fuse chart ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 420 of 1640

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 21 and DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot. If the problem is an

intermittent problem, the system does not become active after the engine starts even though the problem is solved.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 531 of 1640

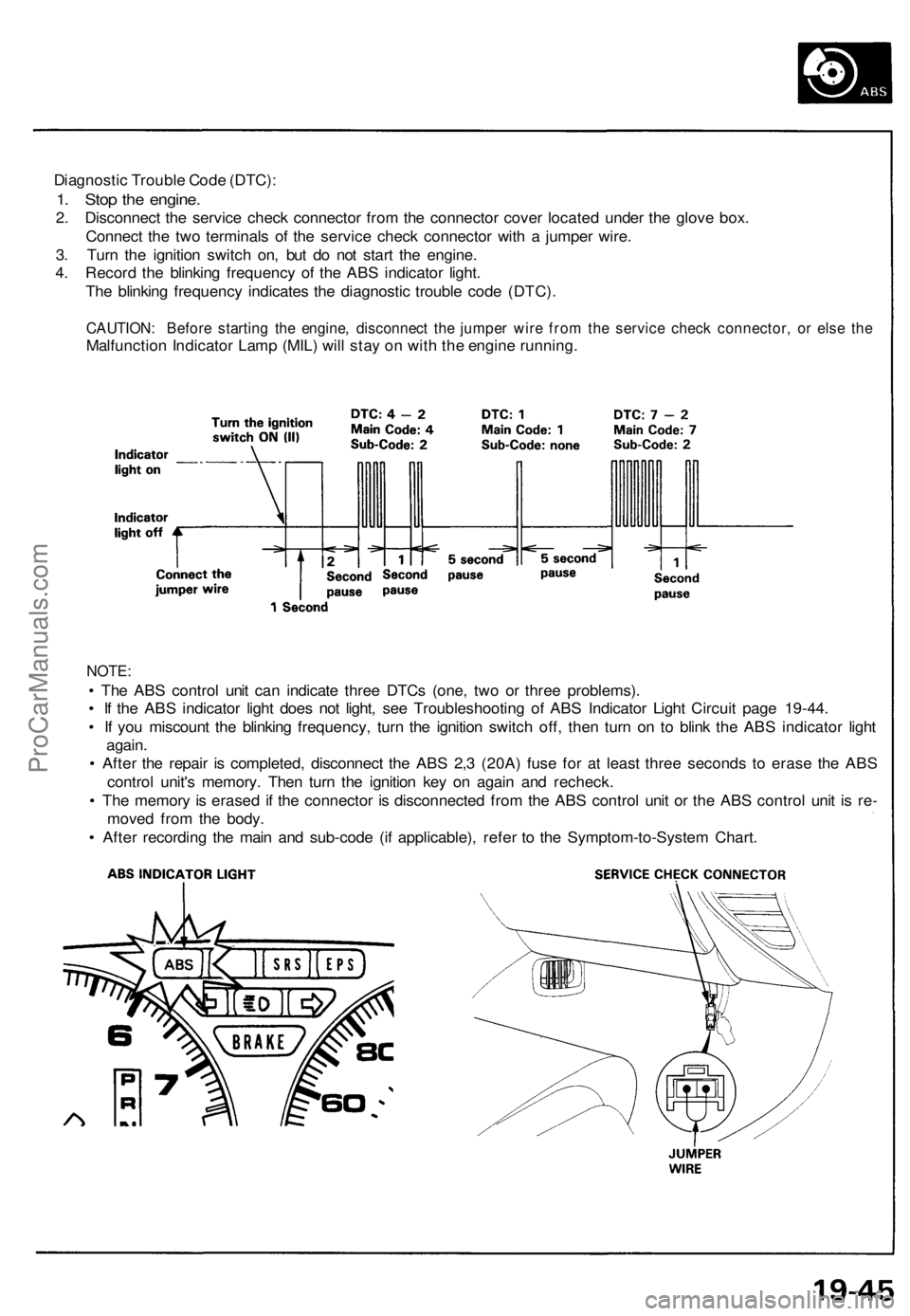

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 1087 of 1640

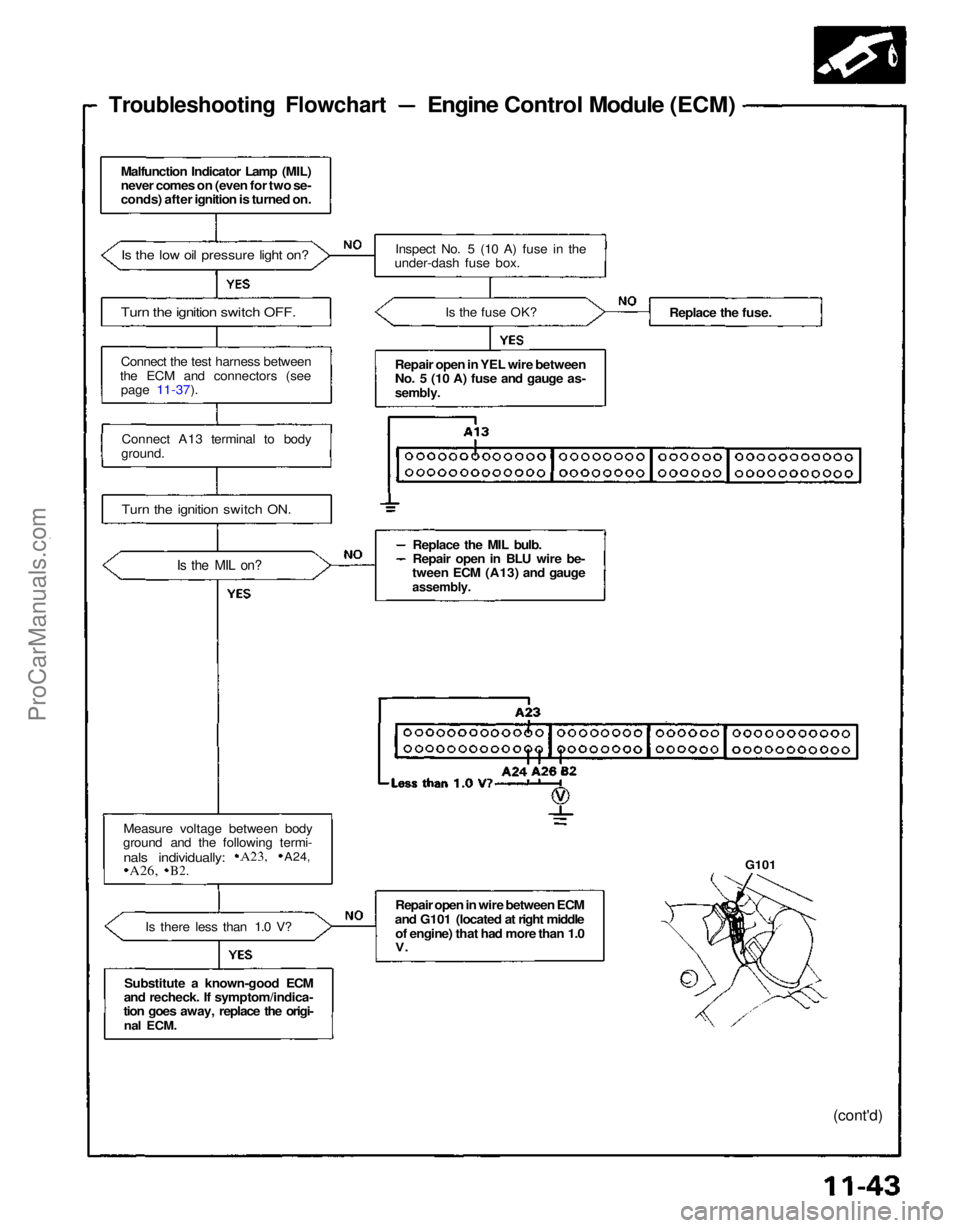

Troubleshooting Flowchart

Engine Control Module (ECM)

Malfunction Indicator Lamp (MIL)

never comes on (even for two se-

conds) after ignition is turned on.

Is the low oil pressure light on?

Turn the ignition switch OFF.

Connect the test harness between

the ECM and connectors (see page 11-37).

Connect A13 terminal to body

ground.

Turn the ignition switch ON.

Is the MIL on?

Measure voltage between body

ground and the following termi-

Is there less than 1.0 V?

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM. Inspect No. 5 (10 A) fuse in the

under-dash fuse box.

Is the fuse OK?

Repair open in YEL wire between

No. 5 (10 A) fuse and gauge as-

sembly.

Replace the MIL bulb.

Repair open in BLU wire be-

tween ECM (A13) and gauge

assembly.

Repair open in wire between ECM

and G101 (located at right middle of engine) that had more than 1.0

V.

Replace the fuse.

G101

(cont'd)

nals individually:

A23,

A24,

A26,

B2.ProCarManuals.com

Page 1088 of 1640

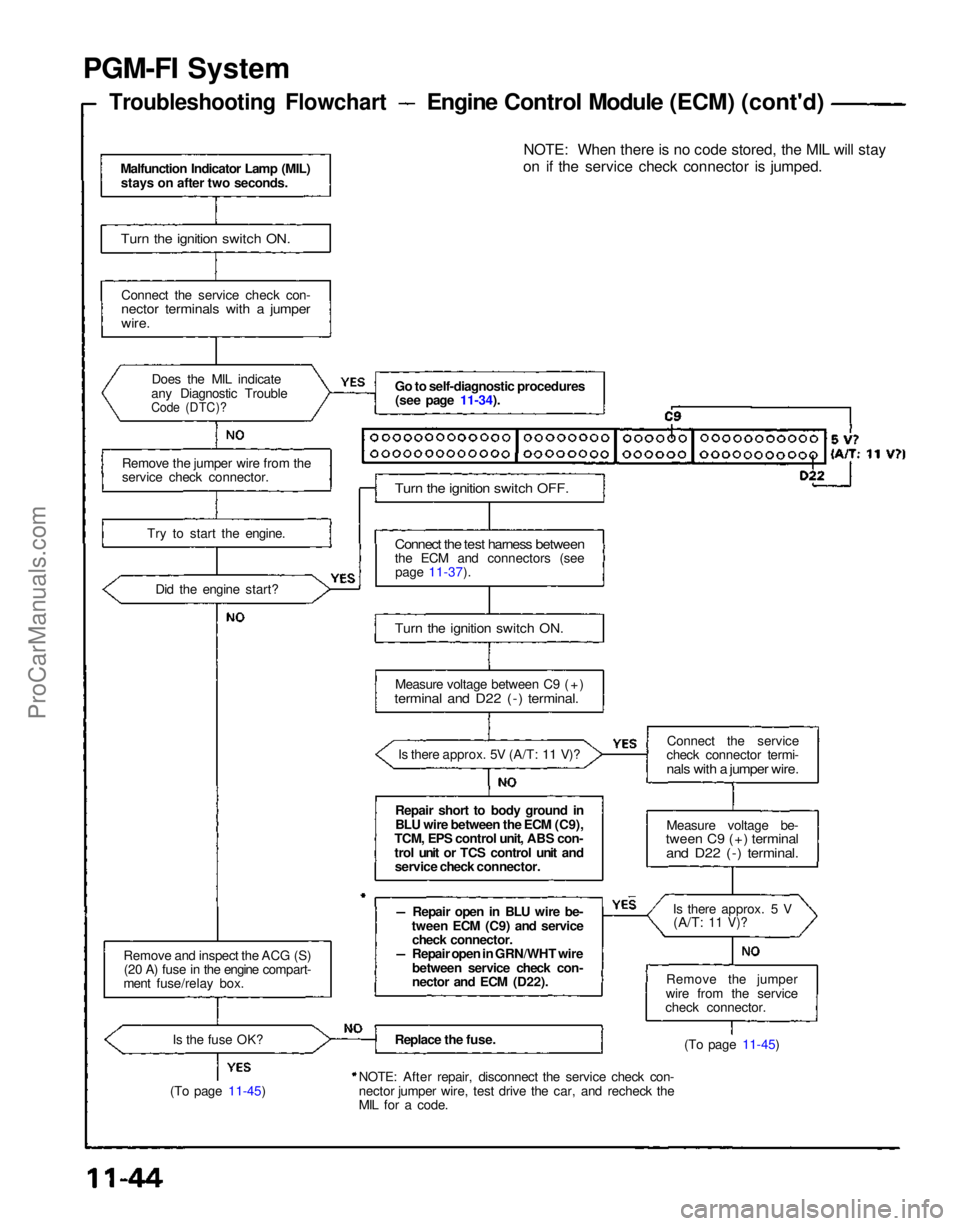

PGM-FI System

Troubleshooting Flowchart

Engine Control Module (ECM) (cont'd)

Malfunction Indicator Lamp (MIL) stays on after two seconds.

Turn the ignition switch ON.

Connect the service check con-

nector terminals with a jumper

wire.

Does the MIL indicate

any Diagnostic Trouble

Code (DTC)?

Remove the jumper wire from the

service check connector.

Try to start the engine.Did the engine start?

Remove and inspect the ACG (S) (20 A) fuse in the engine compart-

ment fuse/relay box.

Is the fuse OK?

(To page 11-45) Go to self-diagnostic procedures

(see page 11-34).

Turn the ignition switch OFF.

Connect the test harness between

the ECM and connectors (see page 11-37).

Turn the ignition switch ON.

Measure voltage between C9 (+)

terminal and D22 (-) terminal.

Is there approx. 5V (A/T: 11 V)?

Repair short to body ground in

BLU wire between the ECM (C9),

TCM, EPS control unit, ABS con-

trol unit or TCS control unit and service check connector.

Repair open in BLU wire be-

tween ECM (C9) and service check connector.

Repair open in GRN/WHT wire

between service check con-

nector and ECM (D22).

Replace the fuse.

NOTE: After repair, disconnect the service check con-

nector jumper wire, test drive the car, and recheck the

MIL for a code. NOTE: When there is no code stored, the MIL will stay

on if the service check connector is jumped.

Connect the service

check connector termi-

nals with a jumper wire.

Measure voltage be-

tween C9 (+) terminal

and D22 (-) terminal.

Is there approx. 5 V(A/T:

11 V)?

Remove the jumper

wire from the service

check connector.

