clutch ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 80 of 1640

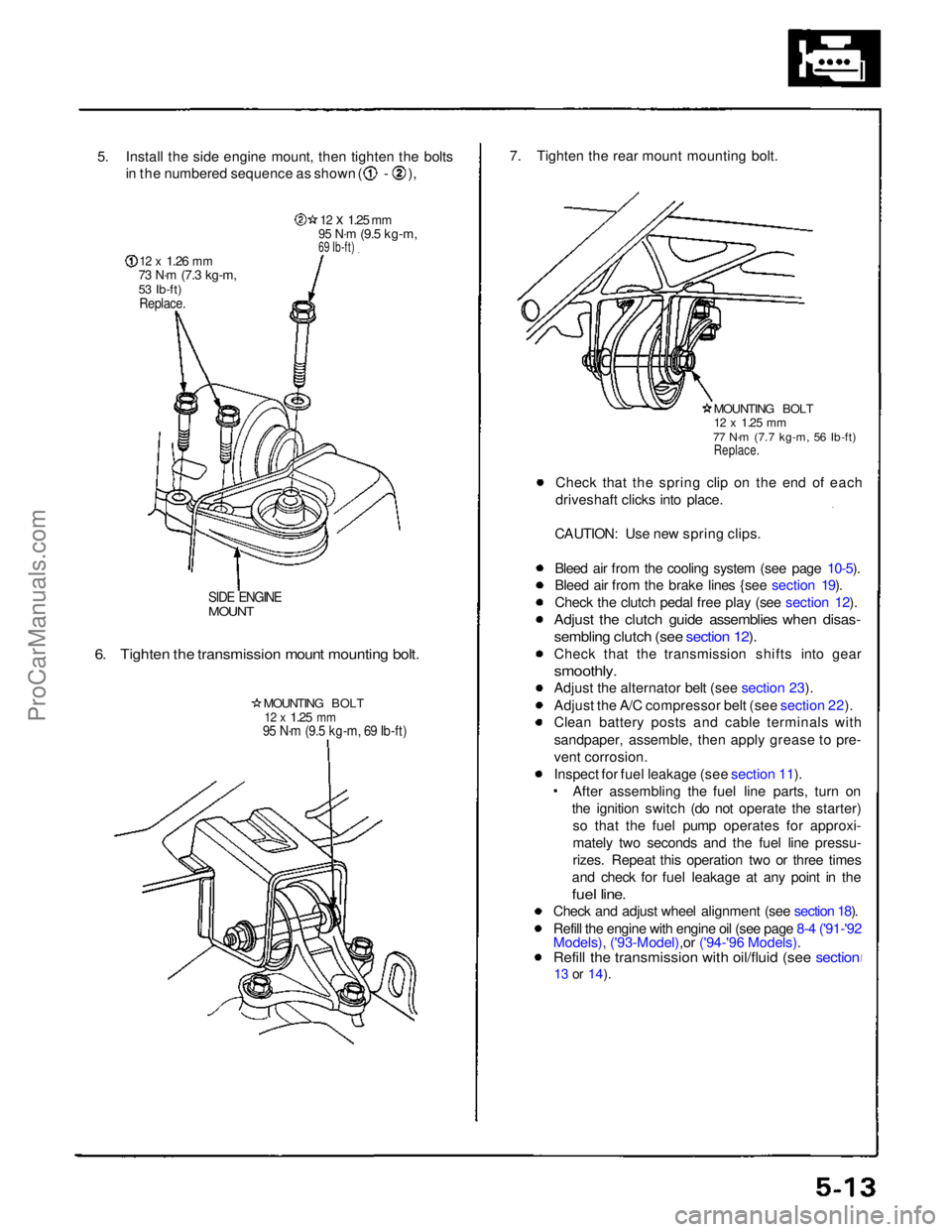

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 237 of 1640

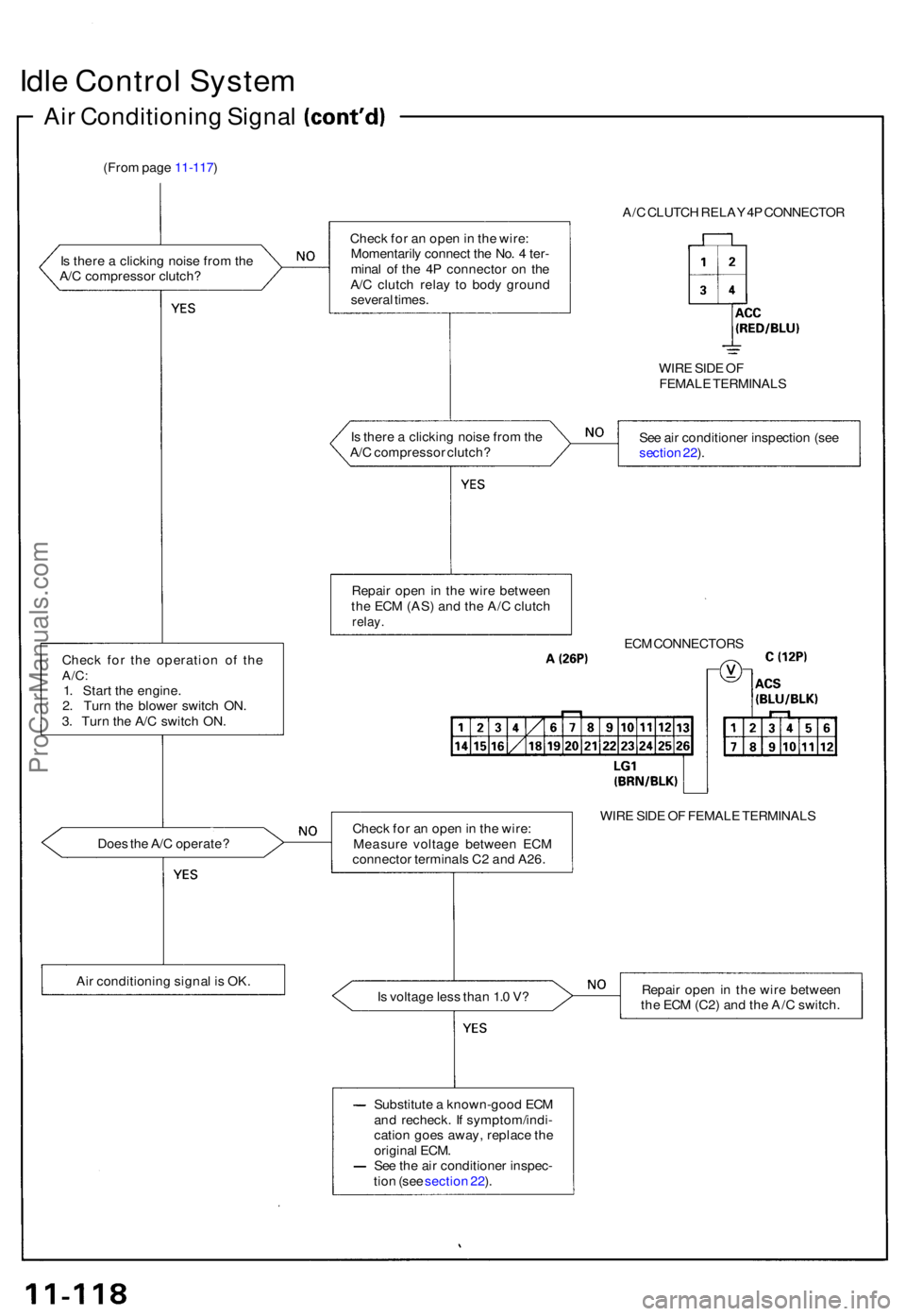

Idle Contro l Syste m

Air Conditionin g Signa l

(From pag e 11-117 )

I s ther e a clickin g nois e fro m th e

A/ C compresso r clutch ?

Chec k fo r th e operatio n o f th e

A/C :1. Star t th e engine .

2 . Tur n th e blowe r switc h ON .

3 . Tur n th e A/ C switc h ON .

Doe s th e A/ C operate ?

Ai r conditionin g signa l i s OK . A/

C CLUTC H RELA Y 4P CONNECTO R

Chec k fo r a n ope n in th e wire :

Momentaril y connec t th e No . 4 ter -

mina l o f th e 4 P connecto r o n th e

A/ C clutc h rela y t o bod y groun d

severa l times .

WIRE SID E O F

FEMAL E TERMINAL S

I s ther e a clickin g nois e fro m th e

A/ C compresso r clutch ? Se

e ai r conditione r inspectio n (se e

sectio n 22 ).

Repai r ope n in th e wir e betwee n

th e EC M (AS ) an d th e A/ C clutc h

relay.

ECM CONNECTOR S

Chec k fo r a n ope n in th e wire :

Measur e voltag e betwee n EC M

connecto r terminal s C 2 an d A26 . WIR

E SID E O F FEMAL E TERMINAL S

I s voltag e les s tha n 1. 0 V ? Repai

r ope n in th e wir e betwee n

th e EC M (C2 ) an d th e A/ C switch .

Substitut e a known-goo d EC M

an d recheck . I f symptom/indi -

catio n goe s away , replac e th e

origina l ECM .

Se e th e ai r conditione r inspec -

tio n (se e sectio n 22 ).

