engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1495 of 1640

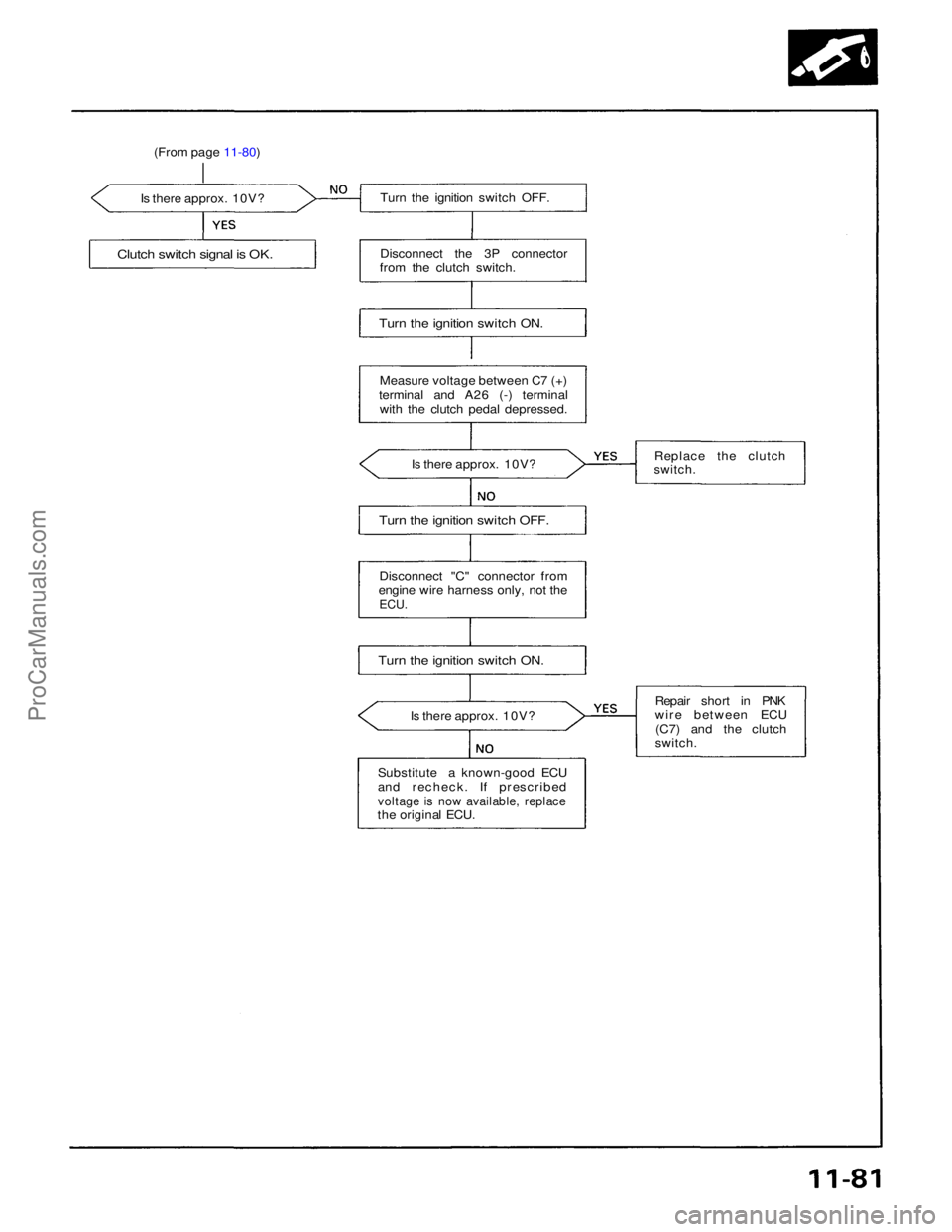

(From page 11-80)

Is there approx. 10V?

Clutch switch signal is OK.

Turn the ignition switch OFF.

Disconnect the 3P connector

from the clutch switch.

Turn the ignition switch ON.

Measure voltage between C7 (+)

terminal and A26 (-) terminal with the clutch pedal depressed.

Is there approx. 10V? Replace the clutch

switch.

Turn the ignition switch OFF.

Disconnect "C" connector from

engine wire harness only, not the

ECU.

Turn the ignition switch ON.

Is there approx. 10V? Repair short in PNK

wire between ECU

(C7) and the clutch

switch.

