engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1535 of 1640

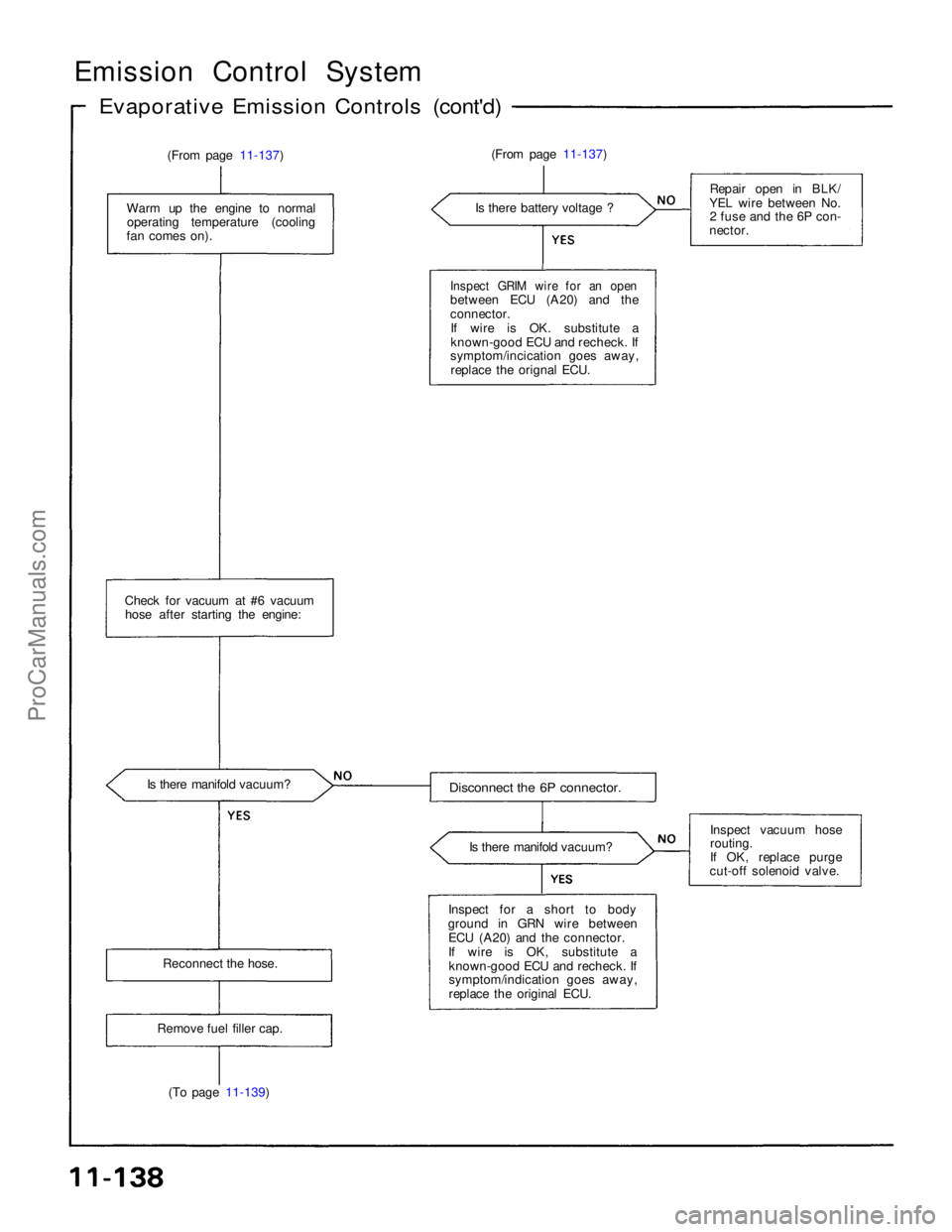

Emission Control System

Evaporative Emission Controls (cont'd)

(From page 11-137)

Warm up the engine to normal operating temperature (cooling

fan comes on). (From page 11-137)

Is there battery voltage ?

Inspect GRIM wire for an open

between ECU (A20) and the

connector. If wire is OK. substitute a

known-good ECU and recheck. If

symptom/incication goes away,

replace the orignal ECU.

Check for vacuum at #6 vacuum hose after starting the engine:

Is there manifold vacuum?

Disconnect the 6P connector.

Is there manifold vacuum?

Reconnect the hose. Inspect for a short to body

ground in GRN wire between ECU (A20) and the connector.

If wire is OK, substitute aknown-good ECU and recheck. If

symptom/indication goes away,

replace the original ECU.

Remove fuel filler cap.

(To page 11-139) Inspect vacuum hose

routing.

