alternator ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 76 of 1640

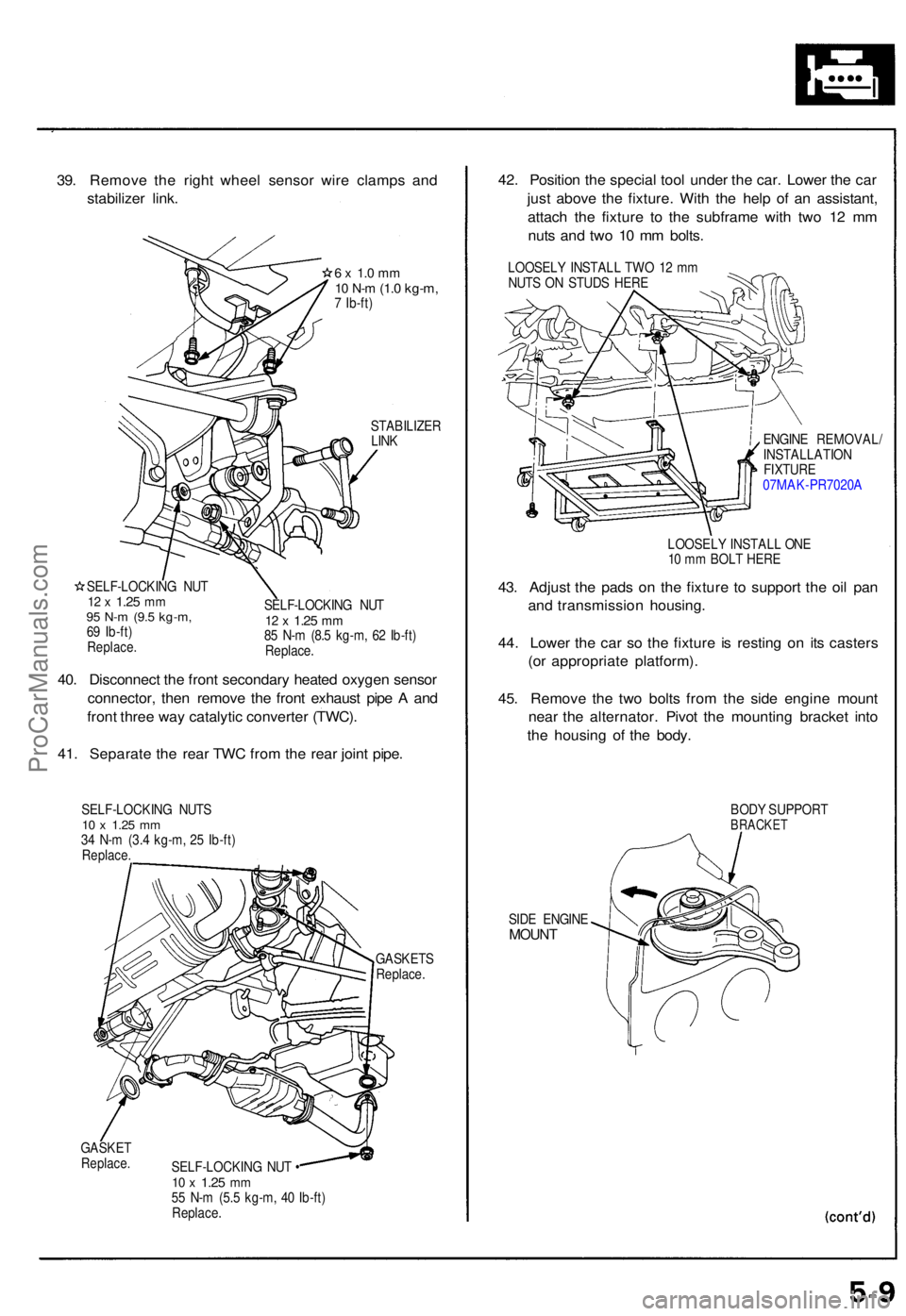

39. Remov e th e righ t whee l senso r wir e clamp s an d

stabilize r link .

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

STABILIZE RLINK

SELF-LOCKIN G NU T

12 x 1.2 5 mm95 N- m (9. 5 kg-m ,69 Ib-ft )Replace .

SELF-LOCKIN G NU T12 x 1.2 5 mm85 N- m (8. 5 kg-m , 6 2 Ib-ft )

Replace .

40. Disconnec t th e fron t secondar y heate d oxyge n senso r

connector , the n remov e th e fron t exhaus t pip e A an d

fron t thre e wa y catalyti c converte r (TWC) .

41 . Separat e th e rea r TW C fro m th e rea r join t pipe .

SELF-LOCKIN G NUT S10 x 1.2 5 mm34 N- m (3. 4 kg-m , 2 5 Ib-ft )Replace .

GASKET SReplace.

GASKETReplace .SELF-LOCKIN G NU T •10 x 1.2 5 mm55 N- m (5. 5 kg-m , 4 0 Ib-ft )Replace .

42. Positio n th e specia l too l unde r th e car . Lowe r th e ca r

jus t abov e th e fixture . Wit h th e hel p o f a n assistant ,

attac h th e fixtur e t o th e subfram e wit h tw o 1 2 m m

nut s an d tw o 1 0 m m bolts .

LOOSEL Y INSTAL L TW O 1 2 m m

NUT S O N STUD S HER E

ENGINE REMOVAL /

INSTALLATIO N

FIXTURE07MAK-PR7020 A

LOOSEL Y INSTAL L ON E

1 0 m m BOL T HER E

43. Adjus t th e pad s o n th e fixtur e t o suppor t th e oi l pa n

an d transmissio n housing .

44 . Lowe r th e ca r s o th e fixtur e i s restin g o n it s caster s

(o r appropriat e platform) .

45 . Remov e th e tw o bolt s fro m th e sid e engin e moun t

nea r th e alternator . Pivo t th e mountin g bracke t int o

th e housin g o f th e body .