Substitute a known-good ECU

and recheck. If prescribed

voltage is now available, replace

the original ECU.ProCarManuals.com

Page 1496 of 1640

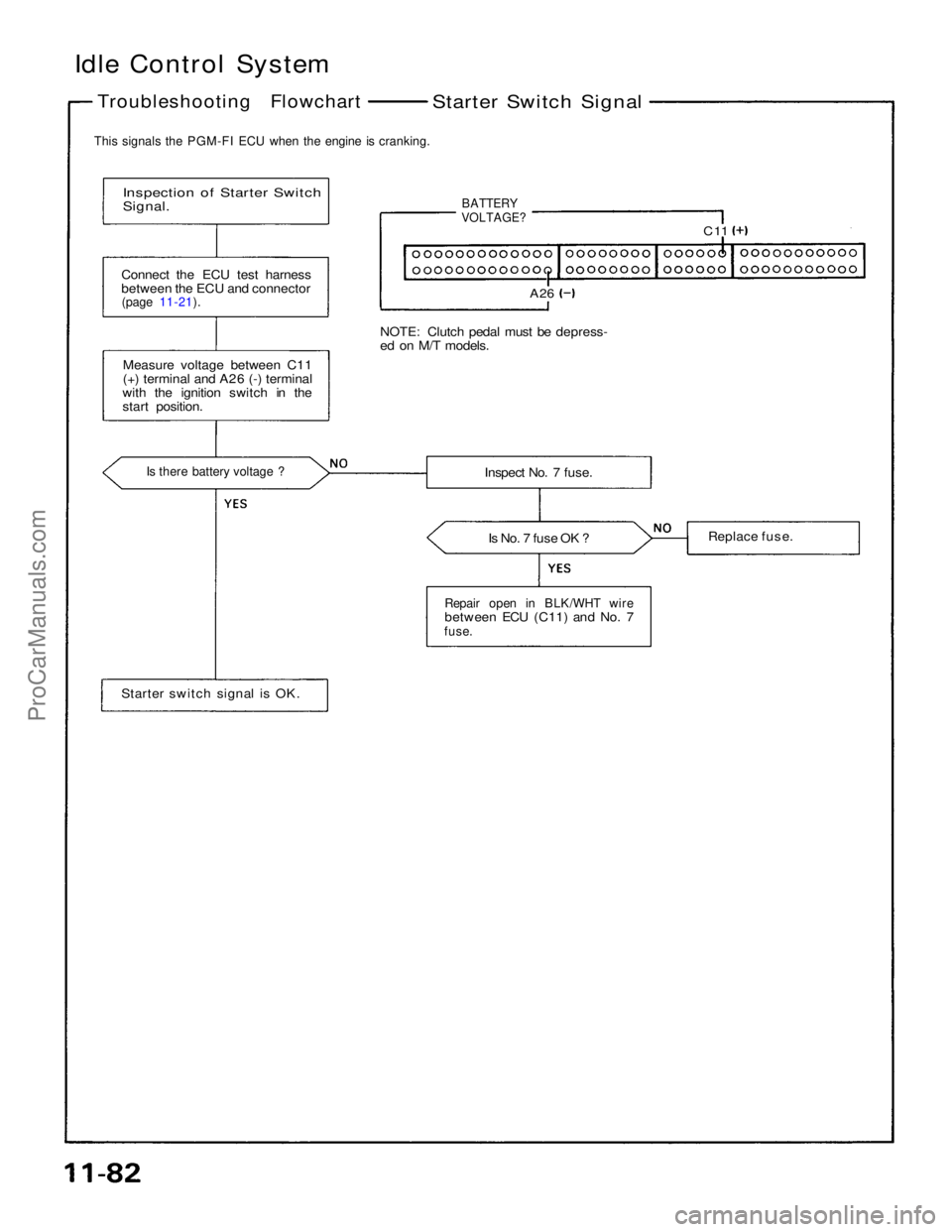

Idle Control System

Troubleshooting Flowchart

Starter Switch Signal

This signals the PGM-FI ECU when the engine is cranking.

Inspection of Starter Switch

Signal.

BATTERY

VOLTAGE?

C 11

A26

NOTE: Clutch pedal must be depress-

ed on M/T models.

Connect the ECU test harness

between the ECU and connector

(page 11-21).

Measure voltage between C11

(+) terminal and A26 (-) terminal

with the ignition switch in the

start position.

Is there battery voltage ?

Inspect No. 7 fuse.

Is No. 7 fuse OK ?

Replace fuse.

Repair open in BLK/WHT wire

between ECU (C11) and No. 7

fuse.