If OK, replace purge

cut-off solenoid valve. Repair open in BLK/

YEL wire between No. 2 fuse and the 6P con-

nector.ProCarManuals.com

Page 1536 of 1640

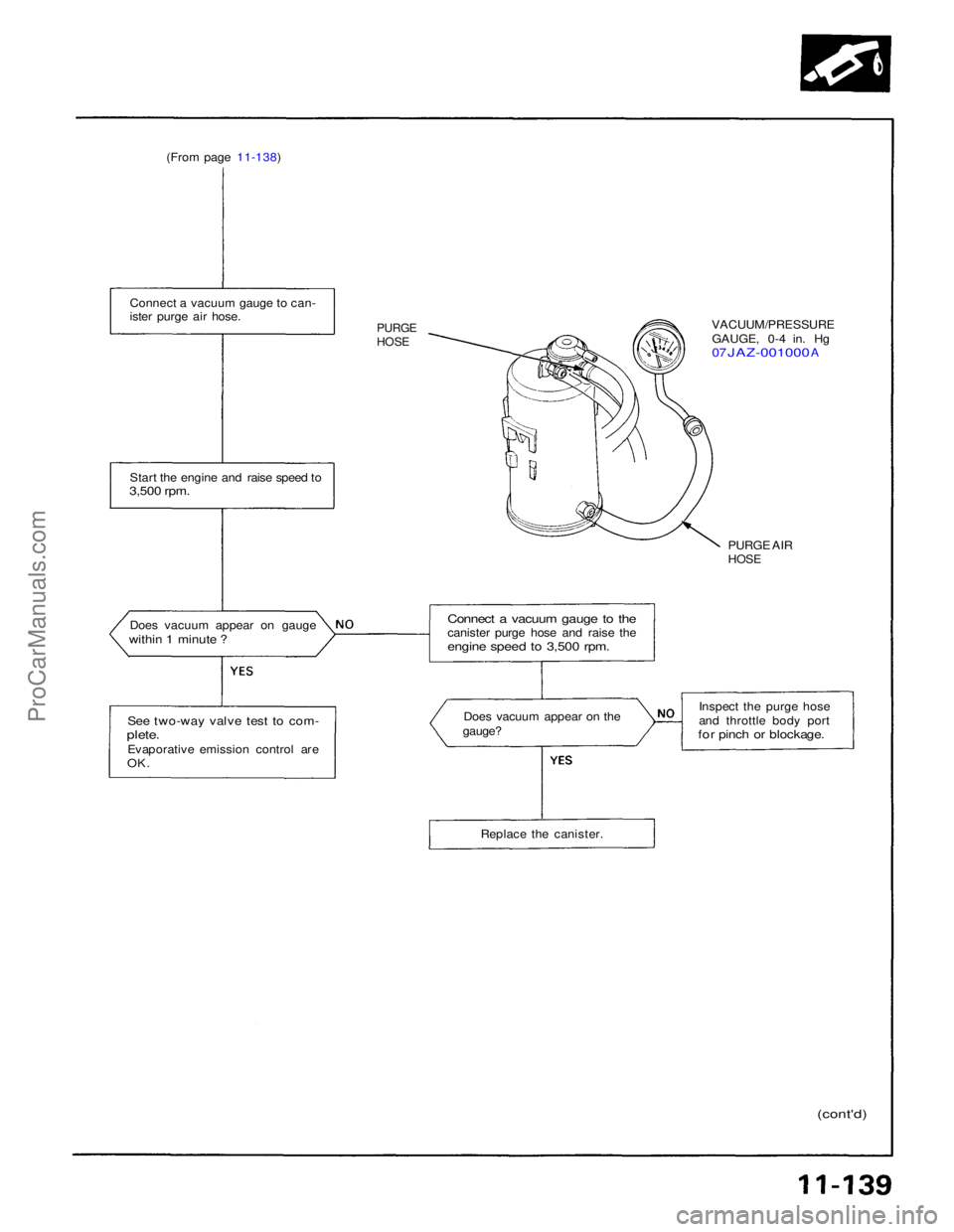

(From page 11-138)

Connect a vacuum gauge to can-

ister purge air hose.

PURGE

HOSE

Start the engine and raise speed to

3,500 rpm.

Does vacuum appear on gauge

within 1 minute ?

See two-way valve test to com-

plete.

Evaporative emission control are

OK.

Connect a vacuum gauge to the

canister purge hose and raise the

engine speed to 3,500 rpm.

Does vacuum appear on the

gauge?

Replace the canister.

(cont'd)

Inspect the purge hose

and throttle body port

for pinch or blockage.

PURGE AIR

HOSE

VACUUM/PRESSURE

GAUGE, 0-4 in. Hg

07

JAZ-001000

AProCarManuals.com

Page 1541 of 1640

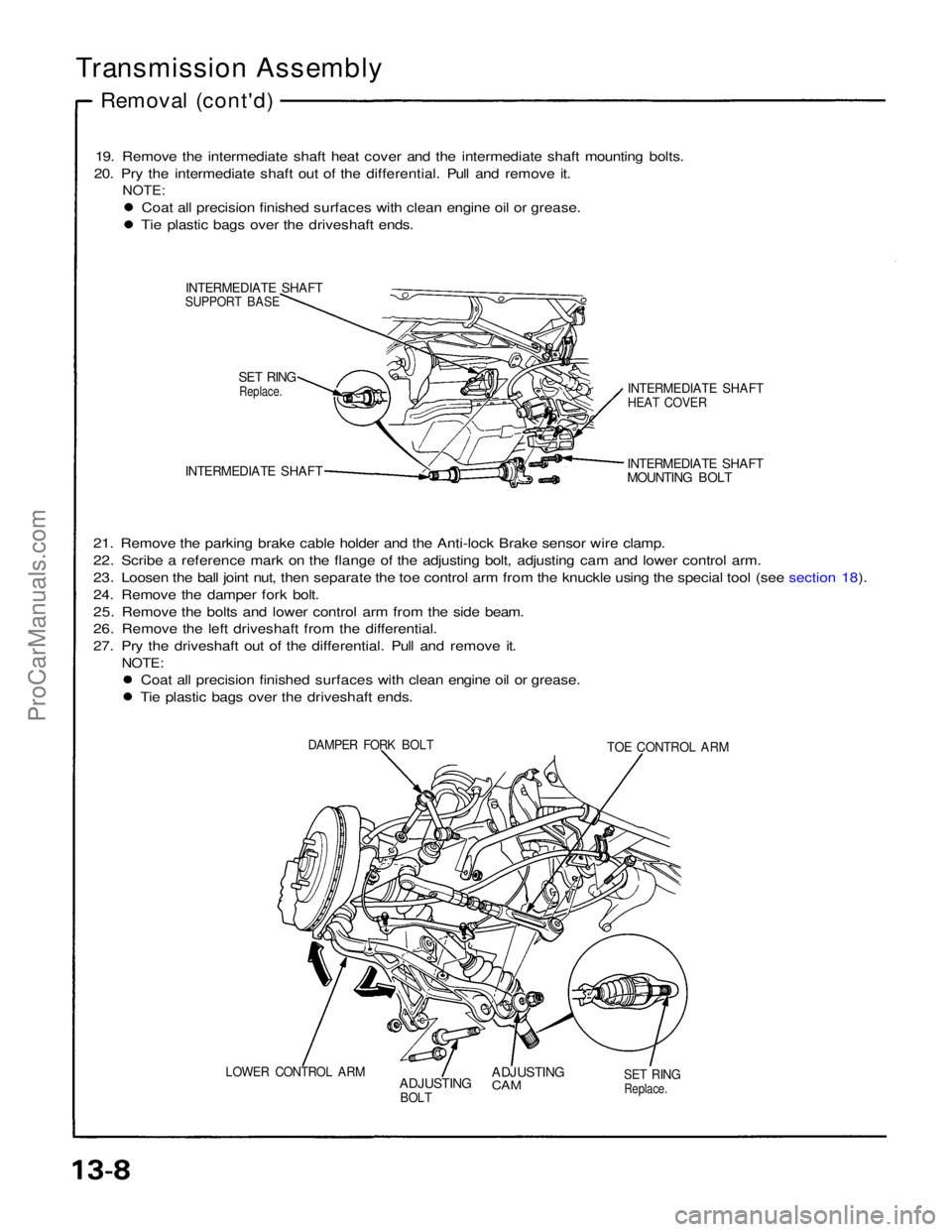

Transmission Assembly

Removal (cont'd)

19. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

20. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease. Tie plastic bags over the driveshaft ends.

INTERMEDIATE SHAFT

SUPPORT BASE

SET RING

Replace.

INTERMEDIATE SHAFT

21. Remove the parking brake cable holder and the Anti-lock Brake sensor wire clamp.

22. Scribe a reference mark on the flange of the adjusting bolt, adjusting cam and lower control arm.

23. Loosen the ball joint nut, then separate the toe control arm from the knuckle using the special tool (see section 18).

