engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1511 of 1640

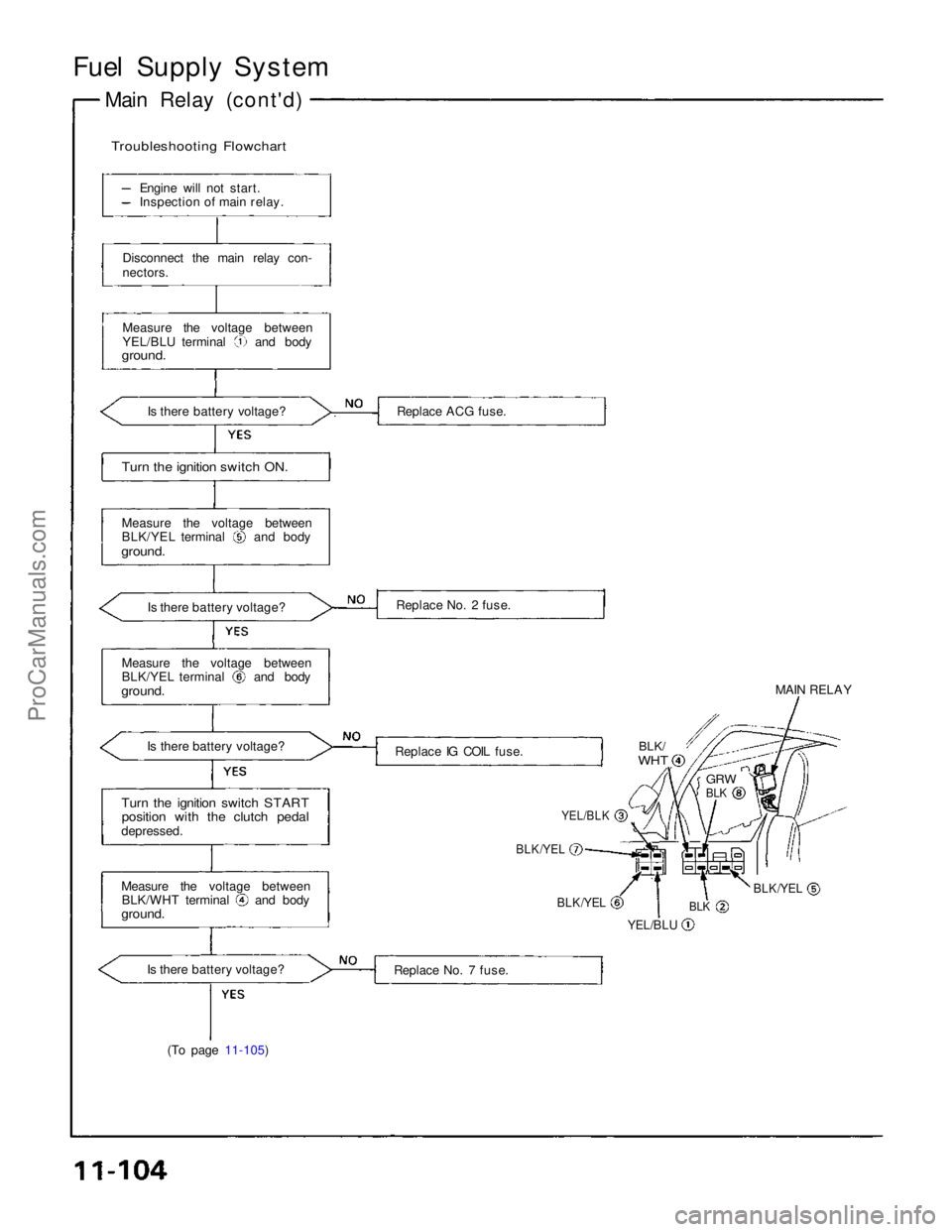

Fuel Supply System

Main Relay (cont'd)

Troubleshooting Flowchart

Engine will not start.

Inspection of main relay.

Disconnect the main relay con-

nectors.

Measure the voltage between YEL/BLU terminal and body

ground.

Is there battery voltage? Replace ACG fuse.

Turn the ignition switch ON.

Measure the voltage between BLK/YEL terminal and body

ground.

Replace No. 2 fuse.

Is there battery voltage?

Measure the voltage between BLK/YEL terminal and body

ground.

Is there battery voltage? Replace IG COIL fuse. MAIN RELAY

BLK/

WHT

GRW

BLK

YEL/BLK

BLK/YEL

BLK/YEL

YEL/BLU

BLK

BLK/YEL

Turn the ignition switch START

position with the clutch pedal

depressed.

Measure the voltage between BLK/WHT terminal and body

ground.

Is there battery voltage? Replace No. 7 fuse.