Starter switch signal is OK.ProCarManuals.com

Page 1497 of 1640

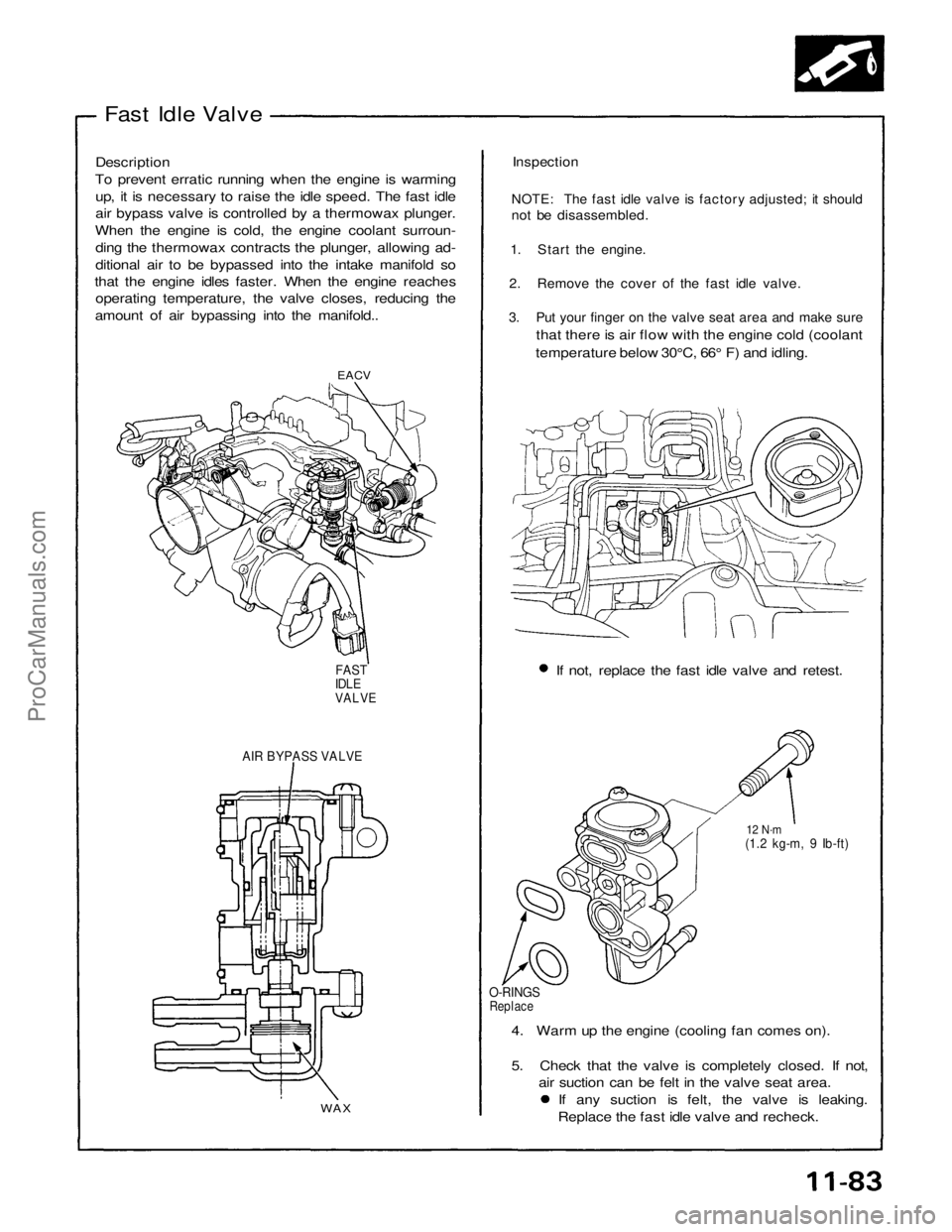

Fast Idle Valve

Description

To prevent erratic running when the engine is warming up, it is necessary to raise the idle speed. The fast idle

air bypass valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surroun- ding the thermowax contracts the plunger, allowing ad-

ditional air to be bypassed into the intake manifold so

that the engine idles faster. When the engine reaches operating temperature, the valve closes, reducing the

amount of air bypassing into the manifold..

Inspection

NOTE: The fast idle valve is factory adjusted; it should

not be disassembled.

1. Start the engine.

2. Remove the cover of the fast idle valve.

3. Put your finger on the valve seat area and make sure

that there is air flow with the engine cold (coolant

temperature below 30°C, 66° F) and idling.

EACV

If not, replace the fast idle valve and retest.

FAST

IDLE

VALVE

AIR BYPASS VALVE

12 N·m

(1.2 kg-m, 9 Ib-ft)

O-RINGS

Replace

4. Warm up the engine (cooling fan comes on).

5. Check that the valve is completely closed. If not, air suction can be felt in the valve seat area. If any suction is felt, the valve is leaking.

Replace the fast idle valve and recheck.