ProCarManuals.com

Page 243 of 1640

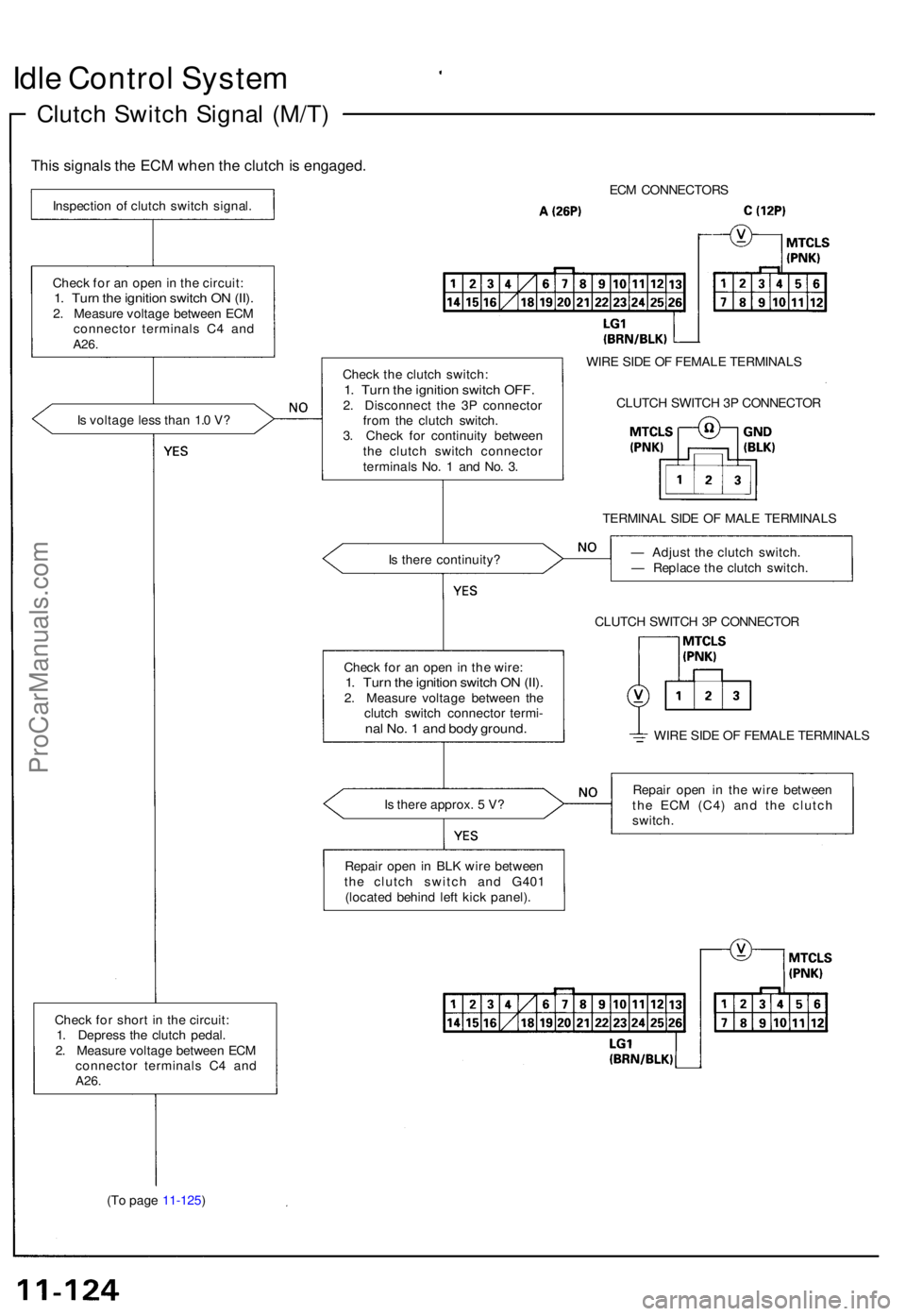

Idle Contro l Syste m

Clutch Switc h Signa l (M/T )

This signal s th e EC M whe n th e clutc h is engaged .

Inspection o f clutc h switc h signal .

Chec k fo r a n ope n in th e circuit :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n EC M

connecto r terminal s C 4 an d

A26.

Is voltag e les s tha n 1. 0 V ?

Chec k fo r shor t i n th e circuit :

1 . Depres s th e clutc h pedal .

2 . Measur e voltag e betwee n EC M

connecto r terminal s C 4 an d

A26.

(To pag e 11-125 ) EC

M CONNECTOR S

Chec k th e clutc h switch :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e 3 P connecto r

fro m th e clutc h switch .

3 . Chec k fo r continuit y betwee n

th e clutc h switc h connecto r

terminal s No . 1 an d No . 3 . WIR