(To page 11-105)ProCarManuals.com

Page 1513 of 1640

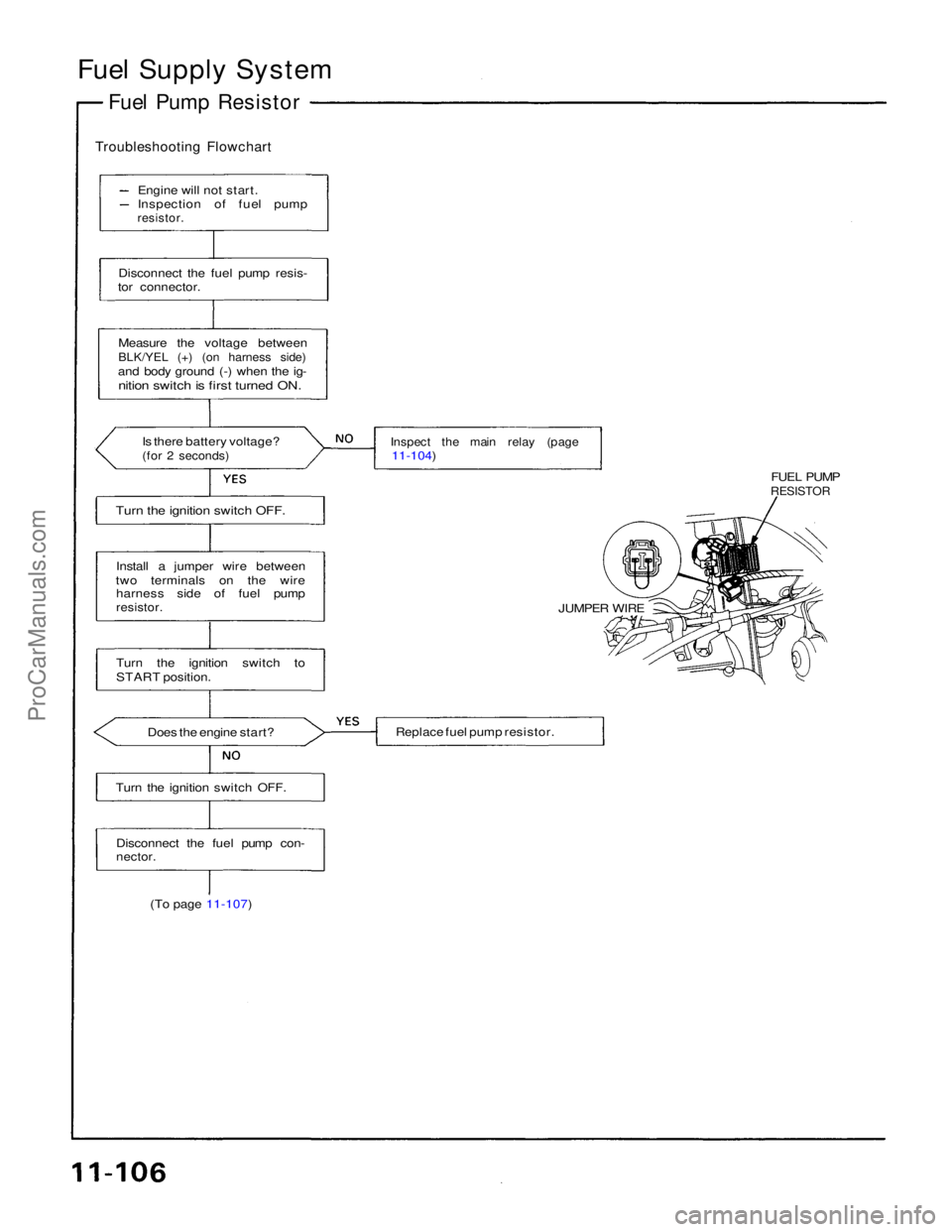

Fuel Supply System

Fuel Pump Resistor

Troubleshooting Flowchart

Engine will not start.

Inspection of fuel pump

resistor.

Disconnect the fuel pump resis-

tor connector.

Measure the voltage between

BLK/YEL (+) (on harness side)

and body ground (-) when the ig-

nition switch is first turned ON.

Is there battery voltage?

(for 2 seconds)

Inspect the main relay (page

11-104)

Turn the ignition switch OFF.

FUEL PUMP

RESISTOR

JUMPER WIRE

Replace fuel pump resistor.

Install a jumper wire between

two terminals on the wire harness side of fuel pump

resistor.

Turn the ignition switch to

START position.

Does the engine start?

Turn the ignition switch OFF.

Disconnect the fuel pump con-

nector.