BODY SUPPOR TBRACKET

SIDE ENGIN EMOUNT

ProCarManuals.com

Page 80 of 1640

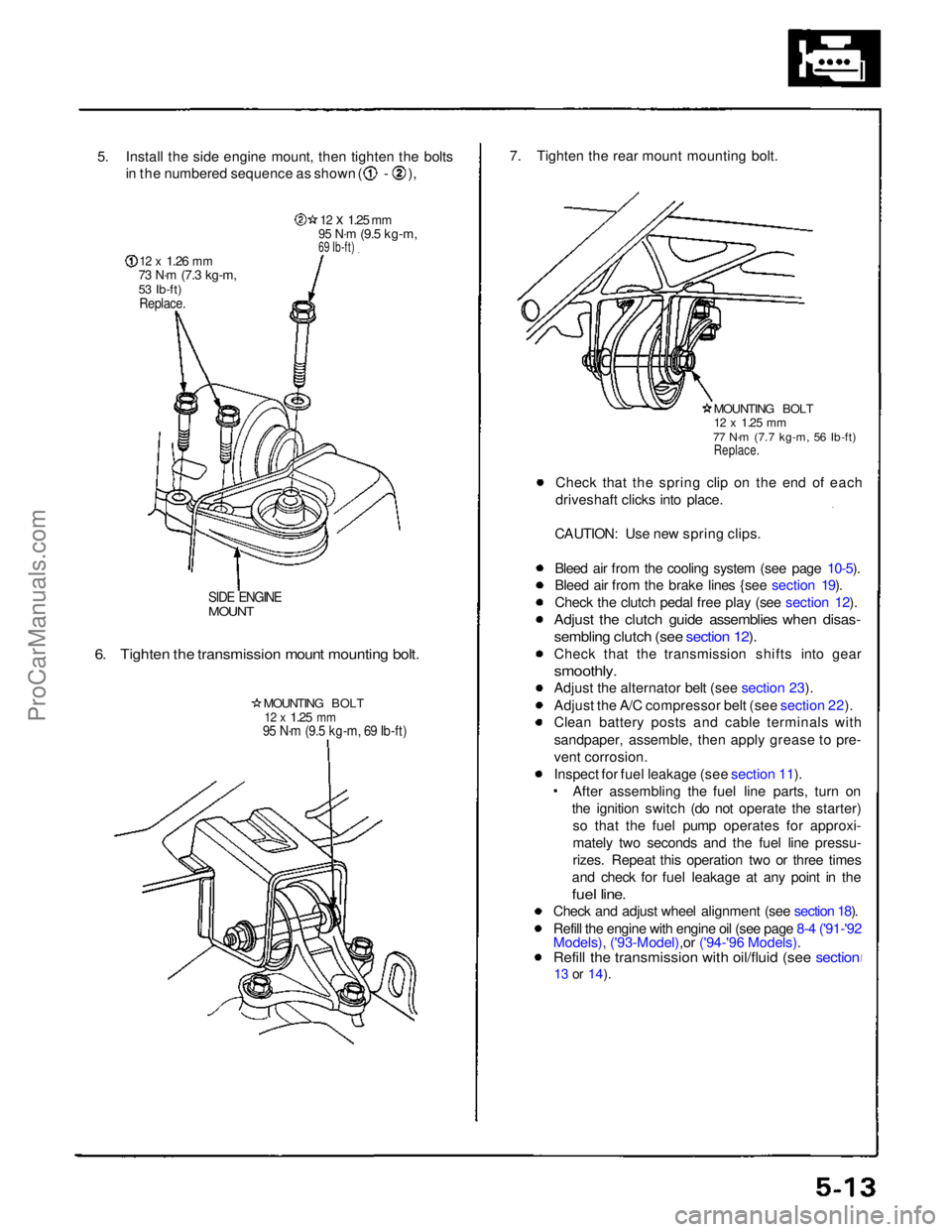

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 91 of 1640

Timing Belt

Removal (cont'd)