(To page 11-45)ProCarManuals.com

Page 1104 of 1640

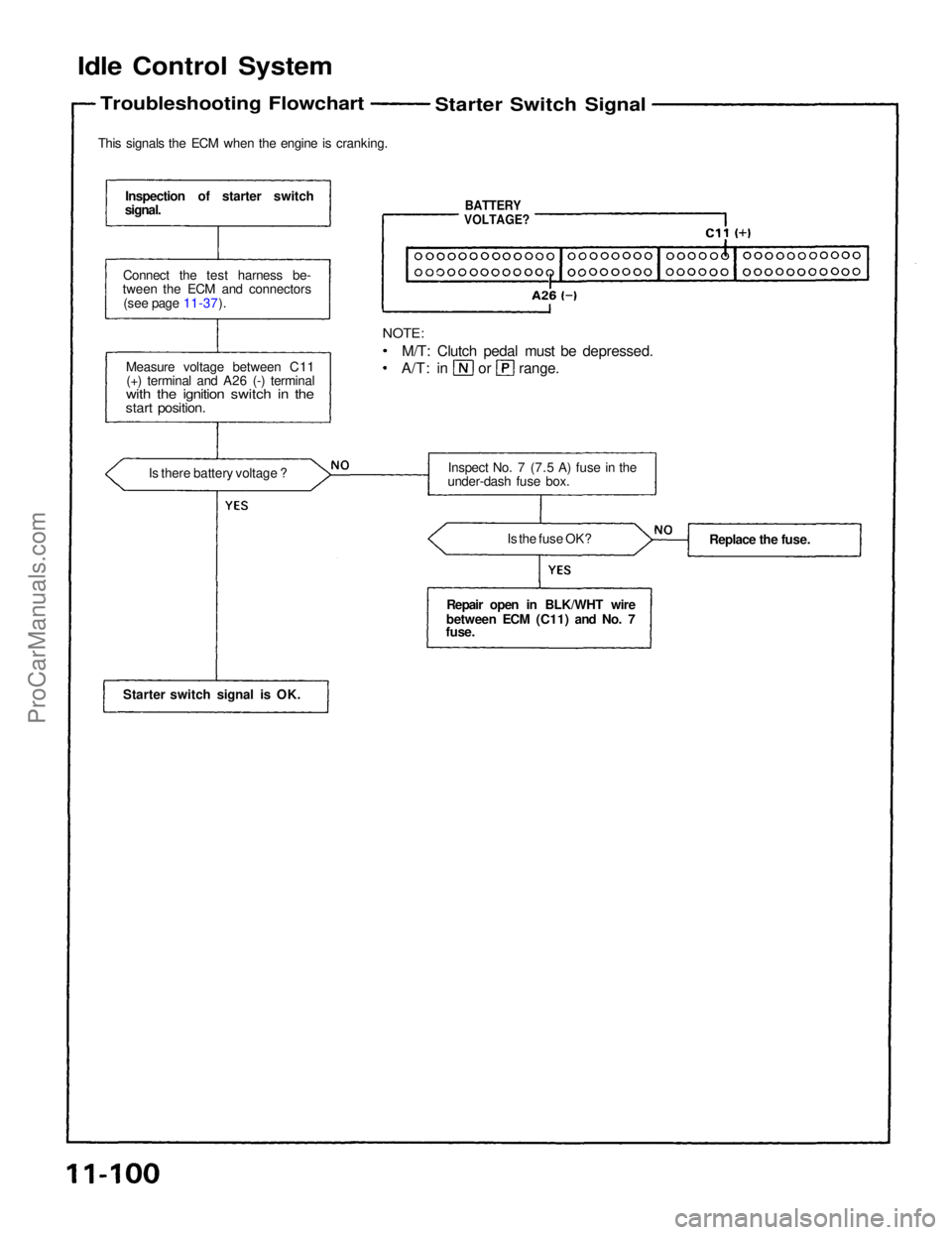

Idle Control System

Troubleshooting Flowchart

This signals the ECM when the engine is cranking.

Inspection of starter switch

signal.

Connect the test harness be-

tween the ECM and connectors

(see page 11-37).

Measure voltage between C11(+) terminal and A26 (-) terminal

with the ignition switch in the

start position.

Is there battery voltage ?

Starter switch signal is OK.

NOTE:

M/T: Clutch pedal must be depressed. A/T: in or range.

Inspect No. 7 (7.5 A) fuse in the

under-dash fuse box.

Is the fuse OK?

Repair open in BLK/WHT wire

between ECM (C11) and No. 7

fuse. Replace the fuse.