(To page 11-107)ProCarManuals.com

Page 1517 of 1640

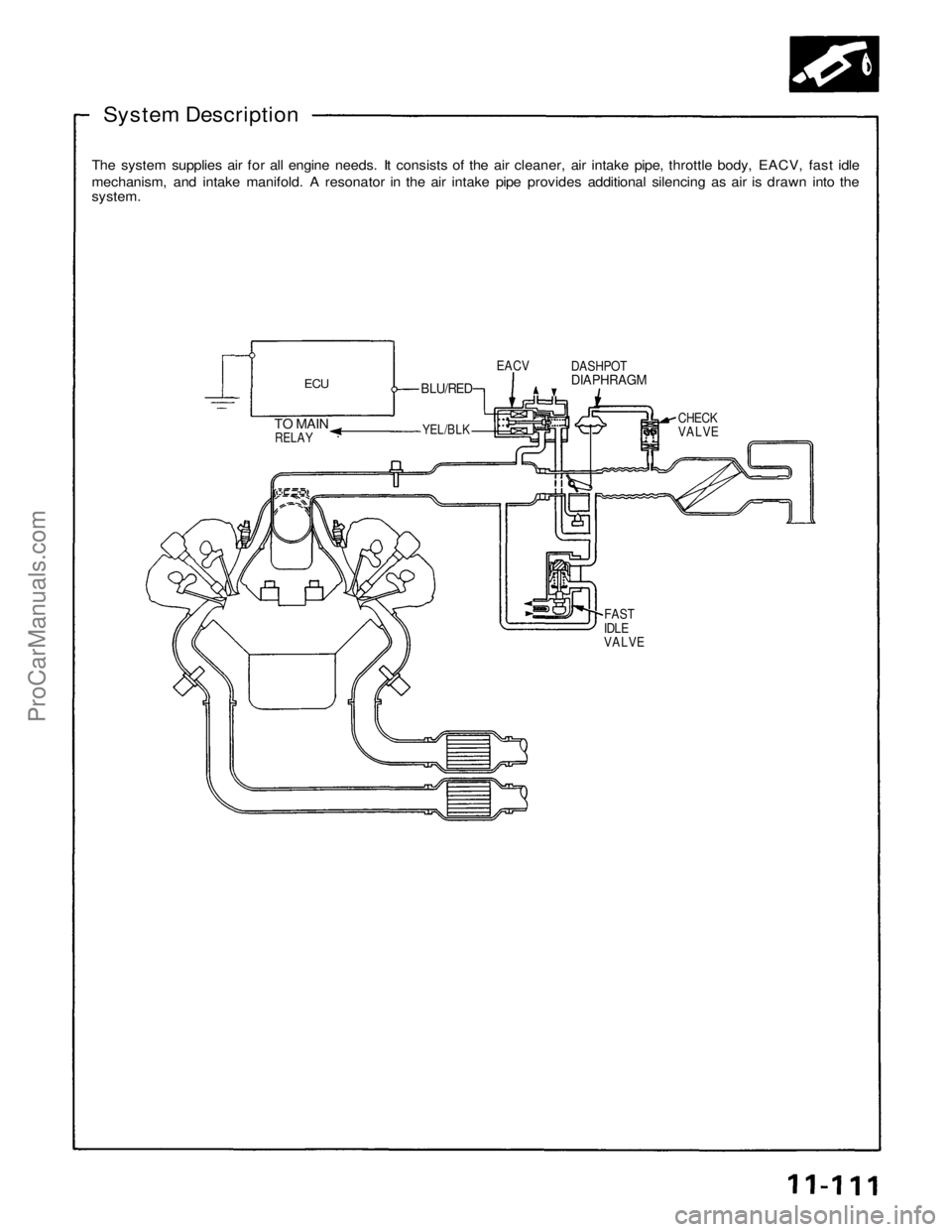

System Description

The system supplies air for all engine needs. It consists of the air cleaner, air intake pipe, throttle body, EACV, fast idle

mechanism, and intake manifold. A resonator in the air intake pipe provides additional silencing as air is drawn into the

system.