WAXProCarManuals.com

Page 1498 of 1640

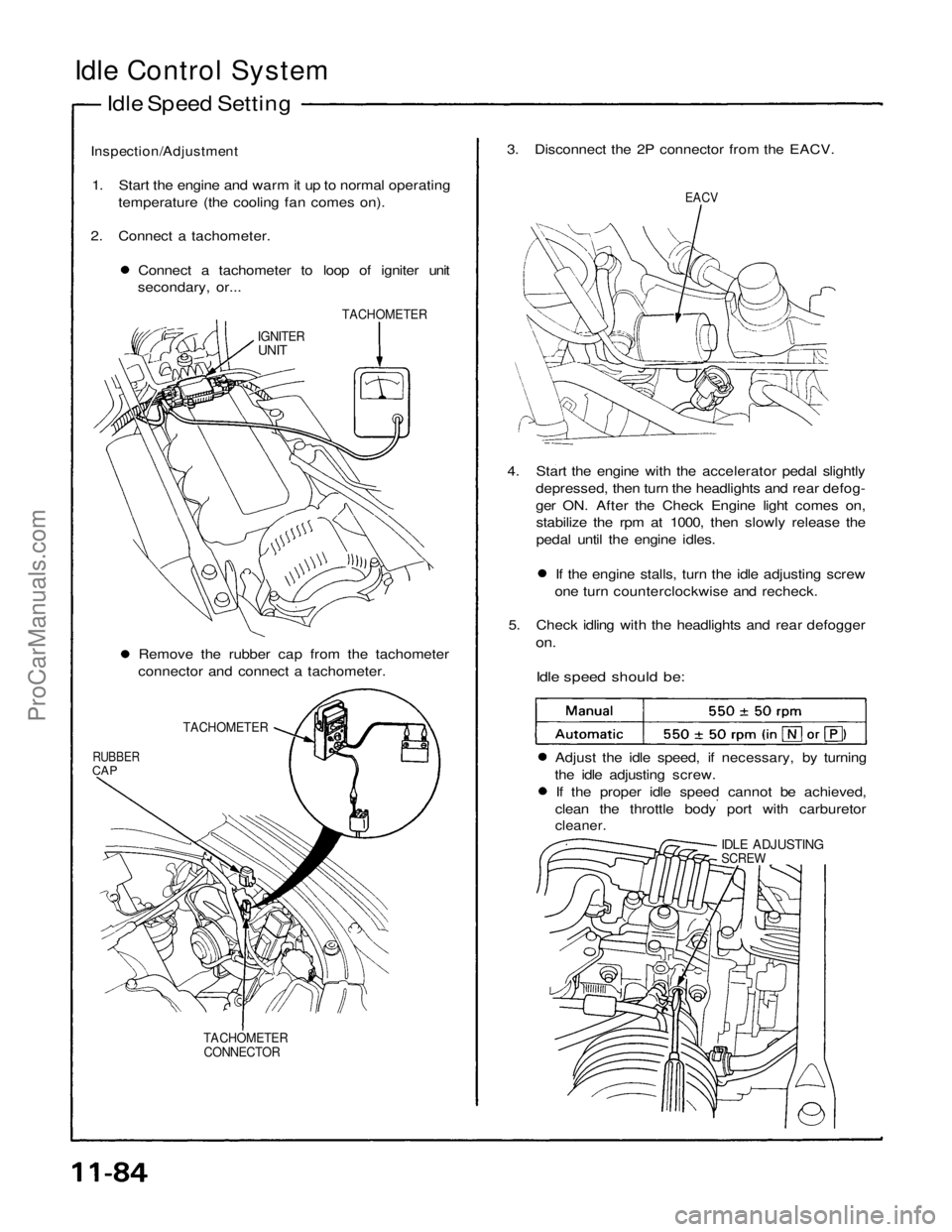

Idle Control System

Idle Speed Setting

Inspection/Adjustment

1. Start the engine and warm it up to normal operating temperature (the cooling fan comes on).

2. Connect a tachometer. Connect a tachometer to loop of igniter unit

secondary, or... 3. Disconnect the 2P connector from the EACV.

EACV

TACHOMETER

IGNITER

UNIT

4. Start the engine with the accelerator pedal slightlydepressed, then turn the headlights and rear defog-

ger ON. After the Check Engine light comes on,stabilize the rpm at 1000, then slowly release the

pedal until the engine idles. If the engine stalls, turn the idle adjusting screw

one turn counterclockwise and recheck.

5. Check idling with the headlights and rear defogger

on.

Idle speed should be:

Remove the rubber cap from the tachometer

connector and connect a tachometer.

TACHOMETER

RUBBER

CAP

Adjust the idle speed, if necessary, by turning

the idle adjusting screw. If the proper idle speed cannot be achieved,

clean the throttle body port with carburetor

cleaner.

IDLE ADJUSTING

SCREW

TACHOMETER CONNECTORProCarManuals.com

Page 1499 of 1640

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the EACV, then

remove CLOCK fuse in the under-hood fuse/relay

box for 10 seconds to reset ECU.

8. Restart and idle the engine with no-load conditions

in which the headlights, blower fan, rear defogger,

cooling fan, and air conditioner are not operating

for one minute, then check the idle speed.

Idle speed should be:ProCarManuals.com

Page 1501 of 1640

System Description

Fuel Pressure

The fuel supply system consists of a fuel tank, in-tank high pressure fuel pump, fuel pump relay, fuel pump

resistor, main relay, fuel filter, pressure regulator, injec-

tors and injector resistor.

This system delivers pressure regulated fuel to the in-

jectors and cuts the fuel delivery when the engine is not

running.

