brake sensor ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 306 of 1640

Transmission Assembly

Removal

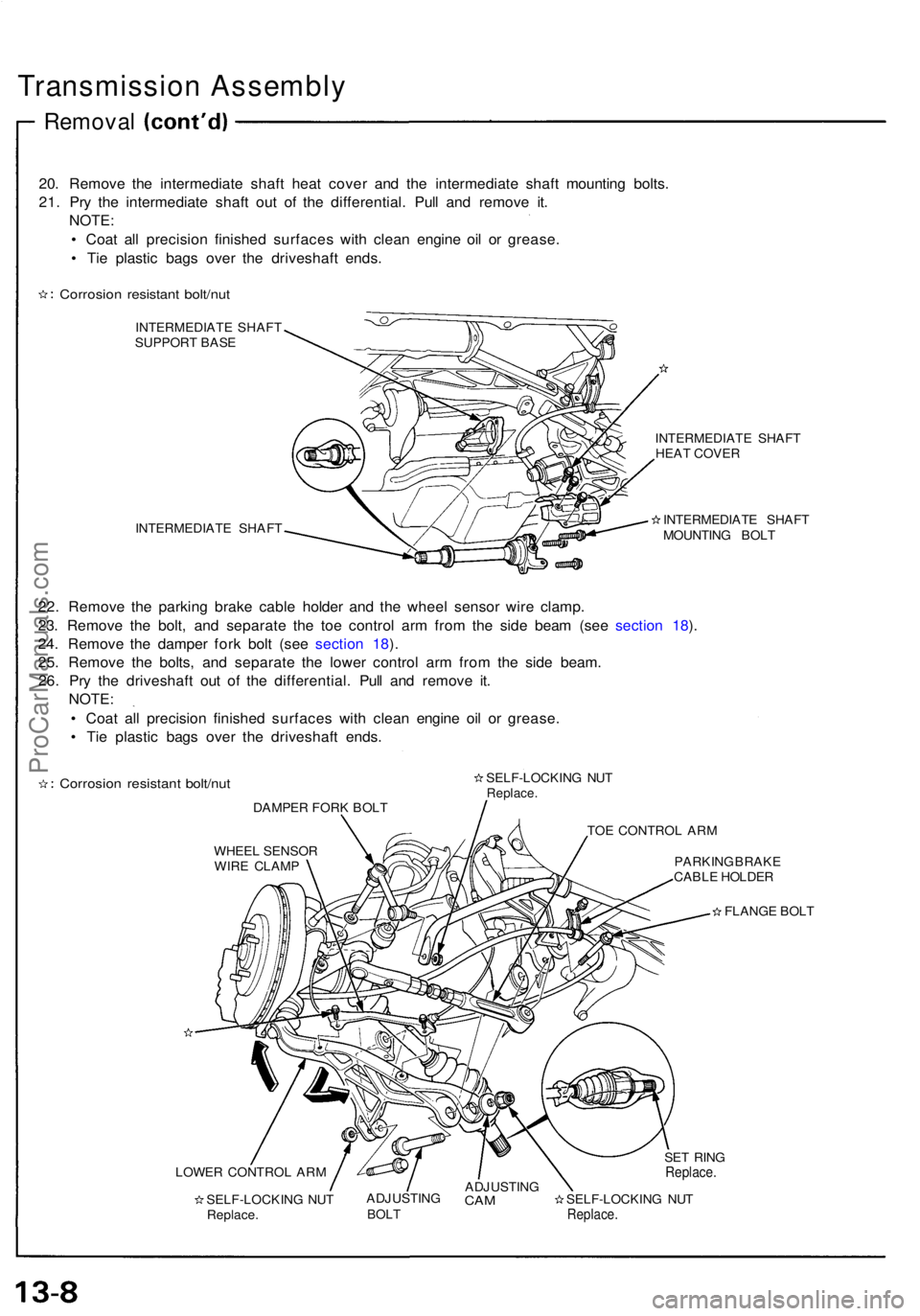

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

INTERMEDIATE SHAFT INTERMEDIATE SHAFT

HEAT COVER

INTERMEDIATE SHAFT

MOUNTING BOLT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt, and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18).

25. Remove the bolts, and separate the lower control arm from the side beam. 26. Pry the driveshaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT SELF-LOCKING NUT

Replace.

TOE CONTROL ARM

WHEEL SENSOR WIRE CLAMP PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.