ECU

EACV

TO MAIN

RELAY

BLU/RED

CHECK

VALVE

DASHPOT

DIAPHRAGM

YEL/BLK

FAST

IDLE

VALVEProCarManuals.com

Page 1519 of 1640

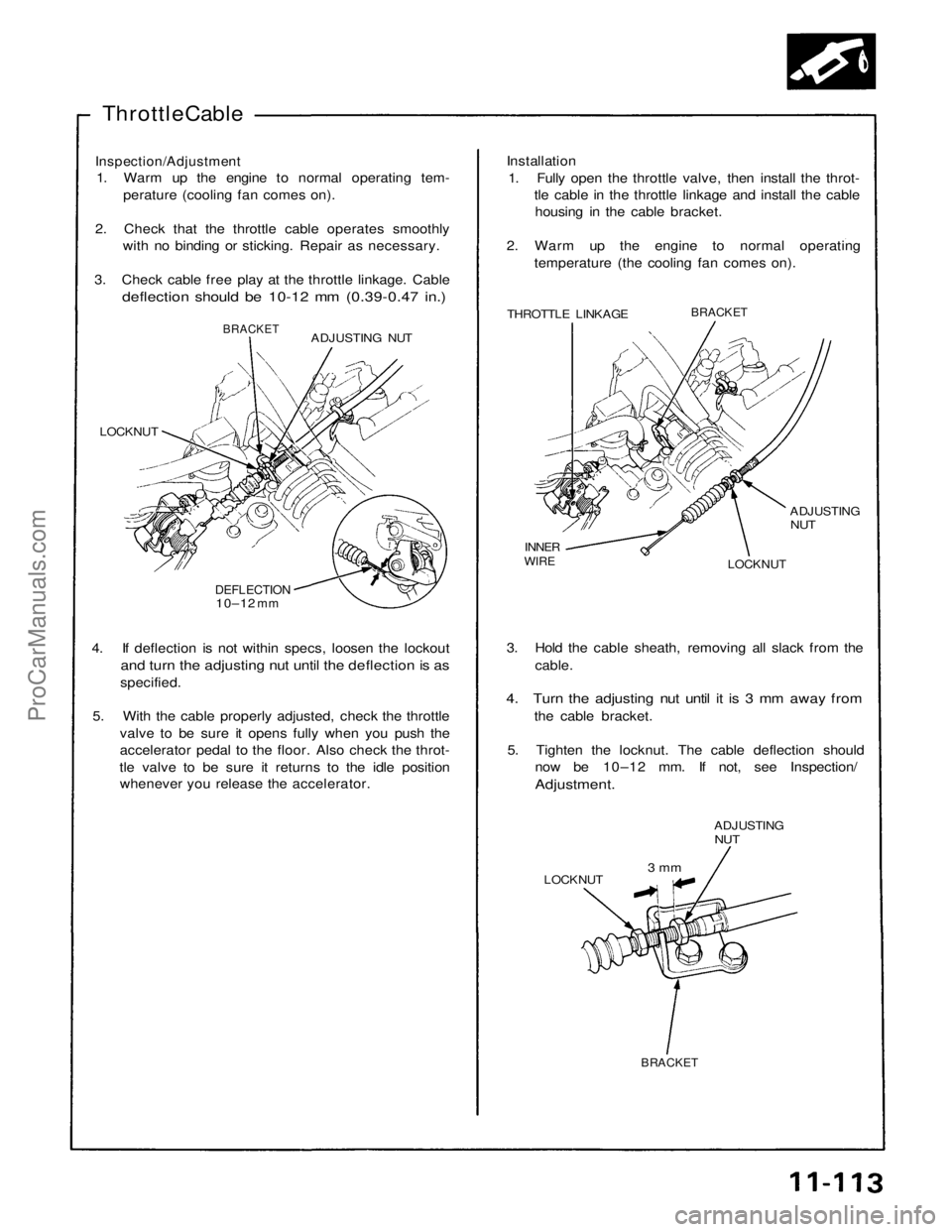

Throttle Cable

Inspection/Adjustment

1. Warm up the engine to normal operating tem-

perature (cooling fan comes on).

2. Check that the throttle cable operates smoothly with no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10-12 mm (0.39-0.47 in.)

Installation

1. Fully open the throttle valve, then install the throt- tle cable in the throttle linkage and install the cablehousing in the cable bracket.

2. Warm up the engine to normal operating temperature (the cooling fan comes on).

THROTTLE LINKAGE

BRACKET

ADJUSTING

NUT

LOCKNUT

INNER

WIRE

ADJUSTING NUT

BRACKET

LOCKNUT

DEFLECTION

10–12

mm

4. If deflection is not within specs, loosen the lockout

and turn the adjusting nut until the deflection is as

specified.

5. With the cable properly adjusted, check the throttle valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position whenever you release the accelerator. 3. Hold the cable sheath, removing all slack from the

cable.

4. Turn the adjusting nut until it is 3 mm away from

the cable bracket.

5. Tighten the locknut. The cable deflection should now be 10–12 mm. If not, see Inspection/

Adjustment.