E SID E O F FEMAL E TERMINAL S

CLUTC H SWITC H 3 P CONNECTO R

TERMINA L SID E O F MAL E TERMINAL S

I s ther e continuity ? —

Adjus t th e clutc h switch .

— Replac e th e clutc h switch .

CLUTC H SWITC H 3 P CONNECTO R

WIR E SID E O F FEMAL E TERMINAL S

I s ther e approx . 5 V ? Repai

r ope n i n th e wir e betwee n

th e EC M (C4 ) an d th e clutc h

switch .

Repai r ope n in BL K wir e betwee n

th e clutc h switc h an d G40 1

(locate d behin d lef t kic k panel) .

Chec

k fo r a n ope n in th e wire :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

clutc h switc h connecto r termi -

nal No . 1 an d bod y ground .

ProCarManuals.com

Page 246 of 1640

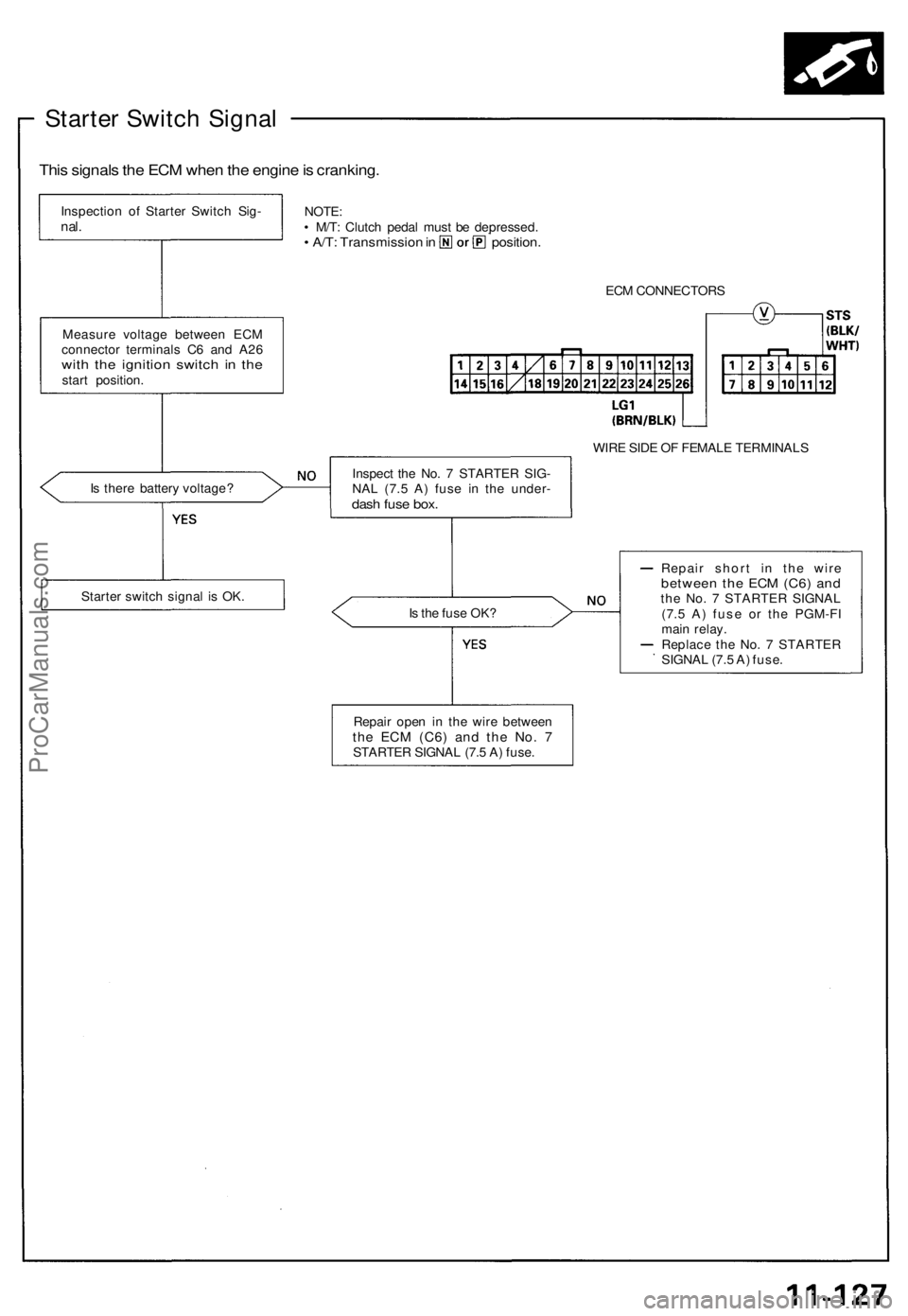

Starter Switch Signal

This signals the ECM when the engine is cranking.