SET RING

Replace.ProCarManuals.com

Page 492 of 1640

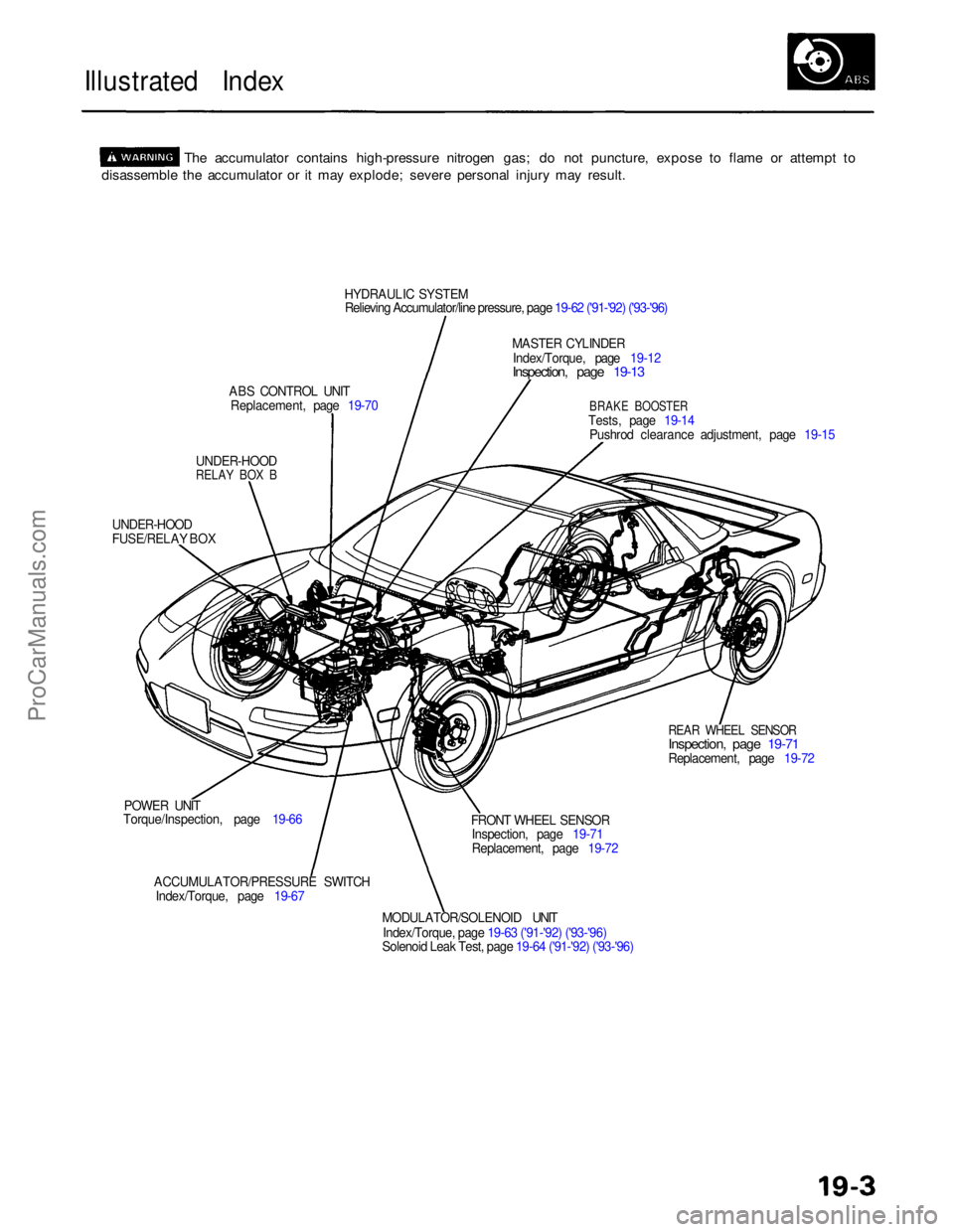

Illustrated Index

The accumulator contains high-pressure nitrogen gas; do not puncture, expose to flame or attempt to

disassemble the accumulator or it may explode; severe personal injury may result.

HYDRAULIC SYSTEM

Relieving Accumulator/line pressure, page 19-62 ('91-'92) ('93-'96)

MASTER CYLINDER

Index/Torque, page 19-12

Inspection, page 19-13

ABS CONTROL UNIT Replacement, page 19-70

BRAKE BOOSTER

Tests, page 19-14 Pushrod clearance adjustment, page 19-15

UNDER-HOOD

RELAY BOX B

UNDER-HOOD

FUSE/RELAY BOX

REAR WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

POWER UNIT

Torque/Inspection, page 19-66

ACCUMULATOR/PRESSURE SWITCHIndex/Torque, page 19-67 FRONT WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

MODULATOR/SOLENOID UNIT

Index/Torque, page 19-63 ('91-'92) ('93-'96)

Solenoid Leak Test, page 19-64 ('91-'92) ('93-'96)

ProCarManuals.com

Page 517 of 1640

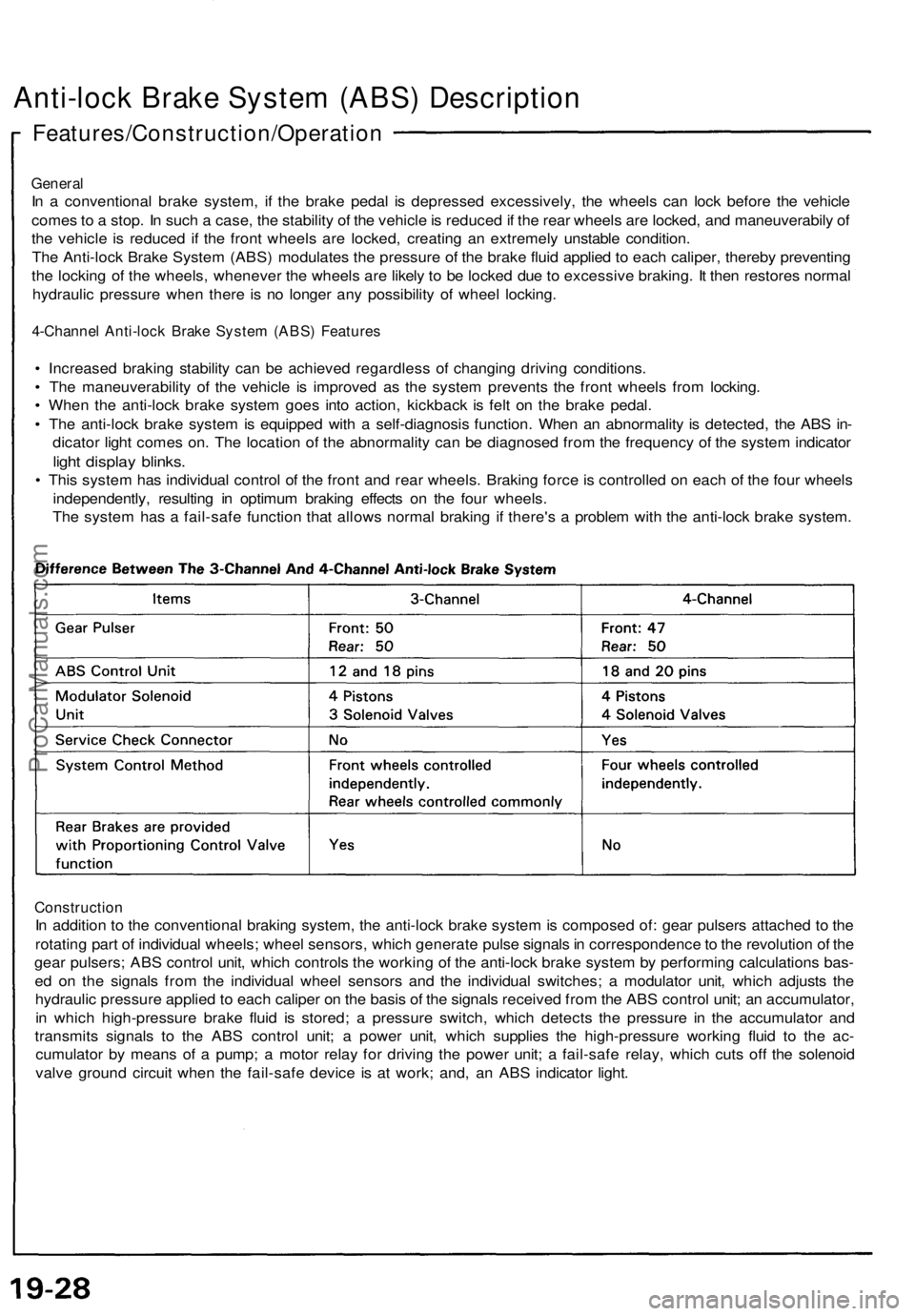

Anti-lock Brake System (ABS) Description

Features/Construction/Operation

General

In a conventional brake system, if the brake pedal is depressed excessively, the wheels can lock before the vehicle

comes to a stop. In such a case, the stability of the vehicle is reduced if the rear wheels are locked, and maneuverabily of

the vehicle is reduced if the front wheels are locked, creating an extremely unstable condition.