ADJUSTING

NUT

LOCKNUT

3 mm

BRACKETProCarManuals.com

Page 1520 of 1640

Air Intake System

Throttle Body

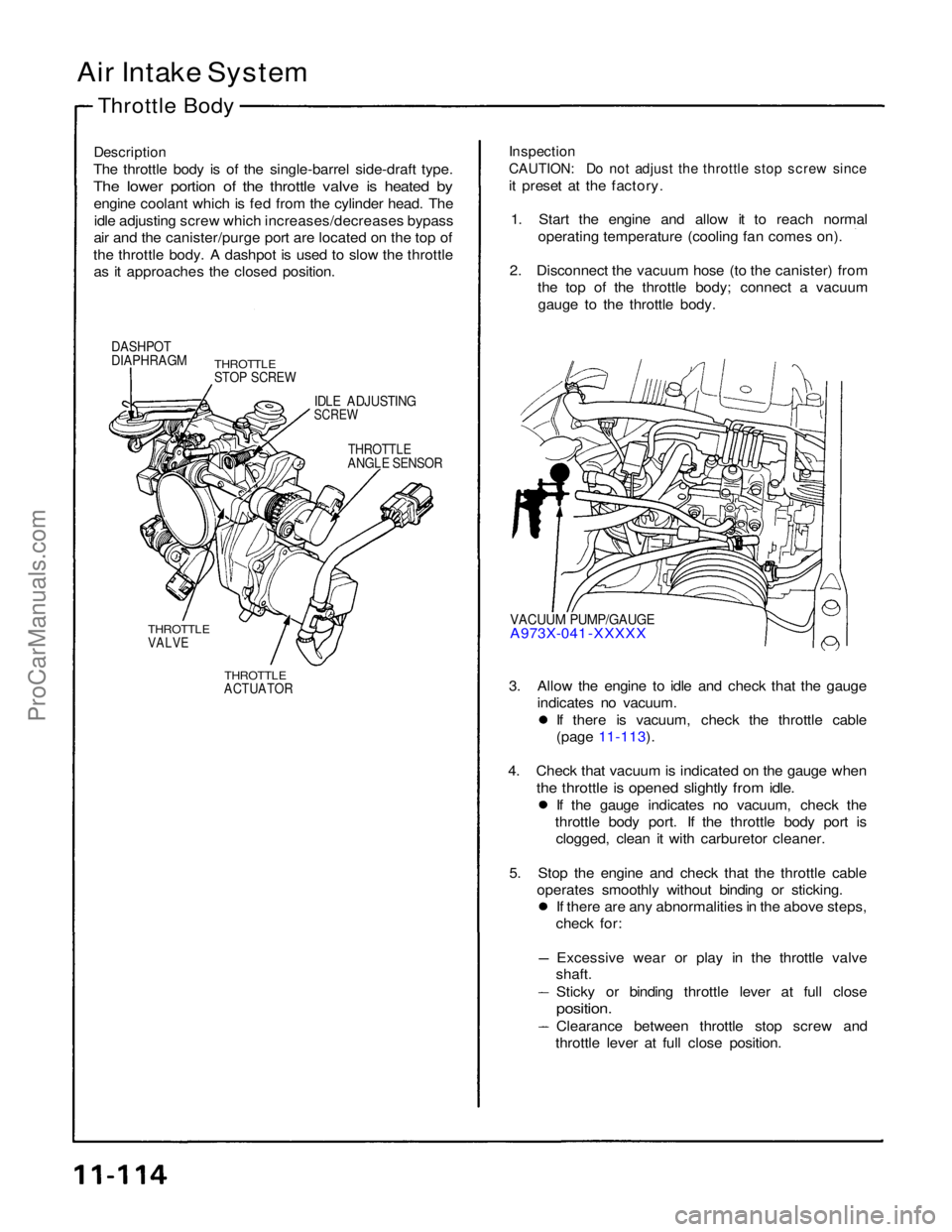

Description

The throttle body is of the single-barrel side-draft type.

The lower portion of the throttle valve is heated by

engine coolant which is fed from the cylinder head. Theidle adjusting screw which increases/decreases bypass

air and the canister/purge port are located on the top of

the throttle body. A dashpot is used to slow the throttle as it approaches the closed position.

Inspection

CAUTION: Do not adjust the throttle stop screw since

it preset at the factory.

1. Start the engine and allow it to reach normal operating temperature (cooling fan comes on).

2. Disconnect the vacuum hose (to the canister) from the top of the throttle body; connect a vacuum

gauge to the throttle body.

DASHPOT

DIAPHRAGM

THROTTLE

STOP SCREW

IDLE ADJUSTING

SCREW

THROTTLE

ANGLE SENSOR

VACUUM PUMP/GAUGE

A973X-041 -XXXXX

THROTTLE

VALVE

THROTTLE

ACTUATOR

3. Allow the engine to idle and check that the gauge

indicates no vacuum. If there is vacuum, check the throttle cable

(page 11-113).

4. Check that vacuum is indicated on the gauge when

the throttle is opened slightly from idle.

If the gauge indicates no vacuum, check the

throttle body port. If the throttle body port is clogged, clean it with carburetor cleaner.

5. Stop the engine and check that the throttle cable operates smoothly without binding or sticking. If there are any abnormalities in the above steps,

check for:

Excessive wear or play in the throttle valve

shaft.

Sticky or binding throttle lever at full close

position.

