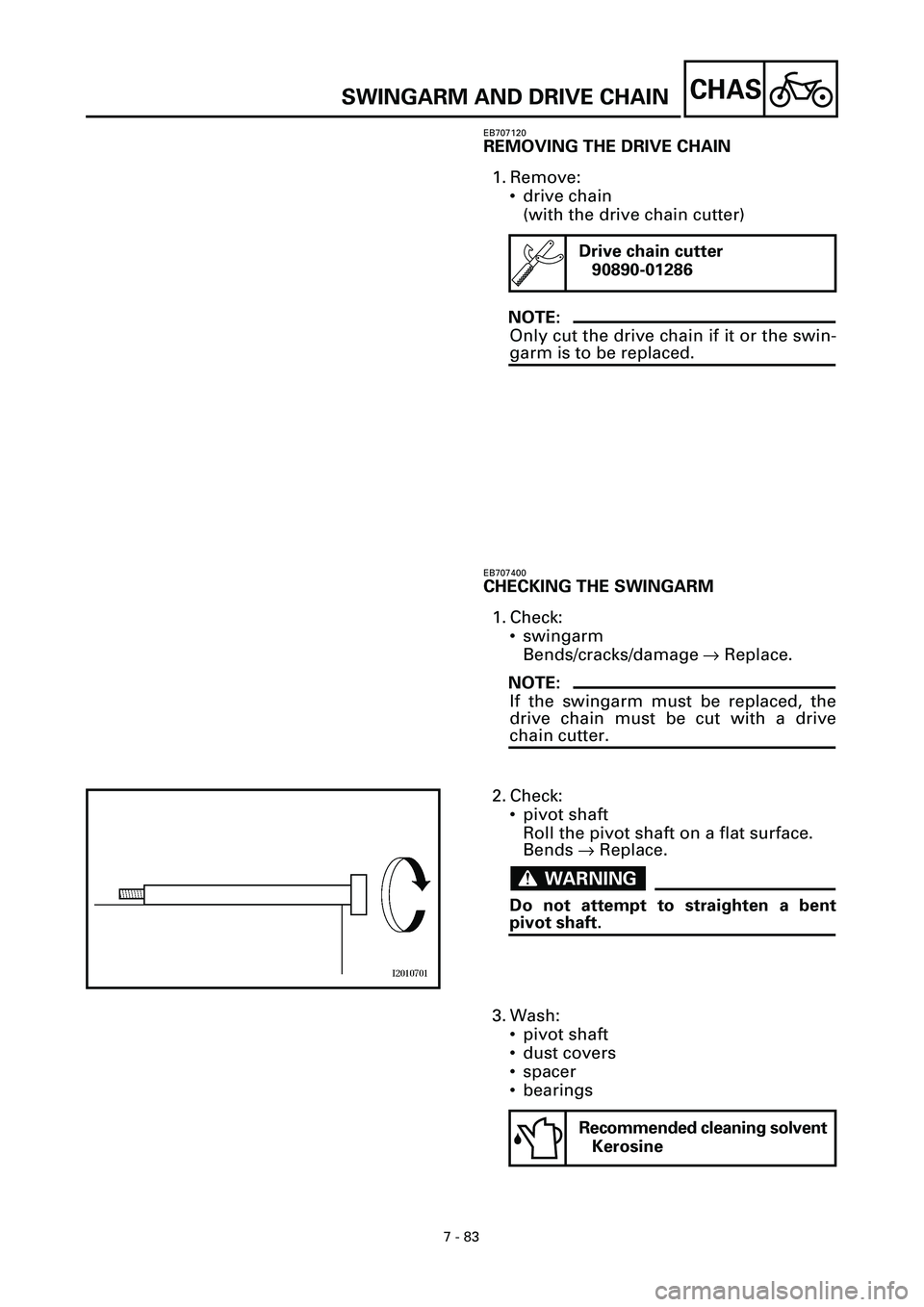

2. Check:

• pivot shaft

Roll the pivot shaft on a flat surface.

Bends ® Replace.

WARNINGWARNING

Do not attempt to straighten a bent

pivot shaft.