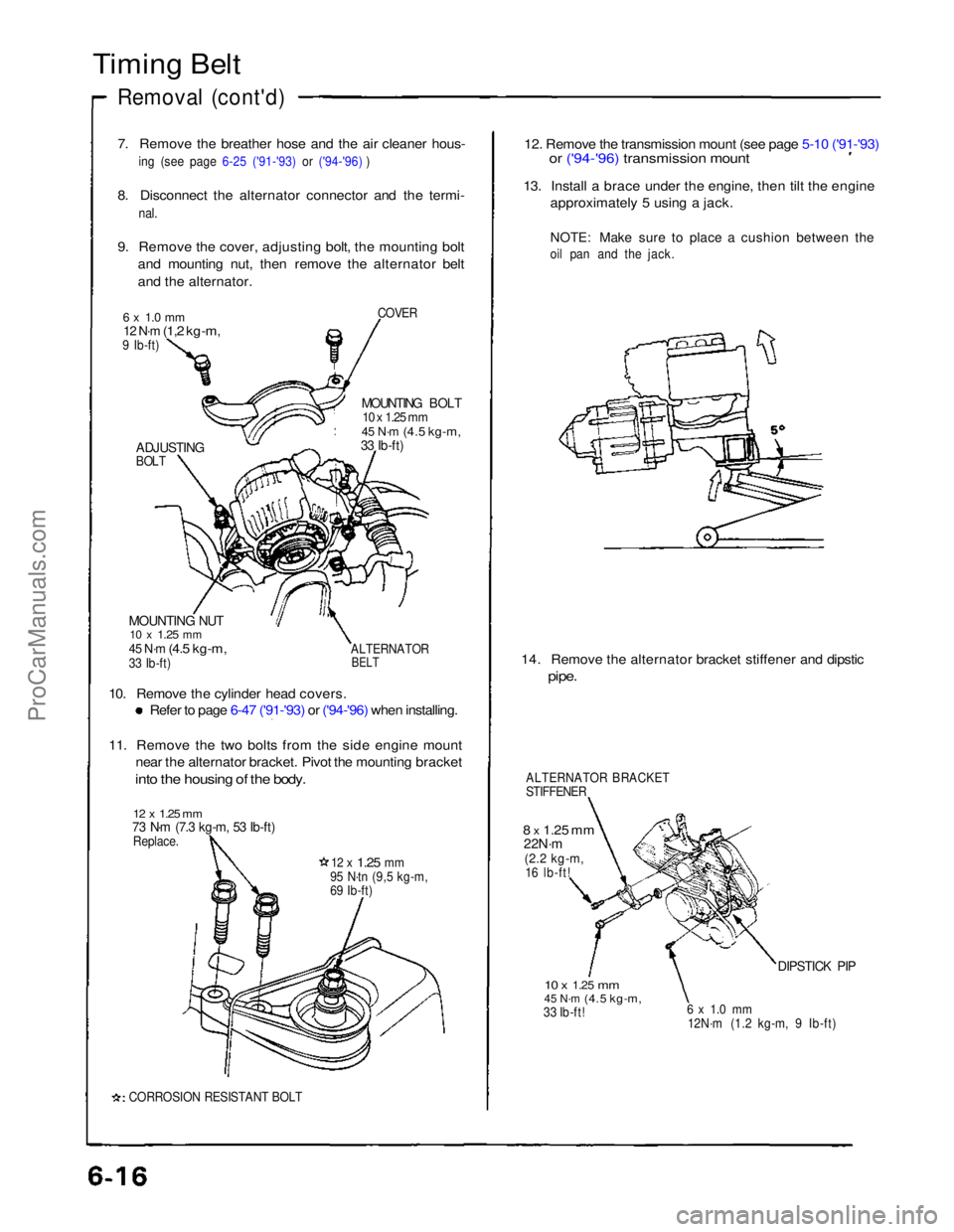

7. Remove the breather hose and the air cleaner hous-

in

g

(see page 6-25 ('91-'93) or ('94-'96) )

8. Disconnect the alternator connector and the termi-

nal.

9. Remove the cover, adjusting bolt, the mounting bolt and mounting nut, then remove the alternator belt

and the alternator.

COVER

6 x 1.0 mm

12 N·m

(1,2 kg-m,

9 Ib-ft)

MOUNTING BOLT

10 x 1.25 mm

45 N·m

(4.5 kg-m,

33 Ib-ft)

ADJUSTING

BOLT

MOUNTING NUT

10 x

1.25

mm

45 N·m

(4.5 kg-m,

33 Ib-ft)

ALTERNATOR

BELT

10. Remove the cylinder head covers.

Refer to page 6-47 ('91-'93) or ('94-'96) when installing.

11. Remove the two bolts from the side engine mount

near the alternator bracket. Pivot the mounting bracket

into the housing of the body.

12 x 1.25 mm

73 N·m (7.3 kg-m, 53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·tn (9,5 kg-m,

69 Ib-ft)

CORROSION RESISTANT BOLT

12. Remove the transmission mount (see page 5-10 ('91-'93)

or ('94-'96) transmission mount

13. Install a brace under the engine, then tilt the engine

approximately 5 using a jack.

NOTE: Make sure to place a cushion between the

oil pan and the jack.

14. Remove the alternator bracket stiffener and dipstic

pipe.

ALTERNATOR BRACKET

STIFFENER

8 x

1.25

mm

22N·m

(2.2 kg-m,

16 lb-ft!