24. Remove the damper fork bolt.

25. Remove the bolts and lower control arm from the side beam.

26. Remove the left driveshaft from the differential.

27. Pry the driveshaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

INTERMEDIATE SHAFT

MOUNTING BOLT

INTERMEDIATE SHAFT

HEAT COVER

DAMPER FORK BOLT

TOE CONTROL ARM

LOWER CONTROL ARM

ADJUSTING

BOLT

ADJUSTING

CAM

SET RING

Replace.

ProCarManuals.com

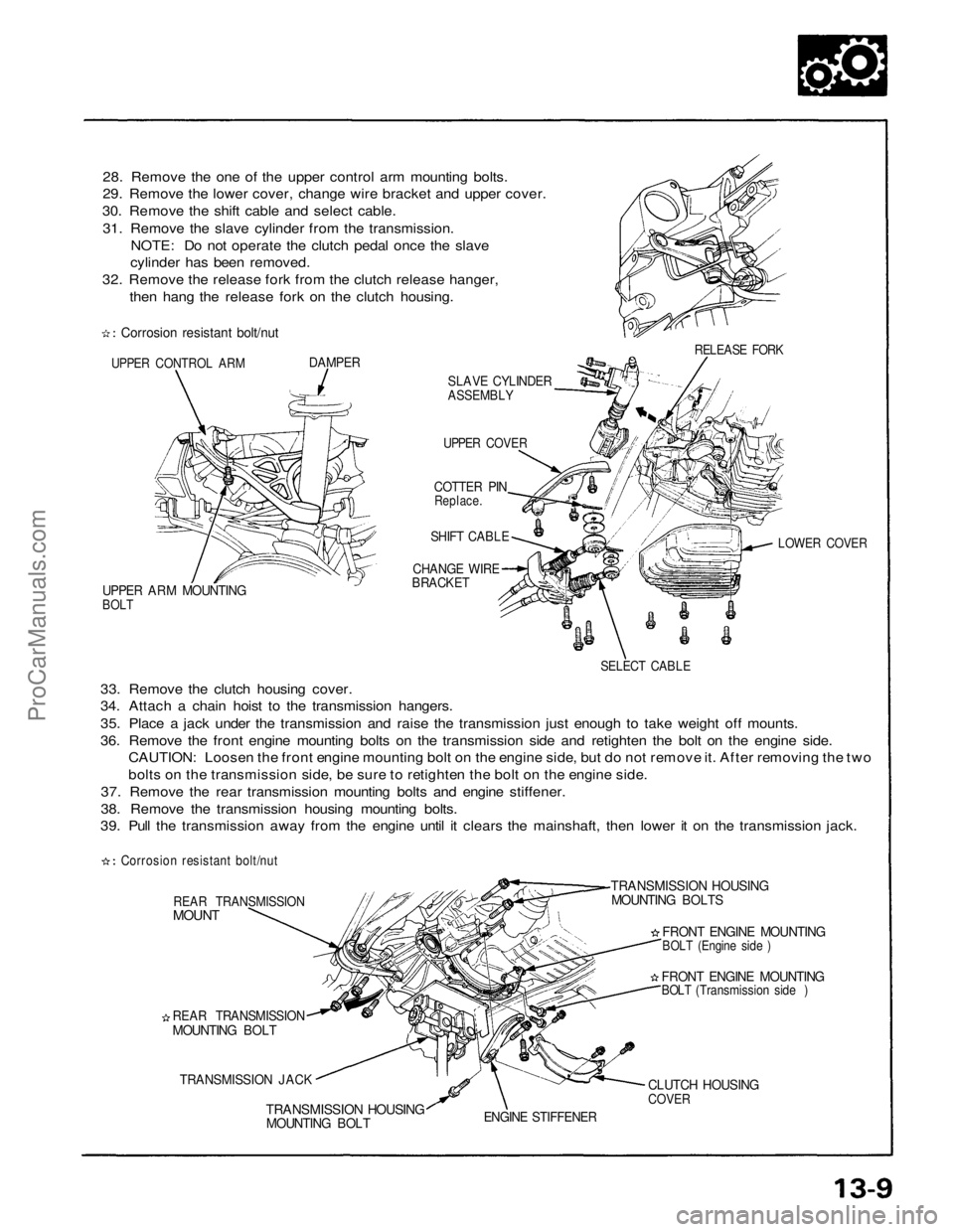

Page 1542 of 1640

28. Remove the one of the upper control arm mounting bolts.

29. Remove the lower cover, change wire bracket and upper cover.

30. Remove the shift cable and select cable.

31. Remove the slave cylinder from the transmission. NOTE: Do not operate the clutch pedal once the slave

cylinder has been removed.

32. Remove the release fork from the clutch release hanger, then hang the release fork on the clutch housing.

Corrosion resistant bolt/nut

UPPER CONTROL ARM

DAMPER

SLAVE CYLINDER

ASSEMBLY

UPPER COVER

COTTER PIN

Replace.

SHIFT CABLE

UPPER ARM MOUNTING

BOLT

CHANGE WIRE

BRACKET

33. Remove the clutch housing cover.

34. Attach a chain hoist to the transmission hangers.

35. Place a jack under the transmission and raise the transmission just enough to take weight off mounts.

36. Remove the front engine mounting bolts on the transmission side and retighten the bolt on the engine side. CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the two

bolts on the transmission side, be sure to retighten the bolt on the engine side.

37. Remove the rear transmission mounting bolts and engine stiffener.

38. Remove the transmission housing mounting bolts.

39. Pull the transmission away from the engine until it clears the mainshaft, then lower it on the transmission jack.

SELECT CABLE

LOWER COVER

RELEASE FORK

Corrosion resistant bolt/nut

REAR TRANSMISSION

MOUNT

REAR TRANSMISSION

MOUNTING BOLT

TRANSMISSION JACK

TRANSMISSION HOUSING

MOUNTING BOLT

ENGINE STIFFENER

CLUTCH HOUSING

COVER

FRONT ENGINE MOUNTING

BOLT (Transmission side

)

FRONT ENGINE MOUNTING

BOLT (Engine side

)