Starter Switch Signal

BATTERY

VOLTAGE?ProCarManuals.com

Page 1120 of 1640

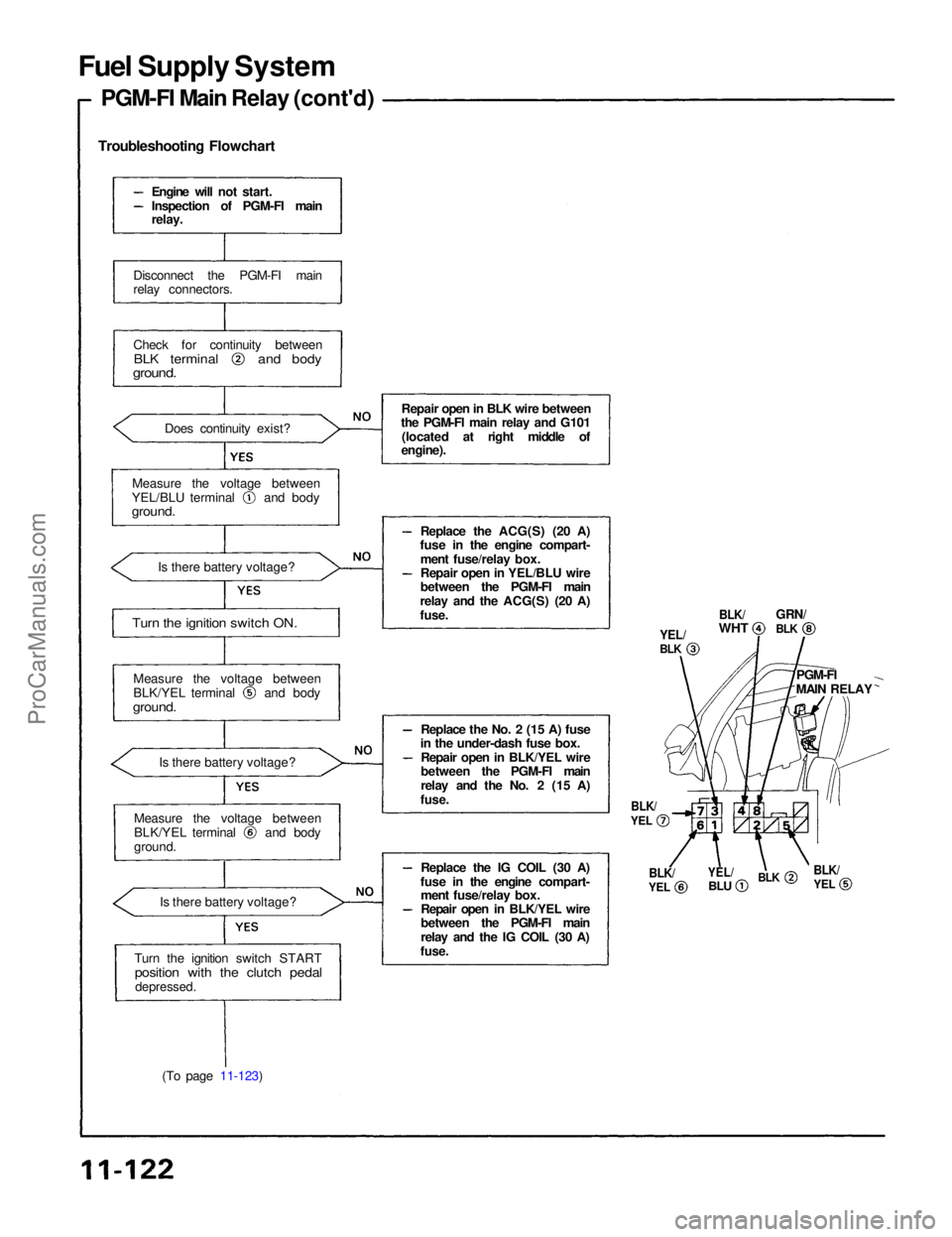

Fuel Supply System

PGM-FI Main Relay (cont'd)

Troubleshooting Flowchart

(To page 11-123)

BLK/

WHT

GRN/

YEL/

BLK

PGM-FI

MAIN RELAY

BLK/

YEL

BLK

YEL/

BLU

BLK/

YEL

BLK/

YEL

BLK

Engine will not start.

Inspection of PGM-FI main

relay.

Disconnect the PGM-FI main

relay connectors.

Check for continuity between

BLK terminal and body

ground.

Does continuity exist?

Measure the voltage between YEL/BLU terminal and body

ground.

Is there battery voltage?

Turn the ignition switch ON.

Measure the voltage between BLK/YEL terminal and body

ground.

Is there battery voltage?

Measure the voltage between BLK/YEL terminal and body

ground.

Is there battery voltage?

Turn the ignition switch START

position with the clutch pedal

depressed.

Repair open in BLK wire between

the PGM-FI main relay and G101

(located at right middle of

engine).

Replace the ACG(S) (20 A)

fuse in the engine compart-

ment fuse/relay box.

Repair open in YEL/BLU wire

between the PGM-FI main

relay and the ACG(S) (20 A)

fuse.

Replace the No. 2 (15 A) fuse

in the under-dash fuse box.

Repair open in BLK/YEL wire

between the PGM-FI main

relay and the No. 2 (15 A)

fuse.

Replace the IG COIL (30 A)

fuse in the engine compart- ment fuse/relay box.

Repair open in BLK/YEL wire

between the PGM-FI main

relay and the IG COIL (30 A)