10 x

1.25

mm

45 N·m

(4.5 kg-m,

33 Ib-ft!

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

DIPSTICK PIPProCarManuals.com

Page 94 of 1640

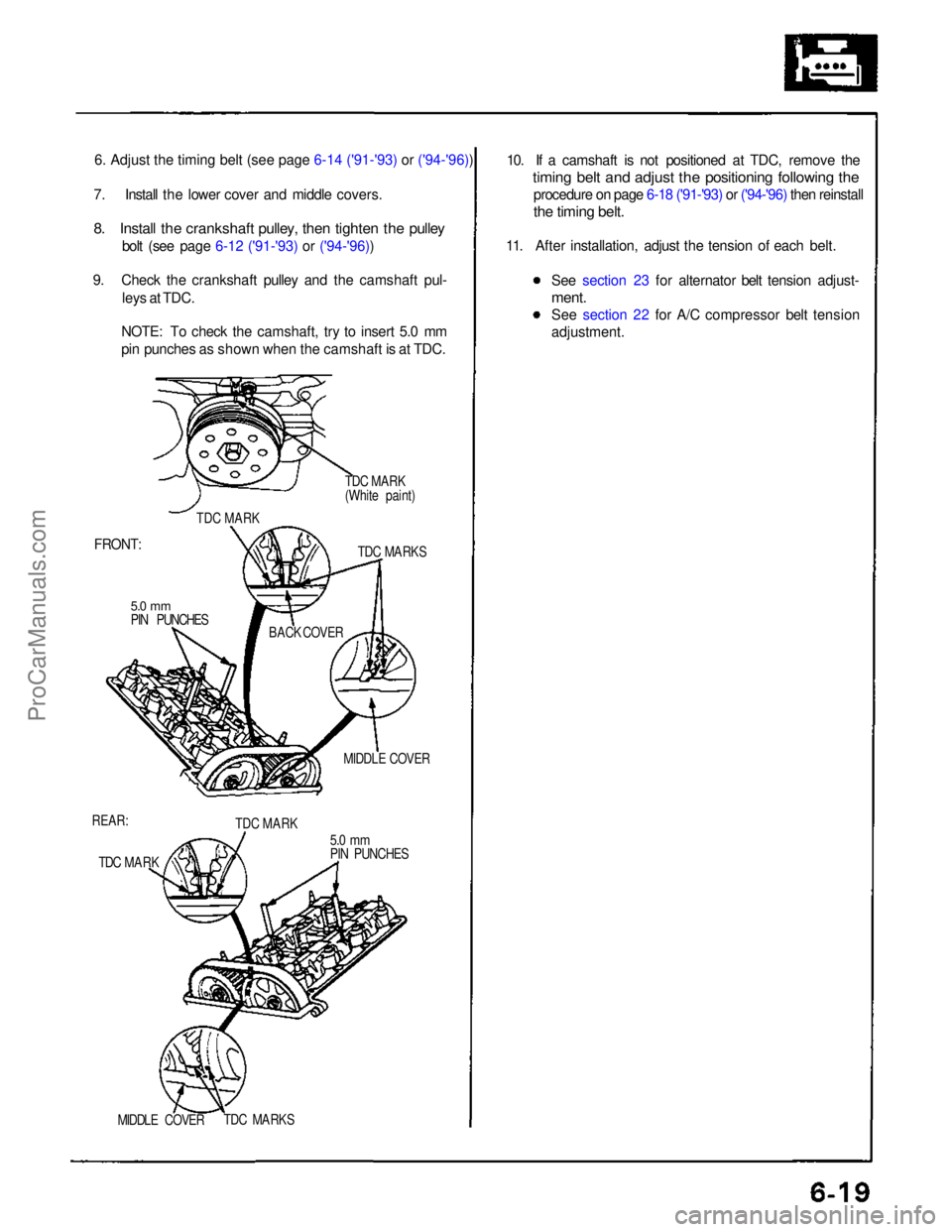

6. Adjust the timing belt (see page 6-14 ('91-'93) or ('94-'96))

7. Install the lower cover and middle covers.

8. Install the crankshaft pulley, then tighten the pulley

bolt (see page 6-12 ('91-'93) or ('94-'96))

9. Check the crankshaft pulley and the camshaft pul- leys at TDC.

NOTE: To check the camshaft, try to insert 5.0 mm

pin punches as shown when the camshaft is at TDC.

TDC MARK

(White paint)

TDC MARK

FRONT:

TDC MARKS

5.0 mm

PIN PUNCHES BACK COVER

MIDDLE COVER

REAR: TDC MARK

5.0 mm

PIN PUNCHES

TDC MARK

MIDDLE COVER

TDC MARKS

10. If a camshaft is not positioned at TDC, remove the

timing belt and adjust the positioning following the

procedure on page 6-18 ('91-'93) or ('94-'96) then reinstall

the timing belt.

11. After installation, adjust the tension of each belt.

See section 23 for alternator belt tension adjust-

ment.

See section 22 for A/C compressor belt tension

adjustment.ProCarManuals.com

Page 102 of 1640

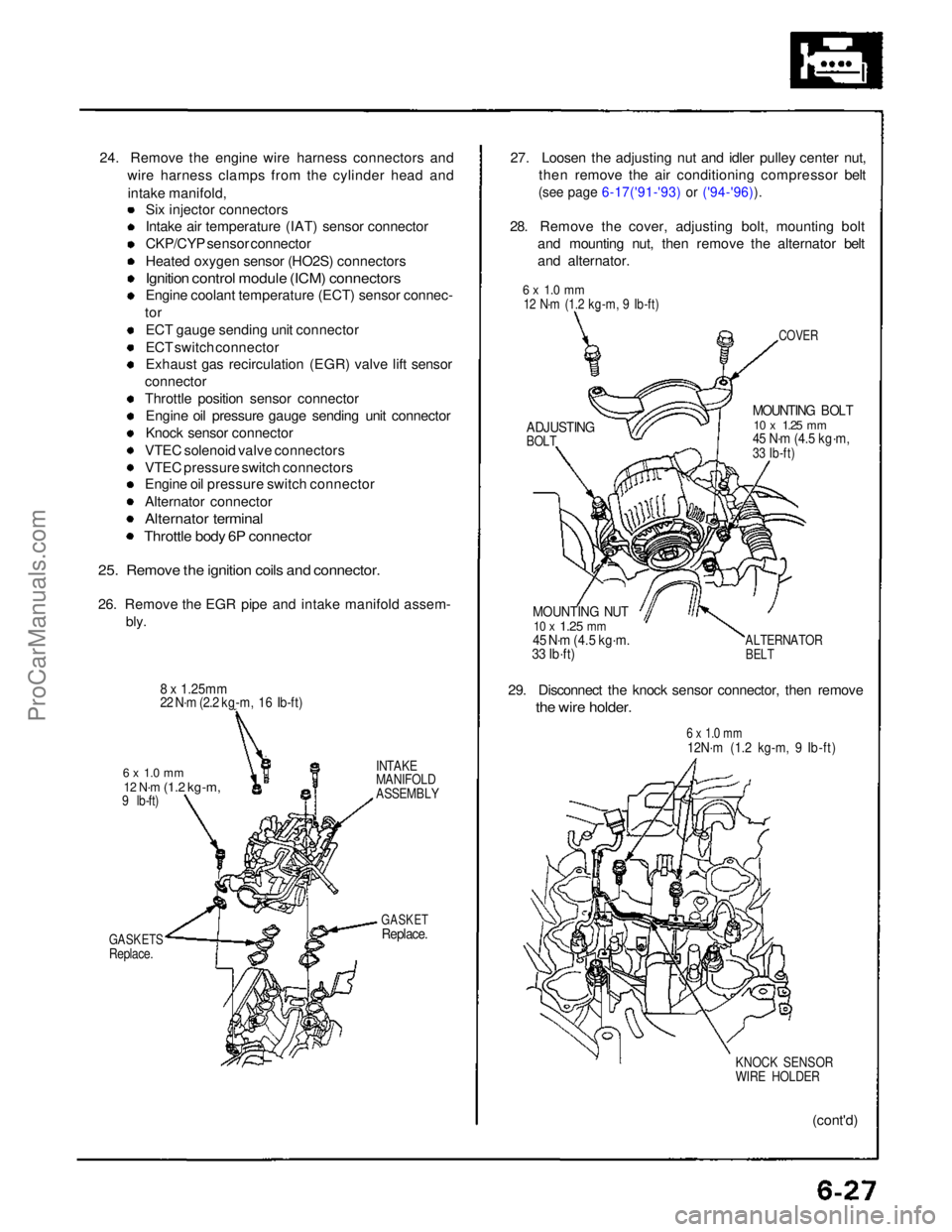

24. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and

intake manifold, Six injector connectors

Intake air temperature (IAT) sensor connector

CKP/CYP sensor connector

Heated oxygen sensor (HO2S) connectors

Ignition control module (ICM) connectors

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Throttle position sensor connector Engine oil pressure gauge sending unit connector

Knock sensor connector

VTEC solenoid valve connectors

VTEC pressure switch connectors

Engine oil pressure switch connector

Alternator connector

Alternator terminal

Throttle body 6P connector

25. Remove the ignition coils and connector.

26. Remove the EGR pipe and intake manifold assem- bly.

8 x 1.25mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

GASKETS

Replace. INTAKE

MANIFOLD

ASSEMBLY

GASKET

Replace.