TRANSMISSION HOUSING

MOUNTING BOLTSProCarManuals.com

Page 1551 of 1640

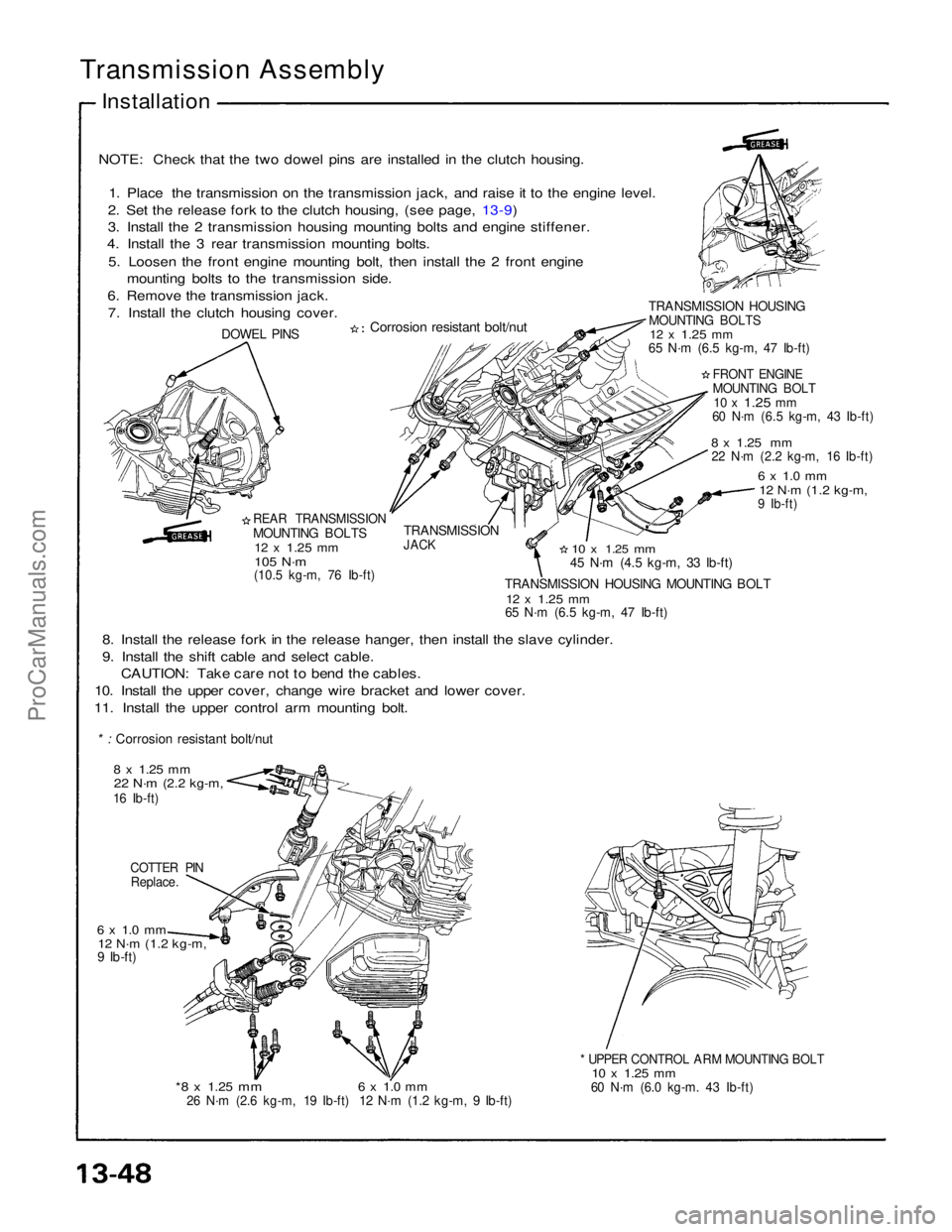

Transmission Assembly

Installation

NOTE: Check that the two dowel pins are installed in the clutch housing. 1. Place the transmission on the transmission jack, and raise it to the engine level.

2. Set the release fork to the clutch housing, (see page, 13-9)

3. Install the 2 transmission housing mounting bolts and engine stiffener.

4. Install the 3 rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, then install the 2 front engine mounting bolts to the transmission side.

6. Remove the transmission jack. 7. Install the clutch housing cover.

DOWEL PINS

REAR TRANSMISSION

MOUNTING BOLTS

12 x

1.25

mm

105 N·m

(10.5 kg-m, 76 Ib-ft)

TRANSMISSION

JACK

8. Install the release fork in the release hanger, then install the slave cylinder.

9. Install the shift cable and select cable. CAUTION: Take care not to bend the cables.

10. Install the upper cover, change wire bracket and lower cover.

11. Install the upper control arm mounting bolt.

*: Corrosion resistant bolt/nut

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

COTTER PIN

Replace.

6 x 1.0 mm 12 N·m

(1.2 kg-m,

9 Ib-ft)

*8 x

1.25

mm

26 N·m (2.6 kg-m, 19 Ib-ft)

* UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N·m (6.0 kg-m. 43 Ib-ft)

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

mm

65 N·m (6.5 kg-m, 47 Ib-ft)

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N·m (6.5 kg-m, 43 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