Clearance between throttle stop screw and

throttle lever at full close position.ProCarManuals.com

Page 1524 of 1640

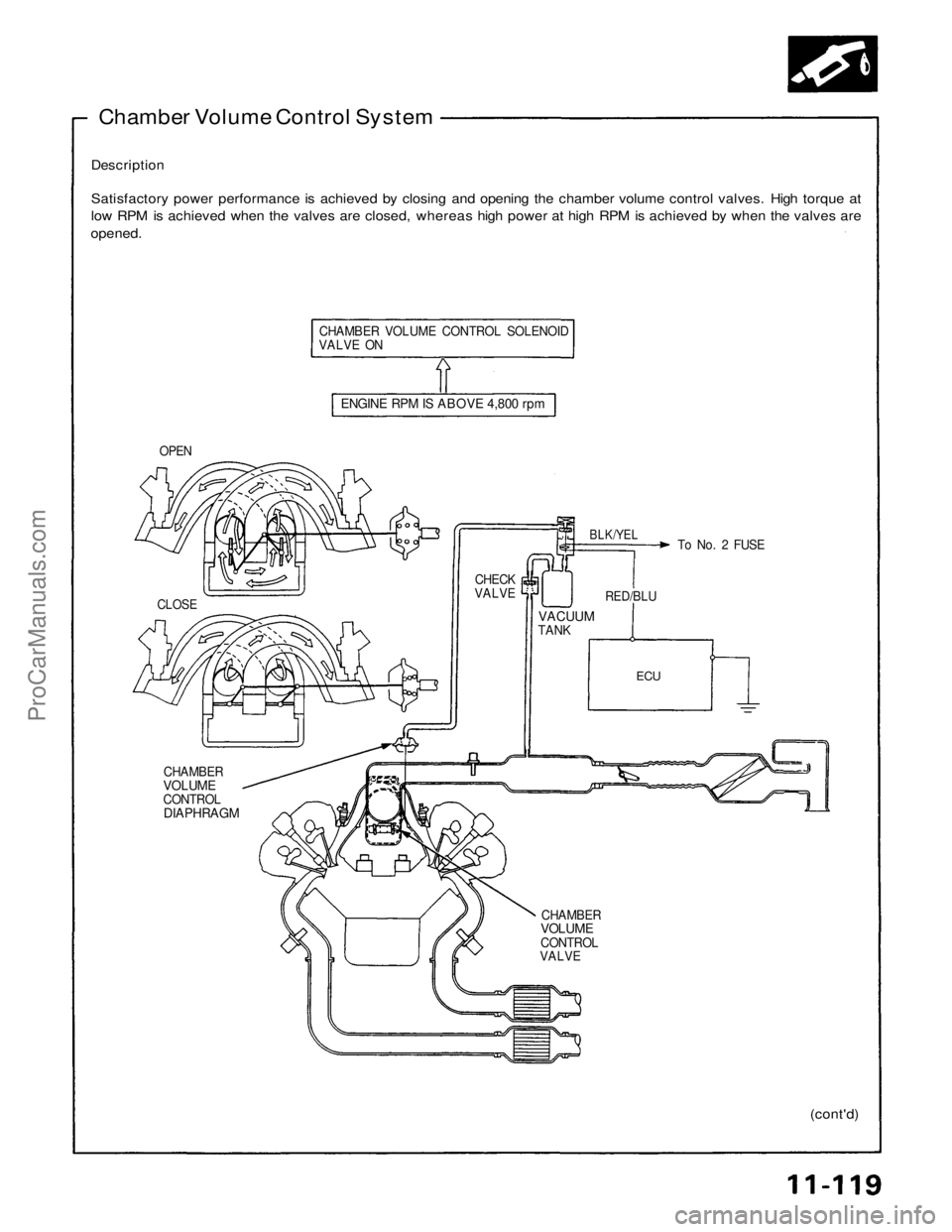

Chamber Volume Control System

Description

Satisfactory power performance is achieved by closing and opening the chamber volume control valves. High torque at

low RPM is achieved when the valves are closed, whereas high power at high RPM is achieved by when the valves are

opened.

CHAMBER VOLUME CONTROL SOLENOID

VALVE ON

ENGINE RPM IS ABOVE 4,800 rpm

OPEN

BLK/YEL

To No. 2 FUSE

CLOSE

CHECK

VALVE

VACUUM

TANK

RED/BLU

ECU

CHAMBER

VOLUME

CONTROL

DIAPHRAGM

CHAMBER

VOLUME

CONTROL

VALVE

(cont'd)ProCarManuals.com

Page 1528 of 1640

System Description

Tailpipe Emission

The emission control system includes a three-way catalytic converter, exhaust gas recirculation (EGR) system,

crankcase ventilation system and evaporative control

system.

The emission control system is designed to meet federal and

state emission standards.

Inspection

Do not smoke during this procedure. Keep

any open flame away from your work area.