3. Wash:

• pivot shaft

• dust covers

• spacer

• bearings

Recommended cleaning solvent

Kerosine

SWINGARM AND DRIVE CHAIN

Page 334 of 381

7 - 84

CHAS

4. Check:

• dust covers

• spacer

• oil seals

Damage/wear ® Replace.

• bearings

Damage/pitting ® Replace.

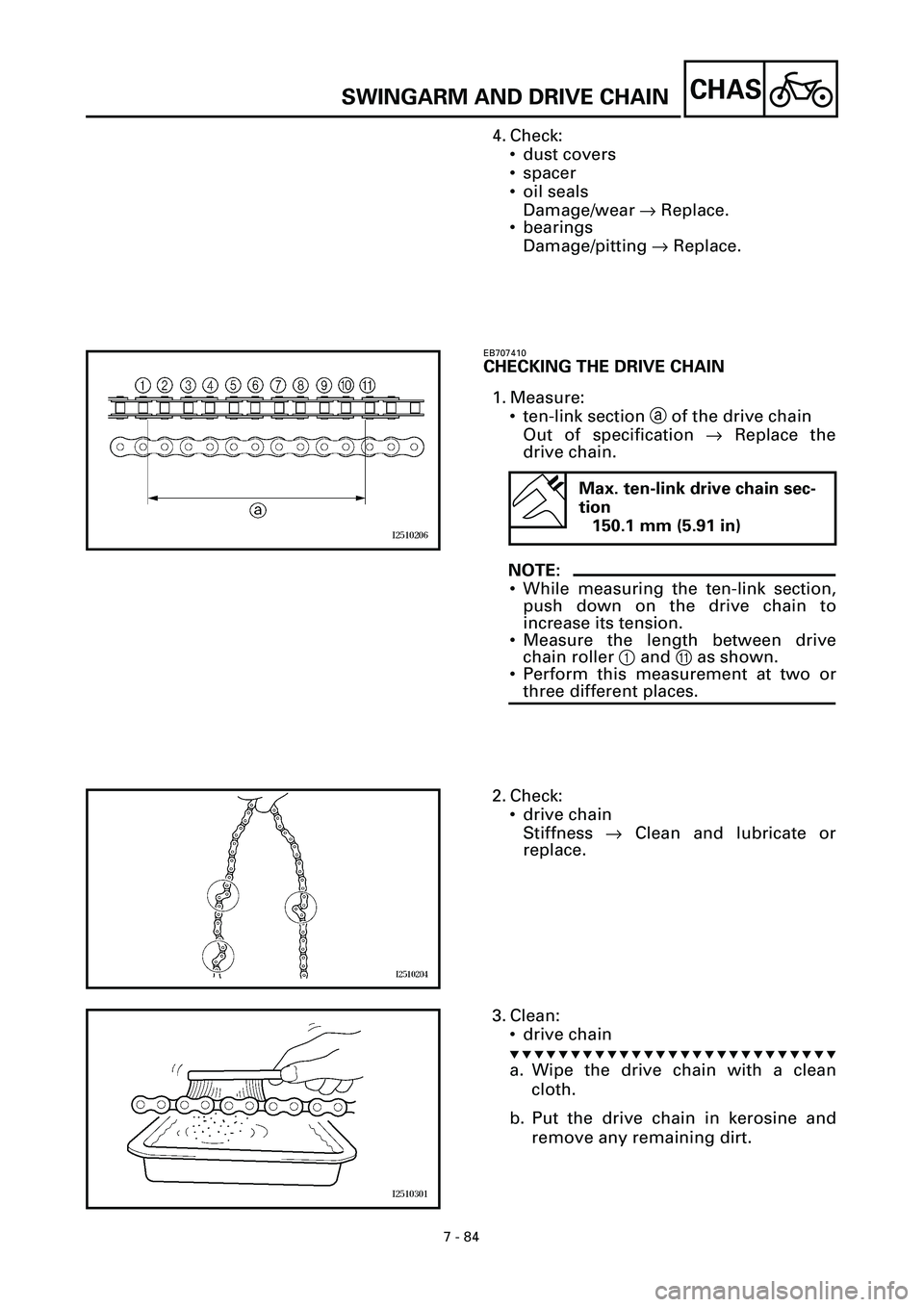

EB707410

CHECKING THE DRIVE CHAIN

1. Measure:

• ten-link section a of the drive chain

Out of specification ® Replace the

drive chain.