27. Loosen the adjusting nut and idler pulley center nut,

then remove the air conditioning compressor belt

(see page 6-17('91-'93) or ('94-'96)).

28. Remove the cover, adjusting bolt, mounting bolt and mounting nut, then remove the alternator belt

and alternator.

COVER

MOUNTING BOLT

10 x

1.25

mm

45 N·m (4.5 kg·m,

33 Ib-ft)

MOUNTING NUT

10 x

1.25

mm

45 N·m (4.5 kg·m.

33 Ib·ft)

ALTERNATOR

BELT

29. Disconnect the knock sensor connector, then remove

the wire holder.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

KNOCK SENSOR

WIRE HOLDER

(cont'd)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

ADJUSTING

BOLTProCarManuals.com

Page 103 of 1640

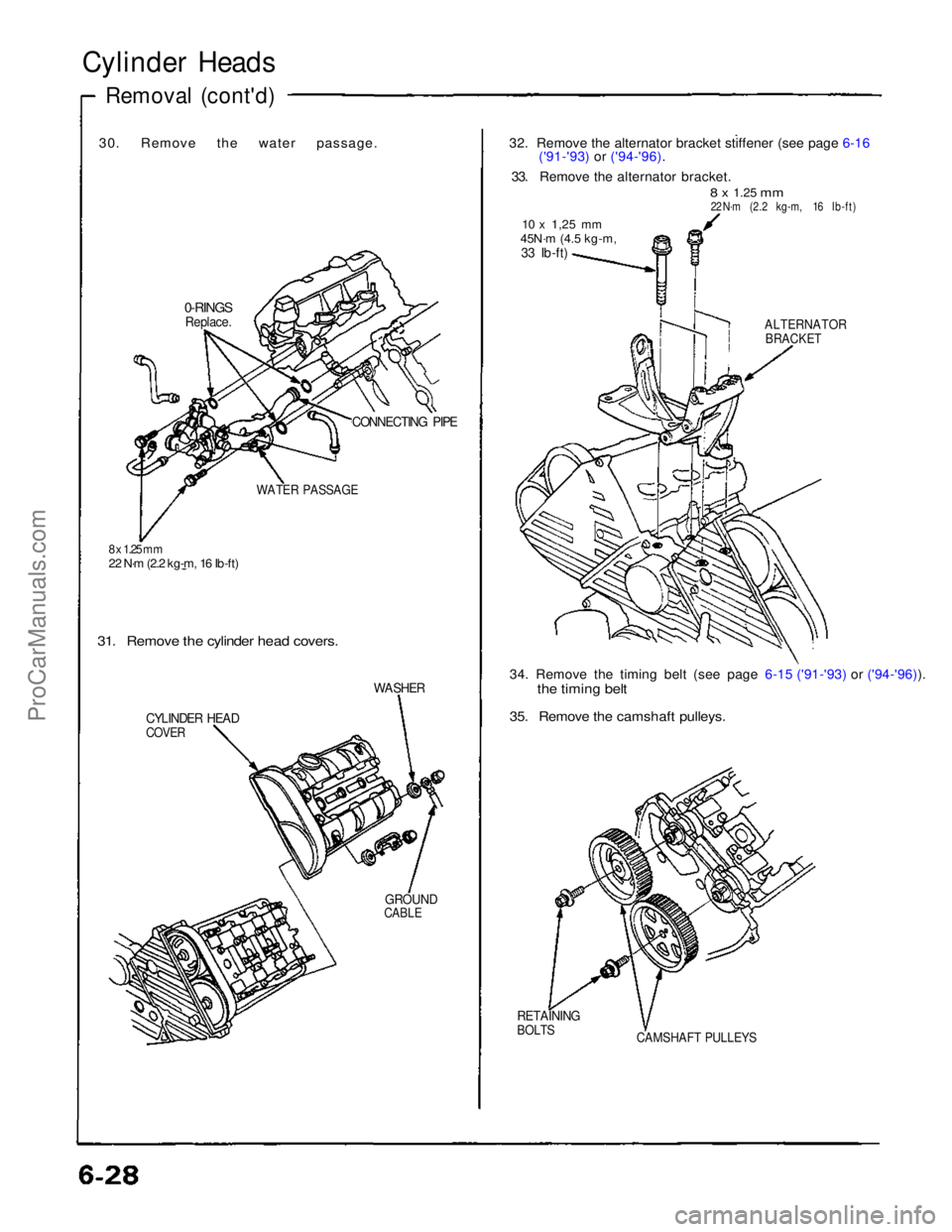

Cylinder Heads

Removal (cont'd)

30. Remove the water passage. \

\

32. Remove the alternator bracket stiffener (see page 6-16

('91-'93) or ('94-'96).

33. Remove the alternator bracket.

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

ALTERNATOR

BRACKET

10 x

1,25

mm

45N·m (4.5 kg-m,

33 Ib-ft)

34. Remove the timing belt (see page 6-15 ('91-'93) or ('94-'96)).

the timing belt

35. Remove the camshaft pulleys.

RETAINING

BOLTS

CAMSHAFT PULLEYS

GROUND

CABLE

WASHER

CYLINDER HEAD

COVER

31. Remove the cylinder head covers.

0-RINGS

Replace.