10 x

1.25

mm

45 N·m (4.5 kg-m, 33 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

65 N·m (6.5 kg-m, 47 Ib-ft)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)ProCarManuals.com

Page 1569 of 1640

Troubleshooting

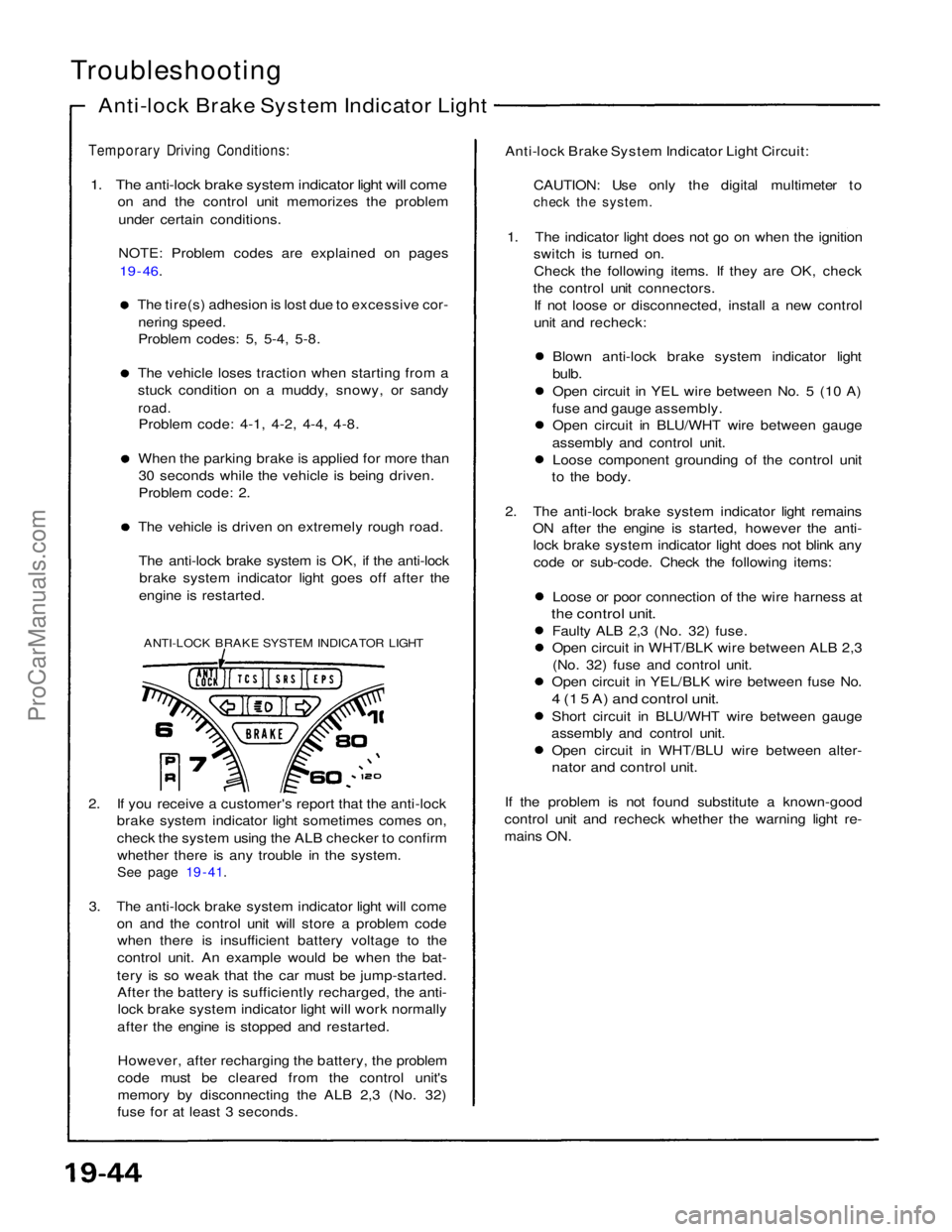

Anti-lock Brake System Indicator Light

Temporary Driving Conditions:

1. The anti-lock brake system indicator light will come

on and the control unit memorizes the problem

under certain conditions.

NOTE: Problem codes are explained on pages

19 - 46.

The tire(s) adhesion is lost due to excessive cor-

nering speed.

Problem codes: 5, 5-4, 5-8. The vehicle loses traction when starting from a

stuck condition on a muddy, snowy, or sandy

road.

Problem code: 4-1, 4-2, 4-4, 4-8. When the parking brake is applied for more than

30 seconds while the vehicle is being driven.

Problem code: 2. The vehicle is driven on extremely rough road.

The anti-lock brake system is OK, if the anti-lock brake system indicator light goes off after the

engine is restarted.

ANTI-LOCK BRAKE SYSTEM INDICATOR LIGHT

2. If you receive a customer's report that the anti-lock brake system indicator light sometimes comes on,

check the system using the ALB checker to confirm

whether there is any trouble in the system.

See page 19 - 41.

3. The anti-lock brake system indicator light will come on and the control unit will store a problem codewhen there is insufficient battery voltage to the

control unit. An example would be when the bat-

tery is so weak that the car must be jump-started. After the battery is sufficiently recharged, the anti-lock brake system indicator light will work normally

after the engine is stopped and restarted.

However, after recharging the battery, the problem

code must be cleared from the control unit's

memory by disconnecting the ALB 2,3 (No. 32)

fuse for at least 3 seconds. Anti-lock Brake System Indicator Light Circuit:

CAUTION: Use only the digital multimeter to

check the system.

1. The indicator light does not go on when the ignition switch is turned on.

Check the following items. If they are OK, check

the control unit connectors. If not loose or disconnected, install a new control

unit and recheck:

Blown anti-lock brake system indicator light

bulb.

Open circuit in YEL wire between No. 5 (10 A)

fuse and gauge assembly. Open circuit in BLU/WHT wire between gauge

assembly and control unit. Loose component grounding of the control unit

to the body.

2. The anti-lock brake system indicator light remains ON after the engine is started, however the anti-lock brake system indicator light does not blink any

code or sub-code. Check the following items:

Loose or poor connection of the wire harness at

the control unit.

Faulty ALB 2,3 (No. 32) fuse.

Open circuit in WHT/BLK wire between ALB 2,3(No. 32) fuse and control unit.

Open circuit in YEL/BLK wire between fuse No.

4 (1 5 A) and control unit.

Short circuit in BLU/WHT wire between gauge

assembly and control unit. Open circuit in WHT/BLU wire between alter-

nator and control unit.