NOTE:

• While measuring the ten-link section,

push down on the drive chain to

increase its tension.

• Measure the length between drive

chain roller 1 and A as shown.

• Perform this measurement at two or

three different places.

Max. ten-link drive chain sec-

tion

150.1 mm (5.91 in)

2. Check:

• drive chain

Stiffness ® Clean and lubricate or

replace.

3. Clean:

• drive chain

t t t t t t t t t t t t t t t t t t t t t t t t t t t

a. Wipe the drive chain with a clean

cloth.

b. Put the drive chain in kerosine and

remove any remaining dirt.

SWINGARM AND DRIVE CHAIN

Page 335 of 381

7 - 85

CHAS

c. Remove the drive chain from the ker-

osine and completely dry it.

ACHTUNG:CAUTION:

This motorcycle has a drive chain with

small rubber O-rings 1 between the

drive chain side plates. Never use high-

pressure water or air, steam, gasoline,

certain solvents (e.g., benzine), or a

coarse brush to clean the drive chain.

High-pressure methods could force dirt

or water into the drive chain’s internals,

and solvents will deteriorate the O-

rings. A coarse brush can also damage

the O-rings. Therefore, use only kero-

sine to clean the drive chain.

s s s s s s s s s s s s s s s s s s s s s s s s s s s

4. Check:

• O-rings 1

Damage ® Replace the drive chain.

• drive chain rollers 2

Damage/wear ® Replace the drive

chain.

• drive chain side plates 3

Cracks/damage/wear ® Replace the

drive chain.

5. Lubricate:

• drive chain

Recommended lubricant

Engine oil or chain lubricant

suitable for O-ring chains

6. Check:

• drive sprocket

• rear wheel sprocket

More than 1/4 tooth a wear ® Replace

the drive chain sprockets as a set.

Bent teeth ® Replace the drive chain

sprockets as a set.

b Correct

1Drive chain roller

2Drive chain sprocket

SWINGARM AND DRIVE CHAIN

Page 336 of 381

7 - 86

CHAS

EB707700

INSTALLING THE SWINGARM

1. Lubricate:

• bearings

• spacers

• dust covers

• pivot shaft

2. Install:

• spacers

• swingarm

• pivot shaft bosses

• pivot shaft

• washer

• pivot shaft nut

3. Install:

• drive chain pullers

NOTE:

Install the drive chain pullers onto the

swingarm so that the sides stamped

“IN” face toward the inside (i.e., the rear

wheel).

4. Install:

• rear shock absorber assembly

• rear wheel

Refer to “REAR SHOCK ABSORBER

ASSEMBLY” and “REAR WHEEL”.

5. Adjust:

• drive chain slack

Refer to “ADJUSTING THE DRIVE

CHAIN SLACK” in chapter 3.

Recommended lubricant

Molybdenum disulfide grease

Drive chain slack

40 ~ 50 mm (1.57 ~ 1.97 in)

T R..125 Nm (12.5 m · kg, 90 ft · lb)

SWINGARM AND DRIVE CHAIN

Page 337 of 381

8 - 1

–+ELEC

ELECTRICAL COMPONENTS

EB800000

ELECTRICAL

ELECTRICAL COMPONENTS

1

Wire harness

2

Main switch

3

Front brake light switch

4

Ignition coils

5

Clutch switch

6

Throttle position sensor

7

Intake air temperature sensor

8

Intake air pressure sensor

9

Atmospheric pressure sensor

0

Turn signal relay

A

Relay unit

B

ECU

C

CDI unit

D

Fuse box

E

Fall detection switch

F

Starter relay

G

Main fuse

H

Main relay

I

Battery

J

Rectifier/regulator

K

Rear brake light switch

L

Neutral switch

M

Speed sensor

N

Sidestand switch

O

Stator coil assembly

P

Oil level switch

Q

Pickup coil

R

Radiator fan

S

Horn

T

Coolant temperature

sender

U

Thermo switch

V

Camshaft sensor

8

Page 338 of 381

8 - 2

–+ELEC

SWITCHES

EB801000

SWITCHES

CHECKING SWITCH CONTINUITY

Check each switch for continuity with the

pocket tester. If the continuity reading is

incorrect, check the wiring connections and

if necessary, replace the switch.