fuse.ProCarManuals.com

Page 1208 of 1640

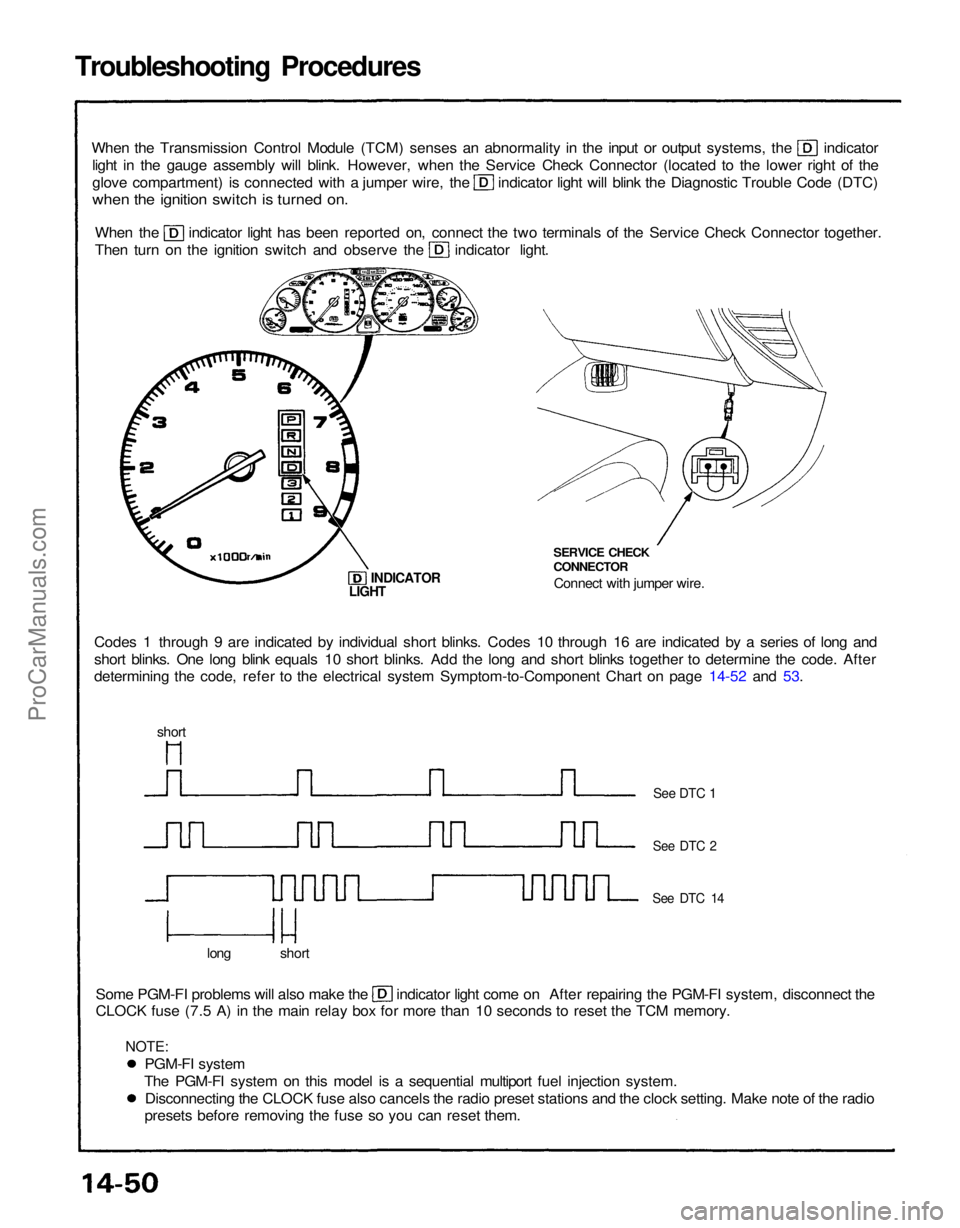

Troubleshooting Procedures

When the Transmission Control Module (TCM) senses an abnormality in the input or output systems, the indicator

light in the gauge assembly will blink. However, when the Service Check Connector (located to the lower right of the glove compartment) is connected with a jumper wire, the indicator light will blink the Diagnostic Trouble Code (DTC)

when the ignition switch is turned on.

When the indicator light has been reported on, connect the two terminals of the Service Check Connector together.

Then turn on the ignition switch and observe the indicator light.

Codes 1 through 9 are indicated by individual short blinks. Codes 10 through 16 are indicated by a series of long and

short blinks. One long blink equals 10 short blinks. Add the long and short blinks together to determine the code. After

determining the code, refer to the electrical system Symptom-to-Component Chart on page 14-52 and 53. SERVICE CHECK

CONNECTOR

Connect with jumper wire.

INDICATOR

Some PGM-FI problems will also make the indicator light come on After repairing the PGM-FI system, disconnect the

CLOCK fuse (7.5 A) in the main relay box for more than 10 seconds to reset the TCM memory.

long short

See DTC 1

See DTC 2

See DTC 14

LIGHT

short

PGM-FI system

The PGM-FI system on this model is a sequential multiport fuel injection system. Disconnecting the CLOCK fuse also cancels the radio preset stations and the clock setting. Make note of the radio

presets before removing the fuse so you can reset them.