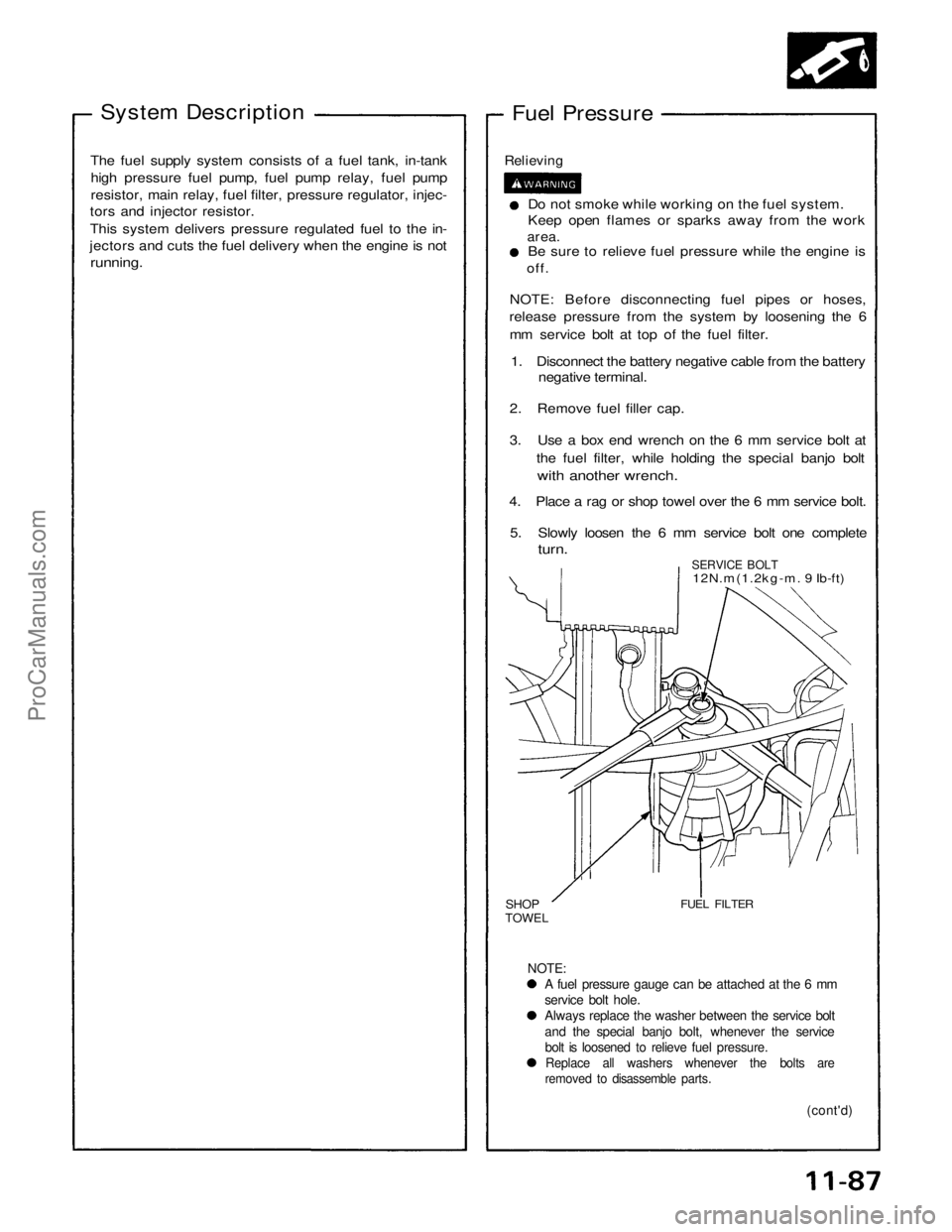

Relieving

Do not smoke while working on the fuel system.

Keep open flames or sparks away from the work

area.

Be sure to relieve fuel pressure while the engine is

off.

NOTE: Before disconnecting fuel pipes or hoses,

release pressure from the system by loosening the 6

mm service bolt at top of the fuel filter.

1. Disconnect the battery negative cable from the battery negative terminal.

2. Remove fuel filler cap.

3. Use a box end wrench on the 6 mm service bolt at the fuel filter, while holding the special banjo bolt

with another wrench.

4. Place a rag or shop towel over the 6 mm service bolt.

5. Slowly loosen the 6 mm service bolt one complete

turn.

SERVICE BOLT

12N.m(1.2kg-m. 9 Ib-ft)

SHOP

TOWEL

FUEL FILTER

NOTE:

A fuel pressure gauge can be attached at the 6 mm

service bolt hole.

Always replace the washer between the service bolt

and the special banjo bolt, whenever the service

bolt is loosened to relieve fuel pressure.

Replace all washers whenever the bolts are

removed to disassemble parts.

(cont'd)

ProCarManuals.com

Page 1502 of 1640

Fuel Supply System

Fuel Injectors (cont'd)

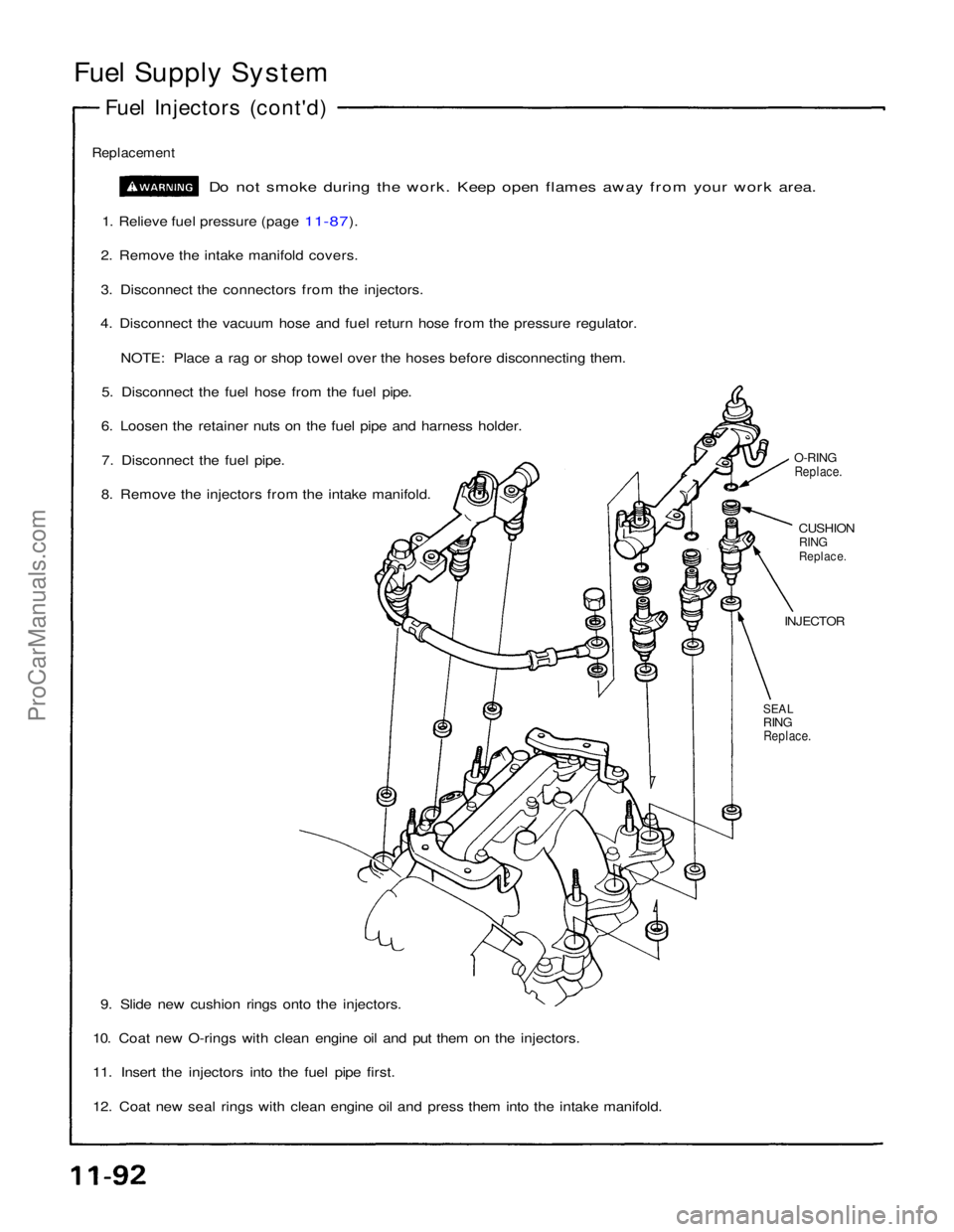

Replacement

Do not smoke during the work. Keep open flames away from your work area.