CAUTION:

Never insert the tester probes into the cou-

pler terminal slots

1

. Always insert the

probes from the opposite end of the cou-

pler, taking care not to loosen or damage

the leads.

NOTE:

• Before checking for continuity, set the

pocket tester to “0” and to the “

W

´

1”

range.

• When checking for continuity, switch back

and forth between the switch positions a

few times.

The terminal connections for switches (e.g.,

main switch, engine stop switch) are shown

in an illustration similar to the one on the

left.

The switch positions

a

are shown in the far

left column and the switch lead colors

b

are shown in the top row in the switch illus-

tration.

NOTE:

“ ” indicates a continuity of electric-

ity between switch terminals (i.e., a closed

circuit at the respective switch position).

The example illustration on the left shows

that:

There is continuity between blue/red and

red when the switch is set to “ ”.

There is continuity between blue/red and

blue, between brown/blue and red, and

between blue/yellow and blue/black when

the switch is set to “ON”.

Pocket tester

90890-03112

ONR

Br/LL/YL/B

OFF

ab

Br/L

L/B R

L/Y

8

Page 339 of 381

8 - 3

–+ELEC

CHECKING THE SWITCHES

EB801010

CHECKING THE SWITCHES

Check each switch for damage or wear, proper connections, and also for continuity between

the terminals. Refer to “CHECKING SWITCH CONTINUITY”.

Damage/wear

® Repair or replace the switch.

Improperly connected ® Properly connect.

Incorrect continuity reading ® Replace the switch.

1Main switch

2Light switch

3Pass switch

4Dimmer switch

5Turn signal switch6Horn switch

7Clutch switch

8Engine stop switch

9Start switch

0Front brake light switchAOil level switch

BRear brake light switch

CFuse

DNeutral switch

ESidestand switch

1L/YL/B

LL/R

R

Br/L

OFF

ONP

L/RLBr/LRL/YL/B

3

4

5

Br/WR/YPLB

Dg Y

G Ch

B/YL/YPASS—

R/YY

67

YG

—BP

(BLUE)

(BLACK)

(BLACK)

R/WBr

R/BB

G/YL/W

B

B

G/YBr

OFF

ChBr/WDg

8R/WR/B

9

0—L/WB

2R/YL•

C

E

(BLUE)

B

B

B D

(BROWN)

Sb

A

W

L/YB/Y

L/YB/Y

Page 340 of 381

8 - 4

–+ELECCHECKING THE BULBS AND BULB SOCKETS

EB801020

CHECKING THE BULBS AND

BULB SOCKETS

Check each bulb and bulb socket for dam-

age or wear, proper connections, and also

for continuity between the terminals.

Damage/wear ® Repair or replace the

bulb, bulb socket or both.

Improperly connected ® Properly con-

nect.

Incorrect continuity reading ® Repair or

replace the bulb, bulb socket or both.

TYPES OF BULBS

The bulbs used on this motorcycle are

shown in the illustration on the left.

• Bulbs A and B are used for headlights

and usually use a bulb holder which must

be detached before removing the bulb.

The majority of these bulbs can be

removed from their respective socket by

turning them counterclockwise.

• Bulb C is used for turn signal and tail/

brake lights and can be removed from the

socket by pushing and turning the bulb

counterclockwise.

• Bulbs

D and E are used for meter and

indicator lights and can be removed from

their respective socket by carefully pulling

them out.

CHECKING THE CONDITION OF THE BULBS

The following procedure applies to all of

the bulbs.

1.Remove:

• bulb