CONNECTING PIPE

WATER PASSAGE

8 x 1.25 mm

22 N·m (2.2 kg-m, 16 Ib-ft)ProCarManuals.com

Page 230 of 1640

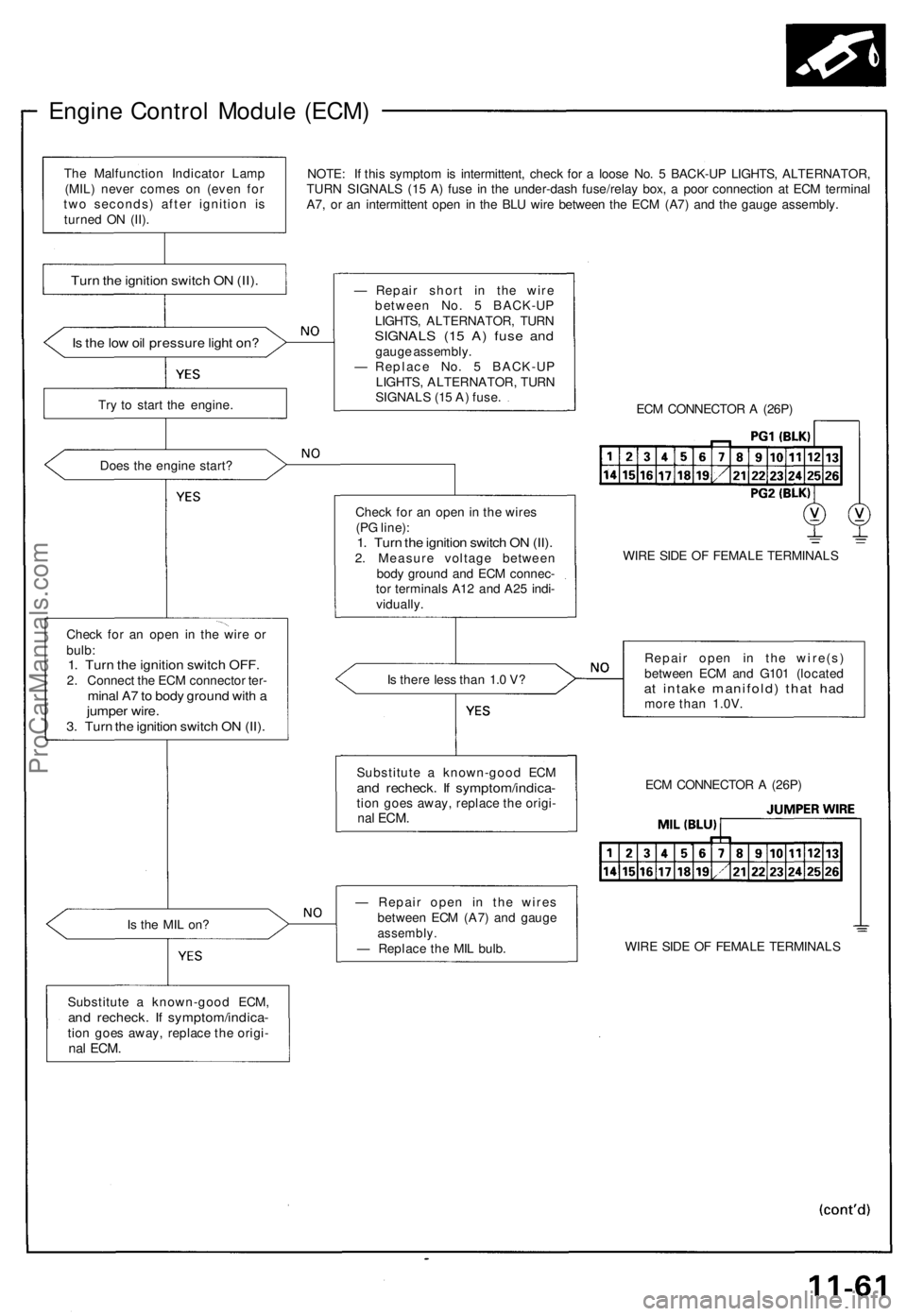

Engine Control Module (ECM)

NOTE: If this symptom is intermittent, check for a loose No. 5 BACK-UP LIGHTS, ALTERNATOR,

TURN SIGNALS (15 A) fuse in the under-dash fuse/relay box, a poor connection at ECM terminal

A7, or an intermittent open in the BLU wire between the ECM (A7) and the gauge assembly.

Is the low oil pressure light on?

Try to start the engine.

Does the engine start?

Check for an open in the wire or

bulb:

1. Turn the ignition switch OFF.

2. Connect the ECM connector ter-

minal A7 to body ground with a

jumper wire.

3. Turn the ignition switch ON (II).

Is the MIL on?

Substitute a known-good ECM,

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

— Repair short in the wire

between No. 5 BACK-UP

LIGHTS, ALTERNATOR, TURN

SIGNALS (15 A) fuse and

gauge assembly.

— Replace No. 5 BACK-UP

LIGHTS, ALTERNATOR, TURN

SIGNALS (15 A) fuse.

ECM CONNECTOR A (26P)

Check for an open in the wires

(PG line):

1. Turn the ignition switch ON (II).

2. Measure voltage between

body ground and ECM connec-

tor terminals A12 and A25 indi-

vidually.

WIRE SIDE OF FEMALE TERMINALS

Is there less than 1.0 V?

Repair open in the wire(s)

between ECM and G101 (located

at intake manifold) that had

more than 1.0V.

— Repair open in the wires

between ECM (A7) and gauge

assembly.

— Replace the MIL bulb.

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR A (26P)

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

Turn the ignition switch ON (II).