1. Starting the engine and warm it up to normal operating temperature by driving the car on theroad.

2. Connect a tachometer.

3. Check idle speed and adjust the idle speed, if necessary (page 11-84).

4. Warm up and calibrate the CO meter according to the meter manufacturer's instructions.

5. Check idle CO with the headlights, heater blower, rear window defogger, cooling fan, and air conditioner off.

CO meter should indicate 0.1 % maximum.ProCarManuals.com

Page 1531 of 1640

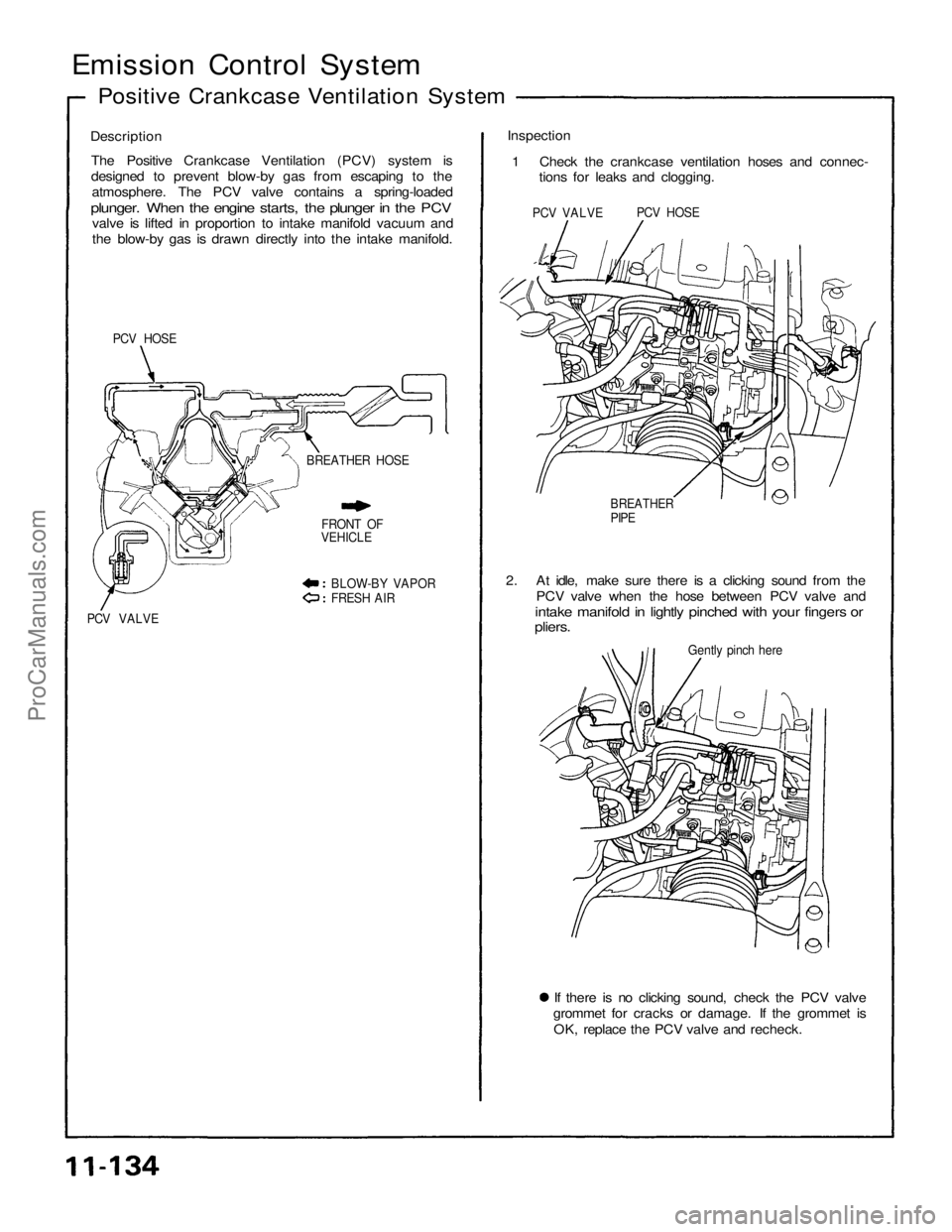

Emission Control System

Positive Crankcase Ventilation System

Description The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to theatmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

PCV HOSE

BLOW-BY VAPOR

FRESH AIR

PCV VALVE

Inspection

1 Check the crankcase ventilation hoses and connec- tions for leaks and clogging.

BREATHER

PIPE

2. At idle, make sure there is a clicking sound from the PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers or

pliers.

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.

PCV VALVE

PCV HOSE

Gently pinch here

BREATHER HOSE

FRONT OF

VEHICLEProCarManuals.com

Page 1532 of 1640

Evaporative Emission Controls

Description

The evaporative controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The system consists of

the following components:

A. Charcoal Canister

A canister for the temporary storage of fuel vapor until the fuel vapor can be purged from the canister into the engine and

burned.

B. Vapor Purge Control System

Canister purging is accomplished by drawing fresh air through the canister and into a port on the throttle body. The

purging vacuum is controlled by the purge control diaphragm valve and the purge cut-off solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the two-way valve, the valve opens and regulates

the flow of fuel vapor to the canister.