NOTE:ProCarManuals.com

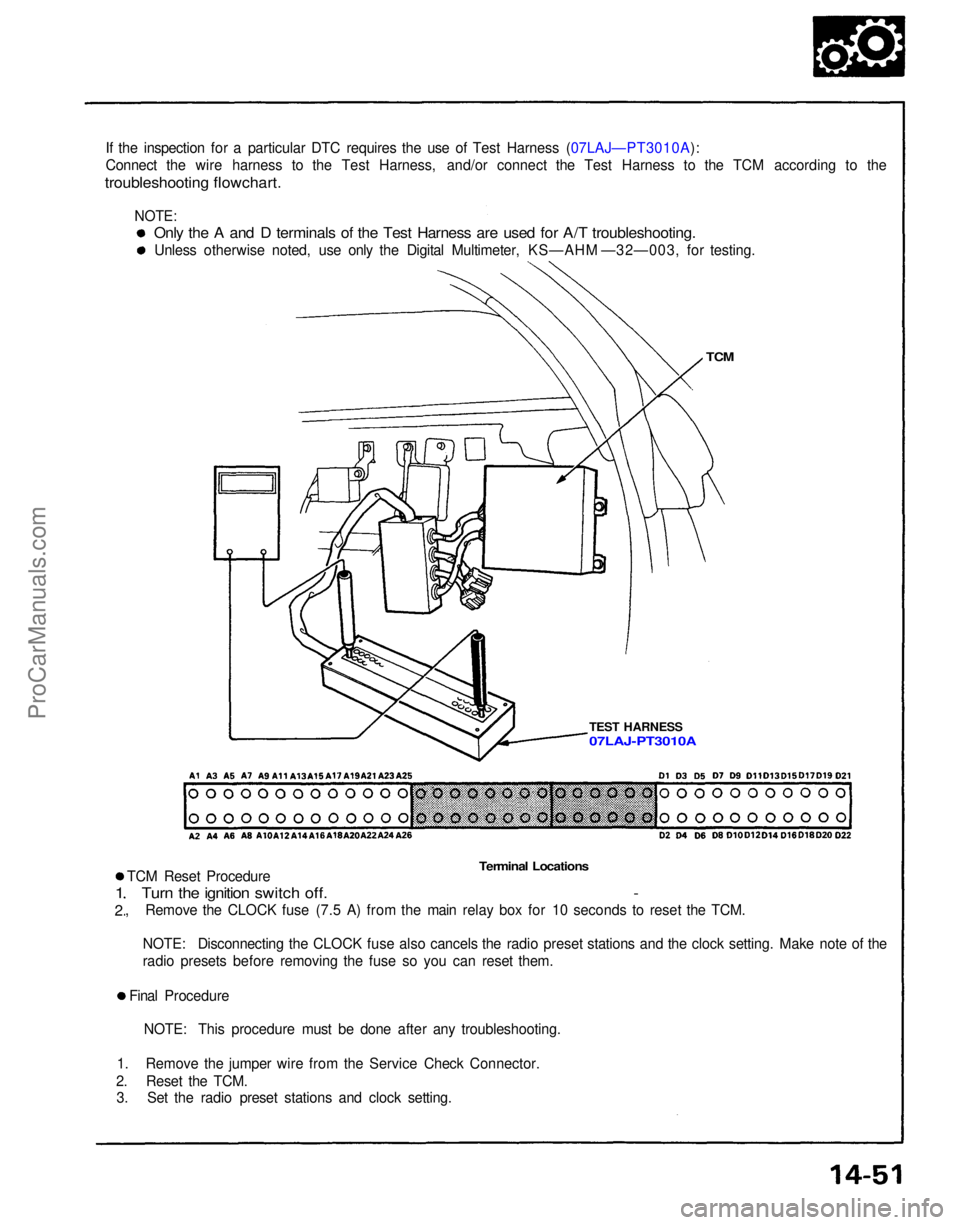

Page 1209 of 1640

If the inspection for a particular DTC requires the use of Test Harness (07LAJ—PT3010A):

Connect the wire harness to the Test Harness, and/or connect the Test Harness to the TCM according to the

troubleshooting flowchart.

TCM

TEST HARNESS

Terminal Locations

TCM Reset Procedure

Turn the ignition switch off. -

, Remove the CLOCK fuse (7.5 A) from the main relay box for 10 seconds to reset the TCM.

1

2

NOTE: Disconnecting the CLOCK fuse also cancels the radio preset stations and the clock setting. Make note of the

radio presets before removing the fuse so you can reset them.

Final Procedure NOTE: This procedure must be done after any troubleshooting.

1. Remove the jumper wire from the Service Check Connector.

2. Reset the TCM. 3. Set the radio preset stations and clock setting.

Only the A and D terminals of the Test Harness are used for A/T troubleshooting.

Unless otherwise noted, use only the Digital Multimeter, KS—AHM —32—003, for testing.