1. Relieve fuel pressure (page 11-87).

2. Remove the intake manifold covers.

3. Disconnect the connectors from the injectors.

4. Disconnect the vacuum hose and fuel return hose from the pressure regulator.

NOTE: Place a rag or shop towel over the hoses before disconnecting them.

5. Disconnect the fuel hose from the fuel pipe.

6. Loosen the retainer nuts on the fuel pipe and harness holder.

7. Disconnect the fuel pipe.

8. Remove the injectors from the intake manifold.

O-RING

Replace.

CUSHION

RING

Replace.

INJECTOR

SEAL

RING

Replace.

9. Slide new cushion rings onto the injectors.

10. Coat new O-rings with clean engine oil and put them on the injectors.

11. Insert the injectors into the fuel pipe first.

12. Coat new seal rings with clean engine oil and press them into the intake manifold.ProCarManuals.com

Page 1506 of 1640

Fuel Supply System

Pressure Regulator (cont'd)

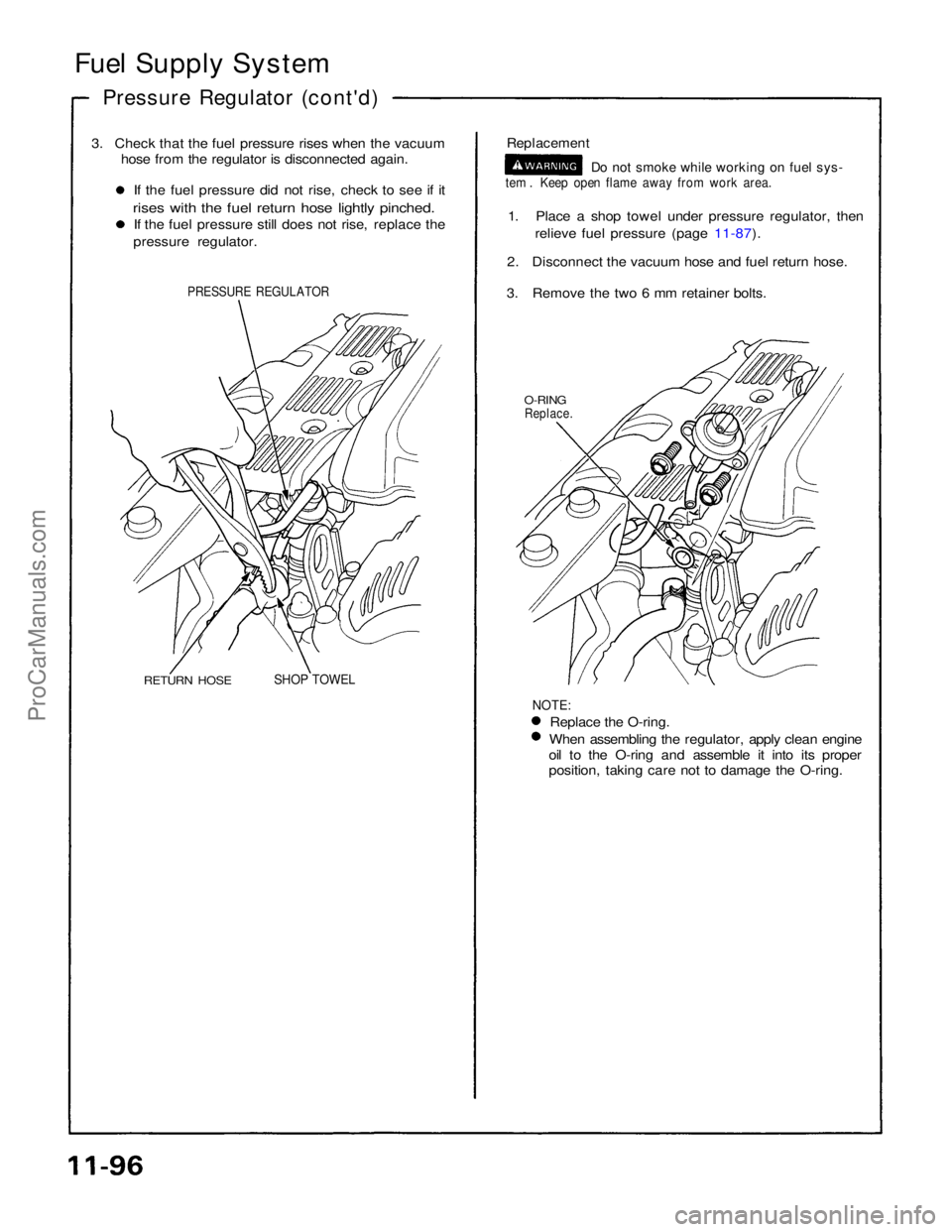

3. Check that the fuel pressure rises when the vacuum hose from the regulator is disconnected again.

If the fuel pressure did not rise, check to see if it

rises with the fuel return hose lightly pinched.

If the fuel pressure still does not rise, replace the

pressure regulator.