Inspection of Starter Switch Sig-

nal.

NOTE:

• M/T: Clutch pedal must be depressed.

• A/T: Transmission in position.

ECM CONNECTORS

Measure voltage between ECM

connector terminals C6 and A26

with the ignition switch in the

start position.

WIRE SIDE OF FEMALE TERMINALS

Is there battery voltage?

Is the fuse OK?

Repair short in the wire

between the ECM (C6) and

the No. 7 STARTER SIGNAL

(7.5 A) fuse or the PGM-FI

main relay.

Replace the No. 7 STARTER

SIGNAL (7.5 A) fuse.

Starter switch signal is OK.

Repair open in the wire between

the ECM

(C6)

and the No. 7

STARTER SIGNAL (7.5 A) fuse.

Inspect the No. 7 STARTER SIG-

NAL (7.5 A) fuse in the under-

dash fuse box.ProCarManuals.com

Page 282 of 1640

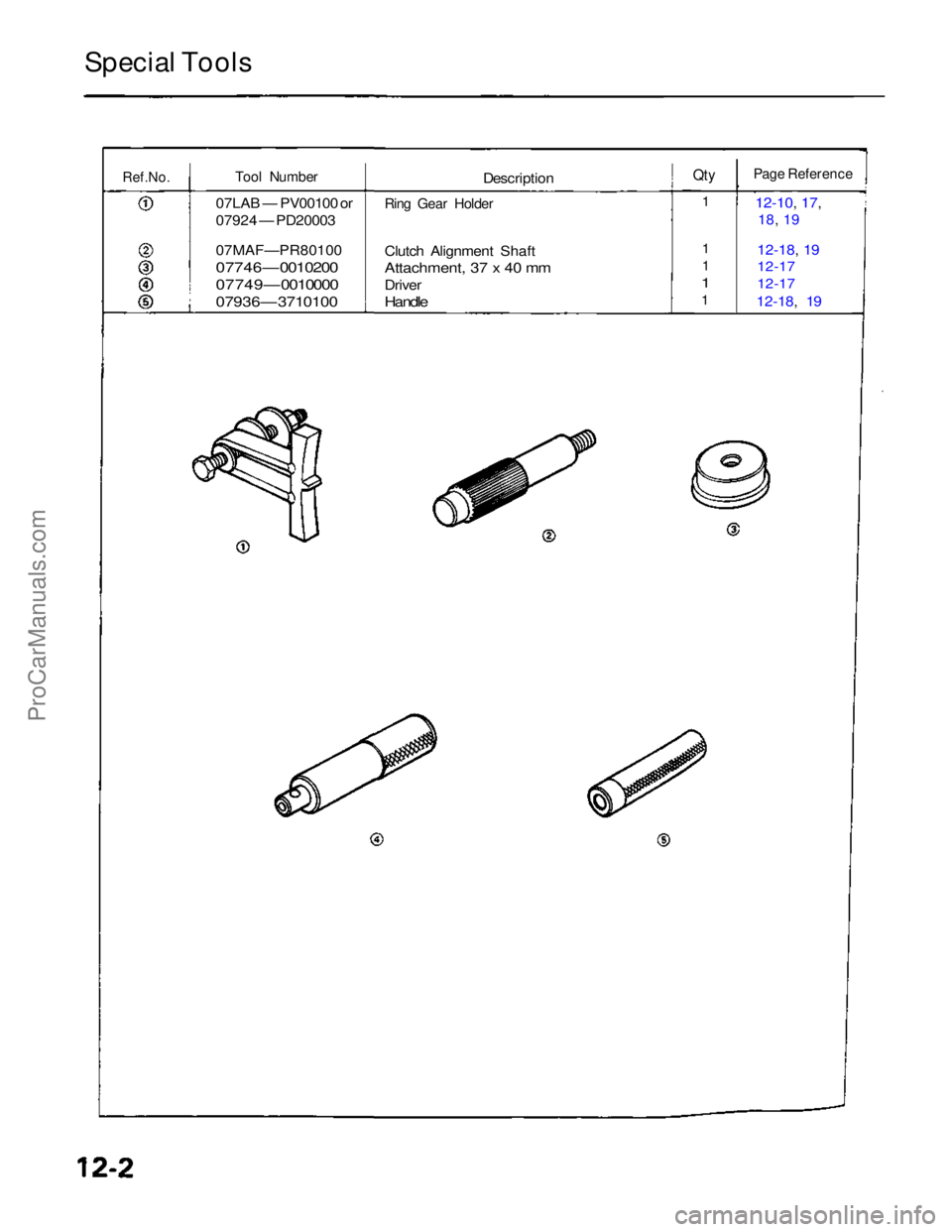

Special Tools

Ref.No.