The Anti-lock Brake System (ABS) modulates the pressure of the brake fluid applied to each caliper, thereby preventing

the locking of the wheels, whenever the wheels are likely to be locked due to excessive braking. It then restores normal

hydraulic pressure when there is no longer any possibility of wheel locking.

4-Channel Anti-lock Brake System (ABS) Features

• Increased braking stability can be achieved regardless of changing driving conditions.

• The maneuverability of the vehicle is improved as the system prevents the front wheels from locking.

• When the anti-lock brake system goes into action, kickback is felt on the brake pedal.

• The anti-lock brake system is equipped with a self-diagnosis function. When an abnormality is detected, the ABS in-

dicator light comes on. The location of the abnormality can be diagnosed from the frequency of the system indicator

light display blinks.

• This system has individual control of the front and rear wheels. Braking force is controlled on each of the four wheels

independently, resulting in optimum braking effects on the four wheels.

The system has a fail-safe function that allows normal braking if there's a problem with the anti-lock brake system.

Construction

In addition to the conventional braking system, the anti-lock brake system is composed of: gear pulsers attached to the

rotating part of individual wheels; wheel sensors, which generate pulse signals in correspondence to the revolution of the

gear pulsers; ABS control unit, which controls the working of the anti-lock brake system by performing calculations bas-

ed on the signals from the individual wheel sensors and the individual switches; a modulator unit, which adjusts the

hydraulic pressure applied to each caliper on the basis of the signals received from the ABS control unit; an accumulator,

in which high-pressure brake fluid is stored; a pressure switch, which detects the pressure in the accumulator and

transmits signals to the ABS control unit; a power unit, which supplies the high-pressure working fluid to the ac-

cumulator by means of a pump; a motor relay for driving the power unit; a fail-safe relay, which cuts off the solenoid

valve ground circuit when the fail-safe device is at work; and, an ABS indicator light.ProCarManuals.com