If the problem is not found substitute a known-good

control unit and recheck whether the warning light re-

mains ON.ProCarManuals.com

Page 1570 of 1640

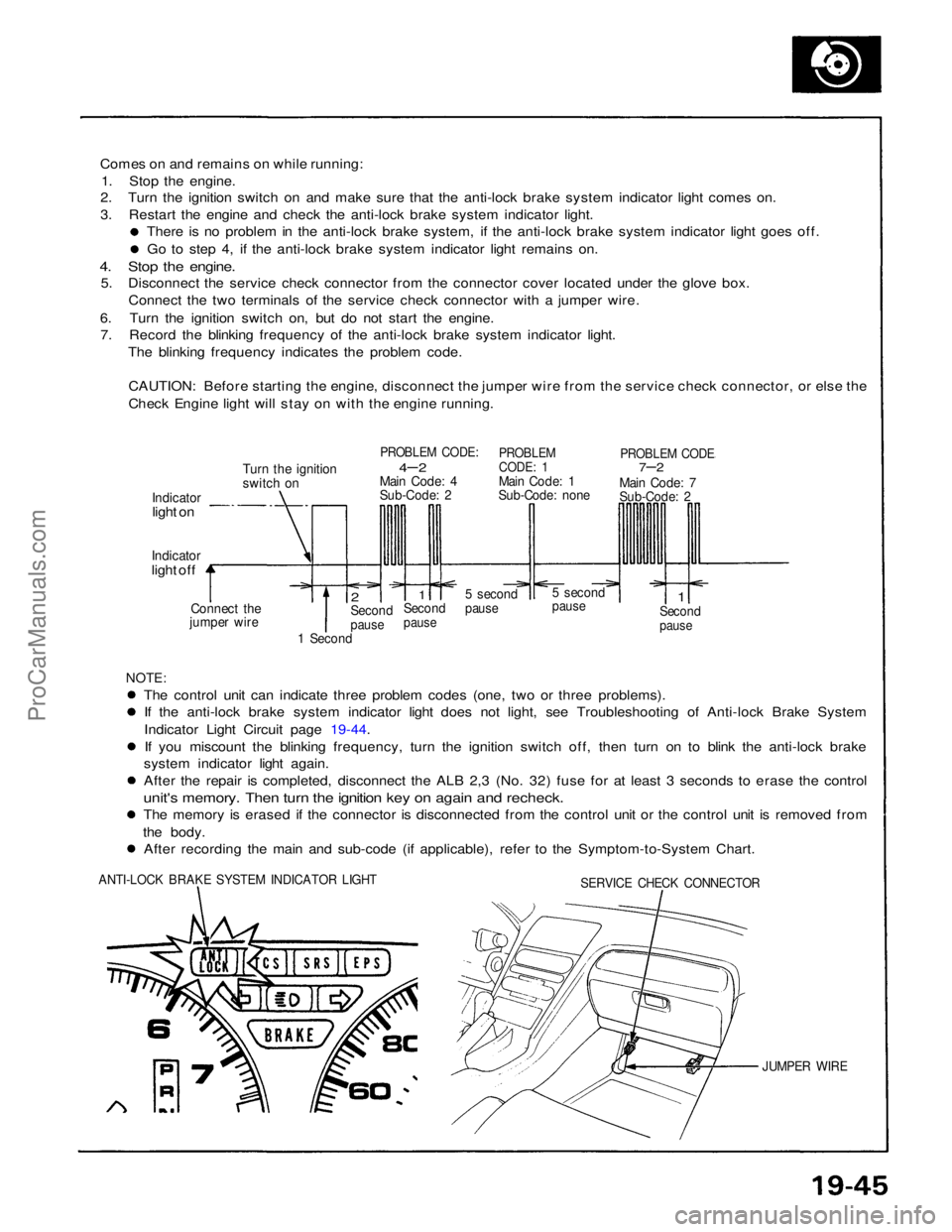

Comes on and remains on while running:

1. Stop the engine.

2. Turn the ignition switch on and make sure that the anti-lock brake system indicator light comes on.

3. Restart the engine and check the anti-lock brake system indicator light.

There is no problem in the anti-lock brake system, if the anti-lock brake system indicator light goes off. Go to step 4, if the anti-lock brake system indicator light remains on.

4. Stop the engine.

5. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

6. Turn the ignition switch on, but do not start the engine. 7. Record the blinking frequency of the anti-lock brake system indicator light.

The blinking frequency indicates the problem code.

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Check Engine light will stay on with the engine running.

Turn the ignition

switch on

PROBLEM CODE:

4– 2

Main Code: 4

Sub-Code: 2

PROBLEM

CODE: 1

Main Code: 1

Sub-Code: none

PROBLEM CODE

7–2

Main Code: 7

Sub-Code: 2

Indicator

light on

Indicator

light off

Connect the

jumper wire

2

Second

pause

1

Second

pause

5 second

pause

5 second

pause

1

Second

pause

1 Second

NOTE:

The control unit can indicate three problem codes (one, two or three problems). If the anti-lock brake system indicator light does not light, see Troubleshooting of Anti-lock Brake System

Indicator Light Circuit page 19-44.

If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the anti-lock brake

system indicator light again. After the repair is completed, disconnect the ALB 2,3 (No. 32) fuse for at least 3 seconds to erase the control

unit's memory. Then turn the ignition key on again and recheck.

The memory is erased if the connector is disconnected from the control unit or the control unit is removed from

the body. After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.

ANTI-LOCK BRAKE SYSTEM INDICATOR LIGHT

SERVICE CHECK CONNECTOR

JUMPER WIREProCarManuals.com

Page 1574 of 1640

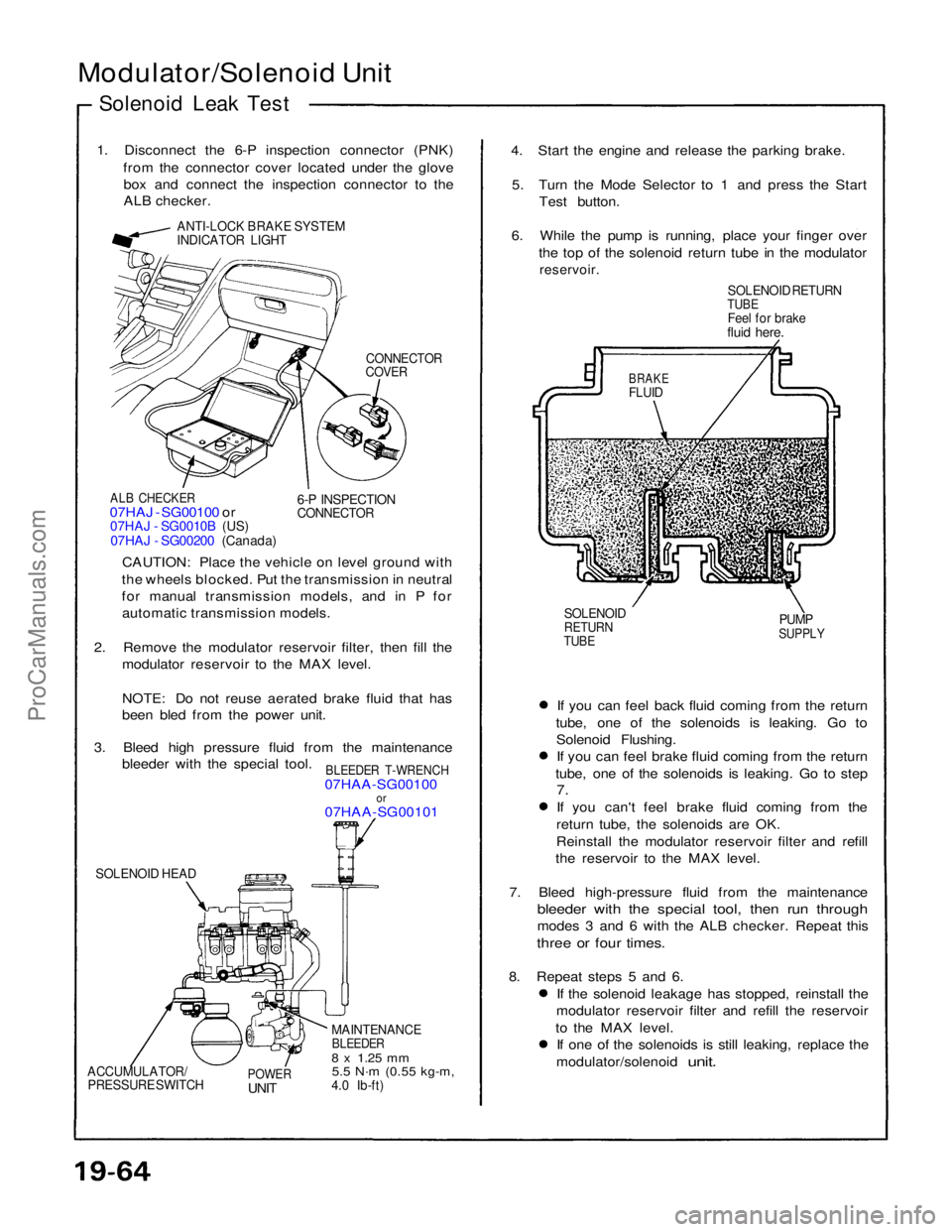

Modulator/Solenoid Unit

Solenoid Leak Test

1. Disconnect the 6-P inspection connector (PNK) from the connector cover located under the glovebox and connect the inspection connector to the

ALB checker.