Replacement

Do not smoke while working on fuel sys-

tem . Keep open flame away from work area.

1. Place a shop towel under pressure regulator, then

relieve fuel pressure (page

11-87).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts.

O-RING

Replace.

PRESSURE REGULATOR

RETURN HOSE

SHOP TOWEL

NOTE:

Replace the O-ring. When assembling the regulator, apply clean engine

oil to the O-ring and assemble it into its proper

position, taking care not to damage the O-ring.ProCarManuals.com

Page 1508 of 1640

Fuel Supply System

Fuel Pump

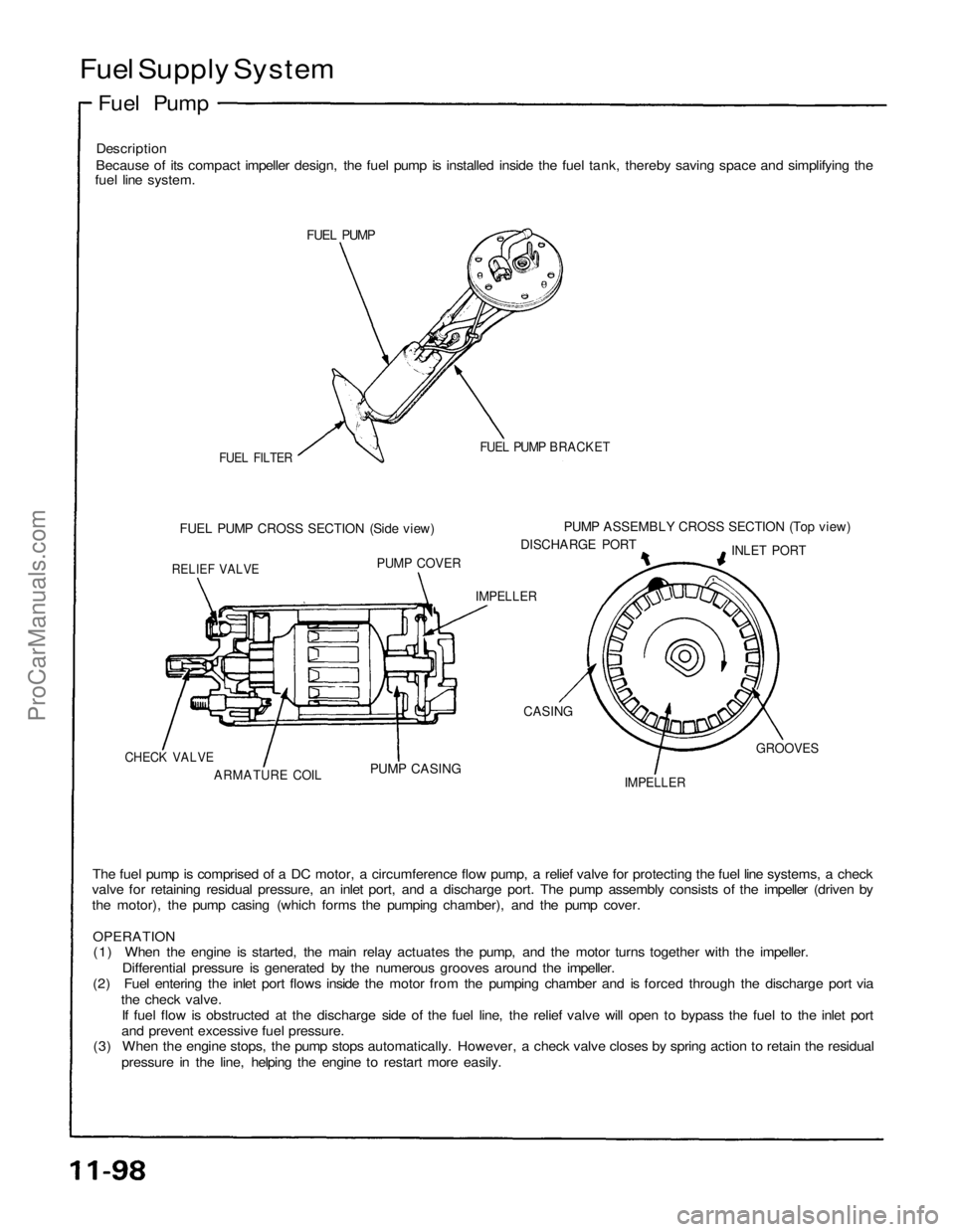

Description

Because of its compact impeller design, the fuel pump is installed inside the fuel tank, thereby saving space and simplifying the

fuel line system.

FUEL PUMP

FUEL FILTER

FUEL PUMP BRACKET

FUEL PUMP CROSS SECTION (Side view)

PUMP ASSEMBLY CROSS SECTION (Top view)

DISCHARGE PORT

INLET PORT

RELIEF VALVE

PUMP COVER

IMPELLER

CASING

IMPELLER

GROOVES

PUMP CASING

ARMATURE COIL

CHECK VALVE

The fuel pump is comprised of a DC motor, a circumference flow pump, a relief valve for protecting the fuel line systems, a check

valve for retaining residual pressure, an inlet port, and a discharge port. The pump assembly consists of the impeller (driven by

the motor), the pump casing (which forms the pumping chamber), and the pump cover.

OPERATION

(1) When the engine is started, the main relay actuates the pump, and the motor turns together with the impeller.

Differential pressure is generated by the numerous grooves around the impeller.

(2) Fuel entering the inlet port flows inside the motor from the pumping chamber and is forced through the discharge port via

the check valve.