Page 521 of 1640

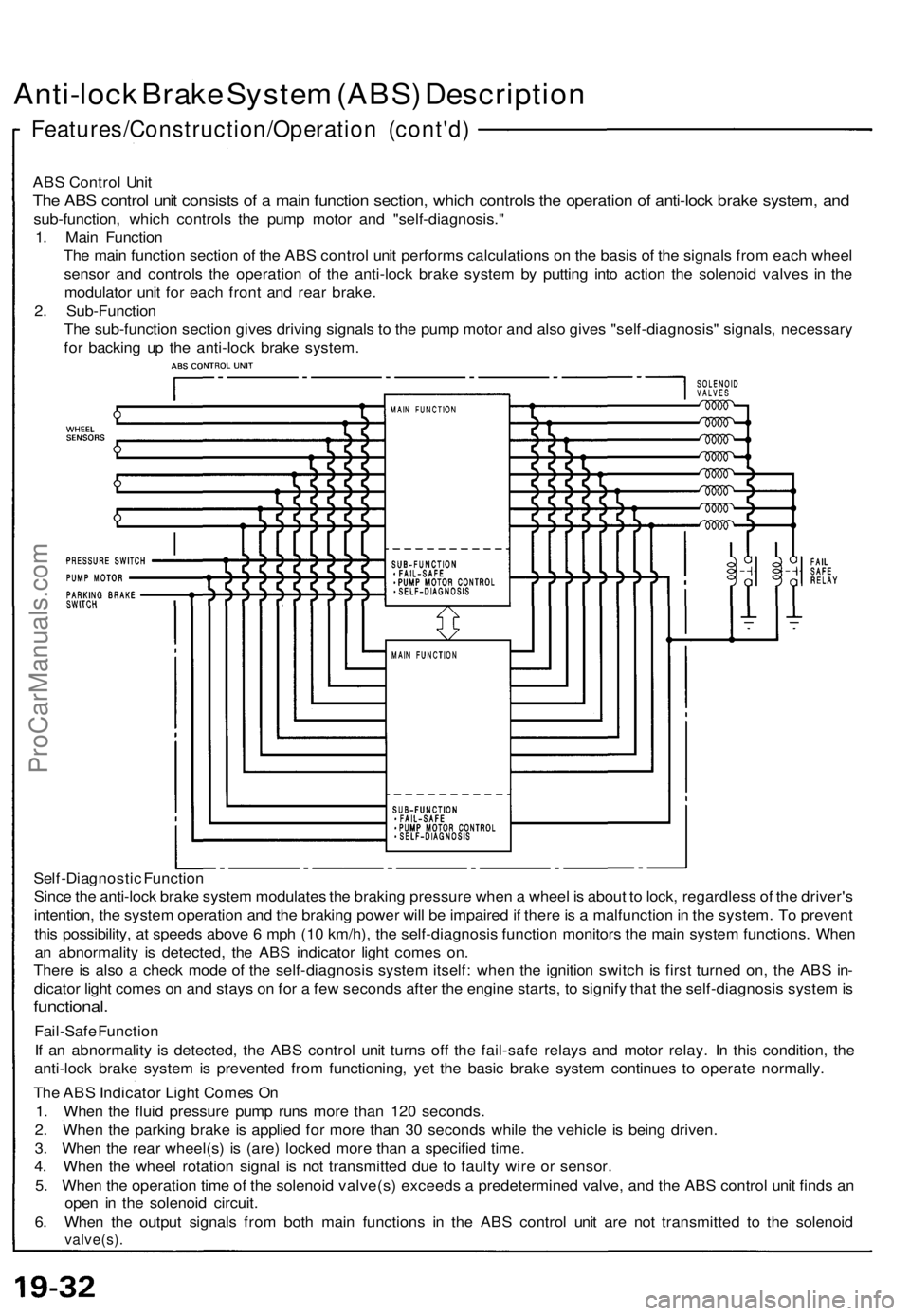

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and

sub-function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the

modulator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary

for backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS in-

dicator light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is

functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the

anti-lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid

valve(s).ProCarManuals.com

Page 527 of 1640

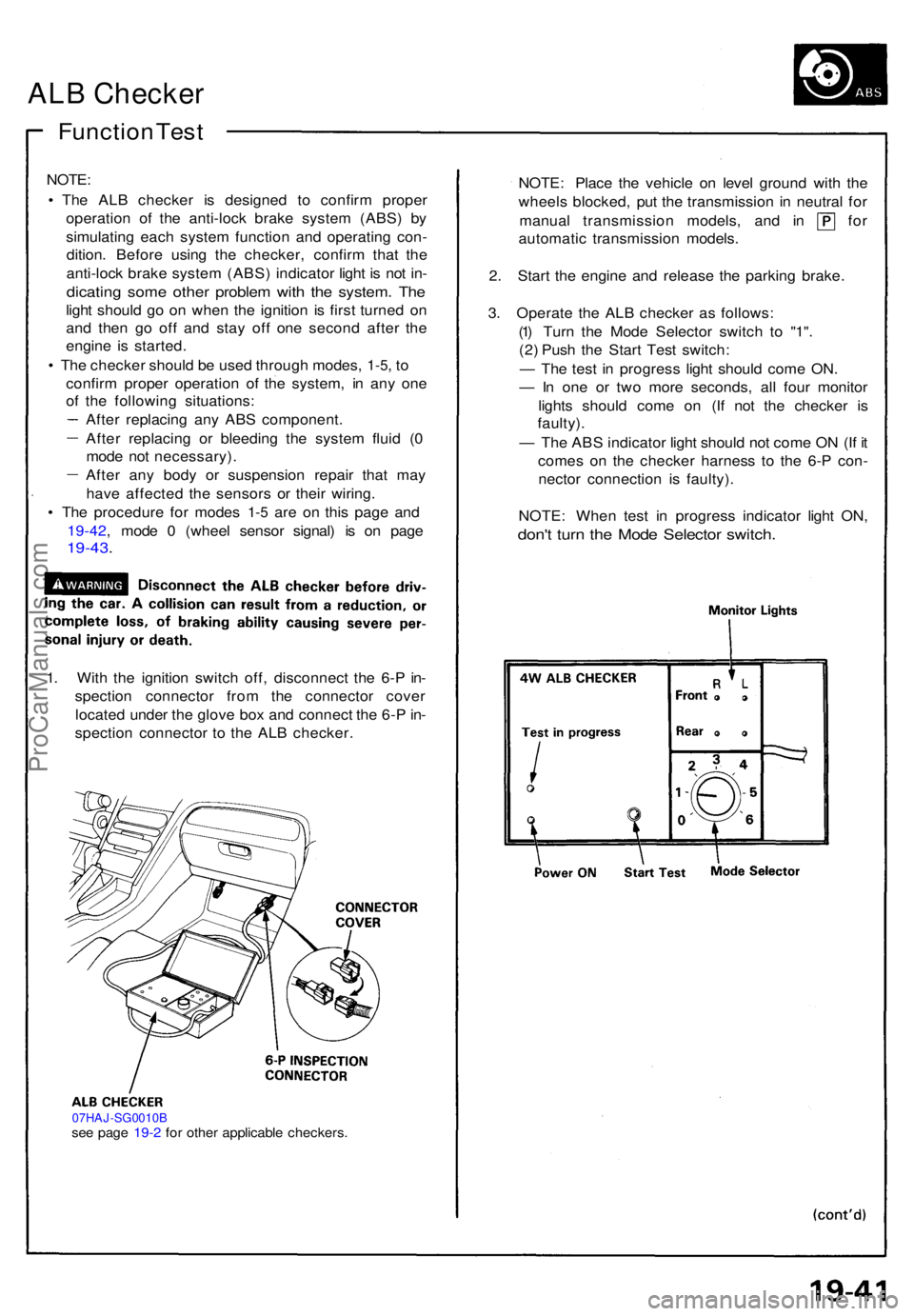

ALB Checke r

Function Tes t

NOTE :

• Th e AL B checke r i s designe d t o confir m prope r

operatio n of the anti-loc k brak e syste m (ABS ) b y

simulatin g eac h syste m functio n an d operatin g con -

dition . Befor e usin g th e checker , confir m tha t th e

anti-loc k brak e syste m (ABS ) indicato r ligh t i s no t in -

dicatin g som e othe r proble m wit h th e system . Th e

light shoul d g o o n whe n th e ignitio n i s firs t turne d o n

an d the n g o of f an d sta y of f on e secon d afte r th e

engin e i s started .

• Th e checke r shoul d b e use d throug h modes ,

1-5, t o

confir m prope r operatio n of the system , i n an y on e

of th e followin g situations :

Afte r replacin g an y AB S component .

Afte r replacin g o r bleedin g th e syste m flui d ( 0

mod e no t necessary) .

Afte r an y bod y o r suspensio n repai r tha t ma y

hav e affecte d th e sensor s o r thei r wiring .

• Th e procedur e fo r mode s

1-5 ar e o n thi s pag e an d

19-42 , mod e 0 (whee l senso r signal ) i s o n pag e

19-43 .

1. Wit h th e ignitio n switc h off , disconnec t th e 6- P in -

spectio n connecto r fro m th e connecto r cove r

locate d unde r th e glov e bo x an d connec t th e 6- P in -

spectio n connecto r t o th e AL B checker .

07HAJ-SG0010Bsee pag e 19- 2 fo r othe r applicabl e checkers .

NOTE: Plac e th e vehicl e o n leve l ground with th e

wheel s blocked , pu t th e transmissio n i n neutra l fo r

manua l transmissio n models , an d i n fo r

automati c transmissio n models .

2 . Star t th e engin e an d releas e th e parkin g brake .

3 . Operat e th e AL B checke r a s follows :

(1 ) Tur n th e Mod e Selecto r switc h t o "1" .