ANTI-LOCK BRAKE SYSTEM

INDICATOR LIGHT

CONNECTOR

COVER

ALB CHECKER

07HAJ - SG00100 or

07HAJ - SG0010B (US)

07HAJ - SG00200 (Canada)

6-P INSPECTION

CONNECTOR

CAUTION: Place the vehicle on level ground with

the wheels blocked. Put the transmission in neutral

for manual transmission models, and in P for automatic transmission models.

2. Remove the modulator reservoir filter, then fill the modulator reservoir to the MAX level.

NOTE: Do not reuse aerated brake fluid that has

been bled from the power unit.

3. Bleed high pressure fluid from the maintenance bleeder with the special tool.

BLEEDER T-WRENCH

07HAA-SG00100

or

07HAA-SG00101

SOLENOID HEAD

MAINTENANCE

BLEEDER

8 x

1.25

mm

5.5 N·m

(0.55 kg-m,

4.0 Ib-ft)

POWER

UNIT

ACCUMULATOR/

PRESSURE SWITCH

If you can feel back fluid coming from the return

tube, one of the solenoids is leaking. Go to Solenoid Flushing.If you can feel brake fluid coming from the return

tube, one of the solenoids is leaking. Go to step

7.

If you can't feel brake fluid coming from the return tube, the solenoids are OK.

Reinstall the modulator reservoir filter and refill

the reservoir to the MAX level.

7. Bleed high-pressure fluid from the maintenance

bleeder with the special tool, then run through

modes 3 and 6 with the ALB checker. Repeat this

three or four times.

8. Repeat steps 5 and 6. If the solenoid leakage has stopped, reinstall the

modulator reservoir filter and refill the reservoir

to the MAX level. If one of the solenoids is still leaking, replace the

modulator/solenoid

unit.

SOLENOID

RETURN

TUBE

PUMP

SUPPLY

BRAKE

FLUID

SOLENOID RETURN

TUBE

Feel for brake

fluid here.

4. Start the engine and release the parking brake.

5. Turn the Mode Selector to 1 and press the Start Test button.

6. While the pump is running, place your finger over the top of the solenoid return tube in the modulator

reservoir.ProCarManuals.com

Page 1575 of 1640

Solenoid Flushing

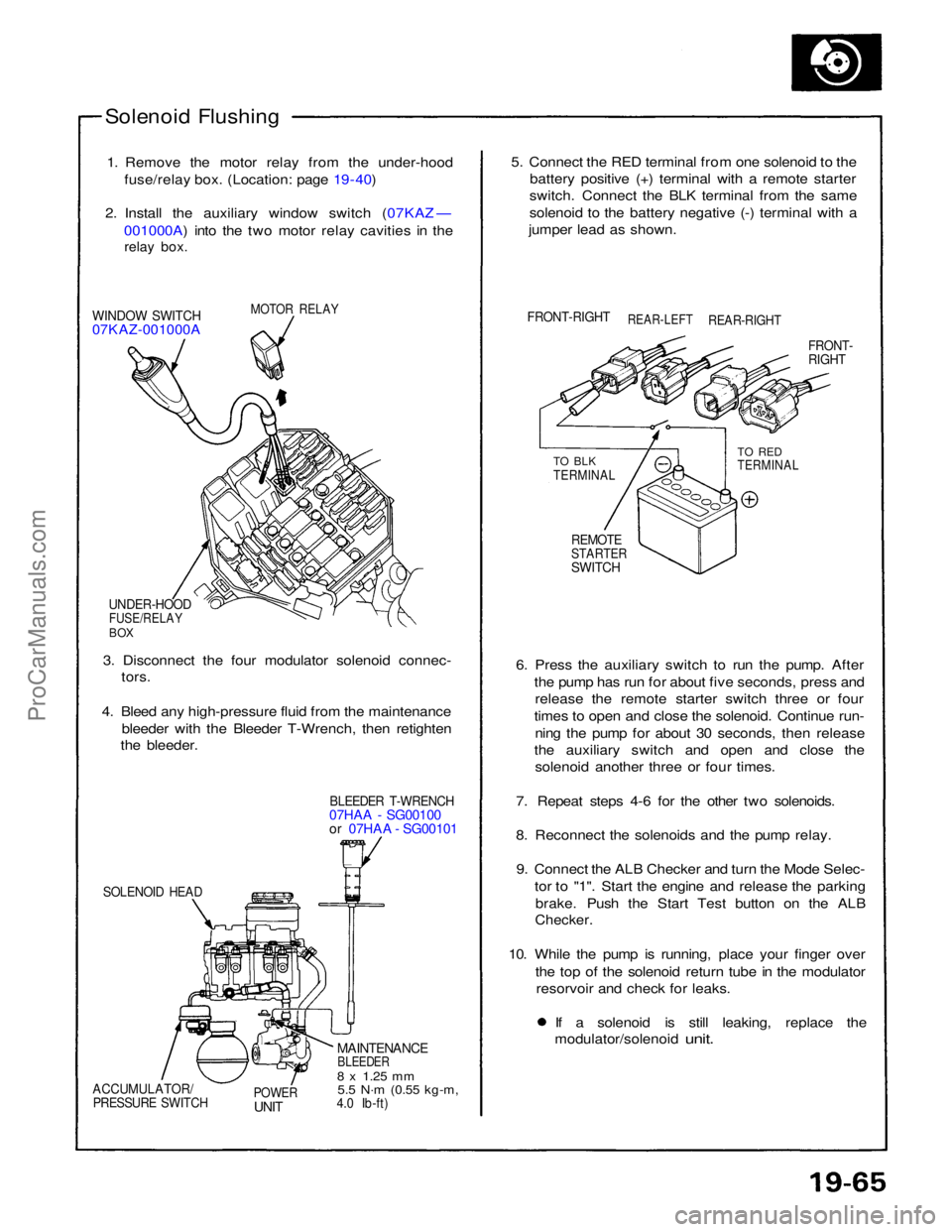

1. Remove the motor relay from the under-hood fuse/relay box. (Location: page 19 - 40)

2. Install the auxiliary window switch (07KAZ — 001000A) into the two motor relay cavities in the

relay box.

MOTOR RELAY

WINDOW SWITCH

07KAZ-001000A

UNDER-HOOD

FUSE/RELAY

BOX

3. Disconnect the four modulator solenoid connec- tors.

4. Bleed any high-pressure fluid from the maintenance bleeder with the Bleeder T-Wrench, then retighten

the bleeder.