Tool Number

07LAB — PV00100 or

07924 — PD20003

07MAF—PR80100

07746 — 0010200

07749 — 0010000

07936 — 3710100

Description

Ring Gear Holder

Clutch Alignment Shaft

Attachment, 37 x 40 mm

Driver

Handle

Qty

Page Reference

12-10, 17,

18, 19

12-18, 19

12-17

12-17

12-18, 19

1

1

1

1

1ProCarManuals.com

Page 283 of 1640

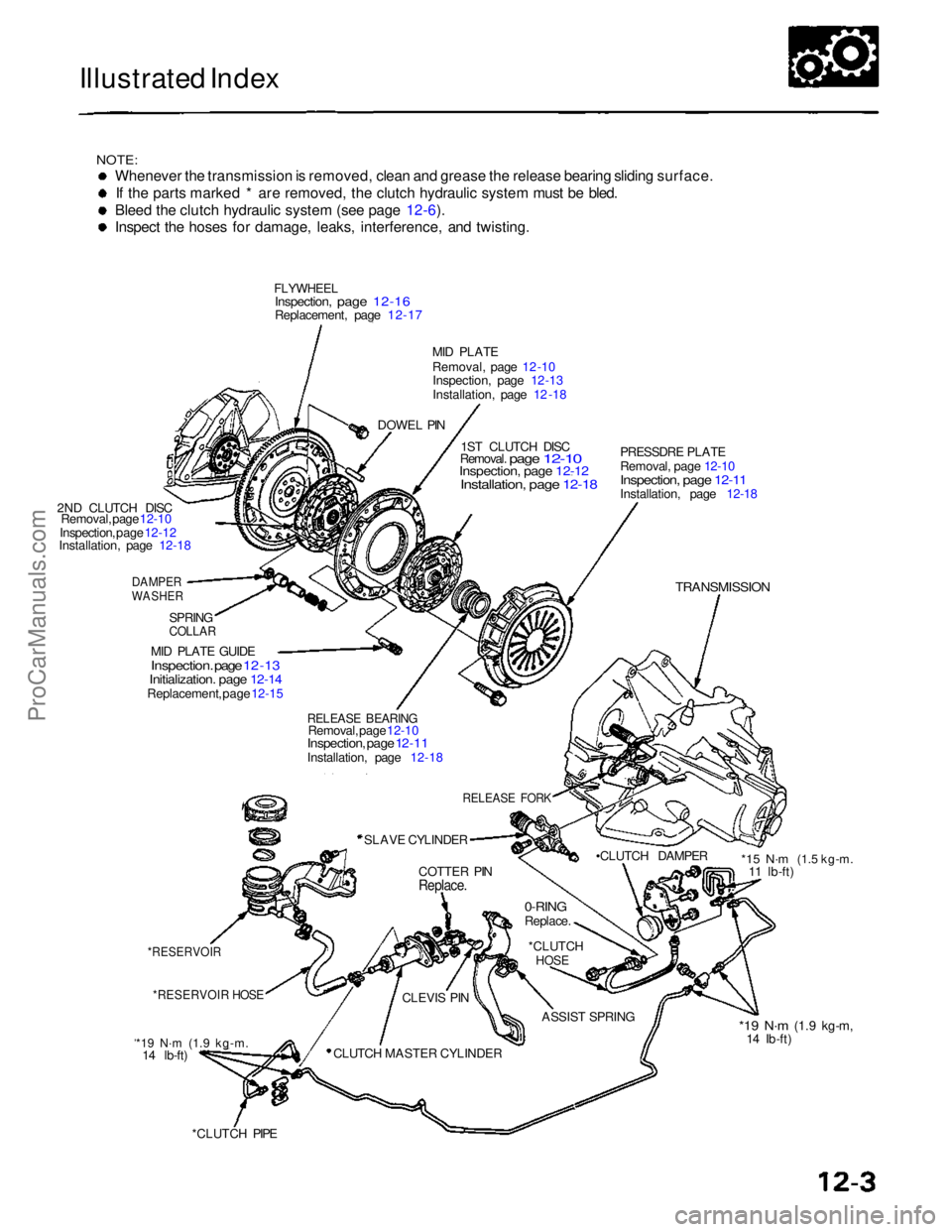

Illustrated Index

NOTE:

Whenever the transmission is removed, clean and grease the release bearing sliding surface.

If the parts marked * are removed, the clutch hydraulic system must be bled.

Bleed the clutch hydraulic system (see page 12-6).

Inspect the hoses for damage, leaks, interference, and twisting.

FLYWHEEL

Inspection, page 12-16

Replacement,

page 12-17

MID PLATE

Removal, page 12 -10

Inspection, page 12 -13

Installation, page 12 -18

2ND CLUTCH DISC Removal, page 12-10

Inspection, page 12-12

Installation, page 12-18

DAMPER

WASHER

PRESSDRE PLATE

Removal, page 12-10 Inspection, page 12-11

Installation, page 12-18

TRANSMISSION

1ST CLUTCH DISC

Removal. page 12-10 Inspection, page 12-12

Installation, page 12-18

SPRING

COLLAR

RELEASE BEARING

Removal, page 12-10

Inspection, page 12-11

Installation, page 12-18

RELEASE FORK

SLAVE CYLINDER •CLUTCH DAMPER

COTTER PIN

Replace.

0-RING

Replace.

*RESERVOIR HOSE

ASSIST SPRING

CLUTCH MASTER CYLINDER

MID PLATE GUIDE

Inspection. page 12 -13

Initialization. page 12-14

Replacement, page 12-15

*15 N·m

(1.5 kg-m.11 lb-ft)

*RESERVOIR

*19 N·m (1.9 kg-m.

14 lb-ft)