(2 ) Pus h th e Star t Tes t switch :

— Th e tes t i n progres s ligh t shoul d com e ON .

— In on e o r tw o mor e seconds , al l fou r monito r

light s shoul d com e o n (I f no t th e checke r i s

faulty) .

— Th e AB S indicato r ligh t shoul d no t com e O N (I f i t

come s o n th e checke r harnes s t o th e 6- P con -

necto r connectio n i s faulty) .

NOTE : Whe n tes t i n progres s indicato r ligh t ON ,

don't tur n th e Mod e Selecto r switch .

ProCarManuals.com

Page 805 of 1640

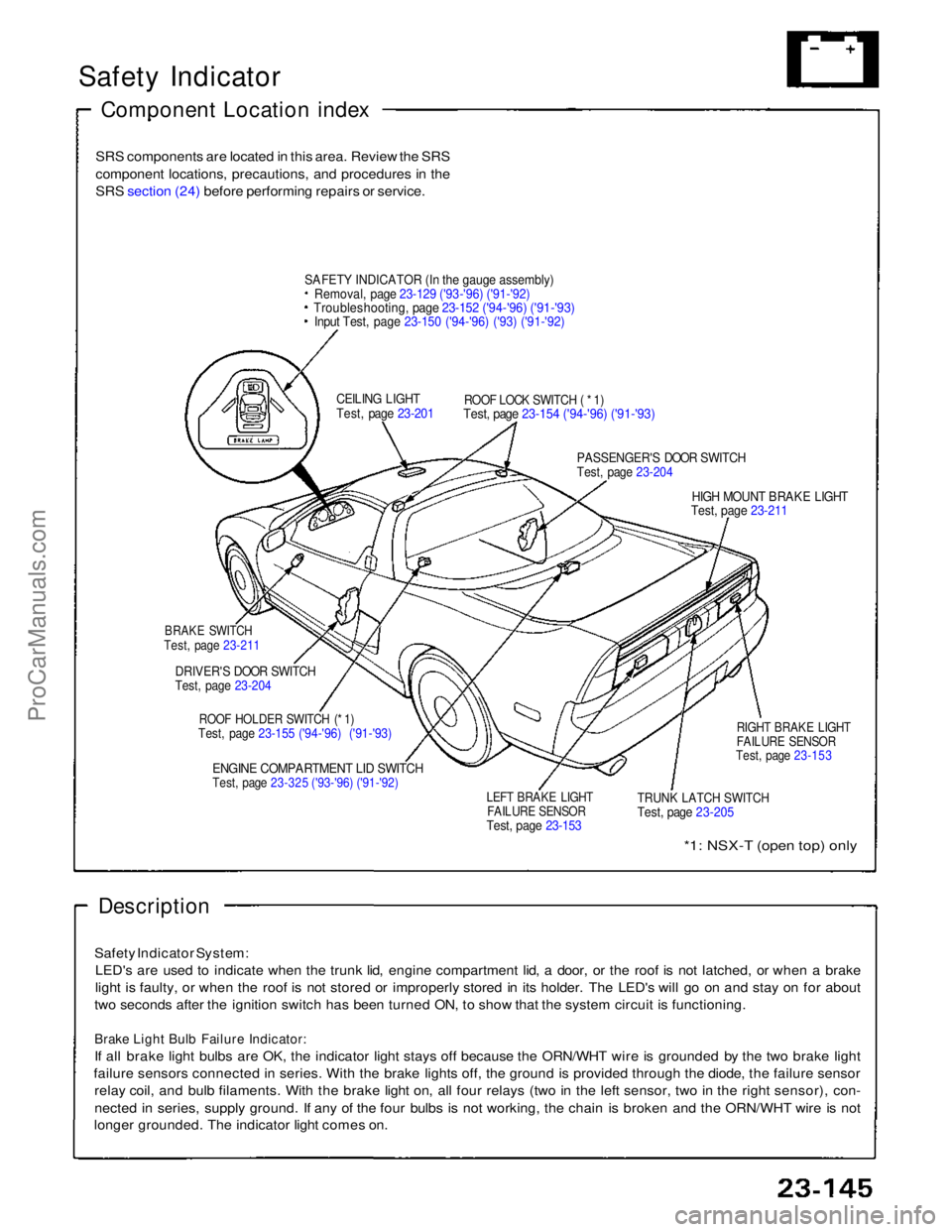

Safety Indicator

Component Location index

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

SAFET

Y

INDICATOR (In the gauge assembly)

Removal, page 23-129 ('93-'96) ('91-'92)

Troubleshooting, page 23-152 ('94-'96) ('91-'93)

Input Test, page 23-150 ('94-'96) ('93) ('91-'92)

CEILING LIGHT

Test, page 23-201

ROOF LOCK SWITCH ( * 1)

Test, page 23-154 ('94-'96) ('91-'93)

PASSENGER'S DOOR SWITCH

Test, page 23-204

HIGH MOUNT BRAKE LIGHT

Test, page 23-211

BRAKE SWITCH

Test, page 23-211

DRIVER'S DOOR SWITCH

Test, page 23-204

ROOF HOLDER SWITCH (* 1)

Test, page 23-155 ('94-'96) ('91-'93)

ENGINE COMPARTMENT LID SWITCH

Test, page 23-325 ('93-'96) ('91-'92)

LEFT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

TRUNK LATCH SWITCH

Test, page 23-205

RIGHT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

*1: NSX-T (open top) only

Description

Safety Indicator System: LED's are used to indicate when the trunk lid, engine compartment lid, a door, or the roof is not latched, or when a brake

light is faulty, or when the roof is not stored or improperly stored in its holder. The LED's will go on and stay on for about

two seconds after the ignition switch has been turned ON, to show that the system circuit is functioning.