The Malfunction Indicator Lamp

(MIL) never comes on (even for

two seconds) after ignition is

turned ON (II).ProCarManuals.com

Page 238 of 1640

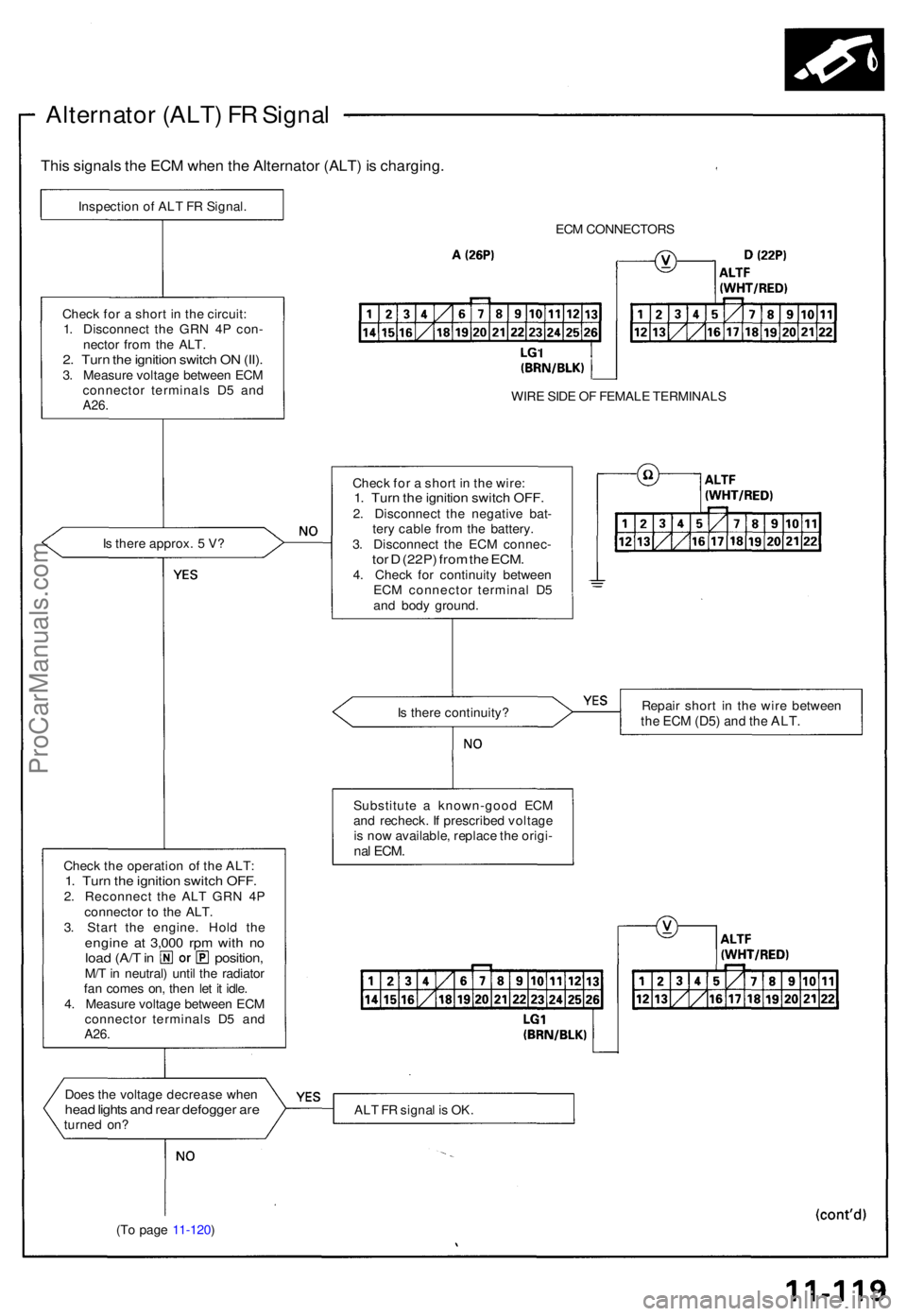

Alternator (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

ECM CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

Chec k fo r a shor t i n th e wire :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

tor D (22P ) fro m th e ECM .4. Chec k fo r continuit y betwee n

EC M connecto r termina l D 5

an d bod y ground .

I

s ther e approx . 5 V ?

Chec

k fo r a shor t i n th e circuit :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26 .

Is ther e continuity ? Repai

r shor t i n th e wir e betwee nthe EC M (D5 ) and th e ALT .

Substitut e a known-goo d EC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal ECM .Chec k th e operatio n o f th e ALT :1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n oloa d (A/ T in position ,M/T in neutral ) unti l th e radiato r

fa n come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26.

Doe s th e voltag e decreas e whe nhead light s an d rea r defogge r ar eturne d on ? AL

T F R signa l i s OK .

(T o pag e 11-120 )