*CLUTCH PIPE

*19 N·m

(1.9 kg-m,

14 Ib-ft)

*CLUTCH

HOSE

CLEVIS PIN

DOWEL PINProCarManuals.com

Page 284 of 1640

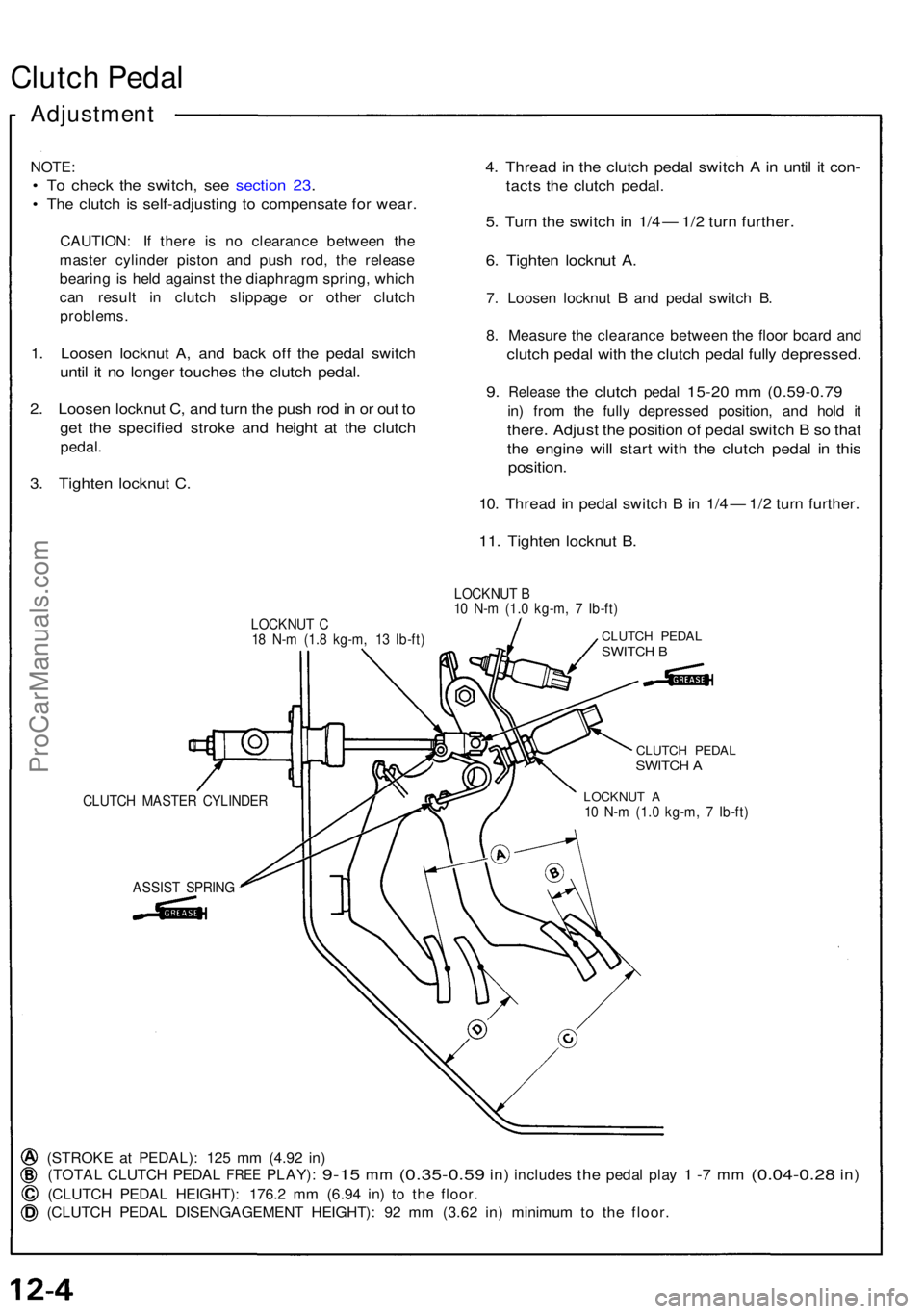

Clutch Peda l

Adjustmen t

NOTE:

• T o chec k th e switch , se e sectio n 23 .

• Th e clutc h i s self-adjustin g t o compensat e fo r wear .

CAUTION : I f ther e i s n o clearanc e betwee n th e

maste r cylinde r pisto n an d pus h rod , th e releas e

bearin g is hel d agains t th e diaphrag m spring , whic h

ca n resul t i n clutc h slippag e o r othe r clutc h

problems .

1. Loose n locknu t A , an d bac k of f th e peda l switc h

until i t n o longe r touche s th e clutc h pedal .

2. Loose n locknu t C , an d tur n th e pus h ro d in o r ou t t o

ge t th e specifie d strok e an d heigh t a t th e clutc h

pedal.

3. Tighte n locknu t C .

4. Threa d in th e clutc h peda l switc h A in unti l i t con -

tacts th e clutc h pedal .

5. Tur n th e switc h in 1/ 4 — 1/2 tur n further .

6. Tighte n locknu t A .

7. Loose n locknu t B an d peda l switc h B .

8 . Measur e th e clearanc e betwee n th e floo r boar d an d

clutc h peda l wit h th e clutc h peda l full y depressed .

9. Releas e the clutc h peda l 15-20 m m (0.59-0.7 9

in) fro m th e full y depresse d position , an d hol d i t

there . Adjus t th e positio n o f peda l switc h B so tha t

the engin e wil l star t wit h th e clutc h peda l i n thi s

position .

10. Threa d in peda l switc h B in 1/ 4 — 1/2 tur n further .

11. Tighte n locknu t B .

LOCKNU T C

1 8 N- m (1. 8 kg-m , 1 3 Ib-ft ) LOCKNU

T B

1 0 N- m (1. 0 kg-m , 7 Ib-ft )CLUTC H PEDA LSWITCH B

ASSIS T SPRIN G

CLUTCH PEDA LSWITCH A

LOCKNU T A10 N- m (1. 0 kg-m , 7 Ib-ft )

(STROK E a t PEDAL) : 12 5 m m (4.9 2 in )

(TOTA L CLUTC H PEDA L FREE PLAY) : 9-15 mm (0.35-0.5 9 in) include s the peda l pla y 1 -7 m m (0.04-0.2 8 in)

(CLUTC H PEDA L HEIGHT) : 176. 2 m m (6.9 4 in ) t o th e floor .

(CLUTC H PEDA L DISENGAGEMEN T HEIGHT) : 9 2 m m (3.6 2 in ) minimu m to th e floor .