Brake Light Bulb Failure Indicator:

If all brake light bulbs are OK, the indicator light stays off because the ORN/WHT wire is grounded by the two brake light

failure sensors connected in series. With the brake lights off, the ground is provided through the diode, the failure sensor relay coil, and bulb filaments. With the brake light on, all four relays (two in the left sensor, two in the right sensor), con-

nected in series, supply ground. If any of the four bulbs is not working, the chain is broken and the ORN/WHT wire is not

longer grounded. The indicator light comes on.ProCarManuals.com

Page 809 of 1640

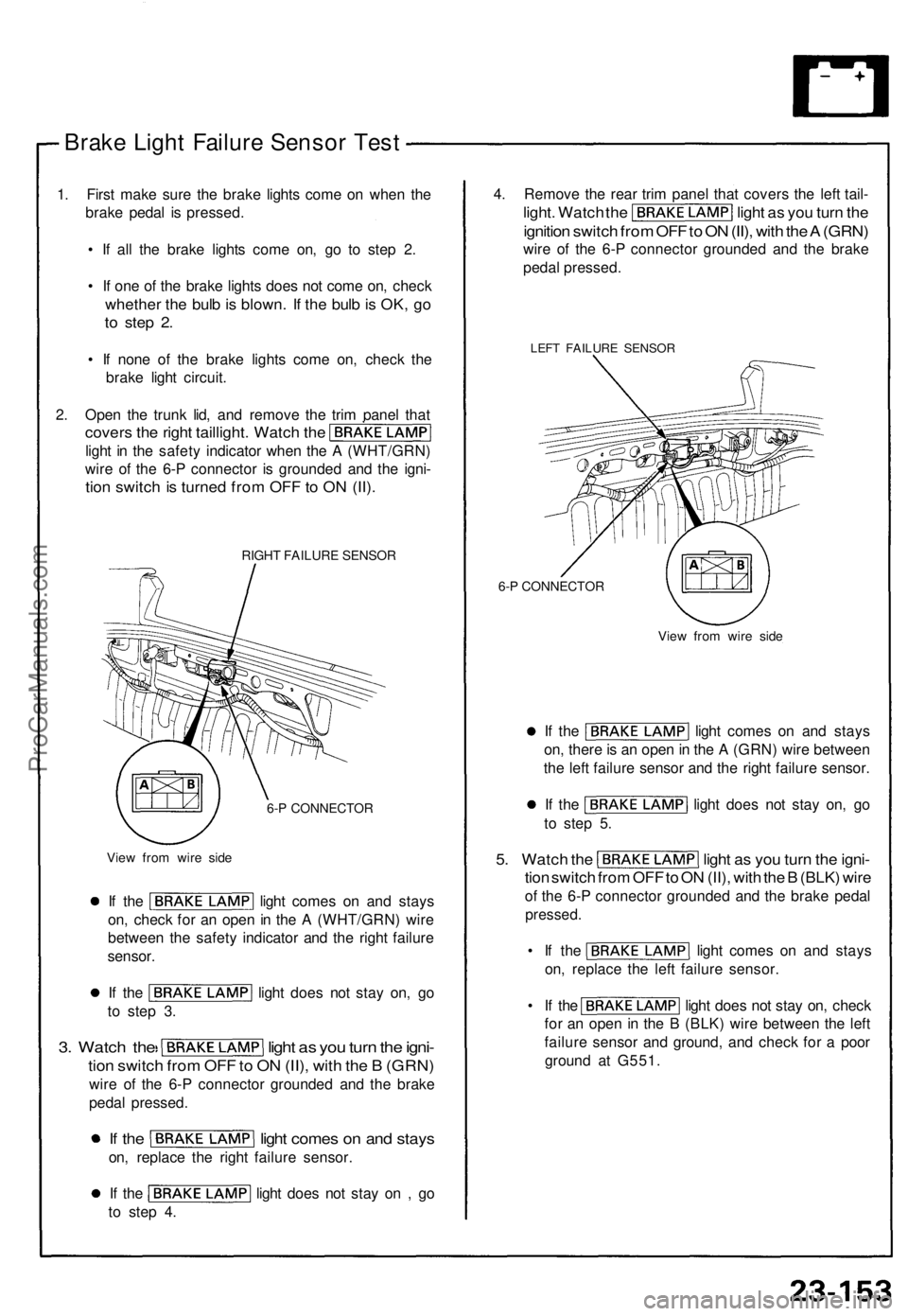

Brake Ligh t Failur e Senso r Tes t

1. Firs t mak e sur e th e brak e light s com e o n whe n th e

brak e peda l i s pressed .

• I f al l th e brak e light s com e on , g o t o ste p 2 .

• I f on e o f th e brak e light s doe s no t com e on , chec k

whethe r th e bul b is blown . I f th e bul b is OK , g o

to ste p 2 .

• I f non e of the brak e light s com e on , chec k th e

brak e ligh t circui t.

2 . Ope n th e trun k lid , an d remov e th e tri m pane l tha t

cover s th e righ t taillight . Watc h th e

ligh t i n th e safet y indicato r whe n th e A (WHT/GRN )

wir e o f th e 6- P connecto r i s grounde d an d th e igni -

tion switc h is turne d fro m OF F to O N (II) .

RIGH T FAILUR E SENSO R

6- P CONNECTO R

Vie w fro m wir e sid e

If th e ligh t come s o n an d stay s

on , chec k fo r a n ope n in th e A (WHT/GRN ) wir e

betwee n th e safet y indicato r an d th e righ t failur e

sensor .

If th e ligh t doe s no t sta y on , g o

t o ste p 3 .

3. Watc h th e ligh t a s yo u tur n th e igni -

tion switc h fro m OF F to O N (II) , wit h th e B (GRN )

wire o f th e 6- P connecto r grounde d an d th e brak e

peda l pressed .

If th e ligh t come s o n an d stay s

on, replac e th e righ t failur e sensor .

If th e ligh t doe s no t sta y o n , g o

t o ste p 4 . 4

. Remov e th e rea r tri m pane l tha t cover s th e lef t tail -

light . Watc h th e ligh t a s yo u tur n th e

ignitio n switc h fro m OF F to O N (II) , wit h th e A (GRN )

wire o f th e 6- P connecto r grounde d an d th e brak e

peda l pressed .

LEFT FAILUR E SENSO R

6-P CONNECTO R

View fro m wir e sid e

If th e ligh t come s o n an d stay s

on , ther e is a n ope n in th e A (GRN ) wir e betwee n

th e lef t failur e senso r an d th e righ t failur e sensor .

If th e ligh t doe s no t sta y on , g o

t o ste p 5 .

5. Watc h th e ligh t a s yo u tur n th e igni -

tion switc h fro m OF F to O N (II) , wit h th e B (BLK ) wir e

of th e 6- P connecto r grounde d an d th e brak e peda l

pressed .

• I f th e ligh t come s o n an d stay s

on , replac e th e lef t failur e sensor .