07LAJ-PT3010A

NOTE:ProCarManuals.com

Page 1336 of 1640

Troubleshooting

Diagnostic Trouble Code (DTC) Display

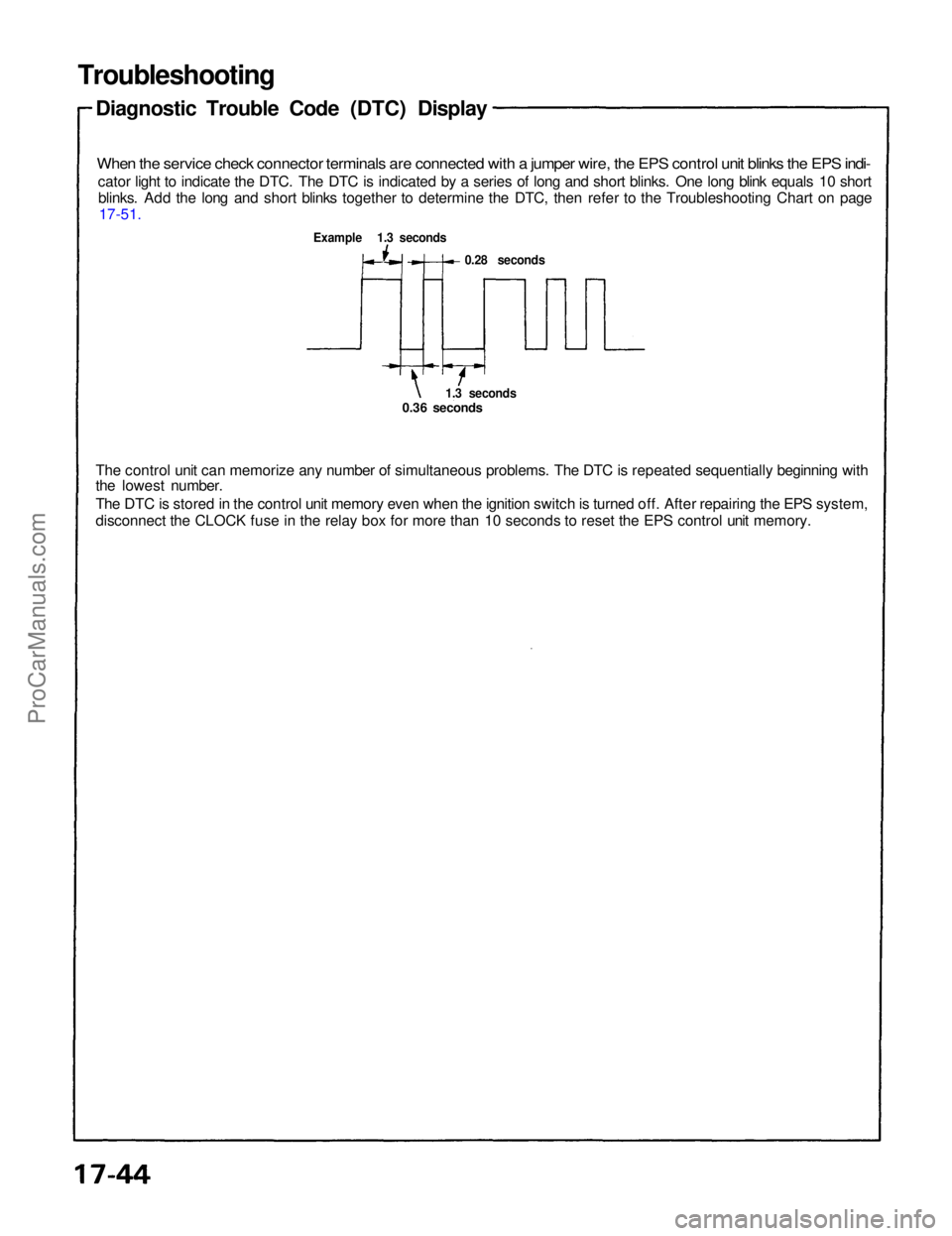

When the service check connector terminals are connected with a jumper wire, the EPS control unit blinks the EPS indi-

cator light to indicate the DTC. The DTC is indicated by a series of long and short blinks. One long blink equals 10 shortblinks. Add the long and short blinks together to determine the DTC, then refer to the Troubleshooting Chart on page 17-51.

Example 1.3 seconds

0.28 seconds

1.3 seconds

0.36 seconds

The control unit can memorize any number of simultaneous problems. The DTC is repeated sequentially beginning with

the lowest number.

The DTC is stored in the control unit memory even when the ignition switch is turned off. After repairing the EPS system,

disconnect the CLOCK fuse in the relay box for more than 10 seconds to reset the EPS control unit memory.ProCarManuals.com

Page 1482 of 1640

PGM-FI Control System

Troubleshooting Flowchart

ECU

Check Engine light never comes

on (even for two seconds) after

ignition is turned on.

Is the oil pressure light on?

Turn the ignition switch OFF.

Inspect No. 5 fuse.

Is No. 5 fuse OK? Replace fuse.

Connect the ECU test harness

between the ECU and connector

(page 11-21).

Connect A13 terminal to body

ground.

Repair open in YEL between

No. 5 fuse and gauge assembly.

A13

Turn the ignition switch ON. Replace the light

bulb.

Repair open in BLU

wire between ECU

(A13) and gauge

assembly.

A23

A24 A26 B2

G101

Less than 1 V

Is Check Engine light on?

Measure voltage between body

ground and the following ter-

minals individually: A23, A24,

A26,

B2.

Is there less than 1V?

Repair open in wire

between ECU and in-

take manifold (G101)

that had more than 1V.

Substitute a known-good ECU and recheck. If symp-

tom/ indication goes away,

replace the original ECU.ProCarManuals.com