CLUTC H MASTE R CYLINDE R

ProCarManuals.com

Page 285 of 1640

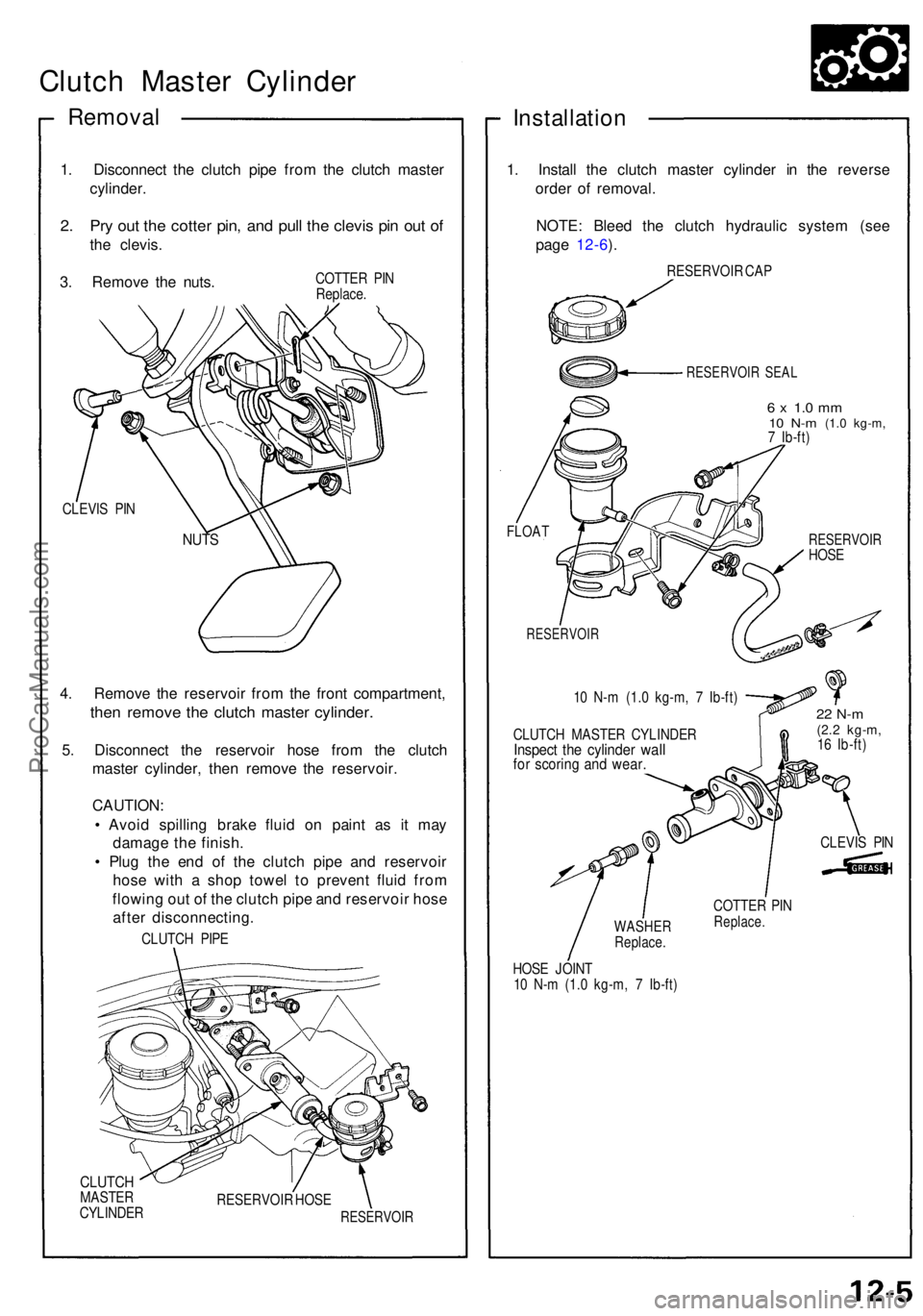

Clutch Maste r Cylinde r

Removal

1. Disconnec t th e clutc h pip e fro m th e clutc h maste r

cylinder .

2. Pr y ou t th e cotte r pin , an d pul l th e clevi s pi n ou t o f

the clevis .

3 . Remov e th e nuts .

COTTE R PI N

Replace .

CLEVI S PI N

4. Remov e th e reservoi r fro m th e fron t compartment ,

then remov e th e clutc h maste r cylinder .

5. Disconnec t th e reservoi r hos e fro m th e clutc h

maste r cylinder , the n remov e th e reservoir .

CAUTION :

• Avoi d spillin g brak e flui d o n pain t a s i t ma y

damag e th e finish .

• Plu g th e en d o f th e clutc h pip e an d reservoi r

hos e wit h a sho p towe l t o preven t flui d fro m

flowin g ou t o f th e clutc h pip e an d reservoi r hos e

afte r disconnecting .

CLUTCH PIP E

CLUTC HMASTE R

CYLINDE R RESERVOI

R HOS E

RESERVOI R

Installation

1. Instal l th e clutc h maste r cylinde r i n th e revers e

orde r of removal .

NOTE : Blee d th e clutc h hydrauli c syste m (se e

pag e 12-6 ).

RESERVOI R CA P

RESERVOI R SEA L

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

FLOA T

RESERVOI R

10 N- m (1. 0 kg-m , 7 Ib-ft )

CLUTC H MASTE R CYLINDE R

Inspect th e cylinde r wal lfor scorin g an d wear .

RESERVOI RHOSE

22 N- m(2.2 kg-m ,16 Ib-ft )

COTTE R PI N

Replace .

HOSE JOIN T

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

NUTS

CLEVI S PI N

WASHE RReplace .

ProCarManuals.com

Page 286 of 1640

Slave Cylinde r

Remova l

1. Disconnec t th e clutc h hos e fro m th e slav e cylinder .

CAUTION :

• Avoi d spillin g brak e flui d o n th e painte d sur -

faces , a s i t ma y damag e th e finish .

• Plu g th e en d o f th e clutc h hos e wit h a sho p

towe l t o preven t brak e flui d fro m comin g out .

2. Remov e th e slav e cylinde r fro m th e clutc h housing .

SLAVE

CYLINDE R

CLUTCHHOSE

O-RIN G

Replace .

BOO T

Remov e an d chec k fo r sign s o f leakin gand deterioration .

Installation

Super Hig h Tem p Ure a Greas e (P/ N

08798-9002) .

Brake Assembl y Lub e o r equivalen t rubbe r

grease .

1. Instal l th e slav e cylinde r o n th e clutc h housing .

SLAVE CYLINDE R

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

10 N- m (1. 0 kg-m ,7 Ib-ft )

(P/N 08798-9002 )(Brake Assembl y

Lube )

2. Blee d th e clutc h hydrauli c system :

• Attac h a hos e t o th e bleede r screw , the n suspen d

th e hos e i n a containe r o f brak e fluid .

• Mak e sur e ther e i s a n adequat e suppl y of flui d a t

the maste r cylinder , the n slowl y pum p th e

clutc h peda l unti l n o mor e bubble s appea r a t th e

bleede r hose .