• I f th e ligh t doe s no t sta y on , chec k

fo r a n ope n in th e B (BLK ) wir e betwee n th e lef t

failur e senso r an d ground , an d chec k fo r a poo r

groun d a t G551 .

ProCarManuals.com

Page 859 of 1640

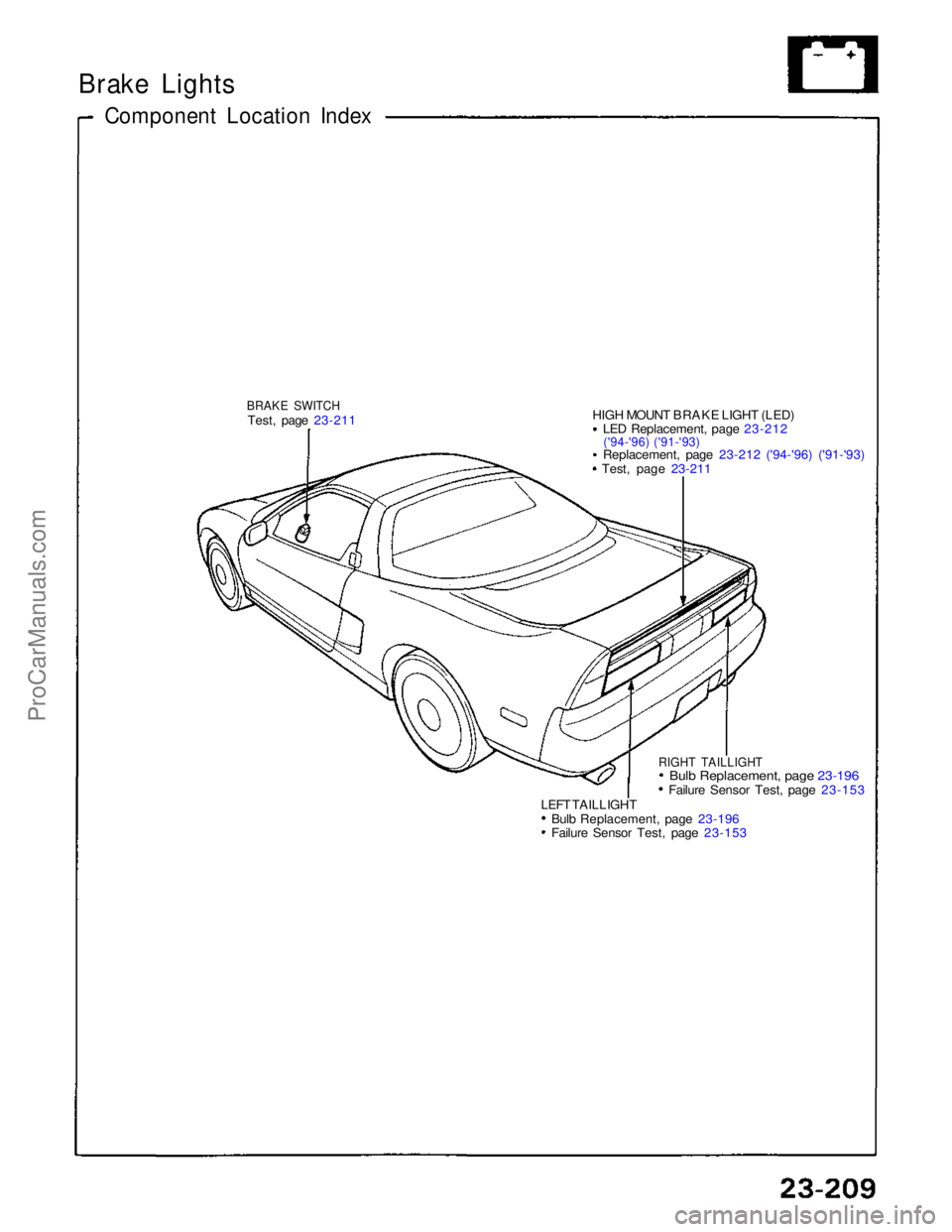

Brake Lights

Component Location Index

BRAKE SWITCH

Test, page 23-211

HIGH MOUNT BRAKE LIGHT (LED)

LED Replacement, page 23-212

('94-'96) ('91-'93)

Replacement, page 23-212 ('94-'96) ('91-'93) Test, page 23-211

RIGHT TAILLIGHT

Bul

b

Replacement, page 23-196

Failure Sensor Test, page 23-153

LEFT TAILLIGHT Bulb Replacement, page 23-196 Failure Sensor Test, page 23-153

ProCarManuals.com

Page 860 of 1640

(G551) '95-'96 Models.