If fuel flow is obstructed at the discharge side of the fuel line, the relief valve will open to bypass the fuel to the inlet port

and prevent excessive fuel pressure.

(3) When the engine stops, the pump stops automatically. However, a check valve closes by spring action to retain the residual

pressure in the line, helping the engine to restart more easily.ProCarManuals.com

Page 1510 of 1640

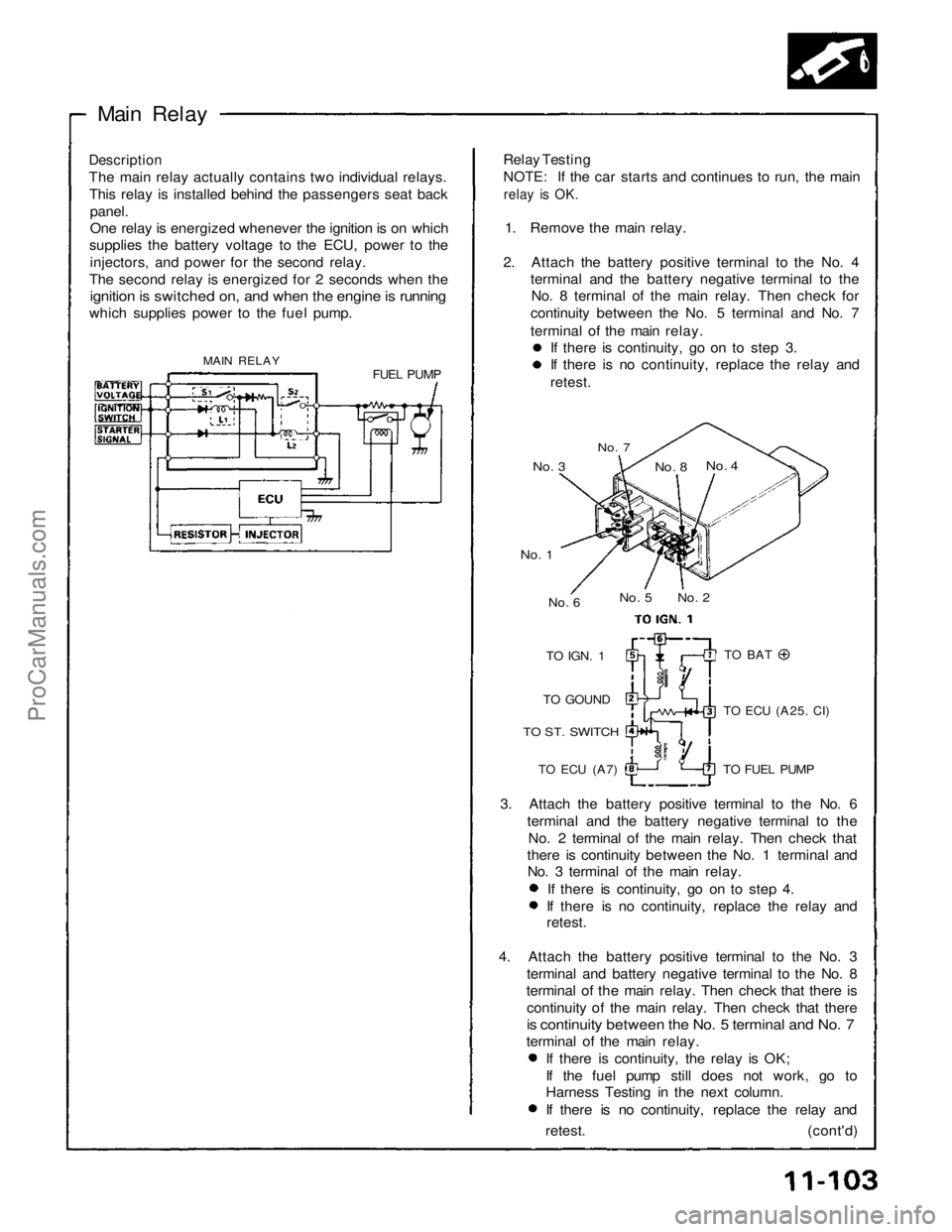

Main Relay

Description

The main relay actually contains two individual relays. This relay is installed behind the passengers seat back

panel.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECU, power to the

injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running

which supplies power to the fuel pump.

MAIN RELAY FUEL PUMPRelay Testing

NOTE: If the car starts and continues to run, the main

relay is OK.

1. Remove the main relay.

2. Attach the battery positive terminal to the No. 4 terminal and the battery negative terminal to theNo. 8 terminal of the main relay. Then check for

continuity between the No. 5 terminal and No. 7

terminal of the main relay. If there is continuity, go on to step 3. If there is no continuity, replace the relay and

retest.

No. 7

No. 3

No. 4

No. 8

No. 2

No. 5

No. 6

No. 1

TO

IGN.

1

TO GOUND

TO ST. SWITCH

TO ECU

(A7)

TO BAT

TO ECU

(A25.

CI)

TO FUEL PUMP

3. Attach the battery positive terminal to the No. 6 terminal and the battery negative terminal to theNo. 2 terminal of the main relay. Then check that

there is continuity between the No. 1 terminal and No. 3 terminal of the main relay.

If there is continuity, go on to step 4. If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 3 terminal and battery negative terminal to the No. 8

terminal of the main relay. Then check that there is

continuity of the main relay. Then check that there

is continuity between the No. 5 terminal and No. 7

terminal of the main relay. If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing in the next column.

If there is no continuity, replace the relay and

retest. (cont'd)ProCarManuals.com