• Refil l th e maste r cylinde r flui d whe n done .

• Us e onl y DO T 3 or 4 brak e fluid .

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 287 of 1640

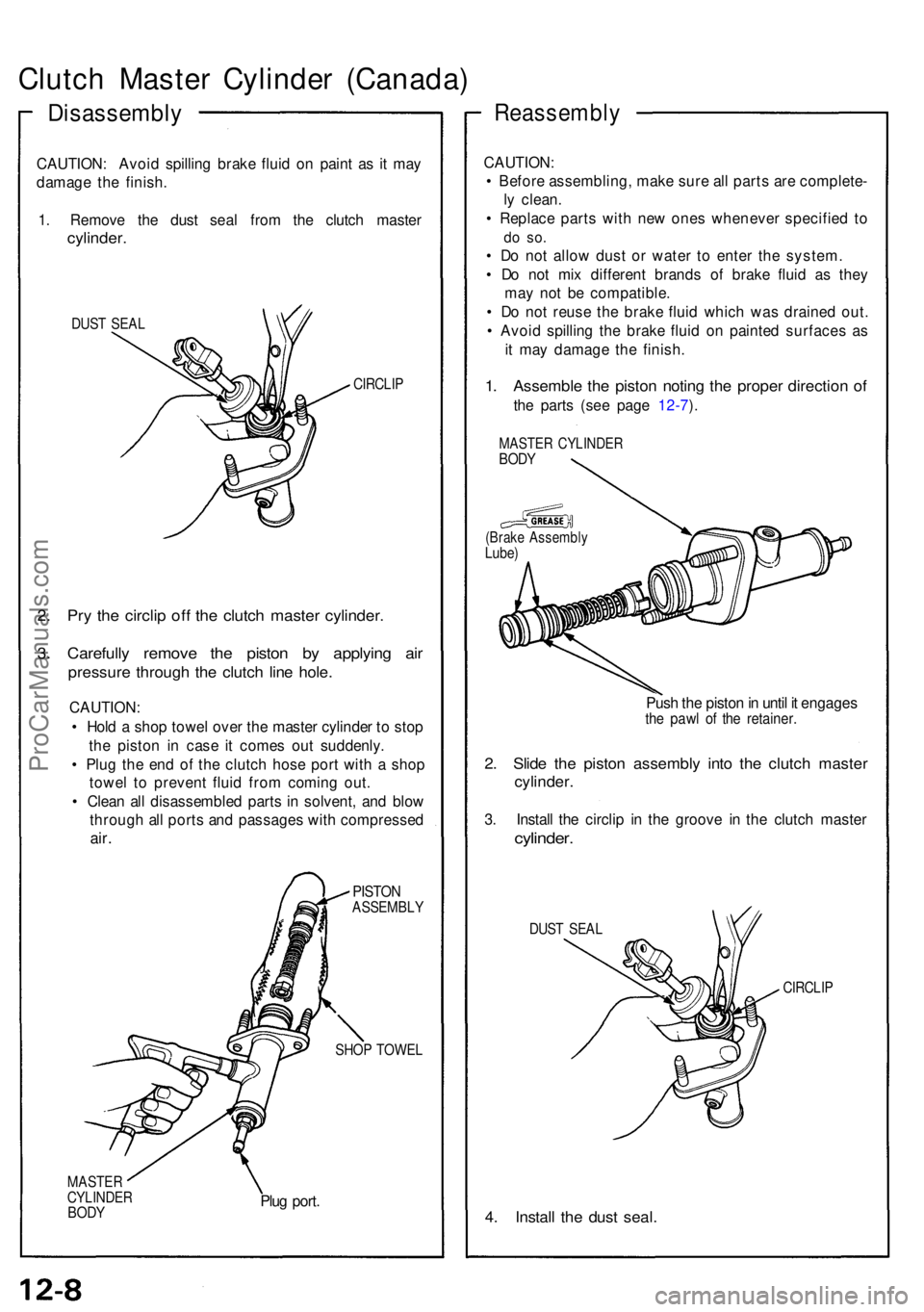

Clutch Maste r Cylinde r (Canada )

Disassembl y

CAUTION: Avoi d spillin g brak e flui d o n pain t a s it ma y

damag e th e finish .

1 . Remov e th e dus t sea l fro m th e clutc h maste r

cylinder.

DUST SEA L

CIRCLI P

2. Pr y th e circli p of f th e clutc h maste r cylinder .

3. Carefull y remov e th e pisto n b y applyin g ai r

pressur e throug h th e clutc h lin e hole .

CAUTION :

• Hol d a sho p towe l ove r th e maste r cylinde r t o sto p

th e pisto n i n cas e i t come s ou t suddenly .

• Plu g th e en d o f th e clutc h hos e por t wit h a sho p

towe l t o preven t flui d fro m comin g out .

• Clea n al l disassemble d part s in solvent , an d blo w

throug h al l port s an d passage s wit h compresse d

air.

PISTO NASSEMBL Y

SHOP TOWE L

MASTE RCYLINDE RBODYPlug port .

Reassembl y

CAUTION:

• Befor e assembling , mak e sur e al l part s ar e complete -

l y clean .

• Replac e part s wit h ne w one s wheneve r specifie d t o

do so .

• D o no t allo w dus t o r wate r t o ente r th e system .

• D o no t mi x differen t brand s o f brak e flui d a s the y

ma y no t b e compatible .

• D o no t reus e th e brak e flui d whic h wa s draine d out .

• Avoi d spillin g th e brak e flui d o n painte d surface s a s

i t ma y damag e th e finish .

1. Assembl e th e pisto n notin g th e prope r directio n o f

the part s (se e pag e 12-7 ).

MASTE R CYLINDE RBODY

(Brak e Assembl yLube)

Push th e pisto n in unti l i t engage sthe paw l o f th e retainer .

2. Slid e th e pisto n assembl y int o th e clutc h maste r

cylinder .

3. Instal l th e circli p i n th e groov e i n th e clutc h maste r

cylinder.

DUST SEA L

CIRCLI P

4. Instal l th e dus t seal .

ProCarManuals.com