ProCarManuals.com

Page 268 of 1640

Intake Air System

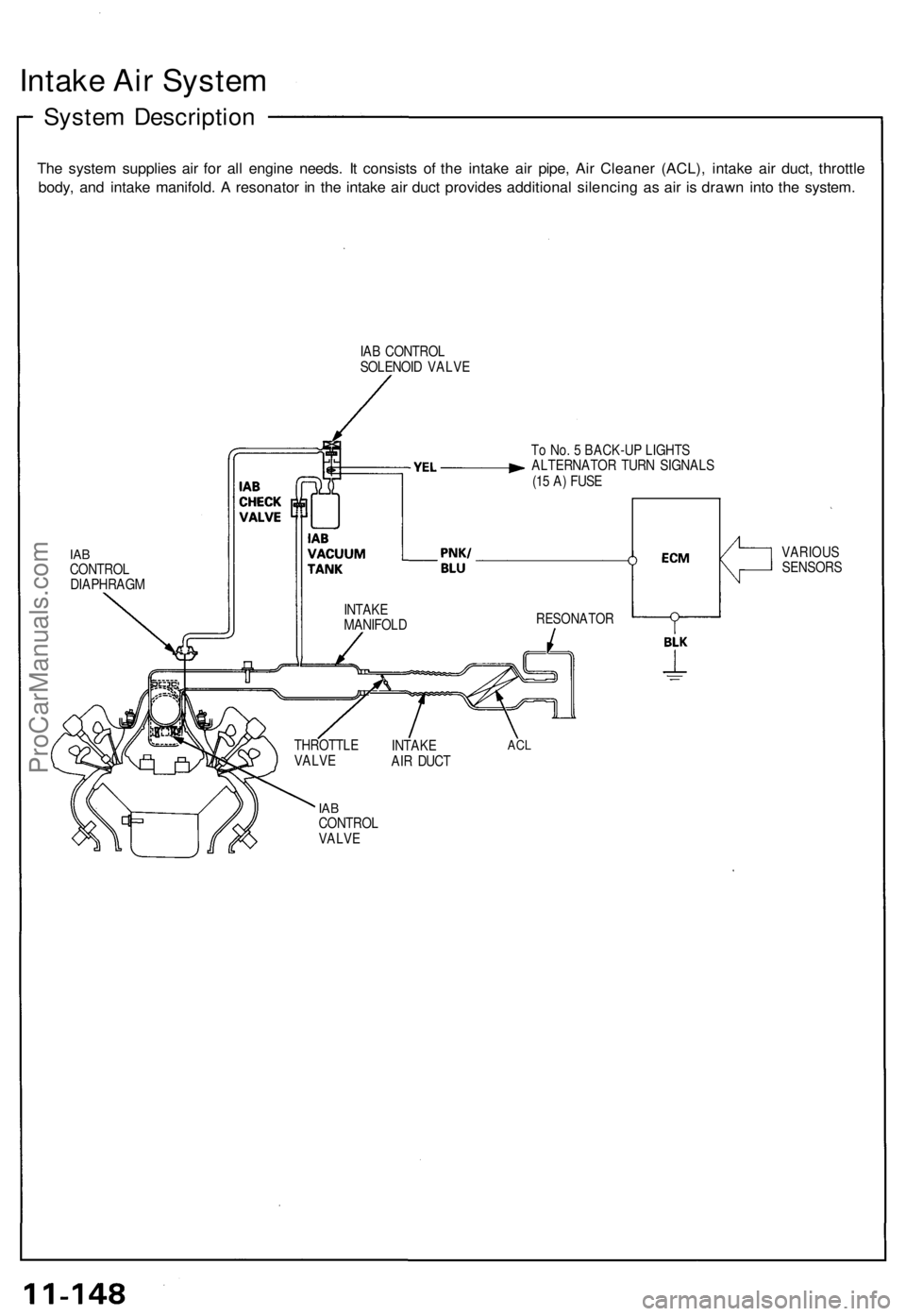

System Description

The system supplies air for all engine needs. It consists of the intake air pipe, Air Cleaner (ACL), intake air duct, throttle

body, and intake manifold. A resonator in the intake air duct provides additional silencing as air is drawn into the system.

IAB CONTROL

SOLENOID VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

THROTTLE

VALVE

INTAKE

AIR DUCT

ACL

RESONATOR

VARIOUS

SENSORS

INTAKE

MANIFOLDProCarManuals.com

Page 274 of 1640

Intake Air System

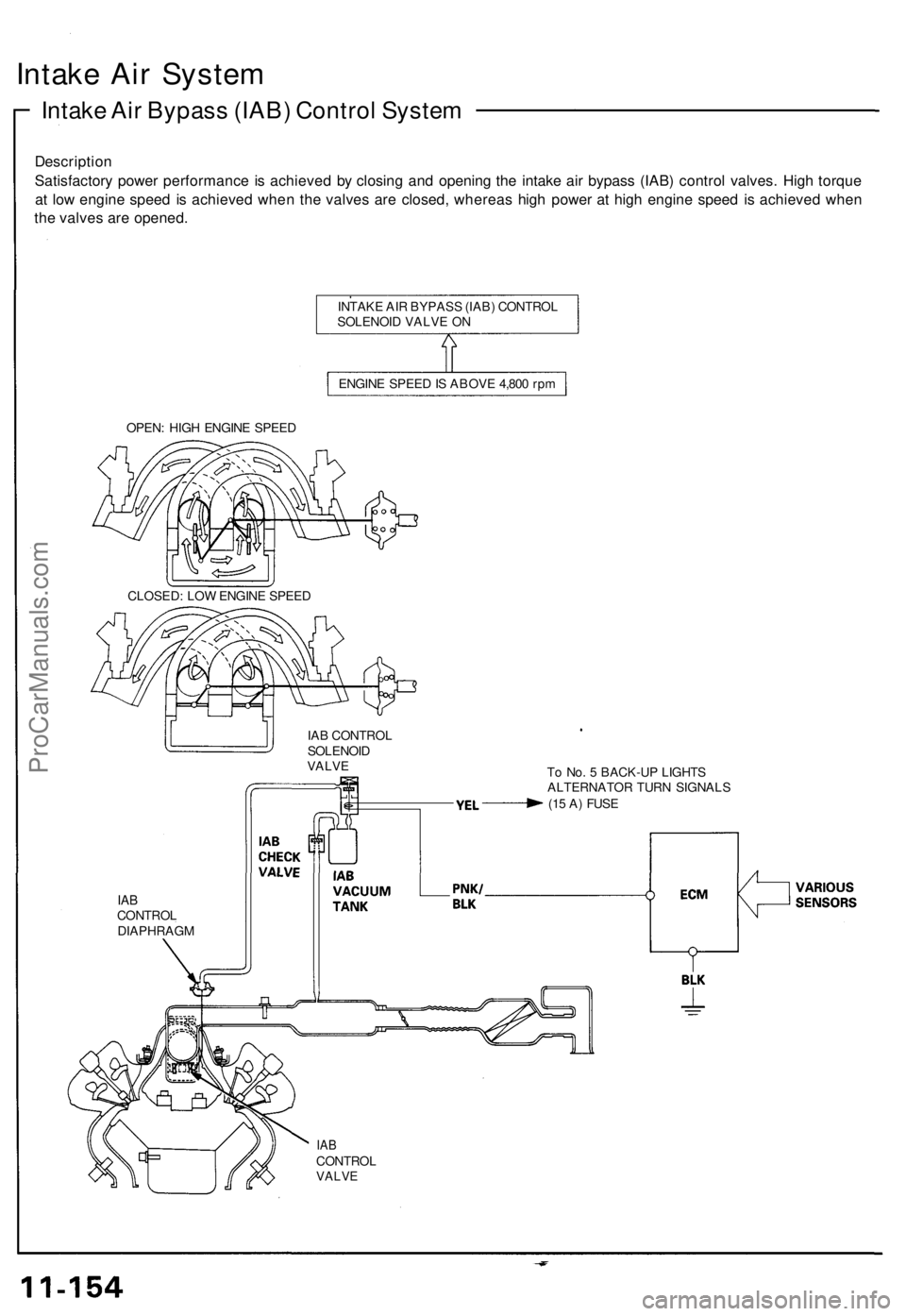

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

CLOSED: LOW ENGINE SPEEDProCarManuals.com