BLEEDER T-WRENCH

07HAA - SG00100

or 07HAA - SG00101

SOLENOID HEAD

MAINTENANCE

BLEEDER

8 x

1.25

mm

5.5 N·m

(0.55 kg-m,

4.0 Ib-ft)

POWER

UNIT

ACCUMULATOR/

PRESSURE SWITCH

6. Press the auxiliary switch to run the pump. After

the pump has run for about five seconds, press andrelease the remote starter switch three or four

times to open and close the solenoid. Continue run- ning the pump for about 30 seconds, then release

the auxiliary switch and open and close the solenoid another three or four times.

7. Repeat steps 4-6 for the other two solenoids.

8. Reconnect the solenoids and the pump relay. 9. Connect the ALB Checker and turn the Mode Selec- tor to "1". Start the engine and release the parkingbrake. Push the Start Test button on the ALB

Checker.

10. While the pump is running, place your finger over the top of the solenoid return tube in the modulatorresorvoir and check for leaks. If a solenoid is still leaking, replace the

modulator/solenoid

unit.

REMOTE

STARTER

SWITCH

TO BLK

TERMINAL

TO RED

TERMINAL

FRONT-

RIGHT

FRONT-RIGHT

REAR-LEFT

REAR-RIGHT

5. Connect the RED terminal from one solenoid to the

battery positive (+) terminal with a remote starter

switch. Connect the BLK terminal from the same

solenoid to the battery negative (-) terminal with a

jumper lead as shown.ProCarManuals.com

Page 1576 of 1640

Bleeding

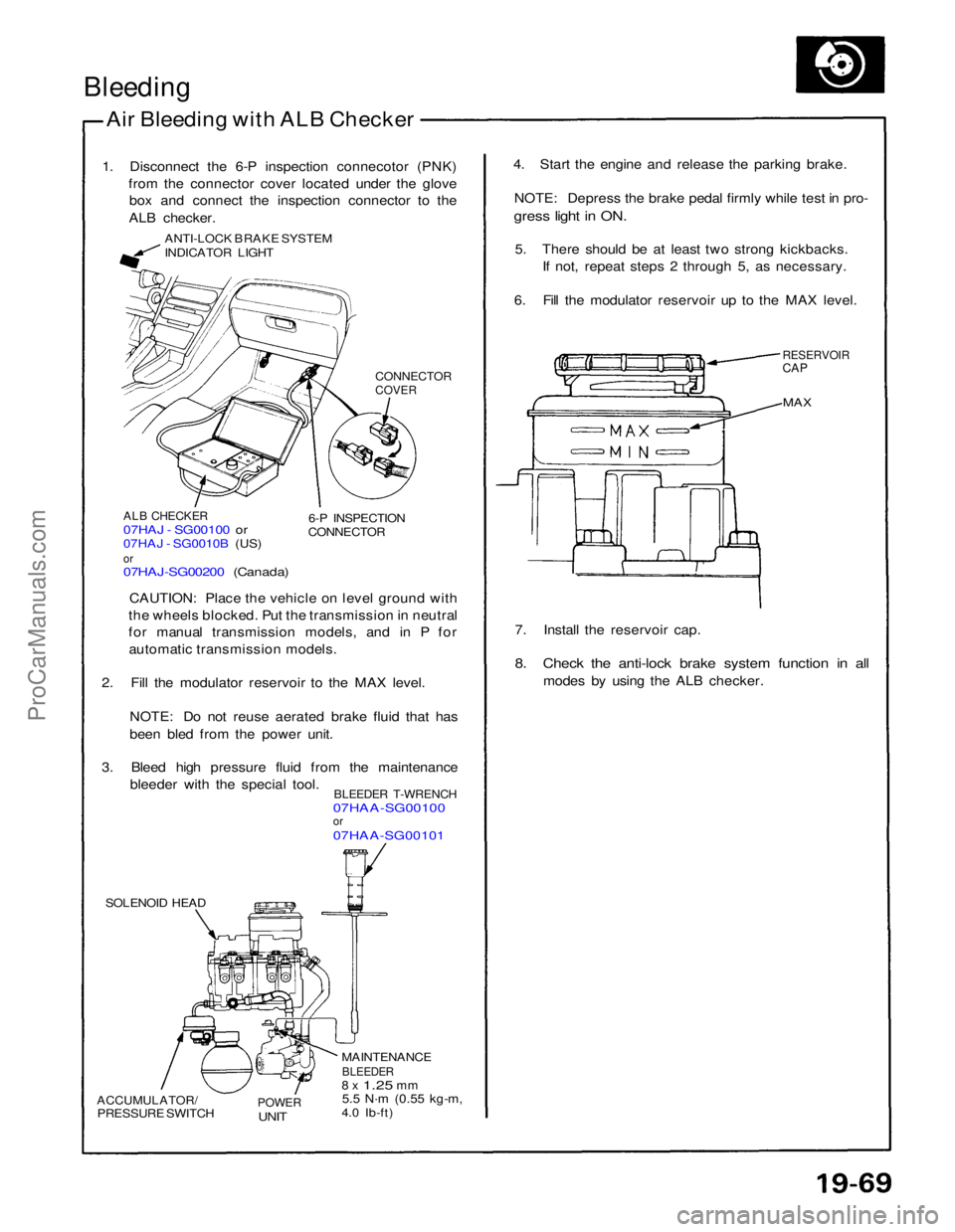

Air Bleeding with ALB Checker

1. Disconnect the 6-P inspection connecotor (PNK) from the connector cover located under the glovebox and connect the inspection connector to the

ALB checker.

ANTI-LOCK BRAKE SYSTEM

INDICATOR LIGHT

CONNECTOR

COVER

ALB CHECKER

07HAJ - SG00100 or

07HAJ - SG0010B (US)

or

07HAJ-SG00200 (Canada)

6-P INSPECTION

CONNECTOR

CAUTION: Place the vehicle on level ground with

the wheels blocked. Put the transmission in neutral

for manual transmission models, and in P for automatic transmission models.

2. Fill the modulator reservoir to the MAX level.

NOTE: Do not reuse aerated brake fluid that has

been bled from the power unit.

3. Bleed high pressure fluid from the maintenance bleeder with the special tool.

BLEEDER T-WRENCH

07HAA-SG00100

or

07HAA-SG00101

SOLENOID HEAD

ACCUMULATOR/

PRESSURE SWITCH

POWER

UNIT

MAINTENANCE

BLEEDER

8 x

1.25

mm

5.5 N·m

(0.55 kg-m,

4.0 Ib-ft) 7. Install the reservoir cap.

8. Check the anti-lock brake system function in all

modes by using the ALB checker.

MAX

RESERVOIR

CAP

4. Start the engine and release the parking brake.

NOTE: Depress the brake pedal firmly while test in pro-

gress light in ON.

5. There should be at least two strong kickbacks. If not, repeat steps 2 through 5, as necessary.

6. Fill the modulator reservoir up to the MAX level.ProCarManuals.com