(G401,G402,G551) '93-94 Models or

Brake Switch

Test

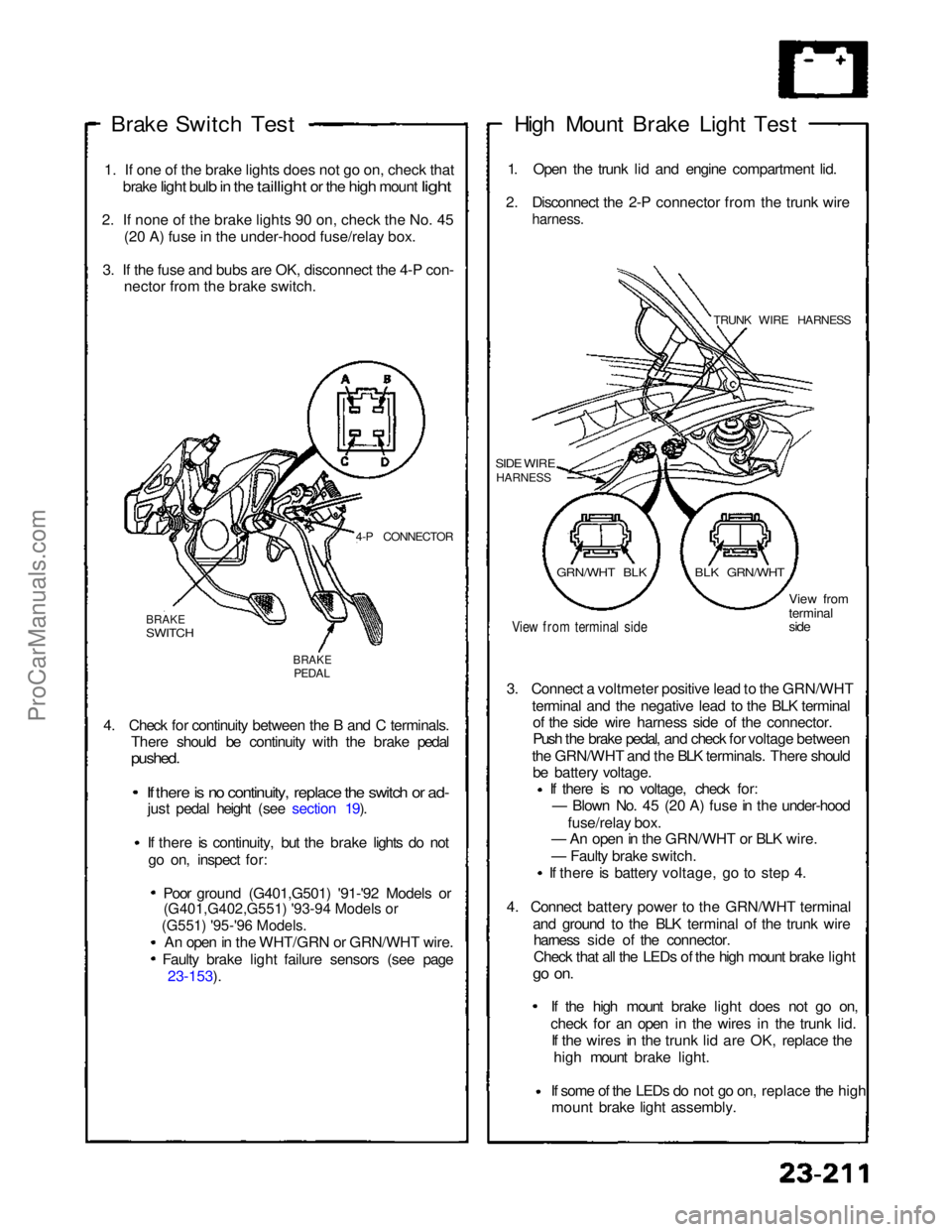

1

.

If one of the brake lights does not go on, check that

brake

light bulb in the taillight or the high mount light

2

.

If none of the brake lights 90 on, check the No. 45 (2

0

A) fuse in the under-hood fuse/relay box.

3

.

If the fuse and bubs are OK, disconnect the 4-P con- necto

r

from the brake switch.

4-P CONNECTOR

BRAKE

SWITCH

BRAKE

PEDAL

4. Check for continuity between the B and C terminals. There should be continuity with the brake pedal

pushed.

If there is no continuity, replace the switch or ad-

just pedal height (see section 19).

If there is continuity, but the brake lights do not

go on, inspect for:

Poor ground (G401,G501) '91-'92 Models or

An open in the WHT/GRN or GRN/WHT wire. Faulty brake light failure sensors (see page 23-153). High Mount Brake Light Test

1. Open the trunk lid and engine compartment lid.

2. Disconnect the 2-P connector from the trunk wire

harness.

TRUNK WIRE HARNESS

SIDE WIRE

HARNESS

View from terminal side

View from

terminal

side

3. Connect a voltmeter positive lead to the GRN/WHT terminal and the negative lead to the BLK terminalof the side wire harness side of the connector.

Push the brake pedal, and check for voltage between

the GRN/WHT and the BLK terminals. There should be battery voltage. If there is no voltage, check for:

— Blown No. 45 (20 A) fuse in the under-hood

fuse/relay box.

— An open in the GRN/WHT or BLK wire.

— Faulty brake switch.

If there is battery voltage, go to step 4.

4. Connect battery power to the GRN/WHT terminal and ground to the BLK terminal of the trunk wireharness side of the connector.

Check that all the LEDs of the high mount brake light

go on.

If the high mount brake light does not go on,check for an open in the wires

in the trunk lid.

If the wires in the trunk lid are OK, replace the

high mount brake light.

If some of the LEDs do not go on,

replace the high

mount brake light assembly.

GRN/WHT BLK

BLK GRN/WHTProCarManuals.com

Page 935 of 1640

Cruise Control

Description

The cruise control system uses mechanically and electri-

cally operated devices to maintain vehicle speed at a

setting selected by the driver.

The ECM receives command signals from the cruise con-

trol main switch and the cruise control set/resume switch.

It receives information about operating conditions from

the brake switch, vehicle speed sensor (VSS), the clutch

switch (with manual transmission), or the A/T gear posi-

tion switch (with automatic transmission). The ECM

sends operational signals to the devices that regulate the

throttle position. The throttle position maintains the

selected vehicle speed. Essentially, the ECM compares

the actual speed of the vehicle to the selected speed.

Then, it uses the result of that comparison to open or

close the throttle.

The brake switch releases the system's control of the

throttle at the instant the driver depresses the brake

pedal. The switch sends an electronic signal to the ECM

when the brake pedal is depressed; the ECM responds

by allowing the throttle to close. The clutch switch (man-

ual transmission) or the A/T gear position switch (auto-

matic transmission) sends a disengage signal to the

ECM that also allows the throttle to close.

Operation:

The cruise control system will set and automatically

maintain any speed above 25 mph (45 km/h). To set,

make sure that the main switch is in the "ON" position.

After reaching the desired speed, press the set switch.

The ECM will receive a set signal and, in turn, will actu-

ate the throttle valve control motor. When the set switch

is depressed and the cruise control system is on, the

"cruise control" ON indicator in the gauge assembly will

light up. You can cancel the cruise control system by

pushing the main switch to "OFF". This erases the set

speed from memory. If the system is disengaged tem-

porarily by the brake switch, clutch switch, or A/T gear

position switch and vehicle speed is still above 25 mph,

press the resume switch. With the resume switch

depressed and the set memory retained, the vehicle

automatically returns to the previous set speed.

For gradual acceleration without depressing the acceler-

ator pedal, push the resume switch down and hold it

there until the desired speed is reached. This will send

an acceleration signal to the ECM. When the switch is

released, the system will be reprogrammed for the new

speed. To slow down, depress the set switch. This will

send a deceleration signal to the ECM causing the car to

coast until the desired speed is reached. When the

desired speed is reached, release the set switch. This

will reprogram the system for the new speed.ProCarManuals.com