(cont'd)

PURGE CUT-OFF SOLENOID VALVE OFF AFTER START-

ING ENGINE

COOLANT TEMPERATURE ABOVE 70°C (1 58°F)ProCarManuals.com

Page 1534 of 1640

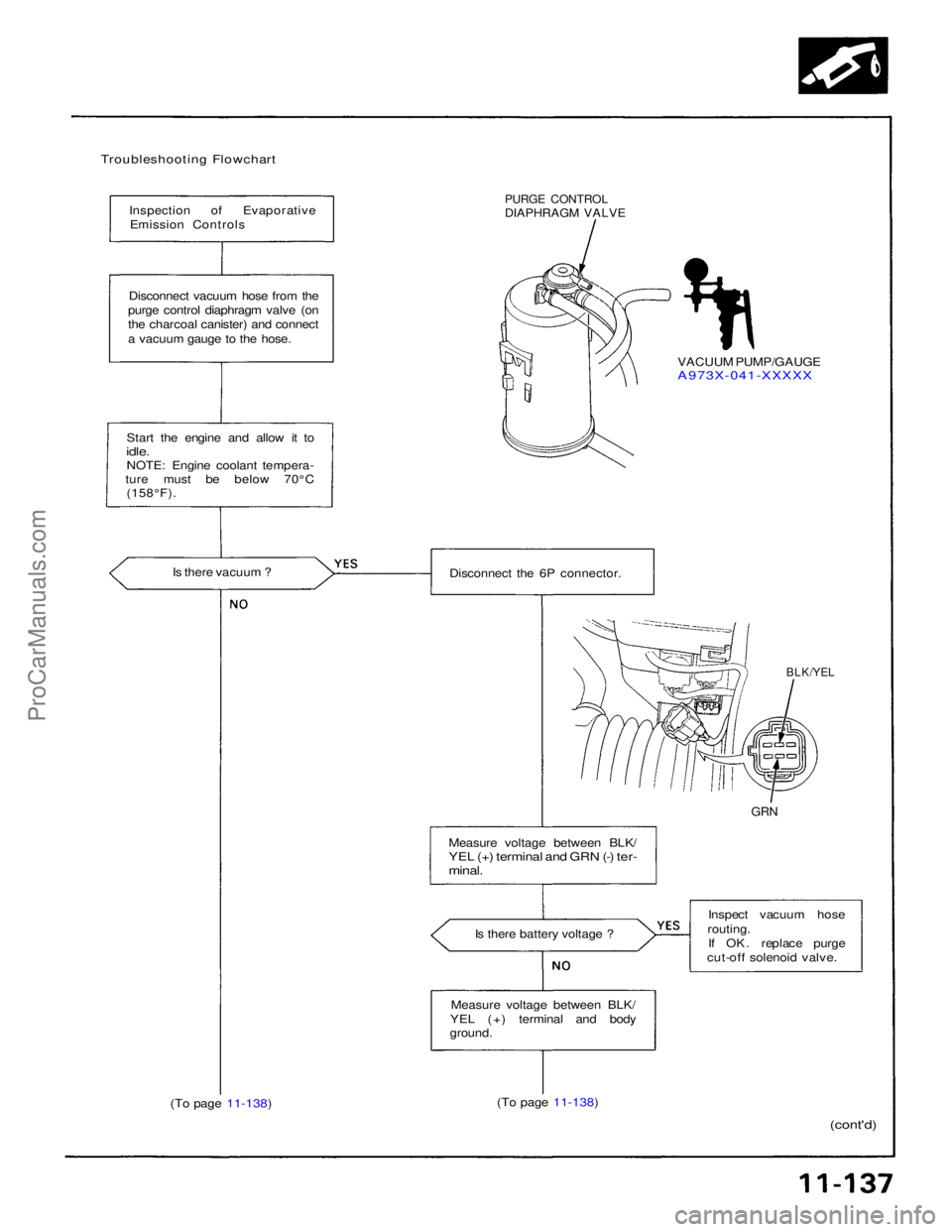

Troubleshooting Flowchart

Inspection of EvaporativeEmission Controls

PURGE CONTROL

DIAPHRAGM VALVE

VACUUM PUMP/GAUGE

A973X-041-XXXXX

Disconnect vacuum hose from the

purge control diaphragm valve (on

the charcoal canister) and connect

a vacuum gauge to the hose.

Start the engine and allow it to

idle.

NOTE: Engine coolant tempera-

ture must be below 70°C

(158°F).

Is there vacuum ? Disconnect the 6P connector.

BLK/YEL

GRN

Measure voltage between BLK/

YEL (+) terminal and GRN (-) ter-

minal.

Is there battery voltage ? Inspect vacuum hose

routing. If OK. replace purge

cut-off solenoid valve.

Measure voltage between BLK/

YEL (+) terminal and body

ground.

(To page 11-138)

(To page 11-138)

(cont'd)ProCarManuals.com